Natural ripening with subsequent additions of gypsum and organic matter is key to successful bauxite residue revegetation

来源期刊:中南大学学报(英文版)2019年第2期

论文作者:周亚凤 HAYNES Richard

文章页码:289 - 303

Key words:bauxite residue; bauxite residue disposal area; substrate amendment; natural ripening; soil formation in bauxite residue

Abstract: The processes involved in the major steps of successful revegetation of bauxite residues are examined. The first phase is the natural physical, chemical and microbial ripening of the profile. This involves allowing the profile to drain, dry, shrink and crack to depth, leaching of soluble salts, alkalinity and Na down out of the surface layers, acidification by direct carbonation and natural seeding of tolerant vegetation with an accumulation of organic matter near the surface and an attendant development of an active microbial community. Following ripening, the surface layer can be tilled and gypsum and organic matter (e.g. manures, composts, biosolids) incorporated. These amendments result in a further decrease in pH, increase in Ca and other exchangeable cations, increased leaching of Na (with a reduction in exchangeable Na and ESP), improved physical properties, particularly aggregation, and a large increase in microbial activity. Other important considerations include the choice of suitable plant species tolerant to salinity/sodicity and local environmental conditions and the addition of balanced fertilizer applications.

Cite this article as: HAYNES Richard, ZHOU Ya-feng. Natural ripening with subsequent additions of gypsum and organic matter is key to successful bauxite residue revegetation [J]. Journal of Central South University, 2019, 26(2): 289–303. DOI: https://doi.org/10.1007/s11771-019-4001-2.

REVIEW

J. Cent. South Univ. (2019) 26: 289-303

DOI: https://doi.org/10.1007/s11771-019-4001-2

HAYNES Richard1, ZHOU Ya-feng(周亚凤)2

1. School of Agriculture and Food Sciences, University of Queensland, St Lucia, QLD 4072, Australia;

2. School of Medical Engineering, Foshan University, Foshan 528000, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract: The processes involved in the major steps of successful revegetation of bauxite residues are examined. The first phase is the natural physical, chemical and microbial ripening of the profile. This involves allowing the profile to drain, dry, shrink and crack to depth, leaching of soluble salts, alkalinity and Na down out of the surface layers, acidification by direct carbonation and natural seeding of tolerant vegetation with an accumulation of organic matter near the surface and an attendant development of an active microbial community. Following ripening, the surface layer can be tilled and gypsum and organic matter (e.g. manures, composts, biosolids) incorporated. These amendments result in a further decrease in pH, increase in Ca and other exchangeable cations, increased leaching of Na (with a reduction in exchangeable Na and ESP), improved physical properties, particularly aggregation, and a large increase in microbial activity. Other important considerations include the choice of suitable plant species tolerant to salinity/sodicity and local environmental conditions and the addition of balanced fertilizer applications.

Key words: bauxite residue; bauxite residue disposal area; substrate amendment; natural ripening; soil formation in bauxite residue

Cite this article as: HAYNES Richard, ZHOU Ya-feng. Natural ripening with subsequent additions of gypsum and organic matter is key to successful bauxite residue revegetation [J]. Journal of Central South University, 2019, 26(2): 289–303. DOI: https://doi.org/10.1007/s11771-019-4001-2.

1 Introduction

Bauxite is processed in alumina refineries by the Bayer process in which Al-containing minerals are dissolved in concentrated sodium hydroxide at high temperatures and pressures. The insoluble solids (bauxite processing residues) are deposited in storage impoundments surrounding the refinery [1, 2]. The global alumina industry produces approximately 150 MT of bauxite residue each year and there is an estimated global stockpile of about three billion tons [1]. The elemental content of residue is dominated by Fe (30%–50% Fe2O3) and its mineralogy often approximates to 10%–30% goethite, 10%–30% hematite, 2%–20% calcite, 0–5% gibbsite, 2%–15% anatase, 3%–10% quartz and 5%–20% sodalite/cancrinite [1, 3]. Despite multiple attempts to find uses for bauxite residues in the construction, environmental, mining and agronomic industries, only 2%–3% of this material is currently re-used or further processed [4, 5]. As a result, almost all bauxite residue produced is stored in land-based bauxite residue storage areas which can have a footprint of several hundred hectares. Revegetation of residue storage areas is a priority in closure strategies because it minimizes dust, reduces leaching (through transpiration losses to the atmosphere) and forms a landscape which provides a habitat for wildlife [3, 6]. However, the residual NaOH in the residue means that it is a highly alkaline and saline-sodic material [7, 8]. In addition, the material is composed principally of silt-sized particles resulting in the material having a mud-like consistency. Thus both its chemical and physical properties make it difficult to revegetate [1, 3].

Successful rehabilitation of bauxite residue is a combination of remediation of the growing medium (and management of the physical, chemical and biological properties) and selection of plant species most suited to the environmental conditions [3]. Normally, the residue deposit is left for a considerable period of time (e.g., 5–20 years) prior to revegetation. During this period, extensive and irreversible changes in the properties of the material (particularly the physical properties) occur. When dredged sediments are deposited on land, the term “ripening” is used to describe the conversion of a waterlogged sediment into soil-like material (i.e., initial soil formation) through drainage, desiccation and structural development [9]. Ripening consists of physical, chemical and biological processes that occur simultaneously and interact with one another [10]. The processes that occur after deposition of bauxite residues into a residue storage area are similar and can be described in analogous terms. After ripening has proceeded, the material is still alkaline, sodic and nutrient deficient and application of gypsum has been shown to lower pH and promote leaching of Na while additions of organic matter (e.g. manures, composts) can increase nutrient status as well as lowering pH and promoting leaching of Na [2, 3]. After amendment of the surface horizon (e.g. with gypsum and organic matter) to improve the properties of residue as a growth medium it can be seeded for successful revegetation [11, 12].

In this paper, the changes that occur during the ripening period are discussed and the effects of the subsequent amendment of the residue with gypsum and organic matter are examined. The combination of the natural ripening processes plus anthropogenic intervention typically provides a medium suitable for successful revegetation.

2 Ripening processes

2.1 Physical ripening

Where residue mud has been deposited as a slurry in a residue storage area, the first phase of rehabilitation is to drain the deposit to a depth of many meters and allow it to thoroughly dry out. With rains predominating over part of the season (summer in tropical climates and winter in temperate ones) this drying process may occur over an extended period (e.g., 10–20 years and sometimes more). Sedimentation of particles begins almost immediately after the residue is deposited as a slurry. This is followed by a period of consolidation where the weight of overlying sediment forces out pore water which drains from the material.

These processes can be speeded up and/or partly circumvented by various management practices. For example, dry stacking involves dewatering and thickening of residue (>50% solids) before deposition in the storage area [13]. The material can be deposited in layers about 0.2–0.5 m thick and allowed to dry (by drainage and evaporation) to about 70% solids. Evaporative loss is often promoted by turning and working the surface using earthmoving equipment. This is termed “mud farming” and typically uses an amphibious scrolling tractor (known as an amphirol) and this process also provides mechanical consolidation of the residue [14]. Once the bed has dried, the process is repeated by depositing a fresh layer of mud and the deposit is built up into a progressive stack. The process is designed so that the dried material becomes self-supporting and as a result it can be safely stacked to considerable heights within containment embankments. Natural consolidation is therefore greatly accelerated.

During further drying, the mud fraction, which is deposited as a structureless pastey matrix, forms a massive dense structure [15]. That is, upon drying the mud solidifies and shrinks causing cracks and macropores to form to depth in the residue deposit [16]. Solidification occurs because pozzolanic materials present in the residue bind the material together the first time when it dries [17, 18]. As a result, the major part of shrinkage is irreversable and the material does not swell significantly upon rewetting. The cracks and surface-connected macropores allow for water movement and aeration to depth as well as forming channels for subsequent downward root growth. Water movement is therefore greatly increased (particularly under saturated flow) (conditions: Ksat≈10–5 m/s) compared to ‘fresh’ (non-cracked) residue (Ksat≈10–9 m/s) (I. Phillips personal communication).

Over time, the solidified material close to the surface breaks into smaller peds and the surface layer can be ripped and tilled to form a stable tilth suitable for plant establishment and growth. A fine fraction of solid material is formed during tillage and natural cleavage of peds. Some of the aggregates in revegetating residue originate from breakdown of the original solidified structure and some from subsequent aggregation of the fine fraction.

