Phase changes in Ge1Sb2Te4 films induced by single femtosecond laser pulse irradiation

HUANG Su-mei (黄素梅), SUN Zhuo (孙 卓), JIN Cai-xia(靳彩霞),

HUANG Shi-yong(黄士勇),CHEN Yi-wei (陈奕卫)

Department of Physics, East China Normal University, Shanghai 200062, China

Received 10 April 2006; accepted 25 April 2006

Abstract: Phase transformations in a Ge1Sb2Te4 system induced by a single femtosecond laser exposure were investigated. The system has a multilayer structure of air/10 nm ZnS–SiO2/80 nm Ge1Sb2Te4/80 nm ZnS–SiO2/0.6 mm polycarbonate substrate. The morphology and contrast of marks written in both amorphous and crystalline backgrounds by single femtosecond pulses were characterized using an optical microscope. X-ray diffraction (XRD) was applied to identify the crystal structures transformed by single 108 fs shots. The characteristics and the conditions of phase transitions in the multilayer structure triggered by single shots were investigated. The pulse energy window for the crystallization in the Ge1Sb2Te4 system was established. The mechanism of phase change triggered by 108 fs laser pulses was discussed.

Key words: femtosecond laser; phase change; optical recording; amorphization; crystallization

1 Introduction

Currently, the amount of digital information is growing very fast and access to this information is made via faster and faster networks. Data storage systems have to keep pace with this explosive growth. High capacity data storage devices with high-speed data transfer rate and optically rewritable are in high demand. Optical data storage techniques based on ultrafast lasers have attracted increasing interest. There are numerous reports about 3D optical data storage techniques based on multiphoton absorption[1-4]. Multiphoton absorption of ultrafast laser light can be used to initiate photochemical or photophysical processes that alter the local optical properties of a material. Because the probability for the simultaneous absorption of n photons is proportional to the laser intensity to the n-th power, at appropriate intensities the changes in optical properties can be localized within the focal volume. The focal 3D position can be controlled precisely. By employing optics with high numerical aperture, focal regions with submicrometre dimensions can be readily attained.

Short pulse width lasers such as the femto to pico second pulse laser have been used to develop ultrafast phase change recording technologies. The promise of these technologies is that ultafast lasers have potentials to resolve the heat diffusion limitation of the conventional laser recording, achieve high area recording densities, and have potentials to increase data transfer rates beyond current limits. The possibility of inducing crystallization or amorphization has been studied in some phase change materials with ultrashort pulses from 100 fs to 30 ps[5-11]. The work has mostly been concentra-ted on Sb-rich, GeSb films[7-11]. It was shown that reversible changes between the amorphous and crystalline states could be achieved in GeSb films on carbon coated mica upon irradiation with single 500 fs laser pulses[7], and phase reversibility was also demons-trated in the GeSb film on the substrate upon irradiation with single 30 ps laser pulses by designing the film configuration (film thickness and substrate) to control the heat flow conditions in the configuration[8, 11].

It is one of the most important goals for any ultrafast phase change recording technology to make it possible to record and retrieve data rapidly using compact and relatively inexpensive equipment with high repetition rates (such as non-amplified laser systems and non-immersion optics) and materials. Any technique allowing for data storage to be achieved under similar constraints will be all the more advantageous. To this end, the investigation of the mechanisms of ultrafast laser- induced phase changes to achieve phase reversibility in phase change materials with single femtosecond shots and establishing laser parameter windows for various phase change systems is very important. The laser parameters should include ultrafast laser pulse duration, pulse energy or intensity, and wavelength because these factors play important roles in ultrafast phase changes of the systems. Chalcogenides are used in reversible optical information storage such as CD-RW and DVD-RW with nanosecond pulsed lasers. This nanosecond laser recording technology is very mature. Stoichiometric compositions on the Sb2Te3–GeTe pseudobinary system, such as Ge1Sb2Te4, Ge2Sb2Te5 and Ge1Sb4Te7 are regarded as fast phase change materials since both amorphization and crystallization can be triggered by laser irradiations of very short duration, 30-100 ns[12]. The study of GeSbTe system has mainly focused on the crystallization or amorphization triggered by nanosecond laser[12-14].

