DOI: 10.11817/j.issn.1672-7207.2017.10.002

铜渣转底炉直接还原磁选与熔分工艺比较

曹志成1, 2,孙体昌1,薛逊1, 2,刘占华1, 2

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京,100083;

2. 神雾科技集团股份有限公司,北京,102200)

摘要:以国内某典型铜渣为研究对象,进行转底炉直接还原-磁选工艺与转底炉直接还原-燃气熔分工艺的对比研究。首先通过基础试验确定最佳的反应参数,在此基础上进行中试扩大试验,并揭示铜渣转底炉直接还原过程机理,最后对它们的能耗进行计算与对比分析。研究结果表明:经过转底炉直接还原,铜渣中的铁橄榄石Fe2SiO4和磁铁矿Fe3O4相转变为含有金属铁Fe、二氧化硅SiO2和少量辉石相Ca(Fe,Mg)Si2O6的金属化球团,铁颗粒聚集长大形成铁连晶,具备通过磨选或熔分进行进一步富集的条件。金属化球团通过磨选工艺获得的金属铁粉TFe品位为91.12%,铁回收率为86.36%,通过燃气熔分工艺获得的铁水TFe品位为94.93%,铁回收率为97.52%。转底炉直接还原-燃气熔分工艺能耗比转底炉直接还原-磨选工艺的高约30%。

关键词:铜渣;转底炉;磁选;燃气熔分;能耗

中图分类号: TF09; X758 文献标志码:A 文章编号:1672-7207(2017)10-2565-07

Comparisons between magnetic separation and gas smelting separation process to treat copper slag by rotary hearth furnace direct reduction

CAO Zhicheng1, 2, SUN Tichang1, XUE Xun1, 2, LIU Zhanhua1, 2

(1. Key Laboratory of Ministry of Education for Efficient Mining and Safety of Metal Mines,

University of Science and Technology Beijing, Beijing 100083, China;

2. Shenwu Technology Group Corp., Beijing 102200, China)

Abstract: Taking a domestic copper slag as the subject, comparison between the rotary hearth furnace direct reduction process followed by a magnetic separation process and the same rotary hearth furnace direct reduction process followed by a gas smelting process, were investigated. Firstly, the optimum reaction parameters were determined by basic tests, based on which the pilot plant scale tests were conducted to reveal the direct reduction mechanism of the copper slag in the rotary hearth furnace direct reduction process. Finally, computation and comparison analysis of energy consumption of both processes were carried out. The results show that after direct reduction in the rotary hearth furnace, fayalite (Fe2SiO4) and magnetite (Fe3O4) in the copper slag are phased-changed into iron (Fe), quartz (SiO2) and trace amounts of augite (Ca(Fe,Mg)Si2O6) in the metallized pellets. The reduced iron grains aggregate and grow into iron chain crystals, which is the precondition for further iron enrichment either in the magnetic separation or smelting process. After the metallized pellets go through the magnetic separation process, iron powder with an iron content of 91.12% and an iron recovery rate of 86.36% is obtained, while hot metal with an iron content of 94.93% and an iron recovery rate of 97.52% is obtained after the metallized pellets go through the gas smelting process. Energy consumption per ton of product of the rotary hearth furnace direct reduction-gas smelting process is about 30% higher than that of the rotary hearth furnace direct reduction-magnetic separation process.