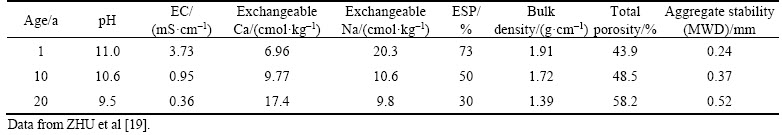

Physical properties in the surface layer change over time. ZHU et al [19] demonstrated that there was a decrease in bulk density and increase in porosity and aggregate stability over the first 10 years and that by 20 years (after plant colonization had begun) total porosity and aggregate stability were greatly increased (Table 1). These changes occur due to aggregation of the fine fraction that is formed during natural cleavage of peds. ZHU et al [20] studied the physical properties of unamended residue mud with increasing age and showed that with time water stable aggregation increased and erodability decreased. ZHU et al [21] used X-ray micro-computed tomography to show that with age there was an increase in porosity, specific surface area, average length of paths and average tortuosity of paths. ZHU et al [22] showed that with increasing deposit age, the dispersiveness of aggregates decreased and there was an increase in the size of the aggregate fraction (250–50 μm) with a concomitant decrease in silt and clay size fractions.

Thus, physical ripening is a process by which a profile of mud is dried and is converted to a more compact, aerated and more permeable material. It causes a major change in the nature of the physical properties of the profile to a depth of many meters with the biggest changes occurring in the plant rooting zone. It is essential that this process is allowed to occur before revegetation is initiated. During the process simultaneous changes in chemical and biological properties also occur (see below).

2.2 Chemical ripening

Residual NaOH present in bauxite residues results in them being highly alkaline. The pH of untreated residue liquor typically varies from 10.0 to 13.0 [7] and in the liquor the main alkaline anions buffering the solution are OH–, CO32–/HCO3– and Al(OH)4– and the alkaline buffering capacity of residues is maintained by alkaline solid phase minerals. These solids are formed during the Bayer process and the alkalinity originates from the NaOH and slaked lime [Ca(OH)2]/lime [CaCO3] added during digestion. Because of the excess Na and balancing alkaline anions present in the liquor the material is highly saline and EC values for untreated bauxite residues range from 3000 to 18000 mS/m [23, 24]. The high pH, presence of OH–, CO32–/HCO3– and Al(OH)4– in solution and the high EC and high Na all limit plant growth in the deposited residue [8].

During the period that the residue is allowed to dry, which may be from 5–20 years (see below), major changes occur in the chemical properties of the residue. Firstly as the surface layers are leached by incoming rainfall, the soluble salts are leached downward in the profile. Sodium leaches with the soluble alkaline anions and this loss of soluble alkalinity results in a decrease in EC and the pH decreases down to 9–10 [25, 26]. Field results presented in Table 1 demonstrate that the EC decreased from 3.73 mS/cm after 1 year to 0.95 mS/cm after 10 years and down to 0.36 mS/cm after 20 years. Dissolution of atmospheric CO2 into the soil solution near the surface results in formation of carbonic acid which has an acidifying effect as it leaches down the profile [27]. This natural carbonation can be promoted by working the residue surface (e.g., amphirolling). Thus, over time the pH of the deposit decreases as does the EC and these effects are greatest near the surface. KHAITAN et al [27] reported pH 10.5 at a 14-year-old residue site and pH 9.4 to a depth of at least 90 cm for 35-year-old site. They showed that pH was decreased most near the surface and that in the 0–20 cm layer pH was about 8.7 after 14 years. Similarly, ZHU et al [19] reported a decrease in residue pH (0–20 cm) from 11.0 in 1-year-old residue site down to 9.5 in a 20-year-old residue deposit (Table 1).

Table 1 Effect of age of bauxite residue deposit on chemical and physical properties in surface 20 cm

Weathering processes will be the most intense under tropical conditions where high temperatures and high rainfall predominate. How long it will take for the pH to be lowered to below 9.0 in the surface 10–20 cm and the ESP to be lowered to below 20%–30% will differ with different residue sources and different climates. There is typically a large reserve of Ca present in bauxite residues as calcite and over time Ca is released into solution through dissolution of the calcite. As noted above, calcite originates from addition of Ca(OH)2/CaCO3 during the Bayer process. Since Ca2+ is held more strongly on cation exchange sites than Na+, it can displace Na+ and over time more Na leaches from the surface horizons and exchangeable Na decreases while exchangeable Ca increases (and consequently exchangeable sodium percentage (ESP) decreases). For example, ZHU et al [19] found that exchangeable Ca and Na to a depth of 20 cm were 6.9 and 20.3 cmol/kg respectively one year after deposition and 17.4 and 9.8 cmol/kg respectively after 20 years (Table 1). Corresponding values for ESP were 73% and 30% respectively (Table 1). There may also be some release of Mg and K from weathering minerals during the ripening period but typically the amount released is very small.

The result of the above changes is that highly saline/sodic tolerant plant species begin to invade the surface of the deposit [19, 28–30]. For example, MISHRA et al [30] identified 14 plant species belonging to eight different families on a 15-year old residue deposit. In general, plants that invade minelands are those with effective seed dispersal mechanisms, high seed production rates in the local area and show tolerance to salinity/sodicity. Organic matter begins to accumulate near the surface of the residue. This occurs because growing plants deposit above-ground litter and root residues onto and into the surface layers. Heterotrophic microorganisms decompose this litter and during the process dark colored, semi-stable material known as humus is formed. As a result soil organic matter begins to accumulate. ZHU et al [19] found that over a 20-year period of natural regeneration, soil organic C content increased from 5.7 to 10.8 g/kg. The presence of plants also speeds up weathering processes because of the large amount of CO2 produced in the rooting volume through root respiration and respiration by the highly active microbial community present in the rhizosphere. This results in increased production and leaching of carbonic acid.

In a tropical climate in Linden, Guyana, SANTINI et al [29] observed spontaneous vegetation cover on some areas of bauxite residue after 27 and 30 years weathering. The vegetated areas generally had coarser textured residue than unvegetated sites leading the authors to speculate that this may have speeded up weathering and the leaching of salinity and alkalinity down to plant-tolerable levels. That is, EC, pH and exchangeable Na were all lower in the vegetated areas. On the vegetated sites organic C content was about 6.5% in the 0–2 cm surface layer compared to < 0.5% in unvegetated areas. It is also possible that the presence of plants helped to modify and acidify the residue through root/microbial respiration and exudation of organic acids [29].

Thus, with time, through the processes of weathering and leaching, there is a decrease in EC, pH, exchangeable Na and ESP and an increase in exchangeable Ca and organic matter content. These effects of chemical ripening are most pronounced near the residue surface and proceed slowly but progressively affect deeper layers of the potential rooting zone over time.

2.3 Biological ripening

When it is first deposited, bauxite residue is a effectively heat- and chemically-treated sterile inorganic component (with an extremely low organic matter content). It therefore has a very low microbial activity. Microbial community assembly occurs mainly by aeolian transport of bacterial cells and fungal spores (e.g., in dust storms) and diverse assemblages of bacteria and fungi can occur on newly exposed parent material within a matter of months [31]. However, microbial activity is limited by low C and N availability so that the early stages of community assembly comprise microflora which typically exists in resting stages. As a result, the size of the community (microbial biomass) and its activity (respiratory CO2 evolution) are extremely low [32].

Early colonisation of residues by alkali- tolerant bacterial populations (e.g., of the families Chitinophagaceae, Beijerinckiaceae, Xanthomonad- aceae, Acetobacteraceae) has been shown to occur within a relatively short time frame [33, 34]. These taxonomic groups are normally associated with alkaline salt lakes and sediments. Acetobacteraceae are organic acid producing bacteria and it is possible that they may contribute to the decreasing pH that occurs on bare, unamended residues [34]. As the alkalinity, pH, salinity and sodicity decrease over time, the microbial community becomes more diverse and more like that present in the surrounding soils. For example, SANTINI et al [33] found that the major driver for bacterial community structure in bauxite residue was salinity while that for fungal community structure was total alkalinity.

