文章编号:1004-0609(2008)07-1268-06

熔体发泡法制备泡沫铝过程中无泡层的形成与控制

李 兵,曹卓坤,王 永,姚广春,华中胜

(东北大学 教育部材料先进制备技术工程研究中心,沈阳 110004)

摘 要:对熔体发泡法制备泡沫铝过程中无泡层的形成与控制进行研究,考察熔体中加入金属镁后的表面张力以及镁的加入对无泡层厚度的影响,结果表明:泡沫铝制备过程中无泡层的形成分为3个阶段,第一阶段为发泡初期短时间内形成,在这个过程中,气泡向上运动,部分液体残留在底部形成无泡层;第二阶段和第三阶段为气泡长大过程,由于液膜液体与Plateau边界处处存在压力差,促使液膜处的液体流向Plateau边界处,最后通过Plateau通道流向底部形成无泡层;向加入3%Ca(质量分数)的纯铝熔体中再加入0.5%Mg后,熔体的表面张力显著降低,泡沫体中无泡层的厚度得到很好的控制。

关键词:泡沫铝;熔体发泡法;无泡层;黏度;表面张力

中图分类号:TG 146.2 文献标识码:A

Formation and control of bubble-free layer during preparation of

Al foam by foaming in melt

LI Bing, CAO Zhuo-kun, WANG Yong, YAO Guang-chun, HUA Zhong-sheng

(Key Laboratory of Ministry of Education for Advanced Preparing Technique of Materials,

Northeastern University, Shenyang 110004, China)

Abstract: The formation and control of bubble-free layer in Al foam block during the preparation was investigated, the surface tension of melt Mg was viewed, and the effect of Mg on the thickness of bubble-free layer was studied. The results show that there exist three processes for the formation of bubble-free layer. The first process is the initial stages of foaming, in this process, bubbles move upwards, and a portion of liquid remains at the bottom and becomes bubble-free layer. The second and the third processes are during the process of growth of bubbles, in these processes, bigger pressure of liquid stored in films makes liquid in films flow to plateau borders, and then the liquid in plateau borders flows to the bottom through plateau channels, and form bubble-free layer. When 0.5%Mg(mass fraction) is added into Al melt containing 3%Ca, the surface tension of melt decreases significantly, and the thickness of bubble-free layer in Al foam block can be controlled very well.

Key words: Al foam; melt foaming method; bubble-free layer; viscosity; surface tension

熔体发泡法制备泡沫铝材料由于生产工艺相对较简单,成本较低,最终得到的产品其内部孔隙较均匀,以及产品的性能较为优良等优点越来越受到人们的关注[1?4]。经过多年的发展,熔体发泡生产闭孔泡沫铝的方法已经从基础研究阶段发展到了工业化生产的阶段。日本神钢钢线工业株式会社(即日本神户钢铁公司钢线工业公司)运用熔体直接发泡法于20世纪末已经实现泡沫铝材料的工业化生产,其生产的泡沫铝的商品名为ALPORAS[5];东北大学经过十几年的努力,2005年底率先在国内实现工业化生产,并经过有关单位的鉴定,其生产技术已经达到国际一流水平[6]。

熔体发泡法生产的泡沫体由两部分组成,即上部泡沫部分和底部无泡层部分,泡沫层部分经过加工可成为最终的产品,而底部无泡层部分最后还得回收再利用,所以泡沫铝块中无泡层的存在将极大地影响生产的成品率和生产成本,随着工业化的发展,如何控制无泡层的厚度,是一个新的课题,有些研究者已经对泡沫的衰败和排液[7?9]进行了研究,但对无泡层形成过程的研究还未见有报道。本文作者对熔体发炮法制备泡沫铝过程中无泡层的形成与控制进行了研究,研究结果将为工业化生产泡沫铝时控制无泡层的厚度提供指导。

1 实验

熔体发泡法制备泡沫铝的过程包括:铝的熔化,铝液的增粘,加入发泡剂并搅拌,发泡和冷却等。实验时,首先在一定温度下,在d 100 mm×240 mm的坩埚内将900 g工业纯铝锭熔化,在860 ℃下加入3%金属钙进行增粘,然后将温度调至690 ℃,向熔体中加入1.2%粒度为47 ?m的发泡剂氢化钛并搅拌混合[10],混合均匀后,随即进入保温发泡阶段。实验时测量泡沫体发泡时高度随时间膨胀的曲线,即在发泡时,用自制的设备测量泡沫体膨胀时高度随时间变化的曲线[11],测量时间间隔为5 s,测量误差为0.5 mm,一定时间后取出泡沫体冷却。

为了研究无泡层的形成过程,随后的实验中根据泡沫体发泡过程的膨胀特点,分别选择5个不同发泡时间来制备泡沫铝样品。当泡沫体达到预定的发泡时间后,迅速将其取出进行底部快速冷却,然后沿其纵向切开,以观察内部泡沫状况以及形成的无泡层状况。

实验最后考察了熔体表面张力对发泡过程以及无泡层的影响,用气泡最大压力法测量加入不同量金属钙以及加入少量金属镁的铝熔体的表面张力,考察金属镁的加入对无泡层厚度的影响。

2 实验结果

2.1 泡沫体的膨胀过程

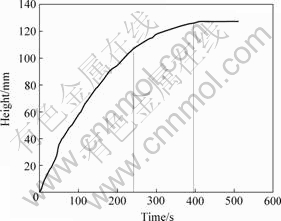

实验过程中对加入3%金属钙和1.2%TiH2的铝熔体的整个发泡过程进行跟踪研究。图1所示为熔体泡沫化过程中泡沫体膨胀时其高度随时间的变化曲线。由图1可知,熔体泡沫化过程可以大致分为3个阶段:较快速膨胀阶段,较慢速膨胀阶段,以及稳定和收缩阶段。

图1 泡沫体高度随时间膨胀曲线

Fig.1 Expanding curve of height of foam block with time

2.2 无泡层的形成过程

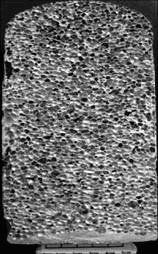

图2所示为发泡不同阶段发泡体进行快速水冷制得的泡沫铝样品的轴向纵切面照片。由图2可知,随着发泡时间的延长,泡沫体的高度逐渐增大,当长大到一定高度以后,再延长发泡时间,泡沫体略微坍塌。在泡沫体长大的过程中,其内部发泡剂分解出的气体经过形核首先形成微小的球形气泡,随着发泡的进行,球形气泡逐渐长大,长大到一定尺寸以后,球形气泡转变为多边形气泡(见图2(d)),多边形气泡随着发泡时间的延长还可进一步长大(见图2(e))。在泡沫体长大和气泡变化的过程中,泡沫体底部的无泡层随着发泡时间的延长而发生变化。

图2 不同发泡时间制取的泡沫铝样品

Fig.2 Al foams produced by different foaming times: (a) 0 min; (b) 2 min; (c) 4 min; (d) 6 min; (e) 10 min

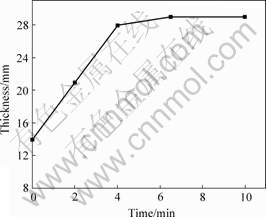

图2(a)所示为未经发泡的泡沫铝样品的纵截面照片。即搅拌结束后随即将装有泡沫体的坩埚取出,进行快速冷却得到的样品。从图中可以看出其底部已经形成比较厚的无泡层(从炉内取出坩埚到开始冷却时间间隔为45 s)。随着发泡时间的延长,无泡层的厚度逐渐变厚,一定的发泡时间后,无泡层的厚度不再变化。将无泡层的厚度与相应的发泡时间绘制成曲线,结果如图3所示。从图3可以看出,在发泡前4 min(即泡沫体内气泡为球形气泡长大时),无泡层的厚度呈直线增加;发泡时间4 min至6 min内(即球形气泡转变为多边形气泡过程),无泡层的厚度略有增加;而在6 min以后(即泡沫体高度达到最高高度以后),无泡层的厚度没有增加。所以可以认为,无泡层主要是在发泡体生长过程中产生,而泡沫的静置排液过程对无泡层厚度的影响不大。

图3 无泡层厚度和发泡时间关系曲线

Fig.3 Curve of bubble-free layer thickness vs foaming time

3 分析与讨论

3.1 无泡层产生的原因

由无泡层的形成过程可知,无泡层的形成可分为3个阶段:第一阶段,搅拌结束后,发泡初期短时间内;第二阶段,球形气泡长大的过程中;第三阶段,球形气泡转变为多边形气泡的过程中。而第一阶段和第二阶段是无泡层形成的主要阶段。

在第一阶段,搅拌刚刚完成,此时在熔体中均匀混合的发泡剂分解出的气体经过形核形成微小的气泡,这些微小的气泡在发泡开始时在熔体中均匀分布。随着发泡的进行,气泡在浮力作用下向上运动,由于底部的气泡运动速度大于上部气泡的运动速度[12]以及熔体具有一定的黏度,所以气泡在泡沫体的上部聚集,而底部则留下未被气泡携带走的液体,这些液体即变成无泡层,这个过程可用图4所示的示意图来描述。图4(a)所示为发泡开始时熔体的状态,图4(b)所示为短时间内,熔体经过气泡长大与向上运动后的内部状况。

图4 发泡初始阶段气泡运动示意图

Fig.4 Sketch maps of bubbles’ movement at initial stage of foaming: (a) Beginning of foaming; (b) Foaming for some time

在熔体中由于存在着多个气泡,运动中气泡间存在相互作用。设熔体中气泡的运动速率为u,搅拌完成时熔体内气泡均匀分布,则u与熔体中单个气泡的运动速率u0的关系为[13]

从式(3)中可以看出,熔体的黏度越大,熔体的含气率越大,气泡的运动速度越慢。从式(4)中可以看出,当熔体的含气率越大时,气泡运动所受到的阻力越大,则气泡向上运动时携带的液体就越多。所以,当熔体的黏度越大,熔体的含气率越大时,底部残留的液体越少。

由于在发泡过程中,气泡不断膨胀,熔体的含气率也在不断增大,当熔体的含气率随时间变化率越快时,最终由于气泡的上浮而使液体残留底部产生无泡层的量越少。

由式(8)可知,发泡剂的分解速率越快,熔体的表面张力越小,熔体的含气率随时间的变化率将会越大。

所以,在无泡层形成的第一阶段,当发泡剂的分解速率越快,熔体的黏度越大,表面张力越小,底部形成的无泡层越少。而发泡剂的分解速率取决于发泡温度和加入发泡剂的量,发泡温度越高、加入发泡剂加入量越大,发泡剂的分解速率越快。但是当发泡温度过高,发泡剂的量过多时,制得的泡沫铝内部将会出现通孔和空洞等缺陷[10]。

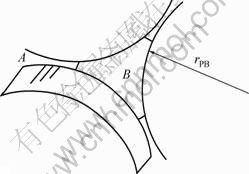

在无泡层形成的第二和第三阶段,熔体被泡沫化以后,气泡就被平面多边形液膜(图5中A区,冷却后即为泡壁)隔开,液膜相接在带有曲面的Plateau边界处[7](图5中B区所示)。由于存在着曲面,所以图5中B区液体的压力pB比A区液体的压力pA要小。B区液体的压力可以表示为

对于平面液膜泡壁,其所受的压力即为与之相连气泡内的压力pG。所以Plateau边界处液体的压力与液膜处的压力差为

图5 Plateau边界示意图

Fig.5 Sketch map of Plateau border

由于存在着压力差,所以就促使A区中的液体向B区流动。所以泡沫中的液体逐渐被挤压到Plateau交界处,即B区。

在第二阶段,由于气泡处于球形,所以Plateau边界横切面曲率半径rPB比第三阶段时气泡处于多边形时小得多,因此,第二阶段A、B两区的压力差大于第三阶段时A、B两区的压力差,所以第二阶段泡沫排液的速度比第三阶段要快得多。

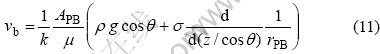

根据Plateau法则可知4个Plateau交于1个通 道[15],所以B区的液体在重力作用下就会沿着这个通道流向底部,设B区液体流动速度为vb,则vb可表示为[7]

式中 k为交界处的形状因子,取k = 49,APB为Plateau交界处的面积,θ为Plateau通道与垂直方向的夹角。从式(10)和(11)可知,当熔体的表面张力越小,黏度越大,Plateau边界处液体的压力与液膜处的压力差越小,B区液体向下流动的速度就越小,在第二阶段和第三阶段形成的无泡层越小。

综上所述,在第一阶段,无泡层是由于气泡上浮使液体残留于底部而形成;在第二和第三阶段,则是由于气泡间的挤压作用,使液体流到底部而形成。由分析可知,当熔体的黏度越大,表面张力越小时,无泡层的厚度越小,所以,控制无泡层必须控制熔体的黏度和表面张力。

3.2 Mg的加入对无泡层厚度的影响

在熔体中随着钙含量的增加,不仅熔体的黏度增加,而且表面张力减小,图6所示为690 ℃时铝熔体的表面张力与金属元素加入量的关系曲线。图6(a)所示为纯铝熔体中加入不同量的金属钙后的表面张力变化曲线,图6(b)所示为纯铝熔体中加入3%Ca后再加金属Mg的表面张力变化曲线。

图6 690 ℃时铝熔体的表面张力与金属元素加入量的关系

Fig.6 Effect of addition alloying elements on surface tension of Al melts: (a) Addition of Ca; (b) Addition of Mg after adding 3%Ca

由图6(a)可知,铝熔体的表面张力随着金属钙加入量的增加显著降低,但是当金属钙的加入量超过3%后,熔体的黏度非常大,发泡剂加入时搅拌十分困难,这样就不易使发泡剂在熔体中均匀混合。但是,当铝熔体中加入3%Ca后再加入少量的金属Mg,熔体的表面张力进一步降低,且熔体的黏度没有太大变 化[16]。这是由于加入Mg后生成金属间化合物Mg5Al8,Mg17Al12和少量的MgO与Al2O3复合氧化物,而金属间化合物的熔点都较低,均在450 ℃左右,在发泡温度690 ℃时已溶解,此时熔体的表面张力减少显著,而黏度增加并不明显。

图7所示为熔体中加入3%Ca和0.5%Mg后加入发泡剂发泡制得的泡沫铝样品。由图7可以看出,加入3%Ca和0.5%Mg后,泡沫铝中的无泡层厚度得到很好的控制。

图7 Al+3%Ca+0.5%Mg发泡后得到的泡沫铝

Fig.7 Al foam foamed by Al+3%Ca+0.5%Mg melts

4 结论

1) 泡沫铝制备过程中无泡层的形成分为3个阶段:第一阶段为发泡初期短时间内形成,在这个过程中,气泡向上运动,部分液体未被气泡运动所携带成为泡沫中的液膜,最后残留在底部形成无泡层;第二阶段和第三阶段为气泡长大过程中,由于Plateau边界处液体与液膜处存在压力差,促使液膜处的液体流向Plateau边界处;最后通过Plateau通道流向底部形成无泡层。

2) 在泡沫铝制备过程中,当熔体的黏度越大,表面张力越小时,无泡层的厚度越小。

3) 向加入3%Ca的纯铝熔体中再加入0.5%Mg后,熔体的表面张力显著降低,制得的泡沫铝中的无泡层厚度得到很好的控制。

REFERENCES

[1] BANHART J. Manufacture, characterization and application of cellular metal and metal foam[J]. Progress in Materials Science, 2001, 46(3): 559?632.