Key words: copper slag; rotary hearth furnace; magnetic separation; gas smelting; energy consumption

在火法炼铜生产工艺中,每生产1 t铜,将产生2.2 t以上的铜渣。在这数量巨大的铜渣中,含有Fe,Cu,Pb和Zn等有价金属,极具回收价值。一些企业将铜渣销售给水泥厂作掺加料,也有企业采用直接堆存的方式,不仅占用土地,污染环境,也没有实现有价金属的回收利用[1-2]。铜渣中的铁主要以铁橄榄石(Fe2SiO4)的形式存在[3-4],回收难度极大。采用直接选矿[5]和氧化改性提铁[6-7]的方法,铁回收率低,而熔融还原提铁[8-9]的方法则能耗较高。杨慧芬等[10]采用直接还原-磁选的方法处理铜渣得到铁品位为92.05%、回收率为81.01%的直接还原铁粉;王爽等[11]获得的金属铁粉的铁品位为92.96%、铁回收率为93.49%;王红玉等[12]采用直接还原-磁选工艺对某二次铜渣进行铁回收,获得铁品位为93.64%、回收率为88.08%的优质磁选铁粉。但上述试验均为基础实验室的研究结果,没有经过大型工业化中试验证。为此,本文作者以国内某铜渣为研究对象,采用转底炉直接还原-磨矿磁选[13-14]和转底炉直接还原-燃气熔分[15-16] 2种工艺流程进行基础试验和工业化中试研究,分别从工艺、产品和能耗3个方面进行比较,不仅得到磨选铁粉和熔分铁块产品,同时在布袋收尘系统收集到ZnO质量分数为68.54%的粉尘,可以作为锌冶炼厂的优质原料,为国内外铜渣中有价金属综合回收提供一种新的方法。

1 原料与试验方法

1.1 原料分析

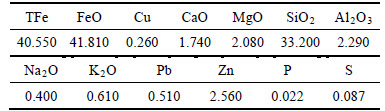

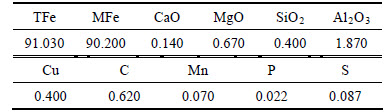

研究用铜渣为国内某闪速炉铜渣选铜后的尾矿,铜渣中化学成分如表1所示。由表1可知:铜渣中有价金属Fe,Cu,Pb和Zn质量分数均较高。该铜渣粒度较小,粒度低于0.043 mm的铜渣质量分数占84.86%。

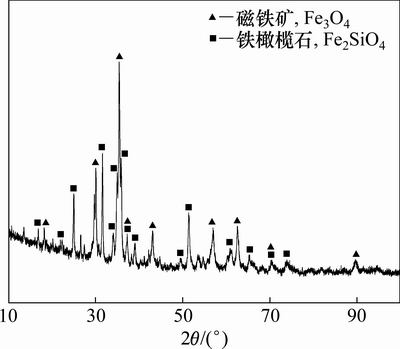

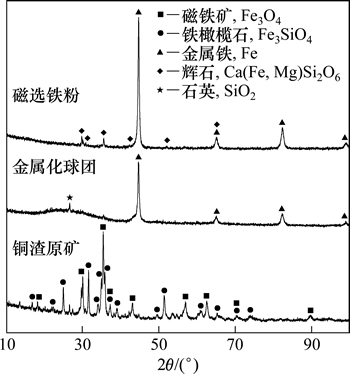

图1所示为铜渣的XRD衍射图谱。由图1可知:铜渣中含铁矿物主要为铁橄榄石(Fe2SiO4)及磁铁矿(Fe3O4),没有发现其他含铁矿物。

选用当地无烟煤作为还原剂,其固定碳质量分数为74.53%;选用工业石灰石做助熔剂,CaCO3质量分数为90.05%,工业纯碱Na2CO3质量分数为98.5%。

表1 铜渣化学成分(质量分数)

Table 1 Chemical composition of copper slag %

图1 铜渣的XRD衍射图谱

Fig. 1 XRD patterns of copper slag

1.2 试验方法

试验分2步进行:首先进行基础试验研究,之后进行转底炉中试研究。基础试验的目的主要是模拟转底炉还原的条件,得出最佳的配料参数、还原参数、金属化球团磨矿磁选参数和金属化球团热装熔分参数,从而为下步中试验提供准确的工艺控制条件。

