J. Cent. South Univ. Technol. (2010) 17: 1344-1350

DOI: 10.1007/s11771-010-0640-z

IFC-based integration tool for supporting information exchange from architectural model to structural model

LIU Zhao-qiu(刘照球)1, 2, LI Yun-gui(李云贵)3, ZHANG Han-yi(张汉义)3

1. School of Civil Engineering, Tongji University, Shanghai 200092, China;

2. School of Civil Engineering, Yancheng Institute of Technology, Yancheng 224051, China;

3. China Academy of Building Research, Beijing 100013, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2010

Abstract: With the purpose of enhancing effective collaboration between architects and structural engineers in the building design field, an integration tool was developed for supporting information exchange from architectural model to structural model. The PKPM (Bopomofo acronym, a Chinese building design software) structural model and an industry foundation classes (IFC) data model were adopted and analyzed to design the framework of the integration tool. The technique of mixed program languages (C++ and FORTRAN) was applied to developing the tool software, and the connectivity relationships and intersection nodes between the structural elements were optimized and simplified. A case study was implemented to illustrate the method to use the integration tool for information exchange from IFC-format architectural model to PKPM structural model. The results show that the tool can extract the information of architectural model and form a corresponding structural model. The presented method can help to enhance the modeling efficiency at the structural design phase.

Key words: architectural model; structural model; industry foundation classes; information exchange

1 Introduction

In the building design field, information exchange and sharing become increasingly important between architects and structural engineers with the emerging use of industry foundation classes (IFC) standard and building information modeling (BIM) technology. However, numerous designers still maintain their disciplines’ independence, and different design companies have different software applications to fulfill their tasks in the Chinese construction industry [1]. Information isolated islands and lack of efficient information management throughout all disciplines involved often result in repeated work, low efficiency and additional cost and time. According to some statistics, about 9.8% of the increasing costs for projects in early phases (architectural phase for 3.3%, structural phase for 3.6%, and others for 2.9%) are caused by the issues above [2].

IFC is a set of building product model specification developed by the international alliance for interoperabi- lity (IAI) for data representation and exchange in the construction industry [3]. The IFC standard suitably provides an information exchange and sharing platform, which can couple with the network technology to form a central database server to facilitate information exchange among different participators from various geographical locations [4]. The building software applications supporting the IFC standard are able to exchange data with other applications that are also IFC-compliant. SERROR et al [5] developed an IFC-based model infrastructure for improving the interoperability between participants in a construction project. PLUME and MITCHELL [6] reported their experience in running a multidisciplinary design studio using a shared building model. WAN et al [7] developed a building model server for supporting data integration between IFC and SAP2000. ABIDEMI et al [8] presented a software solution that could reduce initial knowledge requirement for understanding EXPRESS language of the IFC model. CHEN et al [3] presented an implementation of IFC- based information server for web-enabled collaborative building design between different disciplines. LEE et al [9] developed a design information management system based on IFC standard. KAROLA et al [10] presented a tool, BSPro COM-server, for easier implementation of IFC files for existing and new software tools. FARAJ et al [11] developed an IFC shared project environment based on Web. In China, WANG et al [12] developed a 4D construction management system based on IFC and engineering information model. DENG et al [13] presented an algorithm for forming structural model from IFC-based architectural model.

The current PKPM software, a Chinese leading building software developed by the China Academy of Building Research (CABR), still does not support information exchange with the IFC-compliant architectural model. In order to enhance design efficiency and establish an information channel from IFC-based architectural model to PKPM structural model, the two data models were analyzed, and an integration tool for supporting information exchange was developed. A case study was provided to illustrate the method to use the tool for information exchange from IFC to PKPM.

2 PKPM structural model

The structural model of PKPM software is mainly implemented by plane modeling CAD (PMCAD) module [14]. PMCAD, which is the core of the structural part of PKPM software, has convenient and speedy functions for structural modeling. The objective of the integration tool presented in this work is to implement information exchange from IFC-based architectural model to PMCAD structural model of PKPM.

The standard floor of the general structures is taken by the PMCAD as its modeling foundation. There are two basic assumptions in PMCAD: (1) columns and walls are laid vertically and have the same height with the structural floor; and (2) beams are laid horizontally within the height of the structural floor. Based on the above two assumptions, columns can be located by the nodes, and walls and beams can be located by plane grid lines. These greatly simplify the data management of structural model and all the structural elements of the whole standard floor can be located by plane grid lines. In the modeling of PMCAD, the representation of structural elements can be divided into two steps, that is, the shape definition and whole localization.