[2] ASHBY M F, LU T J. Metal foams: A survey[J]. Science in China B, 2003, 46(6): 521?532.

[3] YU Hai-jun, YAO Guang-chun, WANG Xiao-lin, LI Bing, LIU Ke. Sound insulation property of Al-Si closed-cell aluminum foam bare board material[J]. Trans Nonferrous Met Soc China, 2007, 17(1):93?98.

[4] 赵玉园. 制备泡沫铝的一种新方法: 烧结溶解法[J]. 世界科技研究与发展, 2003, 25(1): 66?71.

ZHAO Yu-yuan. Sintering and dissolution process: A novel method for manufacturing aluminum foam[J]. World Sci-tech R & D, 2003, 25(1): 66?71.

[5] BANHART J. Industrialization of aluminium foam[C]// Technology Proceedings of the 9th International Conference on Aluminium Alloys. Australia: Institute of Materials Engineering Australasia Ltd, 2004: 764?770.

[6] 王 兵. 新型泡沫铝材料日前在东北大学研制成功[J]. 功能材料信息, 2006, 3(4): 41.

WANG Bing. New type Al foam has been developed in northeastern University[J]. Functional Materials Information, 2006, 3(4): 41.

[7] GERGELY V, CLYNE T W. Drainage in standing liquid metal foam: Modeling and experiment observations[J]. Acta Material, 2004, 52(10): 3047?3058.

[8] KOEHLER S A, HILGENFELDT S, STONE H A. A generalized view of foam drainage: Experiment and theory[J]. Langmuir, 2000, 16(15): 6327?6341.

[9] GRASSIA P, NEETHLING S J, CERVANTES C, LEE H T. The growth, drainage and bursting of foams[J]. Colloids and Surfaces A, 2006, 274(1/3): 110?124.

[10] 李 兵, 姚广春, 王 永, 罗洪杰. 纯铝基泡沫铝材料的制备工艺[J]. 东北大学学报: 自然科学版, 2007, 28(8): 1159?1162.

LI Bing, YAO Guang-chun, WANG Yong, LUO Hong-jie. On the preparation process of foamed pure aluminum[J]. Journal of Northeastern University: Natural Science, 2007, 28(8): 1159?1162.

[11] 曹卓坤. 碳纤维复合泡沫铝材料的研究[D]. 沈阳: 东北大学, 2008.

CAO Zhuo-kun. Research on aluminum foam stabilized by carbon fibers[D]. Shenyang: Northeastern University, 2008.

[12] 张建生, 左军建. 气体运输方程及应用[J]. 军械工程学院学报, 2001, 13(2): 33?38.

ZHANG Jian-sheng, ZUO Jun-jian. Bubble transport equation with application[J]. Journal of Ordnance Engineering College, 2001, 13(2): 33?38.

[13] KENDOUSH A A. Hydrodynamic model for bubbles in a swarm[J]. Chem Eng Sci, 2001, 56(1): 235?238.

[14] SONG Zhen-lun, ZHU Jin-song, MA Li-qun, HE De-ping. Evolution of foamed aluminum structure in foaming process[J]. Mater Sci Eng A, 2001, 298(1/2): 137?143.

[15] BHAKTA A, RUCHENSTEIN E. Decay of standing foams: drainage, coalescence and collapse[J]. Advances in Colloid and Interface Science, 1997, 70(7): 1?124.

[16] 罗洪杰. 熔体直接发泡法制备泡沫铝材料的研究[D]. 沈阳: 东北大学, 2005.

LUO Hong-jie. Study on preparation of aluminum foam by foaming in melt[D]. Shenyang: Northeastern University, 2005.

基金项目:国家高技术研究发展计划资助项目(2004AA33G060);国家自然科学基金资助项目(50704012)

收稿日期:2007-10-20;修订日期:2008-04-01

通讯作者:李 兵,博士研究生;电话:024-83686462;E-mail: liyufeng13@163.com

(编辑 龙怀中)