Effect of high density electropulsing treatment on formability of TC4 titanium alloy sheet

SONG Hui(宋 辉), WANG Zhong-jin(王忠金), GAO Tie-jun(高铁军)

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 7 June 2006; accepted 25 October 2006

Abstract: An annealed TC4 titanium alloy sheet was treated by high density electropulsing (Jmax=(5.09-5.26)×103A/mm2, tp=110 μs) under ambient conditions. The effect of electropulsing treatment(EPT) on the plastic deformation behavior of TC4 titanium alloy sheet was studied using uniaxial tension tests. The experimental results indicate that electropulsing treatment significantly changes the mechanical properties of sheet metal: the uniform elongation is increased by 35%, the yield stress is decreased by 19.8% and the yield to tensile ratio is decreased by 17.6%. It is of significant meaning to improve the formability of TC4 titanium alloy sheet. The optical microscope and scanning electron microscope(SEM) were used to examine the changes of the microstructure and the fracture morphology before and after the electropulsing treatment. It is found that recrystallization occurs in the sheet metal and dimples in fracture surface are large and deep after the electropulsing treatment. The research results show that the electropulsing treatment is an effective method to improve the formability of titanium alloy sheets.

Key words: TC4 alloy; titanium alloy sheet; electropulsing treatment; formability

1 Introduction

Titanium alloys are widely used in aeronautics and astronautics applications taking advantage of their high specific strength, superior corrosion resistance, and stable performance at moderate temperatures, for example, aircraft skin, aero-engine by-pass duct as well as aero-engine air casings, are all made of titanium alloy sheets[1-2]. However, their characteristics, such as giant resistance of deformation, low uniform elongation, high yield to tensile ratio (can reach 0.9) and high spring-back [3-6], make cold forming difficult for titanium alloy sheets with good performance (for instance TC4), so they were generally processed by hot forming.

However, hot forming of titanium alloy sheets has its own limitation and weakness[7]. Titanium alloys’ lower thermal conductivity brings about considerable temperature drop in the local section during heating and colling, causing higher internal stress, and even forming cracks. Titanium alloys’ higher chemical activity makes the oxidation layer and the gas absorbing layer form on metals surface during heating, which leads to notable decrease in plasticity, and tendency to brittle failure. Titanium alloy grain grows up easily during heating, which causes the reduction of the service performance of the component. There is a pressing need to seek a method to improve the formability of titanium alloy sheets, so as to make it possible that the titanium alloy sheets can be fabricated by cold-forming operations, which can avoid the negative influence of hot-forming.

In the recent years, many researches indicate that high density electropulsing influences the behavior of materials, such as recovery, recrystallization, phase transformation, grain refinement, and amorphous nanocrystallization[8-14]. The application of high density electropulsing is proved to be an effective method for improving the microstructures of material and its properties, but reports about exploring effect of the electropulsing treatment on plastic deformation behavior of sheet metal from the formability point of view, are hard to find.

The objective of this study is to explore the effect of the electropulsing on the plastic deformation behavior of titanium alloy sheets with the ultimate aim of improving its formability.

2 Experimental

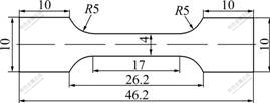

TC4 titanium alloy sheet (thickness 1.4 mm) in the annealed state was used as the experimental material, and its chemical compositions are listed in Table 1. The specimens were cut from TC4 sheet along the rolling direction, and the size of effective part was 17 mm in length, 4 mm in width and 1.4 mm in thickness (see Fig.1). The specimens were divided into three groups. Specimens A were not subjected to electropulsing treatment and used as reference specimens to compare the influence of electropulsing. Both specimens B and C were treated by electropulsing. Specimens B were directly treated by electropulsing (named pre- electropulsing treatment, pre-EPT for short). Specimens C were firstly stretched to produce 8% of pre-plastic deformation, and then unloaded for electropulsing treatment (named intermediate-electropulsing treatment, inter-EPT for short).