Colonization or new sites by soil fauna is more problematic and slower than for microflora, particularly for non-winged organisms. In addition, many desiccation-susceptible species are dependant on accumulation of an organic surface horizon and/or a litter layer so their distribution is indirectly linked to plant growth and subsequent above and below ground litter inputs. Development of an active earthworm community on a newly exposed site can, for example, take 30–50 years [31]. However, as noted below, with addition of organic matter into the surface horizon and seeding with grass species faunal colonization can be much more rapid.

The development of a functioning soil biota is important since it is a key component of a fertile soil. Important roles of soil microbial community include decomposition of organic residues, humus formation and degradation, mineralization/ immobilization turnover of nutrients (e.g., N, S and P) and stabilization of aggregates. Soil fauna are also important components of the below-ground ecosystem and are involved in degradation of organic residues, formation and stabilization of aggregates and creation of macoporosity. Nonetheless, because of a lack of organic matter in newly deposited residue, biological ripening is a much slower process than physical and chemical ripening. Indeed development of intense biotic activity does not normally occur until physical and chemical ripening has proceeded and the residue has then been amended and planted with vegetation.

3 Amendment with gypsum and organic matter

Typically, revegetation of bauxite residues is initiated after the processes of physical, chemical and biological ripening have proceeded for some considerable time (e.g., 5–20 years). The amount of time required for the profile to dry, shrink and crack and for the soluble salts and soluble alkalinity to leach from the plant rooting zone will vary greatly. Under high rainfall (e.g., >1000 mm) and good drainage plus significant dry periods during the year to allow drying to occur, this might be only 5–10 years. Where dry stacking and mud farming are practiced, the time may be reduced even more since the profile is already “semi-dry”. By contrast, where residues are deposited as a slurry into lagoons, drainage of the lagoon and drying of the residue is a more long-term process (e.g., 10–20 years).

Conditions in the residue after ripening are still likely to limit plant growth although there will sometimes be some invasion of naturally seeded tolerant plants.The purpose of amending the residue prior to revegetation is to remediate factors which are limiting plant growth in residue and accelerate the ripening processes (i.e., speed up soil development). By far the most commonly applied amendments are gypsum (CaSO4·2H2O) and organic matter (e.g., composts, manures, biosolids) and the best results have generally been found with a combination of the two [9, 10]. The effects of these amendments are considered below.

3.1 Gypsum

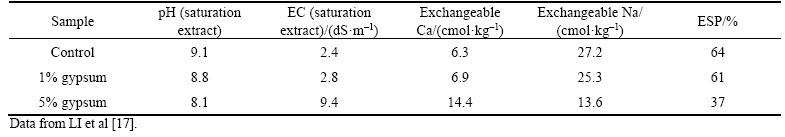

The most common amendment used in revegetation of residues is gypsum. Phosphogypsum, a waste product of the phosphate fertilizer industry, is often used as a cheap readily-available source of gypsum and it has the added benefit of adding some phosphate as well [3, 35]. A decrease in pH following gypsum addition occurs because the added Ca2+ in the gypsum reacts with soluble alkalinity (HCO3, CO32–, Al(OH)4– and OH–) to form precipitates of calcite, tricalcium aluminate and hydrocalumite [7]. Typical application rates to residue mud are 3%–8% and this is normally incorporated into the surface horizon (0–10 or 0–15 cm). Many laboratory/ greenhouse studies have demonstrated substantial decreases in the pH following gypsum application [17, 18, 36–40]. For example, LI et al [17] recorded a pH decrease in seawater neutralized residue mud from 9.1 to 8.8 with gypsum applied at 1% and a decrease down to pH 8.1 with 5% gypsum (Table 2).

Field experiments have recorded both short- and long-term decreases in pH induced by gypsum application [41–46]. In a field study, gypsum applied at rates of 0, 40 and 90 t/ha resulted in pH values of 9.6, 8.3 and 8.0 respectively one year after application [47]. The field results of BRAY et al [48] suggest that a reduction in pH induced by gypsum applications can be sustained in the long-term. They found that pH in the surface 10 cm of unamended residue for 16 years after initiation of a revegetation trial was 10.8 but it remained at about 8.0 in gypsum-amended plots. In the gypsum treatments pH had decreased to a depth of 50 cm (compared with control), well below the 0–10 cm depth of incorporation.

As well as reducing pH, the addition of gypsum is also effective in lowering exchangeable Na and ESP. The divalent cation Ca2+ in gypsum is more strongly held to many of the cation exchange sites than Na+ so added Ca2+ displaces Na+ from exchange sites and it can leach down the profile with the added SO42– as a counterion. With gypsum addition there is therefore an immediate decrease in ESP due to Ca addition followed by a slower decrease as Na is leached out of the profile. Several laboratory-based experiments have demonstrated that addition of gypsum effectively decreases the sodicity of residues and that the effect increases with increasing rates of application. WONG et al [36] measured decreases in ESP from 70% down to 55% at a 2% gypsum addition and down to 12% with a 5% addition. LI et al [17] recorded a decrease in ESP from 64% to 37% after an application of 5% gypsum to residue mud followed by leaching (Table 2). The decrease in ESP was attributable to both an increase in exchangeable Ca and a decrease in exchangeable Na (Table 2).

A sustained reduction in residue ESP is paramount for sustainable revegetation. Desilication product (known as DSP, i.e., sodalite and cancrinite) is considered important component of bauxite residues because Na+ and OH– ions are slowly released from their mineral structure [49]. The release of this Na is often suggested as an important consideration and limitation to revegetation. Residual gypsum present in the residue may therefore be important since it will continue to dissolve releasing Ca2+ which will help to neutralize newly solubilized alkalinity as well as displacing released Na+ and promoting its leaching [17, 18]. In fact, long-term field trials have not revealed any discernible increase in exchangeable Na+ or pH over time [48]. In all likelihood, under field conditions the natural soil processes of acidification and leaching counteract the effect of DSP dissolution.

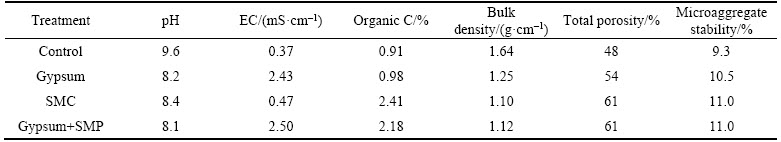

Gypsum might also improve physical properties of residue due to the increase in Ca2+ and decrease in Na+ in soil solution. That is, the dispersive effects of the monovalent Na+ ion are replaced by the flocculating effect of divalent Ca2+ and this should enhance microaggregate stability and consequently the stability of macroaggregates [2, 50].Indeed, a change in aggregate size and stability has been noted during revegetation where gypsum has been applied. For example, COURTNEY et al [46] recorded a dominance of less erodible, more stable aggregates in treatments with high application rates of gypsum. As shown in Table 3, bulk density was lower and microaggregate (diameter <250 μm) stability is greater one year after application of gypsum compared with control.

Table 2 Effect reacting increasing rates of gypsum with bauxite residue for 4 weeks followed by leaching with 6 pore volumes of water on chemical properties of residue

Table 3 Effect of revegetation for 1 year (0–10 cm) on chemical and physical properties of bauxite residue (Treatments were untreated control, gypsum (90 t/ha), spent mushroom compost (SMC) (120 t/ha) or gypsum plus SMC incorporated to a depth of 20 cm)

3.2 Organic matter

Because of its low organic C content, additions of organic residues to bauxite residue can be very beneficial for revegetation. Many works have observed that additions of various organic amendments (manures, biosolids, composts) to bauxite residues can greatly improve plant growth both in greenhouse and field studies [17, 18, 25, 37, 40, 42, 44, 51, 52]. Such effects are normally principally attributable to increased macronutrient supply (N, P, K, Ca and Mg) but also to decreased pH and exchangeable Na and improved physical properties.

In laboratory-based studies, a range of works have demonstrated a modest reduction in residue pH induced by addition of organic amendments such as compost or biosolids [17, 18, 26, 37–39, 53, 54]. The intrinsically lower pH of these organic wastes was compared with bauxite residue; their high buffering capacity was associated with humic materials in the wastes and sometimes the high N content (with ensuing mineralization and nitrification) all contribute to these pH decreases. Where they have high Ca and Mg content, precipitation of soluble alkalinity may also occur. The effectiveness of organic amendments in decreasing pH has been observed in field experiments [41, 46, 47]. For example, COURTNEY et al [46] noted that one year after application of spent mushroom compost at 120 t/ha the pH had decreased from 9.6 to 8.4 (Table 3). The addition of Ca, Mg and K in various organic amendments will also result in displacement of exchangeable Na into solution and thus promote leaching of Na and a reduction in ESP [17, 18].

