DOI: 10.11817/j.issn.1672-7207.2017.09.013

基于过弯缺陷控制的异型管辊弯成型过程有限元仿真

曹建国1, 2,王乐1,刘江1,刘晓立1,赵荣国3,贺增磊1

(1. 北京科技大学 机械工程学院,北京,100083;

2. 北京科技大学 国家板带生产先进装备工程技术研究中心,北京,100083;

3. 江苏帝尔保机械有限公司,江苏 扬州,225000)

摘要:针对辊弯成型不对称“8”字形异型管的成型质量缺陷,应用弹塑性变形理论,采用辊弯成型设计及仿真专业软件COPRA建立异型管辊弯成型的有限元模型,对十二机架完整辊弯成型过程进行有限元仿真。研究结果表明:不对称“8”字形异型管截面的小半径圆角与其相邻直线段交界处易产生应力集中,并且由于管件截面几何形状特征引起的顶端受力不均匀是导致过弯缺陷的主因。仿真设计基于过弯缺陷控制的第7机架平辊新辊形和第8机架立辊新辊形,以抵消受压不平衡所产生的过弯,实际生产的新辊形成型质量好。

关键词:辊弯成型;异形管;COPRA;有限元

中图分类号:TG335.4 文献标志码:A 文章编号:1672-7207(2017)09-2345-07

Finite element simulation of roll forming process based on over-bend defect control of shaped tube

CAO Jianguo1, 2, WANG Le1, LIU Jiang1, LIU Xiaoli1, ZHAO Rongguo3, HE Zenglei1

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. National Engineering Research Center of Flat Rolling Equipment, University of Science and Technology Beijing, Beijing 100083, China;

3. Jiangsu Durable Machinery Co. Ltd., Yangzhou 225000, China)

Abstract: Aiming at the forming defect in actual production of asymmetric “8” type shaped tube, finite element models of shaped tube roll forming were established with the professional roll forming design and FEA software COPRA by applying the elastic-plastic deformation theory, and the whole forming process with twenty stations was simulated. The results show that the stress concentration always occurs on the junction of small radius fillets and their adjacent straight segment, and the main reason leading to the over-bend defects is the uneven force on the top of the cross section which is formed by the special geometry shape characteristics. The good effect is achieved by proposing new roll shape in 7th horizontal roll and 8th vertical roll, which offset the over-bend caused by the imbalance pressure. The good quality product is verified.

Key words: roll forming; shaped tube; COPRA; finite element method

辊弯成型,作为一种高效、节能、先进的板金属成型工艺,广泛应用于各种汽车零部件的生产制造中,因此,辊弯成型工艺技术的研究与发展在汽车轻量化研究中占有非常重要地位。辊弯成型是一种多段逐步成型法,成型过程是由平面板材逐步弯曲成所需要的截面,其产品按照是否经过焊接操作可分为开口冷弯型钢和闭口管件两大类。与热轧型钢相比,冷弯产品具有表面质量好、加工尺寸精度高、材料与能源消耗少、相对刚度与强度大等诸多优点,在建筑、交通、家电等各个方面都有非常广泛的应用[1-2]。目前,汽车工业已成为冷弯型钢最大的用户之一,异型管作为闭口型冷弯产品的一个重要部分,与圆管相比,具有较大的惯性矩和截面模数,抗弯扭能力强,可以大大减轻结构质量,故广泛应用于各种结构件、工具和机械零部件[3]。异型管辊弯连续成形的方式有“直接成型”和“先圆后异”2种。对于本文研究的“8”字形异型管来说(以下简称“8字管”),直接成型是直接将平直带钢弯曲成8字形,然后进行焊接;先成圆后变异是将成型好并焊接的圆管通过轧辊挤压成8字形[4-5]。辊弯成型过程复杂,其设计生产标准目前还不够完善,很多情况下需要依靠设计者的经验。然而冷弯产品的形式和需求种类多,尤其对于异型管来说,对于一种新的产品,单靠经验并不能解决问题,反复尝试又会消耗巨大的成本与精力。这时,利用计算机软件的辅助设计与仿真就能大大减少设计的盲目性[6]。辊弯成型过程属于大变形弹塑性变形,大变形弹塑性有限元法是基于有限元弹塑性变分原理和有限元弹塑性变形理论的数值分析方法。国内外学者利用这种分析方法已经取得了积极成果:HEISLITZ等[7]用三维有限元软件PAM2STAMP成功获得变形回弹后的应变分布情况; BOMAN等[8]应用ABAQUS/Explicit分析了槽钢成型过程,并使用了网格自适应技术(ALE);KSAEI等[9]利用有限元分析软件MSC MARC研究了初始板宽过大产生的纵向压缩以及板带边部沉积问题,并提出一种板宽计算的评价标准;KASSAEI等[10]针对变截面处板带出现纵向褶皱的问题进行有限元分析,提出了柔性成型辊设置的解决方案;SAFFE等[11]研究了帽型钢切断后残余应力的分布情况,并与槽钢进行了对比;KANG等[12]用有限元软件ABAQUS研究马氏体钢MS980的圆成方冷弯成型过程,得出了随着材料强度的增加,成型矩形管的圆角半径减小,角部厚度显著增加的结论;湛利华等[13]研究了不同接触分析方法对MARC有限元分析计算精度的影响,文海新等[14]对大型组合结构的整体有限元建模进行了详细的分析和实验,得出了这类结构需遵循的相应原则。阎昱等[15]探索了有限元仿真过程中不同单元类型选择对高强钢的回弹影响;李楠等[16]研究了不同网格密度和轧辊转速对仿真结果准确性的影响。这些研究为利用有限元工具解决实际问题提供了必要的理论支持,但研究范畴偏重于开口型钢,对于闭口型冷弯管件的研究也多集中在简单截面的圆管或方矩形管。本文作者采用冷弯成型专业计算机辅助软件COPRA,研究复杂截面异型管成型缺陷的形成机理与影响因素,为异型管成型设计和缺陷控制提供依据。