In this work, laser-induced phase changes in Ge1Sb2Te4 films under the action of single femtosecond laser pulse were presented. Femtosecond laser pulses were used to investigate the phase reversibility in a multilayer structure where the active Ge1Sb2Te4 layer is interfaced with a poor thermal conducting layer, e.g. a dielectric ZnS-SiO2 composite, on the polycabonator substrate. Phase transformations induced by the single femtosecond shots in the active Ge1Sb2Te4 layer were examined and characterized using optical microscopy and X-ray diffraction (XRD). The mechanism of the phase transformations was discussed. The conditions to achieve reversible phase transformations in the Ge1Sb2Te4 film within the conventional optical disk structure using single femtosecond laser pulse irradiation were investigated, and the related parameter window was provided.

2 Experimental

The disks were prepared on 0.6 mm-thickness polycarbonate substrates using an ULVAC multi-chamberssputtering technology. The phase change material Ge1Sb2Te4 was sandwiched between two dielectric layers. Amorphous Ge1Sb2Te4 film with thickness of 80 nm was prepared by DC magnetron sputtering. The lower dielectric layer and the upper dielectric layer were deposited by RF magnetron sputtering. The thickness of the lower ZnS-SiO2 layer is 80 nm while that of the upper ZnS-SiO2 layer is 10 nm. The thickness of all the layers is in the conventional thickness range of optical disk structure design. After sputtering, every disk was initialized in half a region of the whole disk. Therefore, every disk provided both amorphous and previously crystallized regions or backgrounds for the femtosecond laser irradiation.

The femtosecond laser system consisting of a Ti:sapphire oscillator (spectra-physics tsunami) and a regenerative amplifier (spectra-physics spitfire) provided femtosecond laser pulses for the study. A self-mode-locked Ti:sapphire laser oscillator produced about 80 fs pulses at a wavelength of 800 nm and a repetition rate of 80 MHz. The oscillator provided seed pulses into the regenerative amplifier, which was based on chirped pulse amplification (CPA) technique. The wavelength of output beam from amplifier was 800 nm. The repetition rate can be adjusted from 1 to 1 000 Hz and the beam profile emitted from the regenerative amplifier was Gaussian shape. The femtosecond laser beam was focused on the disk by a ×20 optical microscope objective. The disk was placed on a 3-axis, X-Y-Z, motion system. Z stage was used to adjust the vertical distance between the disk and microscope objective and the laser beam was focused on the phase change layer of the disk. X-Y motion system was used to move the disk relative to the laser beam on a horizontal plane to write data bits in the disk. During the laser processing, each data point was written only by a single pulse through adjusting the speeds of the X and Y stages as well as the repetition rate of the femtosecond laser beam. In order to adjust the laser energy incident on the disk, external attenuators were used in the optics path before the optical objective. The pulse duration of the laser beam after external attenuators was 108 fs, measured by GRENOUILLE/VideoFROG, model 8-50, Newport. Laser writing and treatment were done by crossing both amorphous and previously crystallized regions every time. After the laser treatment, the morphologies and contrast of the written data bits in the disk were examined using an optical microscope, and X-ray diffraction (XRD) was applied to identify the crystal structure transformed by a single femtosecond shot.

3 Results and discussion

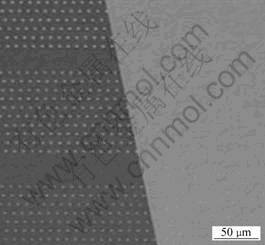

The sample used was a disk with a multilayer structure of air/10 nm ZnS–SiO2/80nm Ge1Sb2Te4/80 nm ZnS–SiO2/0.6 mm polycarbonate substrate, without reflection layer. One half of the disk was initialized to provide both amorphous and crystallized regions or backgrounds for the femtosecond laser irradiation. The femtosecond laser incident side was the air side. Laser irradiation and treatment was done by crossing both the amorphous and previously crystallized regions. Fig.1 shows an optical image of amorphous and crystallized backgrounds after initialization. The morphology and contrast of amorphous or crystallized backgrounds can be clearly observed under the optical microscope by regulating its focused lens and filters. Amorphous and crystallized regions show different contrast under the microscope. The amorphous background shows dark color under the microscope while the crystallized one displays bright color as shown in Fig.1. Fig.2 shows the morphology and contrast of both crystallized and amorphous backgrounds after single femtosecond laser shots with various laser fluences. After single femtosecond laser shots, there are small marks, circular bright spots, formed in the amorphous background as shown in Fig.2, but no change can be observed in the

Fig.1 Optical image of crystallized and amorphous backgrounds before femtosecond laser irradiation

Fig.2 Optical image of morphology and contrast of both crystallized and amorphous backgrounds after single femtosecond laser shots with laser fluences of 22 mJ/cm2 (upper section) and 33 mJ/cm2 (lower section)

crystallized background under microscope. The upper and lower dot arrays in the amorphous background are transformed by laser fluences of 22 and 33 mJ/cm2, respectively. There is a gap without laser treatment between both arrays. The contrast of marks written in the amorphous background is similar to that of the crystallized background shown in Fig.1. The circular marks induced with a fluence of 33 mJ/cm2 are bigger and brighter than those by a lower fluence of 22 mJ/cm2. Fig.3 displays the morphology and contrast of both crystallized and amorphous backgrounds after laser irradiation with higher laser fluences. Four distinct dot arrays are formed in the amorphous background by fluences of 93, 82, 70 and 62 mJ/cm2 from top to bottom, respectively. There is a gap without laser treatment between these four dot arrays. From Fig. 3, with the laser fluenece rising, the data spots obtained in the amorphous background become bigger and brighter. Their morphology and contrast are similar to those of the crystallized region. No change, however, can be observed in the crystallized background with laser fluence in this range. This trend keeps for both backgrounds until the average laser fluence is increased up to 105 mJ/cm2. When an average laser fluence is not less than 105 mJ/cm2, damage is created at the centers of laser spots in amorphous and crystallized regions.

Fig.3 Optical image of morphology and contrast of both crystallized and amorphous backgrounds after single femtosecond laser shots with laser fluences of 93, 82, 70 and 62 mJ/cm2 from top section to bottom section

Fig.4 exhibits the morphology and contrast of both crystallized and amorphous backgrounds after laser irradiation with fluences of 124 and 93 mJ/cm2 from top to bottom, respectively. Small holes appear at the centers of spots in both kinds of backgrounds with this laser fluence. By more carefully adjusting the laser fluence, the morphology and contrast of both crystallized and amorphous backgrounds with laser fluences of 105 and 93 mJ/cm2 are obtained and shown in Fig.5. For the laser fluence of 105 mJ/cm2, very slight damage was created at the centers of the spots in both types of backgrounds. The bright data bit arrays (10 μm×10 μm) with a fluence of 93 mJ/cm2 were produced in an area of 1 cm×1 cm for XRD analysis. Crystallographic texture of

the film in this area was studied at room temperature using Cu Ka X-ray diffractometry. Fig.6 shows the XRD result.

From the above results, bright and white marks produced in the amorphous background are with morphology and contrast very similar to those of the crystallized region shown in Fig.1. The result can be attributed to the transformation from the amorphous to crystalline phase. This crystallization has been achieved upon irradiation with single femtosecond laser pulses when the average laser fluence is greater than 20 mJ/cm2,

Fig.4 Optical image of morphology and contrast of both crystallized and amorphous backgrounds after single femtosecond laser shots with laser fluences of 124 mJ/cm2 (upper section) and 93 mJ/cm2 (lower section)

Fig.5 Optical image of morphology and contrast of both crystallized and amorphous backgrounds after single femtosecond laser shots with laser fluences of 105 mJ/cm2(upper section) and 93 mJ/cm2(lower section)

Fig.6 XRD pattern of sample(1 cm×1 cm) with data bit arrays(10 μm×10 μm) formed in amorphous background of 80 nm thick Ge1Sb2Te4 film with average laser fluence of 93 mJ/cm2

but less than 105 mJ/cm2. When the laser fluence is more than 105 mJ/cm2, damage is created at the centers of the spots in both types of backgrounds, as shown in Figs.4 and 5. A single pulse at a very high fluence of 124 mJ/cm2 induces the crystallization of an amorphous region. The crystallized dot shows a partial ablation at its center shown in Fig.4. This can be attributed to the higher energy density at the center part of the femtosecond spot than at its edge because of the Gaussian-like intensity distribution of the femtosecond laser beam. The portions at the centers of the femtosecond spots are ablated as a consequence of the femtosecond irradiation. Ablation also occurs in the crystallized background with this high fluence. A hole is formed at the laser spot in crystallized background as shown in Fig.4. At a fluence of 105 mJ/cm2, very slight damage is created at the laser spots in both backgrounds. Thus, from Figs.4 and 5, the ablating threshold fluence for amorphous and crystallized backgrounds is about 105 mJ/cm2. The XRD result shown in Fig.6 provides a further evidence for the crystallization. The result confirms the face-centered cubic structure for the amorphous region subjected to single 108 fs laser irradiation[15]. Therefore, crystallization of the amorphized phase has been demonstrated by single 108 fs laser irradiation. However, the inverse transformation, i.e. re-amorphization of the pre-crystallized phase does succeed with single 108 fs laser irradiation by adjusting fluence between the surface melting and damage thresholds in the sample.

A time resolved study on the dynamics of femtosecond laser induced structural transformations in amorphous and crystallized regions was carried out. The irradiation of amorphous regions causes a high reflectivity phase to appear within about 1 ps after excitation. But their final reflectivities or phases are distinct. The material behavior in the sub-picosecond timescale can be interpreted in terms of a non-thermal, electronically induced phase transition. This non-thermal, ultrafast phase transition occurs at the very same spatial location, in which the final crystalline is formed in the sample. In the absence of the ultrafast transient phase, permanent crystallization of the irradiated region does not occur.

Through excitation with an ultrashort pulse, the system undergoes several stages of relaxation before returning to equilibrium. The energy is transferred first to the electrons and then to the lattice. The interaction includes several regimes, carrier excitation, thermalization, carrier removal and thermal and structural effects of carrier excitation and relaxa-tion[16]. Various processes do not occur sequentially. They overlap in time, forming a continuous chain of events spanning the entire range from femtoseconds to microseconds. Excited by an ultrashort pulse, the pulse energy is deposited within a very short time in a very thin surface layer, leading to the high reflectivity, disordered phase (sometimes called a “molten” phase) observed in a few picoseconds after excitation, then melting or ablation (for strong excitation) and resolidification. The inability of the studied sample to amorphize upon single pulse irradiation is related to the ultrashort laser pulse duration and the undercooling achieved prior to solidification. The nanosecond-induced amorphization of GeSbTe films is produced at quenching rates greater than 3.4?109 K/s[5]. The quenching rates expected for irradiation with femtosecond and picosecond are in both cases greater than 1012 K/s and therefore the formation of amorphous phases may be expected for our sample. Nevertheless the undercooling achieved prior to solidification is another important factor involved in the formation of amorphous phases by rapid solidification process. During the initial solidification process into an amorphous one, the solidification enthalpy releases, resulting in lowering the supercooling and promoting the nucleation and growth of the crystalline phase. The amount of solidification enthalpy released depends both on the film thickness and on the nature of the solid phase which nucleates homogeneously (amorphous or crystalline). Both the effects of relaxation excess and recalescence could be prevented by using very thin films on low-thermal-conductivity substrates. The effects of recalescence (undercooling decreases) took place in our sample due to its 80 nm thick phase change layer. These effects impeded the re-amorphization in the sample. Previous research on optical media operated in nanosecond laser pulse showed that in most of stoichiometric systems the amorphous phase cannot be crystallized upon irradiation with pulses shorter than a few tens of nanosecond[12]. But, our work once again confirms that crystallization can be achieved in the Ge1Sb2Te4 system upon irradiation with single 108 fs laser pulses. The final structure induced upon irradiation and the reversibility of the process is strongly conditioned by the thermal properties of the film/substrate system. Therefore, reversible phase transformations of amorphization?crystallization by a single femtosecond pulse of a fix laser in a Ge1Sb2Te4 system can be obtained by changing the laser pulse duration, carefully adjusting the fluence and designing the configuration (dielectric layer /active film thickness/ dielectric layer substrate). The detailed work will be studied further.