Addition of organic matter is also beneficial to the physical properties of residue including increasing porosity and hydraulic conductivity, decreasing bulk density and improving aggregation [38, 40, 53, 55]. ZHU et al [50] showed that addition of vermicompost had a positive effect on the formation and stabilization of water stable aggregates in residue mud. COURTNEY et al [46] showed that one year after application of spent mushroom compost at a rate of 120 t/ha bulk density was decreased from 1.64 to 1.10 g/cm, total porosity was increased from 48% to 61% and microaggregate stability was increased from 9.3 to 11.0 μm (Table 3)

As already noted, the size and activity of soil microbial communities are limited in residues by the low organic matter content. Addition of organic wastes provides a C source for the inactive microbial community present in the residue and also introduces a new community associated with the waste and its decomposition. JONES et al [38] showed that addition of three different sources of organic matter not only increased organic C content of the residue but microbial biomass C was increased 8–16 times by an addition of 40 t/ha and 21–25 times by an addition of 80 t/ha while basal respiration (microbial activity) was increased by 35–65 times by both rates of addition (Figure 1). Other works have recorded similar results [17, 18, 39, 40, 56]. Microbial activity can also be assayed based on the activity of soil enzymes such as b-glucosidase, L-asparaginase and alkaline phosphatase. JONES et al [39] detected no activity in unamended residue and recorded greatly increased activities in residues amended with poultry manure or biosolids. The increased substrate availability (organic matter content) and decreased pH are likely to increase not only the size and activity of the microbial community but also its diversity [32] and addition of a new microbial community with the organic waste will certainly tend to magnify this effect.

3.3 Gypsum plus organic matter

A combination of gypsum plus organic matter has frequently been found to be the most effective treatment for revegetation success, and plant dry matter yields, in both greenhouse [17, 18, 25, 40, 57] and field experiments [42, 43]. For example, COURTNEY et al [42] compared increasing rates of gypsum and spent mushroom compost (and combinations) and found the highest yields of Holcus lanatus in combinations of 80/90, 120/40 and 120/90 t/ha of compost/gypsum. This is because they both help in lowering pH, reducing sodicity and improving soil physical conditions and the organic matter is also a source of macro and micronutrients and a substrate for microbial activity. The combination is generally the most effective treatment to lower pH of residue. This has been shown in both laboratory/greenhouse studies [17, 18, 25, 38–40] and in the field [44, 46, 47]. It is not surprising since that both materials are acidifying.

Figure 1 Effects of two rates of biosolids, mushroom compost (Mushr. Comp.) and green waste compost (Greenw. Comp.) on organic C (a) and microbial biomass C content (b) and basal respiration rate (c) in bauxite residue sand

In addition, the incorporation of gypsum plus organic matter into the surface horizon may have a greater and more rapid effect on reducing exchangeable Na and acidifying the subsurface layers compared with gypsum alone. For example, in an 8-month study, LI [57] showed that addition of gypsum plus cattle manure into the surface 10 cm of residue produced a significant positive interaction in decreasing pH, exchangeable Na, extractable Al and increasing exchangeable Ca and grass root growth in the subsoil (10–30 cm) layer compared to surface incorporation of gypsum alone (Table 4). Such an effect is attributable to downward movement of acidity due to greater acidification in the surface horizon. That is, the greater microbial activity due to the organic matter addition will result in greater carbonic acid production and it is also possible that acidity might move downward with soluble organic matter (e.g., as organic acids) [29]. In addition, added Mg and K in the organic matter tend to displace exchangeable Ca downward resulting in displacement of exchangeable Na out of the subsurface layer [57].

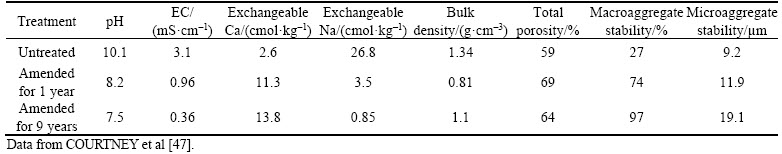

The combination of gypsum plus organic matter has been used in field revegetation experiments at the Aughinish Alumina Refinery for more than 16 years by COURTNEY and co-workers and they have demonstrated the benefits not only in relation to chemical properties and plant growth but also for improvements in physical and biological properties of the residue [48]. COURTNEY et al [47], for instance, found increased total porosity, microaggregate and macroaggregate (diameter>250 μm) stability one year after revegeation with the addition of gypsum plus compost (Table 5).

Table 4 Some chemical and physical properties of sites (0–15 cm) on bauxite residue revegetated for 1 or 9 years compared with an untreated site (Revegetation involved incorporation of residue sand (25% w/w, gypsum (90 t/ha) and compost (100 t/ha) to depth of 20 cm)

Table 5 Effect of incorporation of gypsum and cattle manure into surface layer (0–10 cm) of bauxite residue followed by leaching over a 32-week period on pH and extractable Ca, Na and Al in surface and subsurface (10–30 cm) layers

Further improvements were recorded in treatments established 9 years previously (Table 5) and aggregate stability in these treatments was similar to that for an analogous soil. These changes occurred concurrently with a decrease in pH, EC and exchangeable Na and an increase in exchangeable Ca (Table 5).

COURTNEY et al [58] showed a decrease in gram-negative bacteria with time after revegetation (with addition of gypsum and compost) and interpreted that as ecosystem development towards a more mature system with a shift from chemolithotrophic to heterotrophic communities. The diversity of the bacterial communities increased with age [34]. Bacterial communities in a residue site that had been revegetated for 10–12 years contained populations typical of soils including Acidobacteriaceae, Nitrosomadaceae and Caulobacteraceae [34]. The soil faunal community also develops. COURTNEY et al [59] showed that with increased time since revegetation there was a change in nematode trophic composition and an increase taxa richness. No nematodes were present on the control, unamended treatment. COURTNEY et al [60] surveyed the presence/absence of soil dwelling invertebrates in revegetated bauxite residues. They demonstrated natural establishment of large invertebrates, such as earthworms and ants in sites revegetated for 10 and 12 years. By contrast, on a site that had been revegetated for 1 year there were a large quantity of springtails and Dipteran larvae present and these typify early succession.

4 Other considerations

4.1 Guideline indicators

There are no universal guidelines as to what properties the ripened and amended bauxite residue should have prior to planting/seeding into it. GRAFE et al [61] suggested a pH<9.0, EC<4 dS/m, ESP<9.5 while HAYNES [62] suggested a pH<8.0, EC<5.0 dS/m and ESP <40%. To a large extent, appropriate properties will depend on what plant species are being planted and how much the properties of the material will change during the early stages of plant establishment and growth. As discussed above, not only appropriate/minimum chemical properties need to be defined but also physical and biological properties should be considered. The development of a guideline suite of soil physical, chemical and biological soil quality indicators appropriate for both planting into residue and which should be achieved after plant establishment (e.g., after 10 years revegetation). Although such guidelines would tend to be site and vegetation specific, ranges of values could be developed that were more or less universal. At present, the lack of long-term experimental revegetation field trials on residue plus the lack of well-monitored field revegetation sites makes development of such guidelines problematic.

4.2 Plant type and species

Selection of appropriate plant species is an extremely important aspect of successful revegetation [3]. That is, while natural ripening plus anthropogenic inputs can produce a soil-like material, it still exhibits saline/sodic characteristics and typically has a pH well above 7.0. The species selected therefore need to be able to tolerate high levels of salinity and sodicity and a high pH as well as being adapted to the local climatic conditions. Often grasses and herbaceous species are used (including legumes to fix atmospheric N2) [42, 63] but sometimes it may be desirable to revegetate with plants from native shrub ecosystems so the area blends back into their natural environment [64]. Both alternatives have been successfully accomplished for bauxite residue although long- term (>10 years) field sites are very scarce. In general, the criteria for evaluating successful revegetation include (a) plant biomass and percentage cover comparable with that in uncontaminated soil, (b) self-propagation of introduced plants, (c) establishment of native colonizers and (d) plant survival and productivity maintained for > 10 years [65].

4.3 Nutrient supply

Because the residue has a poor nutrient status, and poor nutrient supplying capacity, large basal fertilizer applications of macro- and micro-nutrients are necessary. The high Fe oxide content of residue means that it has a large capacity to adsorb and fix P as well as micronutrients such as Cu, Zn and Mn while the high pH (>7.0) further promotes adsorption of the micronutrients. In addition, the low organic matter content limits N supply and the high Na content in soil solution lowers uptake of other exchangeable cations such as Ca, Mg and K by plants [3]. As a result, nutrient inputs per ha are generally high in the order of 250–270 kg N, 97–300 kg K, 200–300 kg P, 6–10 kg Ca, 30 kg Mg, 6–15 kg Mn, 6–16 kg Mg, 0.2–0.25 kg Mo and 1.0–1.5 kg B [66, 67]. Where organic matter is added, this will supply some nutrients, thus lowering fertilizer requirements. Actual rates will be dependent on the type of vegetation being planted as well as nutrient availability in the particular residue that is being revegetated. In association with Section 4.2 (above) there is the need to develop target soil test values for macro- and micro-nutrients calibrated in revegetating bauxite residue for the plants being used for revegetation. This would allow fertilizer nutrient inputs to be based on site specific data rather than on educated guesses as the case is at the present time.

The high pH of bauxite residue favours NH3 volatilization losses when NH4-containing fertilizers are surface applied [68]. Losses can amount for 85%–95% of that added [69, 70] so that if fertilizer NH4 is used, it needs to be incorporated into the topsoil layer [3]. The use of NH4 fertilizers may, however, be beneficial for the nitrification of NH4+ to NO3–, an acidifying reaction and would help in arresting any rise in pH.

4.4 Introduction of soil biota

As discussed above, colonization of newly exposed parent material by soil microorganisms is rapid [31] and the major dispersal mechanism is aeolian. Thus, during the process of biological ripening a microbial community assembles at the residue surface and as organic matter begins to form, the size and activity of the community increase. Those species and ecotypes most tolerant to saline, sodic, alkaline conditions will be strongly favoured during the early stages. After ripening, the chemical properties are much less harsh (less saline, sodic and alkaline) and the addition of organic materials such as composts introduces a new large diverse microbial community present in the material. In addition, aeolian transport is continually introducing microflora from the surrounding area. Although it has been suggested that inoculation of residue with a microbial community preconditioned to the local environment (e.g., derived from remediated residue) might be benificial [71], there is to date no evidence to support this. In some cases, specific microorganisms (e.g., mycorrhizal fungi, or rhizobial bacteria) may not establish rapidly and inoculation of vegetation at seeding may be benificial. For instance, BABU e al [72] showed that inoculation of cynodon dactylon with AM fungi improved its growth in bauxite residue.

As noted previously, colonization by soil fauna is characteristically slower than that for microflora. Indeed, it has been suggested by a number of works that inoculation with earthworms is an important strategy for mined land restoration [73] and earthworms have also been successfully introduced into mine tailings along with organic matter amendments [74, 75]. Some further research in this area for bauxite residues is warranted since earthworms can be important in relation to aggregation and creation of macroporosity as well as stimulating soil microbial activity and nutrient cycling.

4.5 Environmental protection

During the ripening period and after initiation of revegetation, environmental monitoring and management will be required. Dust emanating from the surface of residue deposits always needs to be managed and revegetation is an effective way of minimizing dust [3]. During the initial drainage and drying period, alkaline leachate high in Na is sometimes recycled back to the alumina refinery but after its closure the leachate will be released into the wider environment. Such alkaline leachate can sometimes have an elemental content that exceeds environmental guidelines (e.g., Al, Ga, Mo, As and V) [76]. The use of constructed wetlands as a passive treatment technology to increase the pH of leachates [77, 78] and lower the content of contaminant elements [76, 79] is presently being researched. Accumulation of metals/metalloids in herbage growing on residue and the chance of its transfer to grazing animals/wildlife also need to be monitored although, to date, no such problems have been identified.

4.6 Long-term changes

While conditions in bauxite residue can be modified by natural ripening plus anthropogenic amendment so that plants can successfully be grown, it is important to note that changes over a geological time-scale (i.e., in hundreds and thousands of years) will occur in both the nature of the material and the composition of the vegetation present. As noted by SANTINI et al [80], the short geological time-frame over which bauxite residue has been produced and exposed to weathering at the earth’s surface (i.e., <150 years) limits evaluation of the trajectory of its soil formation. Short-term changes in mineralogy have, nevertheless, been noted. For example, KONG et al [81] detected small decreases in the amounts of calcite, hydrogarnet and sodalite minerals present and also in the amorphous mineral fraction over a 20-year period while decreases in goethite, hematite and sodalite in surface layers were noted by SANTINI et al [82] after 10–20 years. Due to the dominance of iron oxides, and the absence of high-activity clay minerals, bauxite residue is most likely to weather towards soils with similar properties to deeply weathered red tropical Nitisols and Ferralsols [83]. Eventually these types of soils, and the sustainability of revegetation strategies employed will be determined over geological timescales and many generations-on from those people currently carrying out the revegetation.

5 Synthesis and conclusions

Revegetation of bauxite residues is initially limited by the poor physical properties of the silty muddy tailings and their alkaline, saline-sodic nature. Drainage of the deposits and drying over time (with regular leaching events during the rainy season) will allow physical and chemical ripening of the material to proceed. Soluble alkalinity OH–, CO32–/HCO3– and Al(OH)4– leaches with Na+ result in a decrease in pH, EC, exchangeable Na and ESP in the surface horizons. Dissolution of calcite in the residue increases exchangeable Ca concentrations and promotes leaching of Na. Dissolution of CO2 into soil solution at surface results in leaching of carbonic acid and further acidification. As the residue dries, it solidifies and irreversibly shrinks. As a result, cracks and surface-connected macropores develop to depth, thus promoting water and air movement. Over time aggregation in the surface layer increases. Microbial colonisation of the residue surface occurs rapidly via aeolian dispersal but the size and activity of the microbial community are extremely low due to a lack of substrate C (i.e., organic matter). Over time, as saline-sodic plants colonise the site, organic matter begins to accumulate at the surface and microbial activity increases.

Once physical and chemical ripening has proceeded, revegetation of the site is possible. The most successful revegetation strategy is to incorporate a combination of gypsum and organic waste (e.g., compost, animal manure, biosolids) into the surface 15 cm before seeding with plants tolerant to alkaline, saline-sodic conditions as well as the local climatic conditions. The addition of these amendments results in a further decrease in pH, an increase in exchangeable Ca (and for organic wastes other exchangeable cations), increased leaching of Na (and a consequent decrease in exchangeable Na and ESP), improved physical conditons (increased porosity, aggregation and aggregate stability) and organic wastes introduction of a new microbial community and a substrate for microbial activity. Allowing time for ripening to occur followed by amendment with gypsum and organic matter results in soil-like properties in the surface horizon (plant rooting zone) and allows for the successful revegetation of bauxite residue.

References

[1] POWER G, GRAFE M, KLAUBER C. Bauxite residue issues: I. Current management, disposal and storage practices [J]. Hydrometallurgy, 2011, 108(1, 2): 33–45. DOI: https://doi.org/ 10.1016/j.hydromet.2011.02.006.

[2] XUE Sheng-guo, ZHU Feng, KONG Xiang-feng, WU Chuan, HUANG Ling, HUANG Nan, HARTLEY W. A review of the characterization and revegetation of bauxite residues (red mud) [J]. Environmental Science and Pollution Research, 2016, 23(2): 1120–1132. DOI: 10.1007/s11356- 015-4558-8.

[3] JONES B E, HAYNES R J. Bauxite processing residue: a critical review of its formation, properties, storage and revegetation [J]. Critical Reviews in Environmental Science and Technology, 2011, 41(1): 271–315. DOI: 10.1080/ 10643380902800000.

[4] KLAUBER C, GRAFE M, POWER G. Bauxite residue issues II: Options for residue utilization [J]. Hydrometallurgy, 2011, 108(1, 2): 11–32. DOI: https://doi.org/10.1016/ j.hydromet.2011.02.007.

[5] UJACZKI E, FEIGL V, MOLNAR M, CUSACK P, CURTIN T, COURTNEY R, O'DONOGHUE L, DAVRIS P, HUGI C, EVANGELOU M W, BALOMENOS E. Re-using bauxite residues: Benefits beyond (critical raw) material recovery [J]. Journal of Chemical Technology and Biotechnology, 2018, 93(9): 2498–2510. DOI: https://doi.org/10.1002/jctb.5687.

[6] LI Y, HAYNES R J. Formation, properties and revegetation prospects for bauxite processing residue and the effects of seawater neutralization [J]. International Journal of Environmental Engineering, 2017, 9(1): 11–39. DOI: https:// doi.org/10.1504/IJEE.2017.087984.

[7] GRAFE M, KLAUBER C, POWER G. Bauxite residue issues: III Alkalinity and associated chemistry [J]. Hydrometallurgy. 2011, 108(1, 2): 60–79. DOI: https://doi.org/10.1016/j.hydromet.2011.02.004.

[8] XUE Sheng-guo, KONG Xiang-feng, ZHU Feng, HARTLEY W, LI Xiao-fei, LI Yi-wei. Proposal for management and alkalinity transformation of bauxite residue in China [J]. Environmental Science and Pollution Research, 2016, 23(13): 12822–12834. DOI: 10.1007/s11356-016- 6478-7.

[9] VERMEULEN J, van DIJK S G, GROTENHUIS J T C, RULKENS W H. Quantification of physical properties of dredged sediments during physical ripening [J]. Geoderma, 2005, 129(3, 4): 147–166. DOI: https://doi.org/10.1016/ j.geoderma. 2004.12.040.

[10] COURTNEY R, MULLEN G, HARRINGTON T. An evaluation of revegetation success on bauxite residue [J]. Restoration Ecology, 2009, 17(3): 350–358. DOI: https://doi.org/10.1111/j.1526-100X.2008.00375.x.

[11] EVANS K. The history, challenges, and new developments in the management and use of bauxite residue [J]. Journal of Sustainable Metallurgy, 2016, 2(1): 316–331. DOI 10.1007/ s40831-016-0060-x.

[12] VERMEULEN J, GROTENHUIS T, JOZIASSE J, RULKENS W. Ripening of clayey dredged sediments during temporary upland disposal a bioremediation technique [J]. Journal of Soils and Sediments, 2003, 3(1): 49–59. DOI: 10.1007/BF02989469.

[13] NGUYEN Q D, BOGER D V. Application of rheology to solving tailings disposal problems [J]. International Journal of Mineral Processing, 1998, 54(3, 4): 217–233. DOI: https:// doi.org/10.1016/S0301-7516(98)00011-8.

[14] WILLAN M B, GHATAORA G S. Management of bauxite residue in temperate climate using mud-farming techniques [C]// JEWELL R J, FOURIE A B. Proceedings of the 18th International Seminar on Paste and Thickened Tailings. Perth, Australia: Australian Centre of Geomechanics, 2015; 209–216. DOI: https://papers.acg.uwa.edu.au/p/1504_14_ Willan/.

[15] WEHR J B, FULTON I, MENZIES N W. Revegetation strategies for bauxite refinery residue: A case study of Alcan Gove in Northern Territory, Australia [J]. Environmental Management, 2006, 37(3): 297–306. DOI: https://doi.org/ 10.1007/ s00267-004-0385-2.

[16] RAO P P. The characteristics and genesis discussion of fracture in dry red mud disposal yard [J]. Industrial Construction 2010, 40(1): 73–77. DOI: https://doi.org/ 10.1016/ j.jenvman.2018.06.070.

[17] LI Y, HAYNES R J, CHANDRAWANA I, ZHOU Y F. Properties of seawater neutralized bauxite residues and changes in chemical, physical and microbial properties induced by additions of gypsum and organic matter [J]. Journal of Environmental Management, 2018, 223(1): 489–494. DOI: https://doi.org/10.1007/s11356-018-2564-3.

[18] LI Y, HAYNES R J, CHANDRAWANA I, ZHOU Y F. Increased leaching and addition of amendments improves the properties of seawater neutralized bauxite residue as a growth medium [J]. Environmental Science and Pollution Research, 2018, 25(25): 25476–25485. DOI: 10.1007/ s11356-015-5537-9.

[19] ZHU Feng, XUE Sheng-guo, HARTLEY W, HUANG Ling, WU Chuan, LI Xiao-fei. Novel predictors of soil genesis following natural weathering processes of bauxite residues [J]. Environmental Science and Pollution Research, 2016, 23(3): 2856–2863. DOI: https://doi.org/10.1016/j.scitotenv. 2016. 08.108.

[20] ZHU Feng, LIAO Jia-xin, XUE Sheng-guo, HARTLEY W, ZOU Qi, WU Hao. Evaluation of microstructures following natural regeneration in bauxite residue as characterized by synchrotron-based X-ray micro-computed tomography [J]. Science of the Total Environment, 2016, 573(1): 155–163.

[21] ZHU Feng, ZHOU Jia-yi, XUE Sheng-guo, HARTLEY W, WU Chuan, GUO Ying. Aging of bauxite residue in association of regeneration: A comparison of methods to determine aggregate stability and erosion resistance [J]. Ecological Engineering, 2016, 92(1): 47–54. DOI: https:// doi.org/10.1016/j.ecoleng.2016.03.025.

[22] ZHU Feng, CHENG Qing-yu, XUE Sheng-guo, LI Chu-xuan, HARTLEY W, WU Chuan, TIAN Tao. Influence of natural regeneration on fractal features of residue microaggregates in bauxite residue disposal areas [J]. Land Degradation and Development, 2018, 29(1): 138–149. DOI: https://doi.org/ 10.1002/ldr.2848.

[23] FULLER R D, NELSON E D P, RICHARDSON C J. Reclamation of red mud (bauxite residues) using alkaline- tolerant grasses with organic amendments [J]. Journal of Environmental Management, 1982, 11(3): 533–539. DOI: 10.2134/jeq1982.00472425001100030040x.

[24] SNARS K, GILKES R J, WONG M. The liming effect of bauxite processing residue (red mud) on sandy soils [J]. Australian Journal of Soil Research, 2004, 42(2): 321–328. DOI: 10.1071/sr03021.

[25] JONES B E, HAYNES R J, PHILLIPS I R. Cation and anion leaching and growth of Acacia saligna in bauxite residue sand amended with residue mud, poultry manure and phosphogypsum [J]. Environmental Science and Pollution Research, 2012, 19(3): 835–846. DOI: 10.1007/s11356- 011-0630-1.

[26] JONES B E, HAYNES R. J, PHILLIPS I R. Influence of amendments on acidification and leaching of Na from bauxite processing sand [J]. Ecological Engineering, 2015, 84(1): 435–442. DOI: https://doi.org/10.1016/j.ecoleng. 2015.09. 054.

[27] KHAITIN S, DZOMBAK D A, SWALLOW P, SCHMIDT K, FU J, LOWRY G V. Field evaluation of bauxite residue neutralization by carbon dioxide, vegetation, and organic amendments [J]. Journal of Environmental Engineering, 2010, 136(10): 1045–1053. DOI: 10.1061/(ASCE)EE.1943- 7870.0000230.

[28] CHAUHAN S, GANGULY A. Standardizing rehabilitation protocol using vegetation cover for bauxite waste (red mud) in eastern India [J]. Ecological Engineering, 2011, 37(3): 504–510. DOI: https://doi.org/10.1016/j.ecoleng.2010. 12.017.

[29] SANTINI T C, FEY M V. Spontaneous vegetation encroachment upon bauxite residue (red mud) as an indicator and facilitator of in situ remediation processes [J]. Environmental Science and Technology, 2013, 47(21): 12089–12096. DOI: 10.1021/es402924g.

[30] MISHRA T, SINGH N B, SINGH N. Restoration of red mud deposits by naturally growing vegetation [J]. International Journal of Phytoremediation 2017, 19(5): 439–445. DOI: 10.1080/15226514.2016.1244162.

[31] HAYNES R J. Nature of the belowground ecosystem and its development during pedogenesis [J]. Advances in Agronomy, 2014, 127(1): 43–109. DOI: https://doi.org/10.1016/B978-0- 12-800131-8.00002-9.

[32] BANNING N C, PHILLIPS I R, JONES D L, MURPHY D V. Development of microbial diversity and functional potential in bauxite residue sand under rehabilitation [J]. Restoration Ecology, 2010, 19(101): 78–87. DOI: https://doi.org/10.1111/j.1526-100X.2009.00637.x.

[33] SANTINI T C, WARREN L A, KENDRA K E. Microbial diversity in engineered haloalkaline environments shaped by shared geochemical drivers observed in natural analogues [J]. Applied and Environmental Microbiology, 2015, 81(15): 5026–5036. DOI: 10.1128/AEM.01238-15.

[34] SCHMALENBERGER A, O’SULLIVAN O, GAHAN J, COTTER P D, COURTNEY R. Bacterial communities established in bauxite residues with different restoration histories [J]. Environmental Science and Technology, 2013, 47(13): 7110–7119. DOI: 10.1021/es401124w.

[35] XUE Sheng-guo, LI Meng, JIANG Jun, MILLAR G M, LI Chu-xuan, KONG Xiang-feng. Phosphogypsum stabilization of bauxite residues: Conversion of its alkaline characteristics [J]. Journal of Environmental Science, 2019, 77: 1–10. DOI: https://doi.org/10.1016/j.jes.2018.05.016.

[36] WONG J W C, HO G E. Use of waste gypsum in the revegetation on red mud deposits: a greenhouse study [J]. Waste Management and Research, 1993, 11(3): 249–256. DOI: https://doi.org/10.1006/wmre.1993.1024.

[37] XENIDIS A, HAROKOPOU A D, MYLONA E, BROFAS G. 2005. Modifying alumina red mud to support a revegetation cover [J]. The Journal of the Minerals, Metals and Materials Society, 2005, 57(2): 42–46. DOI: https://doi.org/10.1007/s11837-005-0214-y.

[38] JONES B E, HAYNES R J, PHILLIPS I R. Effect of amendment of bauxite processing sand with organic materials on its chemical, physical and microbial properties [J]. Journal of Environmental Management, 2010, 91(1): 2281–2288. DOI: https://doi.org/10.1016/j.jenvman.2010. 06.013.

[39] JONES B E, HAYNES R J, PHILLIPS I R. Influence of organic waste and residue mud additions on chemical, physical and microbial properties of bauxite residue sand [J]. Environmental Science and Pollution Research, 2011, 18(2): 199–211. DOI: 10.1007/s11356-010-0364-5.

[40] JONES B E, HAYNES R J, PHILLIPS I R. Addition of an organic amendment and/or residue mud to bauxite residue sand in order to improve its properties as a growth medium [J]. Journal of Environmental Management, 2012, 95(1): 29–38. DOI: 10.1016/j.jenvman.2011.09.014.

[41] COURTNEY R G, TIMPSON J P. Nutrient status of vegetation grown in alkaline bauxite processing residue amended with gypsum and thermally dried sewage sludge– A two year study [J]. Plant and Soil, 2004, 266(1, 2): 187–194. DOI: https://doi.org/10.1007/s11104-005-0872-0.

[42] COURTNEY R G, HARRINGTON T. Growth and nutrition of Holcus lanatus in bauxite residue amended with combinations of spent mushroom compost and gypsum [J]. Land Degradation and Development, 2012, 23(2): 144–149. DOI: 10.1002/ldr.1062.

[43] COURTNEY R G, TIMPSON J P. Reclamation of fine fraction bauxite processing residue (red mud) amended with coarse fraction residue and gypsum [J]. Water, Air, and Soil Pollution, 2005, 164(1–4): 91–102. DOI: 10.1007/s11270- 005-2251-0.

[44] COURTNEY R, TIMPSON J P, GRENNAN E. Growth of Trifolium pratense in red mud amended with process sand, gypsum and thermally dried sewage sludge [J]. International Journal of Surface Mining, Reclamation and Environment, 2003, 17(4): 227–233. DOI: 10.1076/ijsm.17.4.227.17481.

[45] COURTNEY R, MULLEN G. Use of germination and seedling performance bioassays for assessing revegetation strategies on bauxite residue [J]. Water, Air and Soil Pollution, 2009, 197(1–4): 15–22. DOI: 10.1007/s11270- 008-9787-8.

[46] COURTNEY R G, JORDAN S N, HARRINGTON T. Physico-chemical changes in bauxite residue following application of spent mushroom compost and gypsum [J]. Land Degradation and Development, 2009, 20(5): 572–581. DOI: 10.1002/ldr.926.

[47] COURTNEY R G, HARRINGTON T, BYRNE K A. Indicators of soil formation in restored bauxite residues [J]. Ecological Engineering, 2013, 58(1): 63–68. DOI: https://doi.org/ 10.1016/j.ecoleng.2013.06.022.

[48] BRAY A B, STEWART D I, COURTNEY R, ROUT S P, HUMPHRIES P N, MAYES W M, BURKE I T. Sustained bauxite residue rehabilitation with gypsum and organic matter 16 years after initial treatment [J]. Environmental Science and Technology, 2018, 52(1): 152–161. DOI: 10.1021/acs.est.7b03568.

[49] WHITTINGTON B I, FLETCHER B L, TALBOT C. The effect of reaction conditions on the composition of desilication product (DSP) formed under simulated Bayer conditions [J]. Hydrometallurgy, 1998, 49(1): 1–22. DOI: 10.1016/S0304-386X(98)00021-8.

[50] ZHU Feng, HOU Jing-tao, XUE Sheng-guo, WU Chuan, WANG Qiong-li, HARTLEY W. Vermicompost and gypsum amendments improve aggregate formation in bauxite residue [J]. Land Degradation and Development, 2017, 28(7): 2109–2120. DOI: 10.1002/ldr.2737.

[51] JONES D, HAYNES R, PHILLIPS I. Can organic amendments be used to improve the properties of bauxite processing residue sand? [C]// World Congress of Soil Science, Soil Solutions for a Changing World. Brisbane, Australia: IUSS, 2010: 32–35. DOI: http://espace.library. uq.edu. au/view/UQ:234364.

[52] FULLER R D, RICHARDSON C J. Aluminate toxicity as a factor controlling plant growth in bauxite residue [J]. Environmental Toxicological Chemistry 1986, 5(10): 905–915. DOI: 10.1002/etc.5620051007.

[53] WONG J W, HO G. Sewage sludge as organic ameliorant for revegetation of fine bauxite refining residue [J]. Resources, Conservation and Recycling, 1994, 11(1–4): 297–309. DOI: https://doi.org/10.1016/0921-3449 (94) 90097-3.

[54] FORTIN J, KARAM A. Effect of a commercial peat moss-shrimp wastes compost on Pucinellia growth in red mud [J]. International Journal of Surface Mining, Reclamation and Environment, 1998, 12(3): 105–109. DOI: 10.1080/09208118908944032.

[55] WONG J W C, HO G E. Effects of gypsum and sewage sludge amendment on physical properties of fine bauxite refining residue [J]. Soil Science, 1991, 152(5): 326–332. DOI: 10.1097/00010694-199111000-00003.

[56] BANNING N C, SAWADA Y, PHILLIPS I R, MURPHY D V. Amendment of bauxite residue sand can alleviate constraints to plant establishment and nutrient cycling capacity in a water-limited environment [J]. Ecological Engineering, 2014, 62(1): 179–187.

[57] LI Ya-ying. Revegetation strategies for seawater neutralized bauxite residue at Rio Tinto Alcan using various amendments [C]// School of Agriculture and Food Sciences, The University of Queensland, 2017. DOI: https://doi.org/ 10.14264/uql.2017.798.

[58] COURTNEY R, HARRIS J A, PAWLETT M. Microbial community composition in a rehabilitated bauxite residue disposal area: A case study for improving microbial community composition [J]. Restoration Ecology, 2014, 22(6): 798–805. DOI: 10.1111/rec.12143.

[59] COURTNEY R, KEITH A M, HARRINGTON T. Nematode assemblages in bauxite residue with different restoration histories [J]. Restoration Ecology, 2011, 19(6): 758–764. DOI: https://doi.org/10.1111/j.1526-100X.2010.00734.x.