1 初始工艺设计

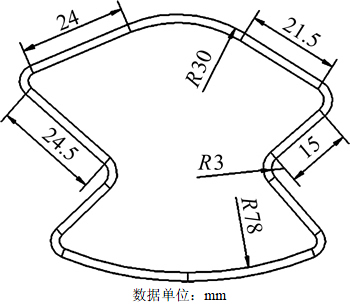

该汽车用8字管壁厚为2 mm,截面形状及关键尺寸如图1所示。由于该管成型后还要进行折弯,因此对焊缝质量要求较高,且必须位于顶部的R30圆弧上。显然,先成圆后变异的成型方法更加适合本案例。

最初的设计思想是保证每个道次变形量和压缩量大致相同,在此基础上,后面的道次变形量逐架递减,设计辊花如图2所示。辊花图是描述轧件通过成型机架时的截面变化情况示意图,该图形由COPRA RF设计生成。

图1 成型管截面形状及部分尺寸示意图

Fig. 1 Schematic diagram of cross section and dimensions of formed shape tube

图2 由COPRA设计的辊花变形图

Fig. 2 Roll flower designed by COPRA

整个成型过程共12个机架,包括10个变形工步、第1架圆管和最后1架矫直。变形工步立辊和平辊交替排列,水平轴中心距为570 mm。

2 产品缺陷评价指标

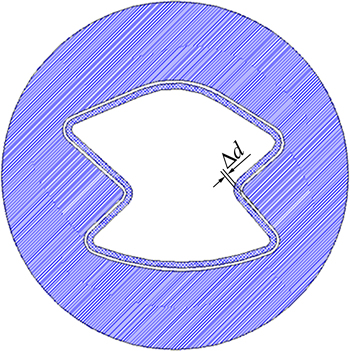

该成品8字管验收的标准是:管材可以穿过按照标准截面尺寸制作的模板管套(见图3),并且管材外边缘与管套之间的最大缝隙不高于1.5 mm,即图中△d≤1.5 mm。

图3 产品截面评价标准示意图

Fig. 3 View of product section evaluation standard

按照该方案设计投产之后,截面成形效果并不理想。初次设计产品真实截面形状如图4所示。可见:管右侧下部斜边(图中标注部分)明显过弯,导致向内凹陷,影响了进一步的弯管操作。测量该处缝隙为2.2 mm(>1.5 mm)超过容许最大偏差。针对这一缺陷,利用COPRA有限元仿真软件进行了模拟计算。