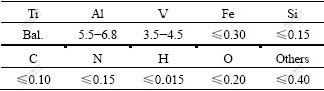

Table 1 Chemical compositions of TC4 titanium alloy sheets (mass fraction, %)

Fig.1 Schematic diagram of specimen (Unit: mm)

The electropulsing treatment experiments were performed under ambient conditions by capacitor bank discharge. The experimental arrangement for electropulsing treatment is shown in Fig.2. Specimen was switched into discharge circuit through copper electrodes, and then capacitor banks were charged, whereafter capacitor banks were discharged into specimen by trigger circuit to produce high density electropulsing. The waveform of electropulsing was detected in situ by a TDS3012 digital storage oscilloscope and it was a damped oscillation wave (see Fig.3). In these experiments, the waveforms of different electropulsing were similar, and the values of period were same (tp=110 μs), but the values of maximum current density were different. For specimens B, the maximum current density Jmax was 5.26×103A/mm2, and for specimens C, 5.09×103A/mm2.

Fig.2 Schematic of experimental arrangement for electro- pulsing treatment

Fig.3 Typical waveform of electropulsing

The tensile tests at room temperature were conducted to examine the mechanical properties using an MTS 810 test machine, and the tensile test speeds were 0.083 mm/s. The microstructure and fracture surface were studied by optical microscopy and scanning electron microscopy(SEM). The samples for micro- structure observation were cut from the specimens A, B and C, respectively. For optical microscopy, the samples were etched at room temperature in the reagent having the following compositions: 2%HF+4%NHO3+94%H2O.

3 Results and discussion

3.1 Uniaxial tension mechanical properties

Table 2 lists the experimental data, in which the data are the average of three specimens. The value of total elongation of specimens B is a little higher than that of specimens A (by 14.7%), but the uniform elongation is increased in evidence. The increase of the uniform elongation of specimens B is 35% compared with specimens A. The plastic resource of specimens C with 8% pre-plastic deformation (80% of maximum plastic deformation of the starting material) is almost completely recovered by electropulsing treatment; the uniform elongation is 9.3% after electropulsing treatment, which is 93% of maximum uniform deformation of starting material; and its uniform deformation reaches 18.01% (see Table 2). In both cases of pre-EPT and inter-EPT, electropulsing increases the uniform deformation of TC4 sheets.

Table 2 Experimental data of TC4 sheet

The true stress—true strain curves for specimens A, B and C are shown in Fig.4. The yield stress of specimens B is significantly decreased (by 167 MPa) in comparison with that of specimens A, but specimens B have almost the same tensile strength as specimens A. Therefore, the yield to tensile ratio of specimens B is greatly reduced, from 0.91 to 0.75. Similar to pre-EPT, the yield stress of specimens C is reduced by 168 MPa, and the yield to tensile ratio is reduced to 0.79 under inter-EPT.

Fig.4 True stress—true strain curves of specimens A, B and C

The decrease in yield stress and yield to tensile ratio is helpful for stamping of the sheet metal and increasing of the formability. A significant decrease in the yield stress reduces spring-back, because the spring-back angle of sheet metal is proportional to the value of σ0.2/E. When the value of E is invariant, the yield stress σ0.2 is reduced, so the value of σ0.2/E is decreased. It is beneficial to the control of sheet metal part’s dimensional accuracy.

The obtained results show that the cold forming property of TC4 titanium alloy sheet after electropulsing treatment is enhanced. Furthermore, because the electropulsing time is very short (about 800 μs), the thick oxidation layer and the thick gas absorbing layer on the metal surface could not be formed after the electropulsing treatment. It overcomes the shortages of hot forming.

3.2 Optical microstructure and fractograph

The optical morphologies of microstructure taken from samples A, B and C are shown in Fig.5. After electropulsing treatment, the microstructures of TC4 sheet have changed significantly. Obvious recrystallization (Figs.5(b) and (c)) occurs in the sheets. In the both cases of pre-EPT and inter-EPT, the grain growth is not found.

Fig.5 Optical microstructures of TC4 sheet: (a) Specimen A; (b) Specimen B; (c) Specimen C

In order to change the microstructure of rolled sheet by a conventional annealing, it requests long time annealing under certain temperature for atom diffusion, which often results in significant grain coarsening. The electropulsing treatment with very low energy and very short duration can not only change the microstructure but also restrain the grain growth, without affecting the service performance of the component. So the electropulsing treatment should not be considered simply a conventional annealing. Electropulsing has the effect that a conventional annealing does not have.