2.1 Shape definition of elements

The elements of the structural model include beams, columns, inclined bracings, walls, and slabs. The shape definition of an element in PMCAD is represented by its geometrical information of section. There are 15 section types in PMCAD that include rectangle, -shaped, U-cross, circularity, crisscross, box, etc, which basically cover the needed types for structural analysis and calculation. In PMCAD, the wall and slab are defined together, which include the type parameters, thickness, material and so on. Holes also belong to slabs from the broad perspective. But because the position of the hole is defined as a whole conception within the wall or slab, it is equivalent to the block concept of AutoCAD. The section of the hole is defined by using its border points and described through a list, and the coordinates of these points are based on the local coordinates of the hole, which means that every hole has its reference location position. This reference position is taken by the local coordinate system as the circle center established.

2.2 Whole localization of model

The description of the structural model in PMCAD is carried out by relative coordinates, and the unified coordinate system is used by PMCAD to create a model. It not only gives the origin of the coordinate and X, Y and Z direction vectors, but also provides a convenient transformation connection for the coordinate system. In PMCAD, the point is established by 3D mode, that is, it contains X, Y and Z coordinates. The localization of elements takes grid lines as reference and is carried out by the element center and the eccentric center of grid lines. The localization of wall and slab adopts the grid lines-enclosure as reference, and each culmination is described by the relative eccentric center of grid lines nodes. The position of the hole in PMCAD is described by the basic point and rotation angle.

3 IFC data model

3.1 Format of IFC project file

IFC project file contains two sections, which are head file section and data file section. An IFC project file often takes “ISO-10303-21;” as file beginning sign and “END-ISO-10303-21;” as file end sign, and the middle of the file includes a head section and a data section.

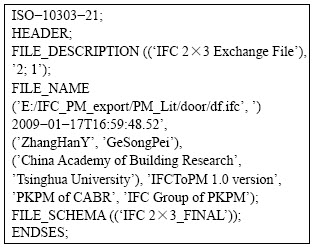

The head file is mainly used to describe the project name, project type, project author and other project information. This is an indispensable part of each IFC exchange file. The head section chooses the keyword “HEADER” as the beginning of the file and “ENDSEC” as the end of the file. The head file includes several parts such as file description, file name and file schema. Fig.1 shows the head file representation of an IFC project.

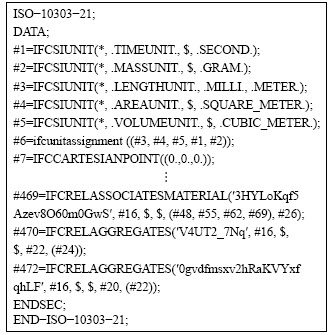

The data file is the main part of the IFC project file because all of the project information is preserved in the data section. The data section is represented by an instance format, each instance takes “#” as the beginning of the sentence, followed by instance number, and the right of equal mark is used to describe the name and attribute of class with the corresponding instance. Fig.2 shows a part of the data file representation of an IFC project.

3.2 IFC spatial structure

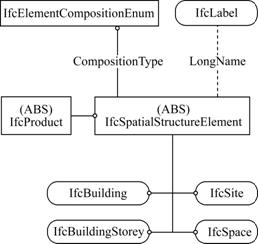

The IFC spatial structure is provided by IfcProduct entity and defined by IfcSpatialStructureElement entity

Fig.1 Head file representation of IFC project

Fig.2 Data file representation of IFC project

(Fig.3). The following four different concepts are subsumed under the IfcSpatialStructureElement entity: IfcBuilding, IfcSite, IfcBuildingStorey and IfcSpace. The four subtypes of IfcSite, IfcBuilding, IfcBuildingStorey and IfcSpace are used to represent the levels of the spatial structure. Each concept has a name (by IfcRoot.Name), a description (by IfcRoot Description) and a long name. The name attribute is used to store the name of the building and building storey.

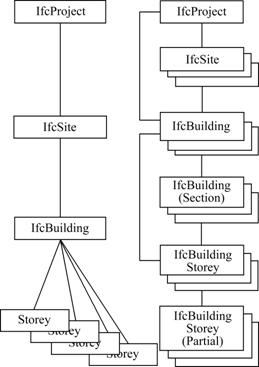

The above different subtypes are contained by each other. They provide a clear hierarchical structure for the building project. Fig.4 shows the spatial structure of a building project. In the spatial structure, the lower the level is, the more detailed the description of the information is required. The IfcRelAggregates entity is used to link the instances of IfcProject, IfcSite, IfcBuilding and IfcBuildingStorey (provided that all levels are applicable).

Fig.3 Definition of IFC spatial structure elements

Fig.4 Spatial structure of IFC building project

In Fig.4, the IfcProject, IfcBuilding and IfcBuildingStorey are mandatory levels for the exchange of complex project data, the IfcSite and IfcBuilding (section) or IfcBuildingStorey (partial) represent optional levels, which may be provided if they contain pertinent data. Each instance of the IfcProject, IfcSite, IfcBuilding and IfcBuildingStorey is connected to other instances of the spatial structure by the IfcRelAggregates entity.

4 Information integration tool

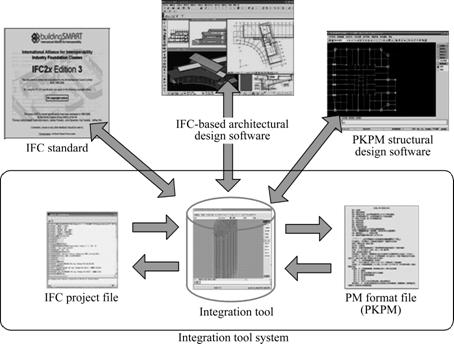

4.1 Structure of integration tool

The implementation scope of the integration tool is to read in IFC data information and form a structural model for PMCAD, which includes four steps. The first step is to identify and read the elements of beams, columns, inclined bracings, slabs, walls, holes on the wall such as doors and windows, spatial information of 3D coordinates, and materials information from IFC project file. The second step is to determine the relationships between IFC elements such as beams, columns, inclined bracings, slabs, walls, doors and windows. The third step is to analyze and determine the connections between beams, columns, inclined bracings, slabs, walls, doors and windows of IFC elements. The last step is to analyze the intersection relationships of elements and optimize the node numbers.

The direct objective of the integration tool is to automatically translate IFC format data to the compliant data for PKPM structural analysis software. Fig.5 shows a sketch map of the whole structure of the integration tool system. The data object extracted from IFC project file should be mapped into the corresponding object of PKPM data structure because IFC data model does not keep one-to-one relationship with the PKPM data structure. As a result, the data structure should be simplified or optimized according to the features of each data model in the development process of the integration tool, such as the simplification of the semantic description of the data of IFC and PKPM, and the intersection analysis and node optimization of structural elements.

4.2 Optimization of structural model

The integration tool simplifies the information of IFC elements by the element intersection analysis and node optimization. According to Ref.[15], there are five categories of topological relationships among building elements and space: (1) one element is adjacent to the other (adjacency); (2) elements are separated from each other (separation); (3) one element lies within the other (containment); (4) one element intersects the other (intersection); and (5) one element connects with the other (connectivity). For structural analysis, only the last two relationships (intersection and connectivity) are used. If the intersection is treated as a special case of the connectivity, the deduction of the topological relationship for structural analysis can be ascribed to finding the connectivity among structural elements. Therefore, the integration tool adopts this simple algorithm to deduce the connectivity among the elements. For the connected elements, tool software merges the crossed nodes and meshes into the least number of nodes and corresponding meshes. These simplified nodes and meshes provide a basis for PKPM’s structural analysis and calculation. The integration tool adopts the simplified algorithm to deduce the connected relationships among structural elements by judging the intersection of an element’s axes lying on the other elements’ surface.

In the IFC model, extruded solid technology is often used to represent the elements. Therefore, the element sections are usually defined by arbitrary patterns (named arbitrary sections). On the contrary, in the PMCAD model, element sections are usually defined by regular methods (named parametric sections). As a result, the element sections defined by IFC should be optimized and identified in order to get the necessary types such asshaped section, crisscross section, and channel section, which can be identified by PMCAD.

Fig.5 Sketch map of whole structure of integration tool system

In the IFC model, the wall does not have equal thickness or height because it is also defined by extruded solid. Therefore, walls in the IFC model should be translated to the solids with equal thickness or height. For unequal thickness walls, the techniques for keeping the section areas of the wall from suffering any changes are adopted, and thickness is optimized according to the initial length of the wall. If there are a set of parallels that exceed usual wall length between the borders of the wall, the space between the parallels will be adopted as the wall thickness, and then the wall length will be calculated. For unequal height walls, the extruded solid area is directly adopted as the solid wall.

In regard to architectural appearance, an irregular shape is often adopted to achieve a better aesthetic feeling for the viewer. Under these circumstances, the general extruded solid technology loses its function, so the “Brep (boundary representation)” technology is often adopted to describe the elements. In the IFC model, Brep technology is often used to define irregular solids. Thus, in the developing process of the integration tool, some irregular solids are simplified, such as the arc beam, arc wall, and truss beam, and their approximate parameters are optimized to correspond to the PMCAD structural model.