图4 初次设计产品真实截面形状

Fig. 4 View of true cross-section shape of initial design

3 有限元模型建立

在COPRA FEA仿真软件中,由于板带在常温、低速下变形,且其刚性远远比轧辊的小,故假设轧辊为刚体,不参与变形。该成形机组起始底径为163 mm,驱动辊底径每架递增0.5 mm,若按实际生产中的轧制速度来设置轧辊的转速,则计算量会比较大;若设置的转速过大又会产生虚拟的惯性效应,则导致计算结果失准。经过反复的尝试,确定了较为合适的转动角速度为200 r/min,换算为板带的线速度大约为270 mm/s。板带靠与轧辊表面之间的静摩擦实现向前的传动,摩擦因数设为0.2。网格的划分可以按照最终截面将小圆角部分细化,其余部分使用较粗的网格,板厚方向层数设置为2层。

材料弹性部分参数如表1所示。

表1 弹性阶段材料属性

Table 1 Material property of elastic state

塑性变形阶段的本构关系式通过Swift型幂硬化模型来表达,其应力与应变关系式为

(1)

(1)

式中:K为应变强化系数;n为硬化指数; 为塑性阶段的真实应力;

为塑性阶段的真实应力; 为初始屈服时对应的应变;

为初始屈服时对应的应变; 为等效塑性应变。

为等效塑性应变。

根据实验得到的真实应力与应变的数据可以拟合得到应力应变曲线,然后针对该模型可得到初始屈服应变 =0.002 4,应变强化系数K=486.477 5,硬化指数n=0.132 3,即该关系式为

=0.002 4,应变强化系数K=486.477 5,硬化指数n=0.132 3,即该关系式为

(2)

(2)

4 仿真结果与分析

4.1 应力应变特性分析

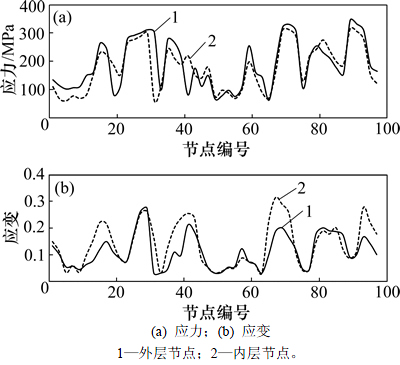

内外层节点在最终机架出口处的应力应变曲线如图5所示。

从图5(a)可见:应力集中区域出现在几个弯曲圆角附近,应力最大的节点并不是圆角中心,而是处于圆角与直边的交界处(见图中节点14,72,88);截面左侧的2个外凸圆角处应力明显高于内凹圆角处,而右侧正好相反;内外层节点的应力情况没有表现出特别的规律,差异较小。

图5 内外层节点应力应变对比

Fig. 5 Comparison of stress and strain of inner and outer layer’s nodes

从图5(b)可见:4个外凸圆角(实体3,7,11和15)附近区域内层节点应变均明显大于外层,而2个内凹圆角内外层节点应变值比较接近;应变最大区域为实体11和15的2个圆角,为开裂危险区。

4.2 不同工艺参数对等效应力的影响

4.2.1 压缩系数的影响

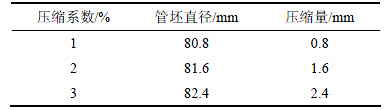

压缩系数又称为延伸系数,对于圆管变形为异形管成形来说,是母管周长与最终成型的异形管周长之比。在异形管成型过程中,为保证在孔型中有足够的材料充实,考虑材料的纵向延伸,需要确定适当的压缩系数,通常取1%~3%。在本案例中,最初的设计方案选用的压缩系数为1%,故另取2%和3% 2种压缩系数进行仿真。各压缩系数对应初始管径如表2所示。

3种压缩系数都按照均匀分布的原则分配到各成型工步,得到最终机架出口处成型稳定点处截面的应力曲线如图6所示。

表2 压缩系数与管坯直径对应关系

Table 2 Relationship between compression coefficient and pipe diameter

图6 压缩系数对内外层节点应力的影响

Fig. 6 Effect of compression coefficient on stress of inner and outer layer’s nodes

从图6(a)可见:外层节点随着压缩系数上升,截面整体的应力提升,但应力增加的幅度有所不同。大圆弧及直线实体随压缩系数上升的幅度比较明显;在圆角区域,尤其是4个外凸的圆角(实体3,7,11,15)附近节点随压缩系数变化幅度不大。从图6(b)可见:内层节点表现的规律与外层基本一致。

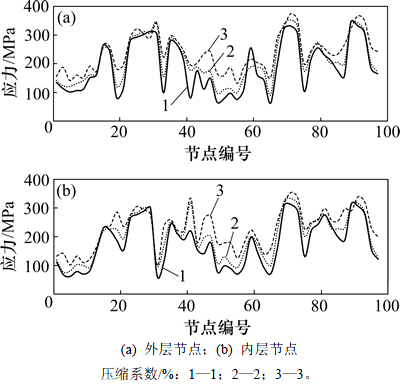

4.2.2 驱动速度的影响

由于冷弯成型是一个相对慢速的过程,若按照实际的驱动速度来模拟,计算时间过长,不利于分析研究。因此,在不产生虚拟惯性效应的前提下,一般会适当加快模拟速度,本文最初选用的模拟速度是驱动辊转速200 r/min。为了研究驱动速度对成型应力的影响,取150 r/min和250 r/min 2种驱动辊转速进行模拟对比分析,结果如图7所示。

从图7可见:轧辊驱动速度变化对最终机架出口处截面内外层节点的应力影响很小,随着转速的提升,截面各部分的应力差距略微有所减小。

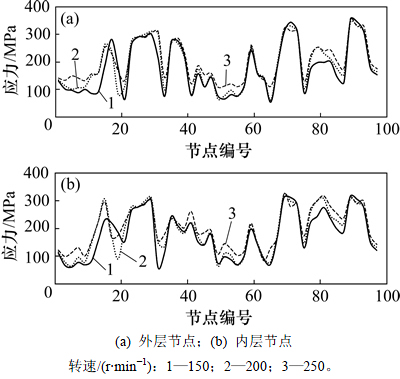

4.2.3 摩擦因数的影响

在冷弯过程研究中,摩擦因数一般取0.2~0.3,本文初次模拟取摩擦因数为0.2。对摩擦因数为0.1和0.3时的应力情况进行分析,模拟结果如图8所示。

从图8可见:改变摩擦因数对内层节点的应力几乎没有影响,对外层节点应力的影响也很小,并且没有明显规律,而且影响部位主要在长圆弧或直边等区域。

图7 驱动速度对内外层节点应力的影响

Fig. 7 Effect of driving velocity on stress of inner and outer layer’s nodes

图8 摩擦因数对内外层节点应力的影响

Fig. 8 Effect of friction coefficient on stress of inner and outer layer’s nodes

4.3 成型截面对比分析

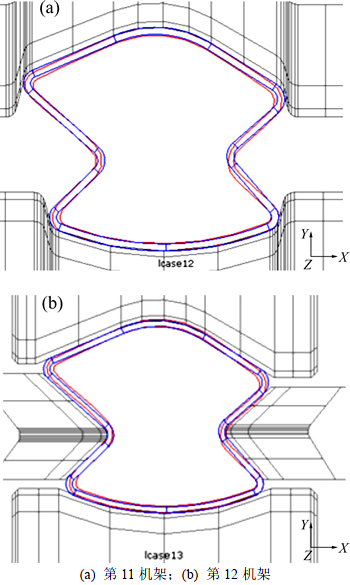

建模及参数设置完成之后进行模拟计算。将计算结果的截面图与设计辊花图对比分析见图9。可见:当管材通过第11机架平辊时,截面右侧下部的变形已经出现过弯内陷;左右2个内弯圆角的圆心本应大致在同一水平线上,而右侧内弯圆角的圆心位置已经明显比左侧的低。当管材通过第12机架四辊矫直时,右侧上部在侧辊的作用下略微上抬,接近目标截面,但下部的过弯内陷并不能依靠矫直机架得到恢复。

图9 设计截面与仿真截面对比

Fig. 9 Comparison of design section and simulate section

5 新辊形方案设计

驱动速度和摩擦因数的变化对截面形状的影响很小,压缩系数选取1%较为合理。从成型截面的变化规律分析得知:由于截面的不对称特性,左右两侧顶端的压下量不同,管材在通过最后2架成型辊时,开始出现明显的过弯内凹缺陷。