在基础试验中,按照设计的不同质量比例将铜渣、还原煤、添加剂和粘结剂混合均匀后,用圆盘造球机将混合好的物料造成圆球,放入150 ℃恒温干燥箱内烘干。烘干的球团放在耐火材料制成的盘上,放入已达到预设温度的马弗炉进行焙烧还原,在整个还原过程中通入N2进行保护。若采用磁选流程,则焙烧结束后取出球团直接进行水淬冷却,冷却后球团过滤烘干,破碎磨矿后进行磁选得到高品位金属铁粉。若采用熔分流程,热态金属化球团直接装入预热的刚玉坩埚中,在升至指定温度的高温炉中进行熔化分离铁和渣,到达熔分时间后将坩埚取出,放在空气中冷却至室温,得到熔分铁块和熔分渣。

2 基础试验结果与分析

2.1 直接还原-熔分流程影响因素研究

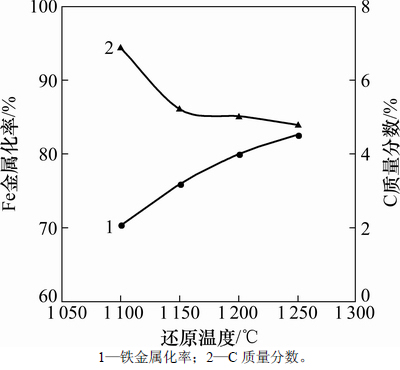

在基础试验中,通过控制还原煤用量、还原温度、还原时间来提高球团的金属化率,在试验过程中,发现还原温度对球团金属化率影响最大。通过理论计算和试验确定还原煤质量为铜渣原矿质量的25%,还原时间为35 min,分别选择还原温度为1 100,1 150,1 200,1 250和1 300 ℃进行试验,结果如图2所示。

图2 还原温度对金属化率和碳含量的影响

Fig. 2 Effect of reduction temperature on metallization rate and carbon content

由图2可知:球团金属化率随着还原温度的升高而不断增大。当还原温度从1 100 ℃升高到1 250 ℃时,球团金属化率从70.32%提高到82.56%;当还原温度继续升高时,球团出现熔化现象。本研究选取还原温度为1 250 ℃,此时球团金属化率为82.56%,剩碳质量分数为4.78%。金属化球团中保留剩碳的原因是为了后续熔分过程中进一步还原球团中的铁元素,从而保证较高的铁回收率。将上述金属化球团作为后续热装熔分的原料,重点考察石灰石质量分数与熔分时间对铁品位和回收率的影响。

2.1.1 石灰石用量对熔分效果的影响

球团热装加入刚玉坩埚中进行熔分,熔分前加入不同质量分数的石灰石,其质量分数分别为金属化球团质量的5%,10%,15%,20%,30%和40%;熔分温度为1 550 ℃,熔分时间为60 min。结果如图3所示。

由图3可知:在还原煤质量分数为25%时,当石灰石质量分数由5%增加到40%后,铁品位相对比较稳定,在93%~94%之间,铁回收率在93.88%~98.12%之间,其中石灰石质量分数为30%时铁回收率最高;随着石灰石质量分数的增加,CaO与SiO2反应加速,FeO反应活度增加,促进了铁和渣的分离,因此渣中铁的质量减少,回收率升高,其主要反应方程式为

Fe2SiO4+2CaO+2C=2Fe+Ca2SiO4+2CO (1)

图3 石灰石用量对熔分效果的影响

Fig. 3 Effect of limestone dosage on smelting

2.1.2 熔分时间对熔分效果的影响

固定还原煤质量分数为25%,还原温度为1 250 ℃,还原时间为35 min,焙烧还原后所得球团金属化率为82.56%,剩碳质量分数为4.78%。热装加入刚玉坩埚中进行熔分,熔分前加入石灰石的质量为金属化球团质量的30%,熔分温度为1 550 ℃,熔分时间分别为30,40,50和60 min。试验结果表明:随着熔分时间的延长,渣铁分离效果逐渐变好,铁的回收率逐渐提高;当熔分时间从30 min延长至60 min时,铁的回收率从93.46%提高至97.87%,铁品位变化不大,维持在93%~94%之间。经综合考虑,选择熔分时间为50 min。

通过上述基础试验,采用直接还原-熔分流程获得最佳的配料条件是:铜渣与还原煤质量比为100:25,还原温度为1 250 ℃,还原时间为35 min,此时球团金属化率为82.56%。将球团热装进行熔分试验,熔分前配入占金属化球团质量30%的石灰石,熔分温度为1 550 ℃,熔分时间为50 min,此时获得熔分铁的TFe品位93.97%,回收率为97.87%。

2.2 直接还原-磨矿磁选流程影响因素研究

为与熔分流程进行比较,对还原-磨矿磁选条件进行研究。前期探索试验表明仅仅使用铜渣与还原煤造球作为配料,虽然金属化率达到85%以上,但磁选结果很不理想,所得金属铁粉TFe品位不足80%,铁回收率小于75%,主要是还原的金属化球团中铁颗粒嵌布粒度较小造成的。为此,首先进行石灰石单独作为助熔剂的试验,磁选所得金属铁粉品位约85%,铁回收率约80%。为了进一步提高铁品位,单独使用助熔剂工业纯碱进行试验,结果表明当工业纯碱用量达到6%时,磁选所得金属铁粉TFe品位才能达到90%以上,铁回收率大于85%。考虑到工业纯碱价格较高,后续进行工业纯碱与石灰石混合造球还原试验。

2.2.1 石灰石用量对磁选效果的影响

前期试验得出最佳的配料条件为铜渣、还原煤与工业纯碱质量比为100:25:3,采用3层球团焙烧,还原温度由1 250 ℃提高到1 280 ℃,还原时间为20 min,焙烧还原后所得球团金属化率为85.46%。采用2段磨矿磁选,磨矿浓度为67%,1段磨矿细度低于0.074 mm的铜渣质量分数占72.10%,磁场强度为143.31 kA/m;2段磨矿细度低于0.074 mm的铜渣质量分数占50.89%,磁场强度为95.54 kA/m,最终得到的金属铁粉TFe品位为90.64%,铁回收率为84.31%。为进一步确定石灰石质量分数对还原效果的影响,分别配加占金属化球团质量5%,10%,15%和20%的石灰石进行试验,结果如图4所示。

图4 石灰石用量对磁选效果的影响

Fig. 4 Effect of limestone dosage on magnetic separation

从图4可以看出:随着石灰石质量分数的增加,铁品位有上升的趋势,铁回收率先上升后下降;当石灰石质量分数为10%时,铁品位为91.04%,铁回收率达到85.98%;当石灰石质量分数分别增加到15%和20%时,上层含碳球团部分熔化阻碍了下层球团的传热,从而影响了还原效果,因此,选择石灰石质量分数为10%进行中试试验。同时试验结果还表明,助熔剂的加入有效促进了铁颗粒聚集长大,为磨矿磁选创造了良好的条件。

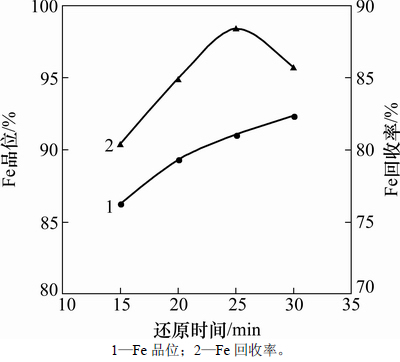

2.2.2 还原时间对磨矿磁选效果的影响

配料条件为铜渣、还原煤、工业纯碱、石灰石的质量比为100:25:3:10,采用3层球团焙烧,还原温度为1 280 ℃,还原时间分别为15,20,25和30 min,磁选条件维持不变,试验结果如图5所示。由图5可知:随着还原时间的延长,铁品位逐渐上升,从86.34%增加到92.23%,铁回收率先上升后下降;当还原时间增加到25 min时效果最好,此时铁品位为91.07%,铁回收率达88.37%。