As reported above, crystallization requires a fluence of 22-105 mJ/cm2 in Ge1Sb2Te4 disks. The correspon-ding single shot energy range is from 3.0 nJ to 14.0 nJ for the crystallization. The Ti:sapphire laser oscillator has a repetition rate of 82 MHz, and its single pulse energy is high up to 13 nJ. Thus, for this model oscillator, the single shot of Ti:sapphire laser oscillator can provide enough energy to achieve amorphous to crystalline phase change in Ge1Sb2Te4 disk. A repetition rate of 80 MHz is three orders of magnitude higher than that of the nanosecond lasers. On the other hand, an important consequence of this behavior is the fact that the extrapolation of the fluences required for crystallization under sub-picosecond laser pulses to a diffraction-limited spot size is consistent with pulse absolute energy in the sub-nJ range. The laser requirements for the application of the material as a sub-picosecond laser-pulse-driven optical recording medium are thus compatible with those provided by compact diode-pumped picosecond/femtose-cond laser oscillators. Recording or retrieving data rapidly is possible by using these oscillators as a laser source because of its very high repetition rate.

4 Conclusions

The phase transformations in a Ge1Sb2Te4 system induced by a single femtosecond laser exposure are investigated. The system has a multilayer structure of air/10 nm ZnS–SiO2/80 nm Ge1Sb2Te4/80 nm ZnS-SiO2/0.6 mm polycarbonate substrate. The morpho-logy and contrast of marks written in both amorphous and crystalline backgrounds by single femtosecond pulses are characterized. The detailed results of optical microscopy evaluation of the morphology and contrast of marks written in both amorphous and crystalline backgrounds by single 108 fs pulses are presented. X-ray diffraction (XRD) is applied to identify the crystal structures formed by single femtosecond shots. A well-defined laser fluence and pulse energy window for achieving amorphous to crystalline phase change in the Ge1Sb2Te4 systems using single 108 fs pulses is provided. The mechanism of phase transformations triggered by femtosecond laser pulses is discussed.

References

[1] GLEZER E N, MILOSAVLJEVIC M, HUANG L, FINLAY R J, HER T H, CALLAN J P, MAZUR E. Three-dimensional optical storage inside transparent materials[J]. Opt Lett, 1996, 21: 2023-2025.

[2] WATANABE M, SUN H B, JUODKAZIS S, TAKAHASHI T, MATSUO S, SUZUKI Y, NISHII J, MISAWA H. Three- dimensional optical data storage in vitreous silica[J]. Jpn J Appl Phys, 1998, 37(12B): L1527-L1530.