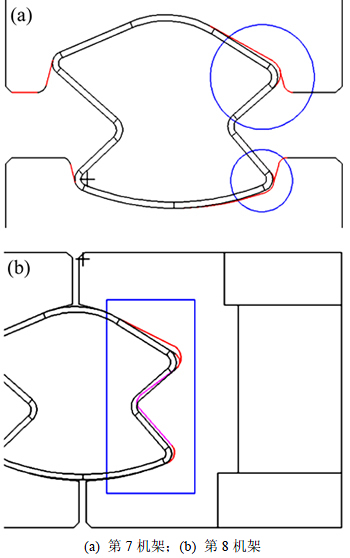

基于上述分析,最简单有效的缺陷修正方案是对轧辊轮廓进行调整。具体调整方案为:将第7机架平辊的右侧轮廓适量放大,见图10(a),尽可能保证截面左右两边顶部的受力接近,从而使中部的2个R3圆弧处于同一水平线上;此外,对第8机架立辊进行修改,见图10(b),用来抵消因受力不均产生的过弯。

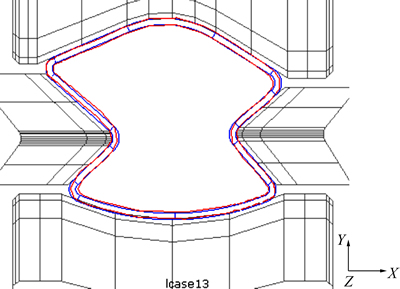

将改进的设计方案继续进行仿真模拟,最终的成型截面对比图见图11。由图11可见:模拟截面与设计截面基本吻合,证明修改方案效果良好,可以投入生产。

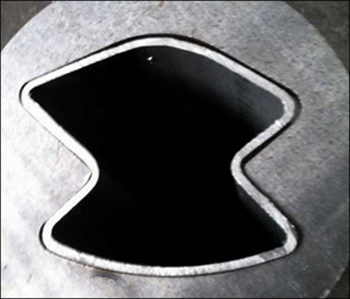

将经过修改的模具进行试轧,生产的8字管产品见图12。经测量最大缝隙不超过规定值,达到客户要求。

图10 辊形修改示意图

Fig. 10 View of roll shape modification

图11 改进方案第12机架设计截面与仿真截面对比

Fig. 11 Comparison of design section and simulate section in 12th station with new scheme

图12 改进设计后产品的真实截面形状

Fig. 12 View of true cross-section shape of new design

6 结论

1) 采用辊弯成型设计及仿真专业软件COPRA建立了十二机架异型管辊弯成型完整过程的仿真模型。应力集中区域位于外凸圆角与内侧直线实体的交界处,且对于该截面来说,左侧应力集中程度要比右侧的高;在屈服极限范围内,压缩系数的变化对圆角区域的应力影响明显比其他区域的小。

2) 异型管成型过弯缺陷产生的主因是截面顶端受到不均匀的轧制力,仿真设计了第7机架平辊和第8 机架立辊的新辊形,实际生产的新辊形成型质量好。

参考文献:

[1] 王先进. 冷弯型钢生产及应用[M]. 北京: 冶金工业出版社, 1994: 25-58.

WANG Xianjin. The production and application of roll formed section steel[M]. Beijing: Metallurgical Industry Press, 1994: 25-58.

[2] 李大永. 辊弯成型数值研究综述及全流程仿真关键问题[J]. 机械科学与技术, 2004, 23(12): 1466-1469.

LI Dayong. Review of numerical research on roll forming and key problems in whole process simulation[J]. Mechanical Science and Technology, 2004, 23(12): 1466-1469

[3] 李连诗. 异型管制造方法[M]. 北京: 冶金工业出版社, 1994: 1-13.

LI Lianshi. Manufacturing method of shape tube[M]. Beijing: Metallurgical Industry Press, 1994: 1-13

[4] 李登超. 冷弯型钢及焊管生产技术[M]. 北京: 化学工业出版社, 2011: 5-40.

LI Dengchao. Manufacturing technology of roll formed section steel and weld tubes[M]. Beijing: Chemical Industry Press, 2011: 5-40.

[5] 崔高建, 吕相艳, 迟正洪. 冷弯型钢成型技术的发展现状[J]. 机械制造, 2005, 43(10): 41-44.

CUI Gaojian, L Xiangyan, CHI Zhenghong. Current situation of the development of roll forming technology[J]. Machinery Manufacturing, 2005, 43(10): 41-44.