图5 还原时间对磁选效果的影响

Fig. 5 Effect of reduction time on magnetic separation

上述基础试验研究结果表明:采用直接还原-磨选流程获得最佳的配料条件是铜渣、还原煤、工业纯碱、石灰石质量比为100:25:3:10,还原温度为1 250 ℃,还原时间为25 min,此时球团金属化率为89.68%。采用2段磨矿磁选,磨矿质量分数为67%,1段磨矿细度低于0.074 mm的铜渣质量分数占72.10%,磁场强度143.31 kA/m;2段磨矿细度低于0.074 mm的铜渣质量分数占50.89%,磁场强度95.54 kA/m,最终金属铁产品(磁选铁粉)中TFe品位为91.07%,铁回收率为88.37%。

3 转底炉中试试验

3.1 中试工艺流程及产品分析

按照基础试验获得的最佳工艺条件进行中试。工艺过程为铜渣、还原煤、添加剂按照质量比混合均匀,采用圆盘造球的方式生产含碳球团,布入转底炉进行还原,球团中的含锌矿物被还原成金属锌挥发出来,通过烟气除尘系统收集得到氧化锌粉;还原后的金属化球团,根据后续处理工艺的不同,分别采用水淬冷却-磨矿磁选得到金属铁粉,或采用金属化球团热装-燃气炉熔分的方式得到金属铁水。中试转底炉外径为10 m,中径为8 m,炉底布料宽度为2 m,每小时处理量可达2~3 t;中试燃气熔分炉每小时处理金属化球团约1 t。

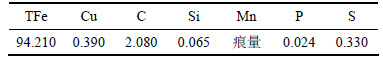

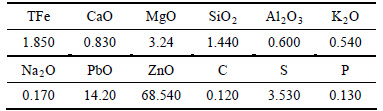

采用转底炉直接还原-磨矿磁选工艺,所得金属铁粉TFe品位为91.12%,铁回收率为86.36%;采用转底炉直接还原-燃气熔分工艺所得铁水TFe品位为94.93%,铁回收率为97.52%。工艺过程中,Zn脱除率为98.81%,通过布袋收尘系统得到的富锌粉尘中,氧化锌含量达65.59%,可以作为副产品销售给锌冶炼厂。表2~4所示分别为磁选铁粉、熔分金属铁块和氧化锌粉尘的最终产品化学多元素分析结果。

图6所示为铜渣原矿、金属化球团以及最终铁产品磁选铁粉的衍射图谱。从图6可以看出:经过转底炉直接还原,铜渣原矿中的铁橄榄石和氧化铁相转变为含有金属铁和二氧化硅以及少量辉石相(质量分数低,未在图中标出)的金属化球团。最终铁产品中已经看不到二氧化硅的衍射峰,并且铁的衍射主峰比金属化球团中的强,说明金属化球团经过磨矿磁选使大部分二氧化硅以杂质的形式进入尾渣,从而使铁在最终

表2 磁选铁粉化学成分(质量分数)

Table 2 Chemical composition of obtained iron powders by magnetic separation %

表3 熔分金属铁块化学成分(质量分数)

Table 3 Chemical composition of obtained iron by smelting %

表4 氧化锌粉尘化学成分(质量分数)