4.3 Techniques of information exchange

PKPM software is mainly developed by mixed program languages such as visual FORTRAN and visual C++. Therefore, the program realization of tool software also adopts the technique of mixed program languages. The techniques of program implementation include: (1) hundreds of classes (corresponding to the EXPRESS entities of IFC2×3) are created in the environment of visual C++; (2) “Add()” functions, transformation functions, “Construct()” functions and other functions are written for each class; and (3) “Main()” function is written in the environment of visual FORTRAN, and the implementation function of the main program is created for the tool software. The role of “Add()” function is to read the entities of IFC project file into the computer memory and parse the characters of IFC file data stream into provisional parameters that can be understood by different classes. “Construct()” function can extract the address that corresponds to the object in the computer memory according to the index of provisional parameters, and then provide a value for each address respectively.

The general implementation process of the tool software includes the following parts. The first part is to read IFC model, and the role of this part is to translate IFC EXPRESS into a language understood by the program. The second part is to get IfcProject. This part acquires information about the project such as name, history, and engineering description. The third part is to get IfcSite, the site information including name, longitude, dimensionality, height, address, etc. The fourth part is to get IfcBuilding and IfcBuildingStorey. The fifth part is to get IfcBuildingElement. In the IFC model, building elements belong to IfcProduct, therefore, the product information should be obtained firstly when the elements’ information is gotten. The building elements included beam, wall, column, slab, door, window, roof, etc. The last part is to get IfcUnit. The implementation flow chart is shown in Fig.6.

Fig.6 Flow chart for getting IFC model information

4.4 Implementation of integration tool

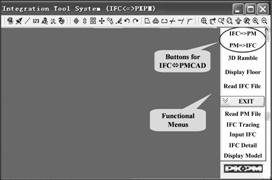

The interface of the tool system is shown in Fig.7. The main menu options and tool bars, from which the model displayed on the interface can be edited or modified, are located at the top of the interface. On the right side of the interface, there are vertical menus for exchanging data information between IFC architectural model and PKPM structural model. The central part of the interface is provided for the model displaying and graphic drawing.

There are two important buttons in the exchange menus, “IFC=>PM” and “PM=>IFC”, which are used to extract information between IFC model and PKPM model. Furthermore, other functional buttons such as “IFC tracing”, “input IFC”, “IFC detail”, “display model”, etc. are also provided to display the detailed information of the transformed model.

Fig.7 Interface of integration tool system

Button “IFC=>PM” can open an IFC format file. When this button is clicked, there will be a pop-up dialog box that can open IFC format file on the interface window. Designers can choose an IFC project file after the dialog box points to “IFC file”, and then, the tool software will read IFC architectural model, and automatically extract structural information used for the structural analysis. When the extracted structural model is fully displayed in the tool interface, designers can modify or edit the model by using the main menus in order to satisfy the requirements of the structural analysis. Finally, the extracted structural model can be saved as a PMCAD-format file. Structural engineers can continue doing the following design tasks based on this structural model.

4.5 Case study

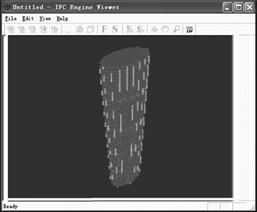

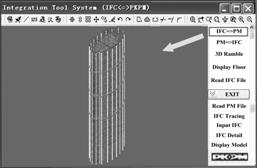

The case study plays an important role in testing the implementation performance of the integration tool, which involves three parts. The first is to test the consistency of the geometrical model from IFC to PKPM. The second is to test the fluency and stability of the tool. The last is to test the exchange velocity of the tool. A high-rise building is adopted as the case study for the tool. An architectural model of the case is generated by the software of IFC engine viewer (Fig.8), which is provided by the IFC standard [16].

Fig.9 shows the structural model formed by the tool from the architectural model of the high-rise building. First, designers open the IFC-format file of the high-rise building by clicking the button “IFC=>PM”. Then, a structural model is generated automatically and displayed on the interface. The whole process of extraction requires time not more than 20 s, and the basic information is contained, including geometrical information, material information, section information and connection attribute information of elements, which are needed by structural analysis of PMCAD. The tool allows the designers to modify and edit the structural model. Furthermore, they can have a closer look of the model by clicking on the zoom button that is found in the tool bar. The structural model generated by the tool can provide structural modeling foundation for the PKPM structural analysis software. The case study shows that the information of the basic elements such as geometrical information, material information, section information, and connection attribute information can be implemented from IFC model to PKPM model by the integration tool.