Xiangyan, CHI Zhenghong. Current situation of the development of roll forming technology[J]. Machinery Manufacturing, 2005, 43(10): 41-44.

[6] 岳崇峰, 余万华, 冯光宏. 冷弯成型技术研究现状[C]// 第六届华北塑性加工学术年会文集. 北京: 冶金工业出版社, 2009: 44-50.

YUE Chongfeng, YU Wanhua, FENG Guanghong, Current situation of the roll forming technology research[C]// The Sixth North China Plastic Processing Academic Annual Meeting Collected Papers. Beijing: Metallurgical Industry Press, 2009: 44-50.

[7] HEISLITZ F, LIVATYALI H, AHMETOGLU M A, et al. Simulation of roll forming process with the 3-D FEM code PAM-STAMP[J]. Journal of Materials Processing Technology, 1996, 59(1/2): 59-67.

[8] BOMAN R, PAPELEUX L, BUI Q V, et al. Application of the Arbitrary Lagrangian Eulerian formulation to the numerical simulation of cold roll forming process[J]. Journal of Materials Processing Technology, 2006, 177(1/2/3): 621-625.

[9] KASAEI M M. Prediction of maximum initial strip width in the cage roll forming process of ERW pipes using edge buckling criterion[J]. Journal of Materials Processing Technology, 2014, 214(2): 190-199.

[10] KASSAEI M M, NAEINIA H M, ABBASZADEH B, et al. Flange wrinkling in flexible roll forming process[J]. Procedia Engineering, 2014, 81: 245-250.

[11] SAFFE S N B M, NAGAMACHI T, ONA H. Residual stress around cut end of hat steel channel by roll forming[J]. Procedia Engineering, 2014, 81: 239-244.

[12] KANG Wen, ZHAO Yixi, YU Wangwei, et al. Numerical simulation and parameters analysis for roll forming of martensitic steel MS980[J]. Procedia Engineering, 2014, 81: 251-256.

[13] 湛利华, 王芳芳, 黄明辉. 不同接触分析方法对计算精度影响的MARC有限元分析[J]. 锻压技术, 2012, 37(4): 153-157.

ZHAN Lihua, WANG Fangfang, HUANG Minghui. MARC FE analysis on influences of different contact analysis methods on calculation precision[J]. Forging and Stamping Technology, 2012, 37(4): 153-157.

[14] 文新海, 黄明辉, 湛利华. 大型组合承载结构整体有限元建模研究[J]. 现代制造工程, 2010(1): 9-14.

WEN Xinhai, HUANG Minghui, ZHAN Lihua. Finite element study of giant structure modeling[J]. Modern Manufacturing Engineering, 2010(1): 9-14.

[15] 阎昱, 贾方辉, 张汉成. 基于不同单元类型的DP980钢辊弯成形仿真与回弹分析[J]. 塑性工程学报, 2015, 22(3): 63-67.

YAN Yu, JIA Fanghui, ZHANG Hancheng. FEM and springback analysis of DP980 steel roll forming based on different elements[J]. Journal of Plasticity Engineering, 2015, 22(3): 63-67.

[16] 李楠, 闫志杰. Q235立柱板冷弯成形过程的有限元分析[J]. 塑性工程学报, 2014, 21(3): 46-51.

LI Nan, YAN Zhijie. Finite element study on cold bending process of Q235 pillar plate[J]. Journal of Plasticity Engineering, 2014, 21(3): 46-51.

(编辑 赵俊)

收稿日期:2016-09-15;修回日期:2016-12-08

基金项目(Foundation item):国家创新方法工作专项项目(2016IM010300);高等学校博士学科点专项科研基金(博导类)资助项目(20120006110015);“绿扬金凤计划”创新领军人才计划项目(yzlyjfjh2015CX055);中央高校基本科研业务费专项资助项目(FRF-BR-15-039A) (Project(2016IM010300) supported by the Innovation Method Fund of China; Project(20120006110015) supported by the Specialized Research Fund for the Doctoral Program of Higher Education of China; Project(yzlyjfjh2015CX055) supported by the “Lvyang Jinfeng Programme” for the Innovation Leading Talents; Project(FRF-BR-15-039A) supported by the Fundamental Research Funds for the Central Universities)

通信作者:曹建国,教授,博士生导师,从事板形控制及轧制自动化、金属塑性成形与先进制造等研究;E-mail: geocao@ustb.edu.cn