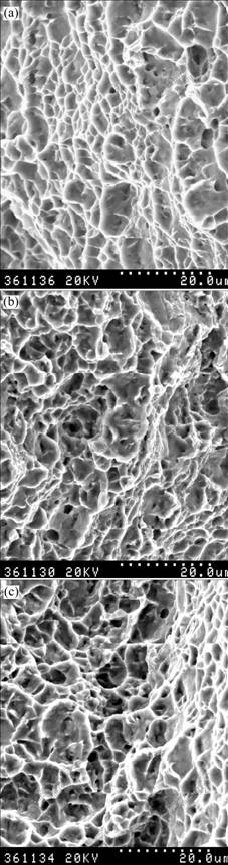

Fractograph indicates that all of the TC4 sheet specimens failure by ductile fracture with the fracture surface characterized by dimples (Fig.6). Shallow and small dimples indicating low ductility are observed in specimens A, and the amount of dimples is large. The dimples are large and deep in specimens B and C, while the amount of dimples is little. The above results indicate that there exist a lot of dimple nucleation sites in specimen A, and a considerable number of micro-cracks are formed in the tensile test processes. The crack propagation is fast, without intensive plastic deformation. But small amount of micro-cracks in specimens B and C are produced during tensile testing before fracture, and each dimple has undergone heavy plastic deformation. The analysis of fractography shows that the deformation damage of TC4 sheets is greatly reduced by electropulsing, thus the formability is improved significantly.

Fig.6 Fractographs of different specimens: (a) Specimen A; (b) Specimen B; (c) Specimen C

3.3 Discussion

The mechanism about the effect of electropulsing treatment on microstructure of materials and its properties is not very clear now. The possible reasons are the electron wind effect, the Joule heating effect, the mosaic thermal action, and the thermal compressive stress[15-18].

The course of temperature rise can be regarded as an adiabatic one due to the very short time during the electropulsing treatment, so the average temperature rise of the specimen by Joule heating is written as follows[19]:

(1)

(1)

where I is the amplitude of pulse; t is the corresponding duration; S is the cross-sectional area of the specimen; γ, ρ and c are the electrical resistivity, the density and the specific heat capacity of the experimental material, respectively. For TC4 sheet, γ=1.8×10-6 Ω?m, ρ=4.44×103 kg/m3, c=750 J/(kg?℃)[20].

According to Eqn.(1) the average temperature rises for specimens B and C are 728 and 697 ℃ respectively. Because the temperature increase is more than the average temperature increase, it is completely possible that recrystallization occurs in the specimens (the recrystallization temperature of TC4 sheet is 950 ℃[21]).

The drift electrons can exert a push on dislocations when high density electric pulse passes through specimen[15]. It can lower dislocation density and enhance the mobility of dislocation, thus can produce a more advanced stage of recrystallization and enhance the nucleation rate of recrystallization[10]. This is also a factor that recrystallization occurs in a metal by electropulsing.

Many defects, such as micro-crack, cavity and void, as well as impurity can always be produced in TC4 sheets during the metallurgical and rolling processes. Because of the existence of these defects, inhomogeneous physical field in a metal is generated. The resistivity in the area with defect is higher than that in the area without defect. When the electropulses pass through a metal specimen, the temperature rise in the area with defect is higher than that in the area without defect due to inhomogeneous resistivity in metal as well as detour of electric current. This inhomogeneous temperature rise results in inhomogeneous thermal expansion, and the area with defect suffers pressure (compressive stress) resulted from higher degree of thermal expansion compared with the area without defect. The diffusion ability of atoms is also increased by inhomogeneous temperature rise (temperature gradient) and compressive stress[17]. Under these effects, the micro-crack defect can be closed or healed[16-17]. For impurity, the relaxation of stress can not be achieved by extruding matrix materials around an impurity in metals. Therefore, the impurity is in three dimensional compressive state (pressure zones are formed around an impurity in metals after electropulsing). This improves the degree of meshing between impurity and matrix materials, and then lowers the probability of micro-crack initiation[18]. The increase of uniform elongation for specimens B and the recovery of plastic resource for specimens C are the macroscopic expression of these microcosmic courses.

4 Conclusions

1) The electropulsing treatment can heal not only the primary defects in sheet metals but also the damage produced during plastic deformation. For the pre- electropulsing treatment (pre-EPE), the uniform elongation is increased from 10% to 13.5 % (by 35%), for intermediate electropulsing treatment (inter-EPT), the plastic resource of sheet metal can be recovered under 8% of pre-plastic deformation (80% of maximum plastic deformation of starting material), and its total uniform deformation is up to 18.01%.

2) The electropulsing treatment gives a significant decrease in yield stress and yield to tensile ratio. Under pre-electropulsing treatment (pre-EPE), the yield strength is decreased from 936 MPa to 769 MPa (by 17.8%), and the yield to tensile ratio is decreased from 0.91 to 0.75 (by 17.6%). Under intermediate electropulsing treatment (inter-EPT), the yield strength is decreased from 936 MPa to 750 MPa (by 19.8%), and the yield to tensile ratio from 0.91 to 0.79 (by 13.2%).

3) The electropulsing treatment can improve the formability of titanium alloy sheets. It is a new way worthy of further exploring to cold forming methods for titanium alloy sheets.

Acknowledgement

The authors are grateful to Professor GUO Jing-dong and WANG Bao-quan of Metal Research Institute, Chinese Academy of Sciences (CAS) for their help in the electropulsing treatment experiments.

References

[1] HANSON B H, KEARNS M W. Properties and applications of titanium sheet [J]. Sheet Metal Industries, 1982, 59(12): 877-878.

[2] PEACOCK D K. Aerospace applications for titanium [J]. Sheet Metal Industries, 1988, 65(8): 406, 408.

[3] SHEN Hao, HAN Ying, JIANG Dong-ming, YUAN Xun. Causative factors of cracking in cold pressed formation of titanium plates and improving measures [J]. Journal of Lanzhou University of Technology, 2004, 30(6): 49-51. (in Chinese)

[4] PENG Sou-hua. Influence factors of cold pressed formation of titanium plates [J]. Petro-chemical Equipment, 1994, 23(1): 39-41. (in Chinese)

[5] WANG Jia-zhi. Hot drawn forming of TC1 and TA2 titanium alloy sheets [J]. Rare Metal Materials and Engineering, 1983(2): 27-32. (in Chinese)

[6] CHEN Yu, KANG Da-chang, XU Yong-chao. Cup-drawing process of BT20 titanium alloy [J]. Trans Nonferrous Met Soc China, 2003, 3(Special 1): 187-190.

[7] MURAV’EV V I. Optimization of heating preform of titanium alloys for stamping: Forging and stamping production [J]. Material Working by Pressure, 1999(1): 31-35. (in Russian)

[8] CONRAD H, KARAM N, MANNAN S. Effect of electric current pulses on the recrystallization of copper [J]. Scripta Metallurgica, 1983, 17: 411-416.

[9] CONRAD H, KARAM N, MANNAN S. Effect of prior cold work on the influence of electric current pulses on the recrystallization of copper [J]. Scripta Metallurgica, 1984, 18: 275-280.

[10] ZHOU Y Z, XIAO S H, GUO J D. Recrystallized microstructure in the cold worked brass produced by electropulsing treatment [J]. Materials Letters , 2004, 58: 1948-1951.

[11] CONRAD H. Effect of electric current on solid state phase transformations in metals [J]. Materials Science and Engineering A, 2000, 287: 227-237.

[12] ZHOU Y Z, ZHANG W, WANG B Q, GUO J D. Ultrafine-grained microstructure in a Cu-Zn alloy produced by electropulsing treatment [J]. J Mater Res, 2003, 18(8): 1991-1997.

[13] MIZUBAYASHI H, HAO T, TANIMOTO H. Low temperature crystallization of amorphous alloys under electropulsing [J]. