Nb对选区激光熔化γ-TiAl基合金组织与性能的影响

来源期刊:中国有色金属学报(英文版)2019年第5期

论文作者:Adam Ismaeel 王存山

文章页码:1007 - 1016

关键词:选区激光熔化;γ-TiAl 基合金;显微组织;性能;Nb添加

Key words:selective laser melting; γ-TiAl based alloys; microstructure; properties; Nb additions

摘 要:采用选区激光熔化技术,在TC4合金基体上制备不同Nb含量的γ-TiAl 基 Ti-Al-Mn-Nb合金。系统分析Nb含量对合金显微组织和性能的影响规律。研究结果表明,合金主是由四方结构的γ-TiAl和密排六方结构的α2-Ti3Al相组成,且随着Nb含量的增加,合金的凝固组织逐渐由枝晶状结构演化为层片状结构。因高含量Nb在γ-TiAl 相中的固溶,以及细小板条状结构的形成,致使Nb含量为7.0 at.%的合金具有最佳的综合性能,即其不仅具有高的硬度(HV 2000)、高的强度(1390 MPa)和良好的塑性变形能力(24.5%),而且具有良好的摩擦磨损和高温抗氧化性能。

Abstract: The γ-TiAl based Ti-Al-Mn-Nb alloys with different Nb additions were fabricated by selective laser melting (SLM) on the TC4 substrate. The effects of Nb content on microstructure and properties of the alloys were investigated. The results reveal that the alloys consist of γ-TiAl phase with tetragonal lattice structure and α2-Ti3Al phase with hcp lattice structure, and show a sequential structure change from near full dendrite to near lamellar structure with the increase of Nb addition. Owing to the higher Nb content in γ-TiAl phase and the formation of near lamellar structure, the alloy with 7.0 at.% Nb addition has the best combination of properties among the studied alloys, namely, not only a high hardness of HV 2000, a high strength of 1390 MPa and a plastic deformation of about 24.5%, but also good tribological properties and high-temperature oxidation resistance.

Trans. Nonferrous Met. Soc. China 29(2019) 1007-1016

Adam ISMAEEL, Cun-shan WANG

Key Laboratory of Materials Modification by Laser, Ion and Electron Beam, Dalian University of Technology, Dalian 116024, China

Received 19 May 2018; accepted 29 December 2018

Abstract: The γ-TiAl based Ti-Al-Mn-Nb alloys with different Nb additions were fabricated by selective laser melting (SLM) on the TC4 substrate. The effects of Nb content on microstructure and properties of the alloys were investigated. The results reveal that the alloys consist of γ-TiAl phase with tetragonal lattice structure and α2-Ti3Al phase with hcp lattice structure, and show a sequential structure change from near full dendrite to near lamellar structure with the increase of Nb addition. Owing to the higher Nb content in γ-TiAl phase and the formation of near lamellar structure, the alloy with 7.0 at.% Nb addition has the best combination of properties among the studied alloys, namely, not only a high hardness of HV 2000, a high strength of 1390 MPa and a plastic deformation of about 24.5%, but also good tribological properties and high-temperature oxidation resistance.

Key words: selective laser melting; γ-TiAl based alloys; microstructure; properties; Nb additions

1 Introduction

The γ-TiAl based alloys are important candidate materials for high temperature applications, especially aerospace and automotive industries, due to their attractive properties such as low density, high specific strength and creep resistance [1-6]. However, the alloys suffer from low ductility and toughness at ambient temperature and are difficult to process by conventional processing routes. Selective laser melting (SLM) is an additive manufacturing technique, and enables the production of individual metal components with complex geometries layer by layer, according to a 3D-CAD volume model, without the need of part-specific tooling or preproduction costs [7-9], which provides a new approach for fabricating difficult-to-machine alloy components.

Last few years, intensive researches have performed in the SLM γ-TiAl based alloys. the microstructure and properties of γ-TiAl based alloys fabricated by SLM were investigated [10-13]. It was found that the SLM alloys exhibited refined structure due to rapid solidification processing, leading to improved strength and ductility. The research of SLM of γ-TiAl based alloys showed that the microstructure of the alloys strongly depended on laser parameters, namely, the high laser energy density and scanning speed were leading to finer microstructures, and higher strength and ductility [14-16]. However, the improvement in the ductility through grain refinement is limited. Moreover, the high temperature oxidation resistance of the alloys is still poor [17-23]. With this respect, the alloying is one of the most effective methods. Therefore, the influences of various additional elements to the γ-TiAl based alloys were studied. The results showed that the ductility and high temperature oxidation resistance were enhanced to some extent through alloying with B, V, Y, Mo, and Cr elements [24-26]. Nb element can dissolve in γ-TiAl phase, which can enhance the directionality of d—d bonds and the P—N stresses so as to increase the critical resolved shear stress (CRSS) for ordinary dislocation slip, leading to a higher strength and ductility [27]. On the other hand, Nb is also an active element and is easy to form Nb2O5 during high temperature oxidation processing [21,28], which will lead to further increase the high temperature oxidation resistance of γ-TiAl based alloys. Therefore, in this work, the γ-TiAl based Ti-Al-Mn-Nb alloys with different Nb additions were fabricated by SLM on the TC4 substrate. The influences of Nb content on microstructure and properties of the alloys were investigated in detail, and the optimized alloy was obtained.

2 Experimental

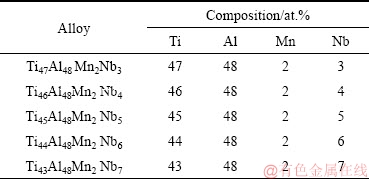

Pure Ti plate with the sizes of 30 mm × 20 mm × 20 mm was chosen as a substrate material. Elemental powders of Ti (99.99% purity, <0.0750 mm), Al (99.90% purity, <0.0750 mm), Mn (99.90% purity, <0.0750 mm), and Nb (99.90% purity, <0.0750 mm) were blended by ball grinder according to the composition as presented in Table 1, which were chosen as SLM materials.

The SLM assembly consists of four primary components: the laser system, the powder delivery system, the controlled environment, and the CAD that is driven motion control system. A 5 kW continuous-wave CO2 laser unit was used. Based on the preliminary experiments, the optimized laser processing parameters were adopted as follows: laser power 2.0 kW, laser beam diameter 3 mm, scanning velocity 2.5mm/s, overlapping 30%, powder feed rate 3.0 g/min, the argon flow rate 7.0 L/min. Specimens with the sizes of 10 mm × 8 mm × 8 mm were prepared using scanning strategies of cross-hatching. During SLM processing, the laser beam was focused on the substrate to create a melt pool into which the powder feedstock is delivered through an inert gas (He) flowing through a special nozzle, where the powder streams converge at the same point on the focused laser beam. An inert gas shroud containing argon was used as a protective atmosphere for preventing oxidation during deposition.

Phase identification of these SLM samples was carried out using XRD-6000 X-ray diffraction, equipped with a Ni filtered, Cu Kα radiation operating at 40 kV and 30 mA. The microstructural characteristics and composition were analyzed using a Zeiss Supra 55 (VP) scanning electron microscopy (SEM) and an EPMA-1720 electron probe micro-analyzer (EPMA). A DMH-2LS microhardness tester was used to measure microhardness under a load of 200 N with the duration of 15 s. The compressive property was measured with an Instron-type testing machine at a strain rate of 0.1 mm/min. The specimens for compressive testing were 6 mm × 3 mm × 3 mm cuboid. Reciprocating friction-wear test was performed using a CETR UMT-2 testing machine. A Si3N4 ball with a diameter of 5.96 mm and a hardness of HV1500 was selected as the wear couple. The experiment was performed at a normal load of 10 N, a sliding speed of 1.0 mm/s, and a wear time of 30 min. Continuous variable-temperature oxidation experiment was performed on TGA/SDTA85 thermal analyzer at a heating rate of 283 K/min and a temperature range of 200-1100 °C. The specimens for oxidation testing were 3 mm × 2 mm × 0.5 mm cuboid.

Table 1 Chemical composition of Ti-Al-Mn-Nb alloys

3 Results and discussion

3.1 Microstructure

Figure 1 shows the X-ray diffraction patterns of the alloys with different Nb additions. The data reveal that all alloys consist of γ-TiAl phase with tetragonal lattice and α2-Ti3Al phase with hcp structure. Further quantitative analysis using reference intensity method reveals that the content of the γ-TiAl phase gradually decreases with increasing Nb addition, while that of the α2-Ti3Al phase changes in the opposite trend.

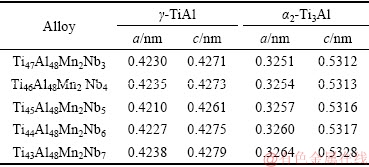

To investigate the influence of Nb additions on structure parameters, the lattice parameters of the constituent phases in each alloy were calculated using the least square method. As shown in Table 2, the lattice parameters of γ-TiAl compound increase with increasing Nb addition from 3.0 at.% to 4.0 at.%, then decrease as the Nb addition reaches 5.0 at.%, and increase again with further increasing Nb addition, while that of α2-Ti3Al compound shows increase in a parameter and less- affected c parameter until Nb reaches 7.0 at.%. This indicates that on the whole, the Nb tends to dissolve into γ-TiAl compound (except for 5.0 at.% Nb addition).

Fig. 1 X-ray diffraction patterns of alloys with different Nb additions

Table 2 Effects of Nb content on lattice parameters of constituent phases

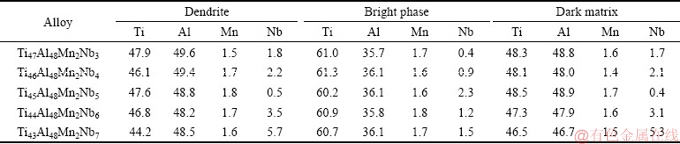

Figure 2 presents typical SEM images of the alloys with different Nb additions. As shown in (Fig. 2(a)), there exist large amount of dendrites in the dark matrix, together with some bright phases in the alloy with 3.0 at.% Nb. EPMA analysis reveals that the dendrite has a similar composition to the dark matrix, in which the mole ratio of titanium to aluminum is nearly 1:1, while the bright phase is rich in titanium (Table 3). Combining with the XRD analysis, it is indexed that dendrite and dark matrix correspond to γ-TiAl phase, while the bright phase corresponds to α2-Ti3Al compound. With increasing the Nb addition, the γ-TiAl dendrite shows a decrease in number and size. The α2-Ti3Al phase has an increase in number while decreasing in size (Fig. 2(b)). When Nb addition reaches 5.0 at.%, there is an obvious change in microstructure. A fine lath-shaped α2-Ti3Al phase is produced instead of granulated one (Fig. 2(c)). With further increasing Nb addition, α2-Ti3Al phase has a significant increase in number and shows characteristics of aggregation growth (Fig. 2(d)). This is followed by the formation of a near lamellar structure consisting of α2-Ti3Al and γ-TiAl phases with 7.0 at.% Nb addition (Fig. 2(e)).

Fig. 2 SEM images of alloys with different Nb additions

Table 3 EPMA analysis results taken from different areas of Ti-Al-Mn-Nb alloys (at.%)

Based on the above fact, it can be inferred that the microstructure evolution of the alloys during solidification process is as follows: the super-cooled liquid is solidified by the dendritic growth of the primary γ-TiAl phase followed by α-Ti transformation of the remaining interdendritic liquid. Upon cooling a eutectoid reaction of α-Ti occurs, leading to the formation of a mixture consisting of α2-Ti3Al plus γ-TiAl according to Ti-Al phase diagram. With the increasing of Nb addition, the composition of the alloys gradually shifts towards rich-Ti zone, which not only decreases the volume fraction of the primary γ-TiAl phase, but also reduces the temperature range of solidification, leading to grain refinement. This in turn, enlarges primary dendrite spacing and increases the inter-dendritic fluid flow rate, causing the decrease of inter-dendritic segregation. As a result, the morphology of the α2-Ti3Al phase changes from irregular shape to fine lath shape when Nb addition reaches 5.0 at.%. Above such an added amount, the volume fraction of α2-Ti3Al phase is significantly increased due to the sequential shift of alloy composition towards rich-Ti zone, resulting in the formation of a near lamellar structure.

EPMA analysis allows for determining the chemical composition of the observed phases. As shown in Table 3, the Nb in γ-TiAl and α2-Ti3Al phases shows a generally increasing trend with increasing Nb addition. But comparatively speaking, the content of Nb in the former is higher than that in the latter, indicating that Nb tends to dissolve into γ-TiAl. However, the alloy with 5.0 at.% Nb is an exception, in which the content of Nb in γ-TiAl is lower than that in α2-Ti3Al phase, which may be connected with the following fact: the decrease in size and number of primary γ-TiAl dendrite enlarges its spacing, resulting in the increase of the inter-dendritic fluid flow rate. This will decrease inter-dendritic segregation, making the more Nb dissolve into the α2-Ti3Al, as Nb is a α2-former [29]. This can be employed to explain why the α2-Ti3Al has larger lattice parameter, while the γ-TiAl has smaller one at 5.0 at.% Nb addition.

3.2 Mechanical properties

Figure 3 displays changing curve of the average microhardness of the alloys with Nb added amount. It is clear that the microhardness values of the alloys increase with increasing Nb addition from 3.0 at.% to 4.0 at.%, as a result of grain refinement and enhanced solution strengthening. Then an obvious hardness drop occurs with 5.0 at.% Nb addition. This may be connected with the decreased Nb content in the γ-TiAl, which makes the major structure low in hardness, so as to decrease the average hardness of the alloy, despite the fact that the microstructure is further refined and the more Nb is dissolved in α2-Ti3Al. When the addition of Nb is more than 5.0 at.%, the alloys exhibit increased hardness again with the even more Nb addition, owing to the continuously increased Nb in γ-TiAl and α2-Ti3Al, despite the fact that the fraction of the hard γ-TiAl decreases. Based on the above analysis, the conclusion can be made that solution strengthening plays a leading role in improving the hardness of the alloys. More Nb in γ-TiAl and α2-Ti3Al is associated with higher hardness.

Fig. 3 Influence of Nb addition on microhardness of alloys

Fig. 4 Stress-strain curves of alloys with different Nb additions under compressive test

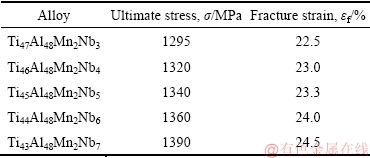

The strain-stress curves of the studied alloys under compressive test are shown in Fig. 4. It is obvious that the variation trend of load can be divided into three stages, namely initial straight-line elastic stage, nonlinear plastic stage and final failure stage. It is also observed that the stress-strain curves of all alloys exhibit “pop-in” phenomenon, which is connected with probable crack initiation, but it does not lead to failure of the alloys. The mechanical test data are summarized in Table 4. The data reveal that ultimate compression stress of the alloys increases with the increase of Nb addition as well as the ductile fracture strain.

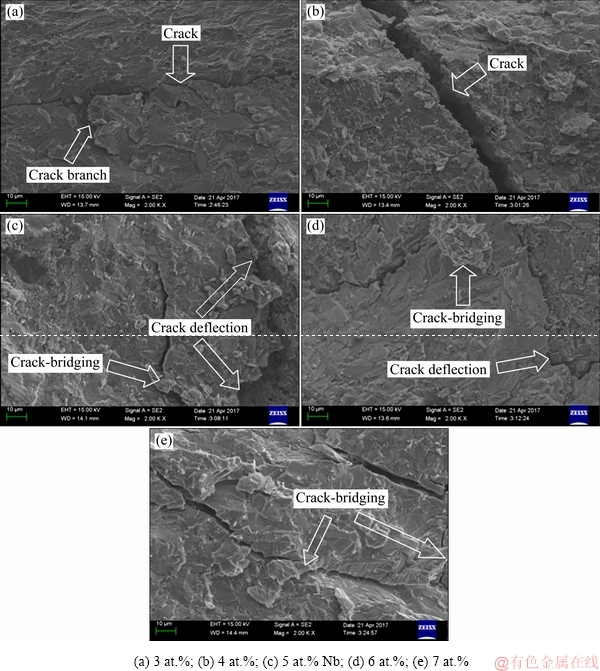

The fractography images of the alloys with different Nb additions are shown in Fig. 5. It can be seen that the fracture features of these alloys are similar and do not change significantly with the increase of Nb addition. The fracture surface essentially shows cleavage facets, and fracture mechanism can be identified as cleavage fracture mode. This can be understood in terms of ordered tetragonal structure of γ-TiAl phase, which will result in the low dislocation density or the lack of mobile dislocation, so that the deformation transition from one grain to another is difficult and that enhances the possibility for γ-TiAl grains to fracture through trans-granular cleavage fracture and grain boundary crack [30-32]. Here, it is worth mentioning that the alloys exhibit different crack paths, although they have the similar cleavage fracture mode. The main crack propagation with crack branches is clearly observed on the fracture surface of the alloy with 3.0 at.% Nb addition (Fig. 5(a)), because the resistance to slip and lack of easy slip systems restrict crack-tip plasticity as main crack advances, which makes local stress levels exceed the cohesive strength, causing the formation of crack branches, especially where the cleavage plane coincides with the dislocation slip and twin habit plane, the crack-growth resistance is believed to be very small. While the alloy with 4.0 at.% Nb exhibits straight crack path, in which no crack branches are observed (Fig. 5(b)). It is well known that α2-Ti3Al phase acts as reinforcement for crack propagation, since the dislocation activity is low. Thus, increased α2-Ti3Al fraction, together with grain refinement, can release the stress concentration at the grain boundaries and reduce the possibility of the generation of crack branches [6,27]. In the case of the alloy with 5.0 at.% Nb, crack deflection repeatedly occurs according to local crystallography, leading to the tortuous zigzag-shaped crack path (Fig. 5(c)), owing to the sequential increase of α2-Ti3Al fraction and the formation of even finer grain. Similar crack paths are also observed on the fracture surfaces of the alloys with 6.0 at.% and 7.0 at.% Nb, but these cracks do not cross the coarsened α2-Ti3Al grain, leaving crack-bridging (Figs. 5(d) and (e)). The crack deflection and crack-bridging formation will consume more fraction energy, being beneficial to improving strength and ductility of the alloys. Furthermore, it has been reported that the increased Nb content in γ-TiAl not only reduces the super-lattice intrinsic stacking fault (SISF) energy of the phase [33-37], but also increases the critical resolved shear stress (SRSS), which also play positive role in enhancing the strength and ductility of the alloys. General speaking, the increased α2-Ti3Al fraction, as well as high Nb content in γ-TiAl, is associated with the high mechanical property.

Table 4 Compressive test results of alloys

Fig. 5 SEM fractography images of alloys with different Nb additions

3.3 Tribological properties

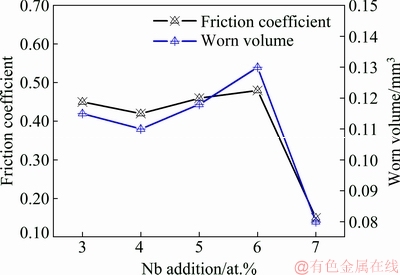

Figure 6 shows changing curves of friction coefficient and worn volume of the alloys with Nb added amount. The friction coefficient and worn volume of the alloys are in the range of 0.15-0.48 and 0.08-0.13 mm3, respectively. Both values show the trend of first decreasing, then increasing, and decreasing again with increasing Nb addition, with the lowest friction coefficient and the lowest worn volume obtained at 7.0 at.% Nb. This result suggests that the alloy with 7.0 at.% Nb has the best anti-friction property and the highest wear resistance among the studied alloys.