Table 4 Chemical composition of obtained zinc oxide dust %

产品中得到富集。

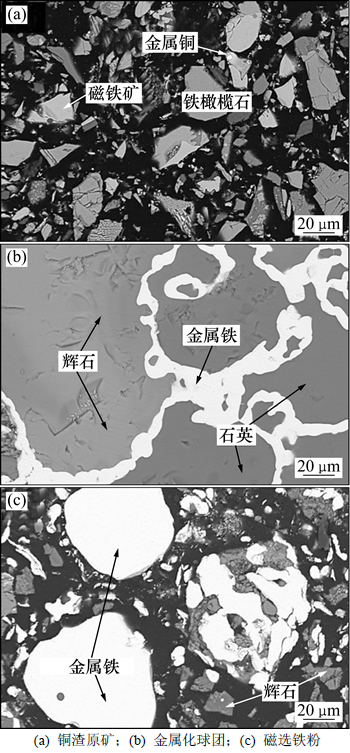

图7所示为铜渣原矿、金属化球团以及磁选铁粉的电镜照片。结合XRD和能谱分析结果可知:铜渣原矿中的物相有铁橄榄石、磁铁矿和铜相,经过直接还原后,铁橄榄石、磁铁矿均被破坏和还原,金属铁在金属化球团中出现聚集现象,铁橄榄石分解出来的SiO2一部分游离,一部分与铁、钙和镁的氧化物形成辉石相。金属化球团经过磨矿磁选后,大多数硅酸盐杂质均与铁分离,得到的金属铁颗粒粒径为80 μm,铁颗粒中还存在少量辉石相的杂质。

图6 铜渣、金属化球团以及磁选铁粉的图谱

Fig. 6 XRD patterns of copper slag, metallization pellets and iron powders by magnetic separation

图7 铜渣、金属化球团以及磁选铁粉的电镜照片

Fig. 7 SEM images of copper slag, metallization pellets and iron powders by magnetic separation

3.2 2种工艺的比较与分析

基础试验研究和中试验证结果表明:转底炉直接还原-磨矿磁选和转底炉直接还原-燃气熔分2种工艺均可以大规模处理铜渣,实现提取铁、锌元素的目的。但2种工艺又各有优缺点。

3.2.1 工艺分析

在转底炉直接还原工艺中,磨矿磁选流程要求配入工业纯碱与石灰石混合的助熔剂,促使金属化球团中的铁颗粒聚集长大;燃气熔分流程只需要配入还原煤,金属化率达到80%以上即可。在产品处理上,磨矿磁选流程所得产品需要浓缩脱水—烘干—压块工序,过程中还需要防止氧化;燃气熔分流程生产的铁水脱硫后可以直接浇铸成铁块。

3.2.2 产品分析

2种工艺所得产品均含有铜元素,可以作为生产含铜钢的配料。磨矿磁选所得金属铁粉TFe品位虽然可以达到91%以上,产品中硫含量较低,可以直接使用,但仍然含有包括钙、镁、硅、铝等杂质(总质量分数大于4%),后续作为炼钢原料只能部分配入,以防止渣量过大。此外,该产品目前没有固定的市场价格;比较而言,熔分产品中硫含量高,后续虽然需加脱硫工序,但产品中铁质量分数高,碳质量分数比高炉生铁的低,与钢的成分接近,可以作为炼钢生铁销售。

3.2.3 能耗分析

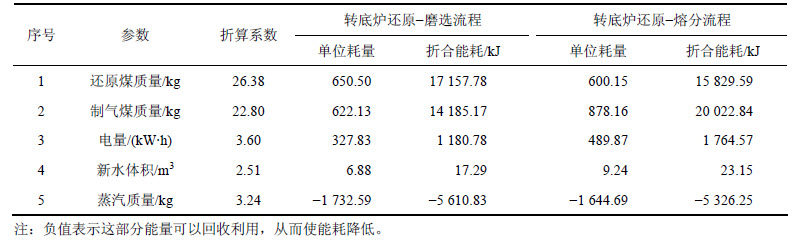

以年处理80万t铜渣为例,转底炉还原-磨选流程年产铁粉压块30.75万t,转底炉还原-熔分流程年产铁块33.33万t。分别将2种流程中每吨铁产品的还原煤、制气煤、电、新水、蒸汽的消耗进行统计,根据GB/T 2589—2008“综合能耗计算通则”能源消耗量计算,1 kg标准煤的低位发热量等于29.307 6 MJ,各种能源消耗及折算系数如表7所示。

从表7可以看出:转底炉还原-磨选流程每吨铁各项能耗合计26 930.20 kJ,转底炉还原-熔分流程各项能耗合计32 313.90 kJ,换算成每吨铜渣的能耗分别为10 349.77 kJ和13 460.71 kJ。磨选流程比熔分流程的能耗低约30%,主要原因是熔分流程后续采用煤气将金属化球团熔分,需要消耗较多的制气煤,制气煤能耗比磨选流程的能耗高5 837.66 kJ。

4 结论

1) 采用转底炉还原-磨选流程,所得金属铁粉TFe品位为91.12%,铁回收率为86.36%;采用转底炉还原-熔分流程,所得铁块TFe品位为94.93%,铁回收率为97.52%,通过收尘系统回收的粉尘中ZnO质量分数达到65.59%。

2) 磁选流程在直接还原工序中,需要配入适量的助熔剂以促进球团中铁颗粒的聚集长大,为后续磨矿磁选创造有利条件;熔分流程在直接还原工序中只需配入适量的还原剂,后续熔分工序中添加石灰石可以进一步完成深度还原,从而提高铁的回收率。

3) 采用转底炉还原-磨选流程处理铜渣比转底炉还原-熔分流程节能约30%,且转底炉直接还原工艺和磨矿磁选工艺均较为成熟,建议采用转底炉直接还原-磨选流程大规模处理铜渣。

表7 2种流程每吨铁产品能耗

Table 7 Energy consumption per ton of iron product for two processes

参考文献:

[1] 刘慧利, 胡建杭, 王华, 等. 铜渣煅烧过程中的多相转变[J]. 中南大学学报(自然科学版), 2013, 44(8): 3159-3160.

LIU Huili, HU Jianhang, WANG Hua, et al. Multiphase transformation during process of copper slag calcination[J]. Journal of Central South University (Science and Technology), 2013, 44(8): 3159-3160.

[2] 徐露, 库建刚, 林存键, 等. 从铜渣中回收铁的研究进展[J]. 现代化工, 2016, 36(2): 26-29.

XU Lu, KU Jiangang, LIN Cunjian, et al. Progress in iron recovery from copper slags[J]. Modern Chemical Industry, 2016, 36(2): 26-29.

[3] 王琛, 田庆华, 王亲猛, 等. 铜渣有价金属综合回收研究进展[J]. 金属材料与冶金工程, 2014, 42(6): 50-56.

WANG Chen, TIAN Qinghua, WANG Qinmeng, et al. Research progress in comprehensive recovery of valuable metals from copper slag[J]. Metal Materials and Metallurgy Engineering, 2014, 42(6): 50-56.

[4] 姜平国, 吴朋飞, 胡晓军, 等. 铜渣综合利用研究现状及其新技术的提出[J]. 中国矿业, 2016, 25(2): 76-79.

JIANG Pingguo, WU Pengfei, HU Xiaojun, et al. Copper slag comprehensive utilization development and new technology is put forward[J]. China Mining Magazine, 2016, 25(2): 76-79.

[5] 曾军龙, 肖坤明. 分散剂用于炉渣中回收铁的研究[J]. 有色金属科学与工程, 2011, 2(6): 71-73.

ZENG Junlong, XIAO Kunming. The research on using dispersant agent to iron recovery in slag[J]. Nonferrous Metals Science and Engineering, 2011, 2(6): 71-73.

[6] HU G, XU S P, LI S G, et al. Steam gasification of apricot stones with olivine and dolomite as downstream catalysts[J]. Fuel Processing Technology, 2006, 87(5): 375-382.

[7] 杨慧芬, 袁运波, 张露, 等. 铜渣中铁铜组分回收利用现状及建议[J]. 金属矿山, 2012, 41(5): 165-168.

YANG Huifen, YUAN Yunbo, ZHANG Lu, et al. Present situation and proposed method of recycling iron and copper from copper slag[J]. Metal Mine, 2012, 41(5): 165-168.

[8] 袁守谦, 董洁, 王超, 等. 综合处理铜选矿尾渣和镍熔融渣的工艺研究[J]. 稀有金属, 2014, 38(1): 108-114.

YUAN Shouqian, DONG Jie, WANG Chao, et al. Comprehensive Treating Copper Tailing and Nickel residue[J]. Chinese Journal of Rare Metals, 2014, 38(1): 108-114.

[9] MANSOOR B, KENETHS C. Electrical and electronic conductivity of CaO-SiO2-FeOX slags at various oxygen potentials: Part 1. Experimental Results[J]. Metallurgical and Materials Transoctions B, 2006, 37(2): 41-49.

[10] 杨慧芬, 景丽丽, 党春阁. 铜渣中铁组分的直接还原与磁选回收[J]. 中国有色金属学报, 2011, 21(5): 1165-1170.

YANG Huifen, JING Lili, DANG Chunge. Iron recovery from copper-slag with lignite-based direct reduction followed by magnetic separation[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 1165-1170.

[11] 王爽, 倪文, 王长龙, 等. 铜尾渣深度还原回收铁工艺研究[J]. 金属矿山, 2014, 43(3): 156-160.

WANG Shuang, Ni Wen, WANG Changlong, et al. Study of deep reduction process for iron recovery from copper slag tailings[J]. Metal Mine, 2014, 43(3): 156-160.

[12] 王红玉, 李克庆, 倪文, 等. 某高铁二次铜渣深度还原—磁选试验研究[J].金属矿山, 2012, 41(11): 141-144.

WANG Hongyu, LI Keqing, NI Wen, et al. Experimental research of deep reduction and magnetic separation process of a high-iron copper slag[J]. Metal Mine, 2012, 41(11): 141-144.

[13] 高金涛, 周春芳, 朱荣, 等. 转底炉分区域供热研究[J]. 北京科技大学学报, 2014, 36(S1): 110-116.

GAO Jintao, ZHOU Chunfang, NIU Rong, et al. Research on the heat supply of different sections in a rotary hearth furnace[J]. Journal of University of Science and Technology Beijing, 2014, 36(S1): 110-116.

[14] 曹志成, 孙体昌, 吴道洪, 等. 转底炉直接还原铜渣回收铁、锌技术[J]. 材料与冶金学报, 2017, 16 (1): 38-41.

CAO Zhicheng, SUN Tichang, WU Daohong, et al. Technology of recovery of iron and zinc from copper slag by RHF direct reduction[J]. Journal of Materials and Metallurgy, 2017, 16 (1): 38-41.

[15] 佘雪峰, 王静松, 韩毅华, 等. 转底炉直接还原工艺综合数学模型[J]. 北京科技大学学报, 2013, 35(12): 1580-1587.

SHE Xuefeng, WANG Jingsong, HAN Yihua, et al. Comprehensive mathematical model of direct reduction for rotary hearth furnaces[J]. Journal of University of Science and Technology Beijing, 2013, 35(12): 1580-1587.

[16] 万新宇, 齐渊洪, 高建军, 等. 水淬铜渣还原熔分回收粒铁和铜[J]. 钢铁研究学报, 2016, 28(10): 22-29.

WAN Xinyu, QI Yuanhong, GAO Jianjun, et al. Reduction and melting of copper slag for nuggets and copper recovery[J]. Journal of Iron and Steel Research, 2016, 28(10): 22-29.

(编辑 伍锦花)

收稿日期:2016-12-29;修回日期:2017-02-17

基金项目(Foundation item):北京市科技专项项目(Z151100001615027)(Project(Z151100001615027) supported by the Beijing Science and Technology Special Project)

通信作者:孙体昌,博士,教授,从事复杂难选矿及冶金渣综合利用研究;E-mail:suntc@ces.ustb.edu.cn