Fig.8 IFC-format architectural model from IFC engine viewer software

Fig.9 Extracting structural model from IFC to PKPM by using integration tool

5 Conclusions

(1) An integration tool is developed by using the technique of mixed program languages (VC++ and FORTRAN). The tool can automatically exchange data information from IFC architectural model to PKPM structural model, which helps to enhance the modeling efficiency at the structural design phase and establish a collaboration work platform between architects and structural engineers.

(2) A case study is provided to illustrate the method by which the model information is extracted from IFC to PKPM by use of the tool. The geometrical information, material information, section information and connection attribute information of basic elements can be exchanged by the tool, which provides an efficient way for PKPM software supporting the IFC standard.

(3) The integration tool now is only a one-way channel for the information exchange from IFC to PKPM, and does not implement the information exchange of loads and support conditions of building elements. Future research will serve to develop a two-way channel for the model information exchange and sharing at the architectural and structural design phase.

References

[1] LI Yun-gui, LIU Zhao-qiu, QIU Kui-ning. Studies of IFC standard and its application in China [C]// World Engineers’ Convention 2008 (WEC2008). Brasilia, 2008: 434-443.

[2] DAVIS D. The issues of social needs, business drivers and converging technologies are making BIM an inevitable method of delivery and management of the building environment [J]. Journal of Building Information Modeling, 2007, 1(1): 16-18.

[3] CHEN Po-han, CUI Lu, WAN Cai-yun. Implementation of IFC-based web server for collaborative building design between architects and structural engineers [J]. Automation in Construction, 2005, 14(1): 115-128.

[4] LIEBICH T, ADACHI Y. IFC2×Edition 4 alpha version [EB/OL]. [2009-08-21]. http: //www.buildingsmart.com/bim/.

[5] SERROR M H, INOUE J, ADACHI Y, FUJINO Y. Shared computer-aided structural design model for construction industry (infrastructure) [J]. Computer-Aided Design, 2008, 40(7): 778-788.

[6] PLUME J, MITCHELL J. Collaborative design using a shared IFC building model-Learning from experience [J]. Automation in Construction, 2007, 16(1): 28-36.

[7] WAN C Y, CHEN P h, TIONG P. Assessment of IFCs for structural analysis domain [J]. Journal of Information Technology in Construction, 2004, 9(6): 75-95.

[8] ABIDEMI O, CHIMAY J A, ASHRAF E H, COLIN H. Development of an industry foundation classes assembly viewer [J]. Journal of Computing in Civil Engineering, 2006, 20(2): 121-131.

[9] LEE K Y, CHIN S Y, KIM J. A core system for design information management using industry foundation classes [J]. Computer-Aided Civil and Infrastructure Engineering, 2003, 18(4): 286-298.

[10] KAROLA A, LAHTELA H, HANNINEN R. BSPro COM-server—Interoperability between software tools using industrial foundation classes [J]. Energy and Buildings, 2002, 34(9): 901-907.

[11] FARAJ I, ALSHAWI M, AOUAD G, CHILD T. An industry foundation classes web-based collaborative construction computer environment: WISPER [J]. Automation in Construction, 2000, 10(1): 79-99.

[12] WANG H J, ZHANG J P, CHAU K W, ANSON M. 4D dynamic management for construction planning and resource utilization [J]. Automation in Construction, 2004, 13(5): 575-589.

[13] DENG X Y, CHANG T Y, WANG G J. IFC based design integration between architectural and structural models [C]// Proceedings of the Sixth International Conference on Tall Buildings. Hong Kong, 2005: 552-556.

[14] YANG Xing. Application of PKPM structural design software from rudiment to conversance [M]. Beijing: China Architecture and Building Press, 2008: 57-120. (in Chinese)

[15] NAUYEN T H, OLOUFA A A, NASSAR K. Algorithms for automated deduction of topological information [J]. Automation in Construction, 2005, 14(1): 59-70.

[16] MIEDEMA H, SCHMIDT D, BRACHT M V. IFC engine viewer [EB/OL]. [2009-09-08]. http: //www.ifcbrowser.com/.

(Edited CHEN Wei-ping)

Foundation item: Project(2006BAJ01B01-01) supported by the National Key Technologies R&D Program of China during the 11th Five-Year Plan Period

Received date: 2010-01-12; Accepted date: 2010-05-28

Corresponding author: LIU Zhao-qiu, Doctoral candidate; Tel: +81-10-64517848; E-mail: liuzhaoqiu88@sina.com