Fig. 6 Changing curves of friction coefficient and worn volume of alloys with Nb added amount

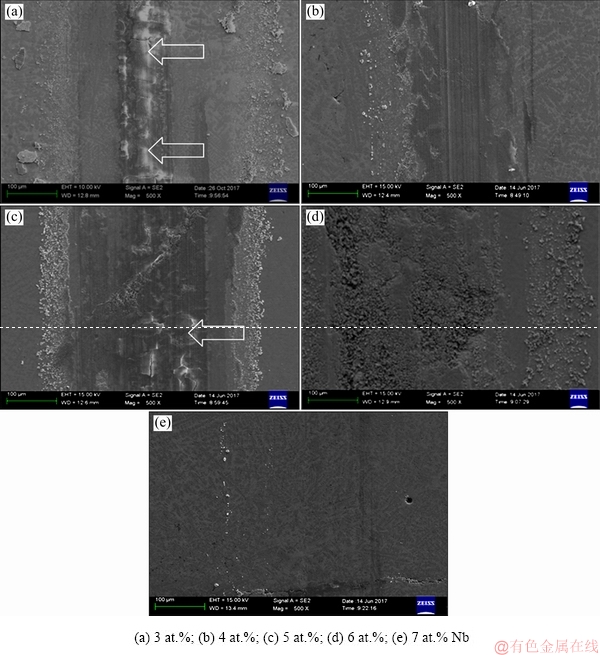

In order to identify the mechanism underlying the above change, the worn surface morphologies of the alloys were observed by SEM. As shown in (Fig. 7(a)), besides the plowing grooves characterizing abrasive wear, stress fatigue wear (indicated with arrows) takes place on the worn surface of the alloy with 3.0 at.% Nb. This fact may be connected with the formation of near full γ-TiAl. Owing to the low yield strength of the phase, plastic deformation may occur in the subsurface of the alloy under the repeated plowing action of the hard Si3N4 ball, which easily leads to the sharp increase of dislocation density, inducing the nucleation and growth of the crack. As sliding continues, some of the materials will be separated from the surface, leading to stress fatigue wear. With increasing Nb addition, stress fatigue wear is obviously weakened, since the increased fraction of α2-Ti3Al phase improves yield strength of the alloy. Meanwhile, the plowing grooves become narrow in width and shallow in depth resulting from the increased hardness (Fig. 7(b)). But when the addition of Nb reaches 5.0 at.%, stress fatigue wear is observed again, because the fine lath-shaped α2-Ti3Al phase is quite effortlessly cut by cracks propagation, as shown in Fig. 7(c), despite the fact that the fraction of α2-Ti3Al phase is further increased. At the same time, the anti-abrasive wear ability of the alloy is decreased due to a decrease of hardness, which is demonstrated by broader and deeper plowing grooves. With further increasing Nb addition, there is a definite change in the worn surface morphology of the alloy. A plastic smearing phenomenon is clearly observed (Fig. 7(d)). A possible explanation for this adhesive wear is that the sustained increase of α2-Ti3Al phase enhances the adhesive tendency between the alloy and the Si3N4 counterpart, which easily causes junctions at the contacting asperities under a compressive load. As sliding continues, the junctions will be broken under shearing stress, and then squeezed on the surface of the alloys, producing plastic smearing. When increasing Nb addition to 7.0 at.%, owing to the formation of a near lamellar structure with high hardness and low lattice mismatch, only slight abrasive wear takes place on the worn surface of the alloy as shown in Fig. 7(e).

3.4 High temperature oxidation-resistance

Figure 8 presents mass gain-temperature curves of the alloys with different Nb additions in TGA test. In the initial oxidation stage, the mass gain of the alloys is very small, indicating that oxidation scale yielded in this stage is protective for the alloys. When the temperature exceeds a certain threshold, the significant oxidation takes place, which may be attributable to the local spallation of oxidation scale. Although these alloys exhibit similar oxidation kinetic, the kinetic parameters change with increasing Nb addition. As shown in Table 5, the initial temperature of the vigorous oxidation shows a generally increasing trend with increasing Nb addition, while the mass gain and mass gain rate change in the opposite trend. Based on the data, one can draw a conclusion that increased Nb addition is beneficial to improving the oxidation resistance of the alloys. It is worth mentioning that the alloy with 5.0 at.% Nb is exception, its oxidation resistance is second only to that of the alloy with 7.0 at.% Nb.

Fig. 7 Worn surface morphologies of alloys with different Nb additions

Fig. 8 Mass gain-temperature curves in TGA test

Table 5 Kinetic parameters obtained from mass gain- temperature curves of alloys

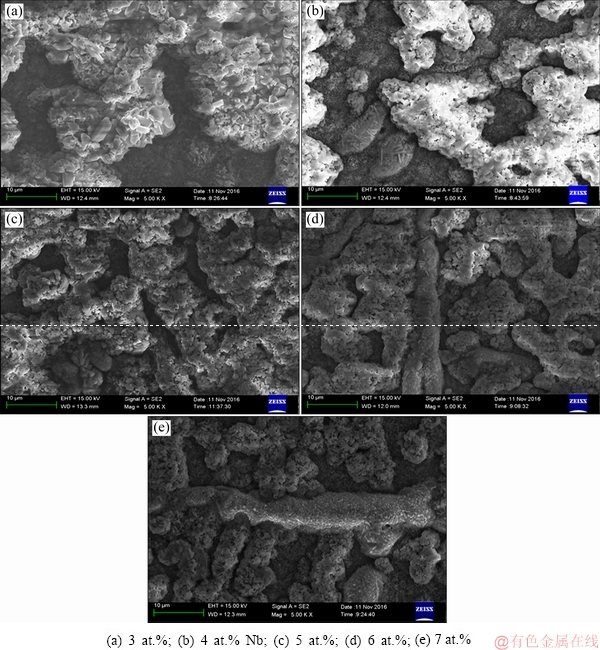

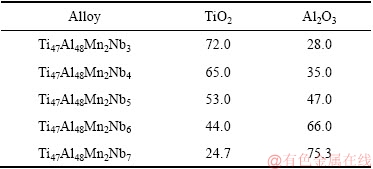

Figure 9 presents the oxidized surface morphologies of the alloys with different Nb additions. Grained oxides cover the surface of the alloys with some oxidation etching pits left in the inter-dendrites, where the grained oxides remain visible. With increasing the addition of Nb, the grained oxides are gradually refined, and the oxidation etching pits show a decrease in area and depth. XRD analysis reveals that the scales formed on the alloys consist of TiO2 and Al2O3 oxides, no diffraction peaks from Nb2O5 are observed (see Fig. 10), indicating that Nb ion mostly dissolves into TiO2 oxide. The data also reveal that the content of TiO2 oxide gradually decreases with the increasing Nb addition, while that of Al2O3 oxide steadily increases (Table 6).

Based on the above fact, it can be inferred that general behavior of the alloys during continuous variable-temperature oxidation process is as follows: in the initial state, Ti and Al will be oxidized simultaneously to form TiO2 and Al2O3, respectively, because the two oxides have the similar standard free energy of formation. Upon prolonged exposure to air, TiO2 starts to overgrow Al2O3 as TiO2 provides a fast diffusion path for oxygen. EPMA analysis reveals that the scales contain Nb and show an increasing trend in Nb content with increasing Nb addition (Table 7); however, no Nb2O5 is detected. This indicates that Nb as a slowly diffusing element may enrich at the interface, forming Nb2O5 oxide that will dissolve into TiO2. The doping of Nb5+ ion in the TiO2 lattice decreases the oxygen vacancy, which will inhibit the growth of TiO2 and enhance the growth of Al2O3. An indirect evidence for this is that the content of TiO2 in the scales decreases with increasing Nb addition, while that of Al2O3 increases as revealed by XRD, because the more the Nb ion content in the scales is, the stronger the inhibition on growth of TiO2 is. The Al2O3 oxide in the scale plays a role in improving the oxidation resistance of the alloys, as it is more stable than TiO2 and hinders the diffusion of oxygen. This can also be used to explain why the initial temperature of the vigorous oxidation is increased with increasing the addition of Nb. When the temperature exceeds a certain threshold, the doping effect of Nb ion will be weakened due to its consumption with the oxidation entering the stage of vigorous oxidation. In this stage, the local spallation easily takes place, especially in the α2-Ti3Al phase as it contains relative low fractions of Al and Nb. Combining with SEM and EPMA analyses, it can be found that the spalling degree is closely related to the Nb content in the α2-Ti3Al phase, the more Nb content in the α2-Ti3Al phase is, the smaller the spalling degree is. As a result, the mass gain and mass gain rate of the alloys are decreased. This suggests that Nb is a very effective element for improving the oxidation resistance of the alloys.

Fig. 9 Oxidized surface morphologies of alloys with different Nb additions

Fig. 10 X-ray diffraction patterns taken from oxidized surface of alloys with different Nb additions

Table 6 Content of oxides obtained from XRD pattern of oxidized surface of alloys (wt.%)

Table 7 EPMA analysis results of oxidized surfaces for alloys (at.%)

4 Conclusions

(1) The alloys consist of γ-TiAl and α2-Ti3Al compounds and exhibit a sequential structure change from near full dendrite to near lamellar structure with the increase of Nb addition.

(2) With the increase of Nb addition, hardness, friction coefficient, and worn volume of the alloys change in fluctuating way, with the highest hardness, the best tribological properties obtained at 7.0 at.% Nb, while the strength, ductility, and high temperature oxidation resistance increase monotonically. These suggest that the alloy with 7.0 at.% Nb addition has the best combination of mechanical, tribological, and high temperature oxidation resistance properties among the studied alloys.

References

[1] DIMITRIU S, DOBRESCU M. DUMITRIU G. The wear behaviour of titanium based alloys [J]. Metalurgija-MJoM, 2011, 17: 151-156.

[2] SRIVASTAVA D, CHANG I T H, LORETTO M H. The effect of process parameters and heat treatment on the microstructure of direct laser fabricated TiAl alloy samples [J]. Intermetallics, 2001, 9: 1003-1013.

[3] SRIVASTAVA D, HU D, CHANG I T H, LORETTO M H. The influence of thermal processing route on the microstructure of some TiAl-based alloys [J]. Intermetallics, 1999, 7: 1107-1112.

[4] MENAND A, HUGUET A, NERAC-PARTAIX A. Interstitial solubility in γ and α2 phases of TiAl-based alloys [J]. Acta Materialia, 1996, 44: 4729-4737.

[5] QU H P, LI P, ZHANG S Q, LI A, WANG H M. The effects of heat treatment on the microstructure and mechanical property [J]. Material and Design, 2010, 31: 2201-2210.

[6] ZHANG S Z, ZHANG C J, DU Z X, HOU Z P, CHEN Y Y. Microstructure and tensile properties of hot forged high Nb containing TiAl based alloy with initial near lamellar microstructure [J]. Science and Engineering A, 2015, 642: 16-21.

[7] KENEL C, DASARGYRI G, BUAER T, COLLELLA A, SPIERINGS A B, LEINENBACH C, WEGENER K. Selective laser melting of an oxide dispersion strengthened (ODS) γ-TiAl alloy towards production of complex structure [J] Material and design, 2017, 134: 81-90.

[8] LI Wei, LIU Jie, ZHOU Yan, WEN Shi-feng, WEI Qing-song, YAN Chun-ze, SHI Yu-sheng. Effect of substrate preheating on the texture, phase and nanohardness of a Ti-45Al-2Cr-5Nb alloy processed by selective laser melting [J]. Scripta Materialia, 2016, 118: 13-18.

[9] LIU Y J, LI S J, WANG H L, HOU W T, HAO Y L, YANG R, SERCOMBE T B, ZHANG L C. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting [J]. Acta Materialia, 2016, 113: 56-67.

[10] LI Rui-di, WANG Min-bo, YUAN Tie-chui, SONG Bo, CHEN Chao, ZHOU Ke-chao. Selective laser melting of a novel Sc and Zr modified Al-6.2 Mg alloy: Processing, microstructure, and properties [J]. Powder Technology, 2017, 319: 117-128.

[11] YANG Guang-yu, JIA Wen-peng, ZhAO Pei, JIA Liang, LIU Nan, WANG Jian, TANG Hui-ping. Microstructures of as-fabricated and post heat treated Ti-47Al-2Nb-2Cr alloy produced by selective electron beam melting(SEBM) [J]. Rare Metal Materials and Engineering, 2016, 45: 1683-1686.

[12] LUKAS L, FRANK P S, UTA K, FLORIAN P, JURGEN E. Selective laser melting of a beta-solidifying TNM-B1 titanium aluminide alloy [J]. Journal of Materials Processing Technology, 2014, 214: 1852-1860.

[13] ZHU Yan-yan, CHEN Bo, TANG Hai-bo, CHENG Xu, WANG Hua-ming, LI Jia. Influence of heat treatments on microstructure and mechanical properties of laser additive manufacturing Ti-5Al-2Sn- 2Zr-4Mo-4Cr titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 36-46.

[14] LI Wei, LIU Jie, ZHOU Yan, LI Shuai, WEN Shi-feng, WEI Qing-song, YAN Chun-ze, SHI Yu-sheng. Effect of laser scanning speed on a Ti-45Al-2Cr-5Nb alloy processed by selective laser melting: Microstructure, phase and mechanical properties [J]. Journal of Alloys and Compounds, 2016, 688: 626-636.

[15] TOMAS M, MALOT T, AUBRY P, COLIN C, VILARO T, BERTRAND P, The prospects for additive manufacturing of bulk TiAl alloy [J]. Material at High Temperature, 2016, 33: 571-577.

[16] LI X P, HUMBEECK J V, KRUTH J P. Selective laser melting of weak-textured commercially pure titanium with high strength and ductility: A study from laser power perspective [J]. Materials and Design, 2017, 116: 352-358.

[17] XU Sheng-hang, LIU Yong, LIU Bin, WANG Xin, CHEN Zhi-xing. Microstructural evolution and mechanical properties of Ti-5Al- 5Mo-5V-3Cr alloy by heat treatment with continuous temperature gradient [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 273-281.

[18] GUSSONE J, HAGEDRON Y C, CHRISTIAN Y, GHEREKHLOO H, KASPEROVICH G, MERZOUK T, HAUSMANN J. Microstructure of γ-titanium aluminide processed by selective laser melting at elevated temperature [J]. Intermetallics, 2015, 66: 133-140.

[19] LIN J P, XU X J, WANG Y L, HE S F, ZHANG Y, SONG X P, CHEN G L. High temperature deformation behaviors of a high Nb containing TiAl alloy [J]. Intermetallics, 2007, 15: 668-674.

[20] LIU Yan-bin, LIU Yong, WANG Bin, QIU Jing-wen, LIU Bin, TANG Hui-ping. Microstructures evolution and mechanical properties of a powder metallurgical titanium alloy with yttrium addition [J]. Materials & Manufacturing Processes, 2010, 25: 735-739.

[21] BACOS M P, THOMAS M. Processing and characterization of tial-based alloys: Towards an industrial scale [J]. Aerospace Lab, 2011, 3: 1-11.

[22] ZHONG Hong, YANG Yan-long, LI Jin-shan, WANG Jun, ZHANG Tie-bang, LI Sheng, ZHANG Ji. Influence of oxygen on microstructure and phase transformation in high Nb containing TiAl alloys [J]. Material letters, 2012, 83: 198-201.

[23] WU Y, HWANG S K. Microstructural refinement and improvement of mechanical properties and oxidation resistance in EPM TiAl-based intermetallics with yttrium addition [J]. Acta Materialia, 2002, 50: 1479-1493.

[24] IMAYEV R M, IMAYEV V M, OEHRING M, APPEL F. Alloy design concepts for refined gamma titanium aluminide based alloys [J]. Intermetallics, 2007, 15: 451-460.

[25] ZHAO E T, NIU H Z, ZHANG S Z, FENG L, YANG S Y. Microstructural control and mechanical properties of a β-solidified γ-TiAl alloy Ti-46Al-2Nb-1.5V-1Mo-Y [J]. Materials Science and Engineering A, 2017, 701: 1-6.

[26] JABBAR H, MONCHOUX J P, THOMAS M, COURET A. Microstructures and deformation mechanisms of a G4 TiAl alloy produced by spark plasma sintering [J]. Acta Materilia, 2011, 59: 7574-7585.

[27] ZHAO Y B, ZHANG S Z, ZHANG C J, LIN P, HOU Z P, CHEN Y Y. Microstructural evaluation of hot-forged high Nb containing TiAl alloy during high temperature tension [J]. Materials Science and Engineering A, 2016, 678: 116-121.

[28] WU Y, HWANG S K. The effect of yttrium on microstructure and dislocation behavior of elemental powder metallurgy processed TiAl-based intermetallics [J]. Materials Letters, 2004, 58: 2067-2072.

[29] FU Bin-guo, WANG Hong-wei, ZOU Chun-ming, WEI Zun-zie. The effects of Nb content on microstructure and fracture behavior of near α titanium alloys [J]. Material and Design, 2015, 66: 267-273.

[30] MENAND A, ZAPOLSKY-TATRENKO H, NERAC-PARTAIX A. Atom-probe investigations of TiAl alloys [J]. Materials Science and Engineering A, 1998, 250: 55-64.

[31] LI Jian-bo, LIU Yong, LIU Bin, WANG Yan, LIANG Xiao-peng, HE Yue-hui. Microstructure characterization and mechanical behaviors of a hot forged high Nb containing PM-TiAl alloy [J]. Materials Characterization, 2014, 95: 148-156.

[32] ZHANG Hao-ming, HE Xin-bo, QU Xuan-hui, ZHAO Li-ming. Microstructure and mechanical properties of high Nb containing TiAl alloy parts fabricated by metal injection molding [J]. Materials Science and Engineering A, 2009, 526: 31-37.

[33] CAO R, LIN Y Z, HU D, CHEN J H. Fracture behaviour of a TiAl alloy under various loading modes [J]. Engineering Fracture Mechanics, 2008, 75: 4343-4362.

[34] JABBAR H, MONCHOUX J P, HOUDELLIER F, DOLLEM, SCHIMANSKY F P, PYCZAK F, THOMAS M, COURET A. Microstructure and mechanical properties of high niobium containing TiAl alloys elaborated by spark plasma sintering [J]. Intermetallics, 2010, 18: 2312-2321.

[35] FRITZ A, JONATHAN D H P, OEHRING M. Gamma titanium aluminide alloys [M]. Weinheim: Elsevier, 2011.

[36] KIM Young-won, SMARSLY W, LIN Jun-pin, DIMIDUK D, APPEL F. Gamma titanium aluminide alloys [M]. New Jersey: Elsevier, 2014.

[37] KONG Fan-tao, CUI Ning, CHEN Yu-yong, ZHANG De-liang, SU Yong-jun. Microstructure and mechanical properties of TiAl alloys produced by powder metallurgy [J]. The Minerals, Metals, Materials Society, 2014, 3: 203-205.

Adam Ismaeel,王存山

大连理工大学 三束材料改性重点实验室,大连 116024

摘 要:采用选区激光熔化技术,在TC4合金基体上制备不同Nb含量的γ-TiAl 基 Ti-Al-Mn-Nb合金。系统分析Nb含量对合金显微组织和性能的影响规律。研究结果表明,合金主是由四方结构的γ-TiAl和密排六方结构的α2-Ti3Al相组成,且随着Nb含量的增加,合金的凝固组织逐渐由枝晶状结构演化为层片状结构。因高含量Nb在γ-TiAl 相中的固溶,以及细小板条状结构的形成,致使Nb含量为7.0 at.%的合金具有最佳的综合性能,即其不仅具有高的硬度(HV 2000)、高的强度(1390 MPa)和良好的塑性变形能力(24.5%),而且具有良好的摩擦磨损和高温抗氧化性能。

关键词:选区激光熔化;γ-TiAl 基合金;显微组织;性能;Nb添加

(Edited by Xiang-qun LI)

Foundation item: Project (51371041) supported by Chinese Scholarship Council and the National Natural Science Foundation of China

Corresponding author: Cun-shan WANG; Tel: +86-411-84707930; E-mail: laser@dlut.edu.cn

DOI: 10.1016/S1003-6326(19)65009-0