[3] CUMPSTON B H, ANANTHAVEL S P, BARLOW S, DYER D L, EHRLICH J E, ERSKINE L L, HEIKAL A A, KUEBLER S M, LEE I-Y S, MCCORD-MAUGHON D, QIN JINQUI, ROCKEL H, RUMI M, WU XIANG-LI, MARDER S R, PERRY J W. Two-photon polymerization initiators for three-dimensional optical data storage and microfabrication[J]. Nature, 1999, 398(6722): 51-54.

[4] DAY D, GU M, SMALLRIDGE A. Use of two-photon excitation for erasable–rewritable three-dimensional bit optical data storage in a photorefractive polymer[J]. Opt Lett, 1999, 24(14): 948-950.

[5] OHTA T. Phase-change optical memory promotes the DVD optical disk[J]. J Optoelectron Adv Mater, 2001, 3(3): 609-626.

[6] SIEGEL J, SCHROPP A, SOLIS J, AFONSO C N,WUTTIG M. Rewritable phase-change optical recording in Ge2Sb2Te5 films induced by picosecond laser pulses[J]. Appl Phys Lett, 2004, 84(13): 2250-2251.

[7] AFONSO C N, SOLIS J, CATALINA F, KALPOUZOS C. Ultrafast reversible phase change in GeSb films for erasable optical storage[J]. Appl Phys Lett, 1992, 60(25): 3123-3125.

[8] MORILLA M C, SOLIS J, AFONSO C N. Phase change cycling for erasable optical storage driven by ultrashort laser pulses[J]. Jpn J Appl Phys, 1997, 36(8A): L1015-L1018.

[9] SIEGEL J, AFONSO C N, SOLIS J. Dynamics of ultrafast reversible phase transitions in GeSb films triggered by picosecond laser pulses[J]. Appl Phys Lett, 1999, 75(20): 3102-3104.

[10] CALLAN J P, KIM A M-T, ROESER C A D, MAZUR E, SOLIS J, SIEGEL J, AFONSO CN, D E SANDE J C G. Ultrafast laser-induced phase transitions in amorphous GeSb films[J]. Phys Rev Lett, 2001, 86 (16): 3650-3653.

[11] SOLIS A, AFONSO C N. Ultrashort-laser-pulse-driven rewritable phase-change optical recording in Sb-based films[J]. Appl Phys A: Mater Sci Process, 2003, 76: 331-338.

[12] YAMADA N, OHNO E, NISHIUCHI K, AKAHIRA N, TAKAO M. Rapid-phase transitions of GeTe-Sb2Te3, pseudobinary amorphous thin films for an optical disk memory[J]. J Appl Phys, 1991, 69: 2849-2856.

[13] WEIDENHOF V, PIRCH N, FRIEDRICH I. Atomic force microscopy study of laser induced phase transitions in Ge2Sb2Te5[J]. J Appl Phys, 1999, 86(10): 5879-5887.

[14] WEIDENHOF V, FRIEDRICH I, ZIEGLER S, WUTTIG M. Laser induced crystallization of amorphous Ge2Sb2Te5 films[J]. J Appl Phys, 2001, 89(6): 3168-3176.

[15] MAO Z L, CHEN H, JUNG A L. The structure and crystallization characteristics of phase change optical disk material GelSb2Te4[J]. J Appl Phys, 1995, 78(4): 2338-2342.

[16] SUNDARAM S K, MAZUR E. Inducing and probing non-thermal transitions in semiconductors using femtosecond laser pulses[J]. Nature Materials, 2002, 1: 217-224.

(Edited by CHEN Wei-ping)

Foundation item: Project(05PJ14037) supported by Foundations of Pujiang Talented Person Plans of Shanghai Science and Technology; Project(0519) supported by Shanghai-Applied Materials Research and Development Fund; Project(0552nm042) supported by the Shanghai Science and Technology Committee

Corresponding author: HUANG Su-mei; Tel: +86-21-62233227; Fax: +86-21-62232413; smhuang@phy.ecnu.edu.cn