[60] COURTNEY R, FEENEY E, O’GRADY A. An ecological assessment of rehabilitated bauxite residue [J]. Ecological Engineering, 2014, 73(1): 373–379. DOI: 10.1016/ j.ecoleng.2014.09.064.

[61] GRAFE M, KLAUBER C. Bauxite residue issues: IV. Old obstacles and new pathways for in situ residue bioremediation [J]. Hydrometallurgy, 2011, 108(1, 2): 46–59. DOI: 10.1016/j.hydromet.2011.02.005.

[62] HAYNES R J. Sustainable vegetation [C]// Proceedings of the 10th International Alumina Quality Workshop, Post Conference Workshop-Maintaining a Flexible Approach to Closure and Rehabilitation of Residue Storage Areas. Perth, Australia, 2015.

[63] COURTNEY R, MULLEN G, HARRINGTON, T. An evaluation of revegetation success on bauxite residue [J]. Restoration Ecology, 2009, 17(3): 350–358. DOI: https:// doi.org/ 10.1111/j.1526-100X.2008.00375.x.

[64] BELL D T, WILKINS C F, VAN DER MOEZEL P G, WARD S C. Alkalinity tolerance of woody species used in bauxite waste rehabilitation, Western Australia [J]. Restoration Ecology, 1993, 1(1): 51–58. DOI: https://doi.org/ 10.1111/j.1526-100X.1993.tb00008.x.

[65] MENDEZ M O, MAIER R M. Phytostabilization of mine tailings in arid and semiarid environments: An emerging remediation technology [J]. Environmental Health Perspectives, 2016, 116(3): 278–283. DOI: 10.1289/ehp. 10608.

[66] EASTHAM J, MORALD T. Effective nutrient sources for plant growth on bauxite residue: 2. Evaluating the response to inorganic fertilizers [J]. Water, Air and Soil Pollution, 2006, 171(1–4): 315–331. DOI: 10.1007/s11270-005- 9055-0.

[67] MEECHAM J R, BELL L C. Revegetation of alumina refinery wastes: 2. Glasshouse experiments [J]. Australian Journal of Experimental Agriculture, 1977, 17: 689–696.

[68] PHILLIPS I R, CHEN C. Surface charge characteristics and sorption properties of bauxite-processing residue sand [J]. Australian Journal of Soil Research, 2010, 48(1): 77–87. DOI: https://doi.org/10.1071/SR09056.

[69] CHEN C R, PHILLIPS I R, WEI L L, XU Z H. Behaviour and dynamics of diammonium phosphate in bauxite processing sand in Western Australia–I. NH3 volatilization and residual nitrogen availability [J]. Environmental Science and Pollution Research, 2010, 17(5): 1098–1109. DOI: 10.1007/s11356-009-0268-4.

[70] CHEN C R, PHILLIPS I R, CONDRON L M, GOLORAN J, XU Z H, CHAN K Y. Impacts of biochar on ammonia volatilization from bauxite processing residue sand [J]. Plant and Soil, 2013, 367(1, 2): 301–312. DOI: https://doi.org/ 10.1007/s11104-012-1468-0.

[71] SANTINI T C, KERR J K, WARREN L A. Microbially-driven strategies for bioremediation of bauxite residue [J]. Journal of Hazardous Materials, 2015, 293(1): 131–157. DOI: 10.1016/j.jhazmat.2015.03.024.

[72] BABU A G, REDDY M S. Influence of arbuscular mycorrhizal fungi on the growth and nutrient status of bermudagrass grown in alkaline bauxite processing residue [J]. Environmental Pollution, 2011, 159(1): 25–29. DOI: 1016/j.envpol.2010.09.032.

[73] BUTT K R. Earthworms in soil restoration: lessons learned from United Kingdom case studies of land reclamation [J]. Restoration Ecology, 2008, 16(4): 637–641. DOI: 10.1111/j.1526-100X.2008.00483.x.

[74] CHENG Jie-min, WONG Ming-hung. Effect of earthworms (Pheretima sp) density on revegetation of lead/zinc metal mine tailings amended with soil [J]. Chinese Journal of Population Resources and Environment, 2008, 6(2): 43–48. DOI: 1080/10042857.2008.10684867.

[75] RUTHERFORD P M, AROCENA J M. Organic amendments and eatrthworm addition improve properties of nonacid mine tailings [J]. Applied Environmental Soil Science, 2012, Article ID 395964. DOI: http://dx.doi.org/ 10.1155/2012/395964.

[76] HUA T, HAYNES R J, ZHOU Y-F, BOULLEMANT A, CHANDRAWANA I. Potential for use of industrial waste materials as filter media for removal of Al, Mo, As, V and Ga from alkaline drainage in constructed wetlands– adsorption studies [J]. Water Research, 2015, 71(1): 32–41. DOI: 10.1016/j.watres.2014.12.036.

[77] BUCKLEY R, CURTIN T, COURTNEY R. The potential for constructed wetlands to treat alkaline bauxite residue leachate: Laboratory investigations [J]. Environmental Science and Pollution Research, 2016, 23(14): 14115–14122. DOI: 10.1007/s11356-016-6582-8.

[78] HIGGINS D, CURTIN T, COURTNEY R. Effectiveness of a constructed wetland for treating alkaline bauxite residue leachate: A 1-year field study [J]. Environmental Science and Pollution Research, 2017, 24(9): 8516–8524. DOI: https://doi.org/10.1007/s11356-017-8544-1.

[79] HUA T, HAYNES R J, ZHOU Y F. Potential use of two filter media in constructed wetlands for simultaneous removal of As, V and Mo from alkaline wastewater-Batch adsorption and column studies [J]. Journal of Environmental Management, 2018, 2018(1): 190–199. DOI: 10.1016/ j.jenvman.2018.04.038.

[80] SANTINI T C, BANNING N C. Alkaline tailings as novel soil forming substrates: Reframing perspectives on mining and refining wastes [J]. Hydrometallurgy, 2016, 164(1): 38–47. DOI: https://doi.org/10.1016/j.hydromet.2016.04.011.

[81] KONG Xiang-feng, TIAN Tao, XUE Sheng-guo, HARTLEY W, HUANG Long-bin, WU Chuan, LI Chu-xuan. Development of alkaline electrochemical characteristics demonstrates soil formation in bauxite residue undergoing natural rehabilitation [J]. Land Degradation and Development, 2018, 29(1): 58–67. DOI: 10.1002/ldr.2836.

[82] SANTINI T C, FEY M V. From tailings to soil: Long-term effects of amendments on progress and trajectory of soil formation and in situ remediation in bauxite residue [J]. Journal of Soils and Sediments, 2018, 18(5): 1935–1949. DOI: https://doi.org/10.1007/s11368-017-1867-1.

[83] SANTINI T C, FEY M V, GILKES R J. Experimental simulation of long-term weathering in alkaline bauxite residue tailings [J]. Metals, 2015, 5(3): 1241–1246. DOI: 10.3390/met5031241.

(Edited by YANG Hua)

中文导读

自然熟化及施用石膏和有机物质是赤泥堆场修复的关键

摘要:本文探讨了赤泥堆场生态修复的主要过程。第一个重要过程就是赤泥物理、化学和微生物特性的自然熟化,主要包括:允许剖面排水、干燥、收缩和开裂至一定的深度;表面层可溶性盐、碱和钠的向下溶淋,并通过直接碳酸化进行酸化;抗性植被的自然播种、表层附近有机质的富集以及随之而产生的活性微生物群落的形成。堆场赤泥熟化后,表层施用石膏和有机特质(如粪肥、堆肥、生物固形物),这些改良剂的添加会进一步降低pH,提高钙和其他可交换阳离子的水平,促进钠的溶淋(降低可交换钠离子和ESP),改善赤泥的物理性质、提高微生物的活性。其他重要因素还包括选择合适的耐盐、耐碱及适应当地环境条件的植物种类、施用合适的肥料等。

关键词:赤泥;赤泥堆场;自然熟化;基质改良;赤泥土壤化

Received date: 2018-10-23; Accepted date: 2018-12-12

Corresponding author: ZHOU Ya-feng, PhD, Professor; E-mail: y.zhou3@uq.edu.au; ORCID: 0000-0001-6606-9068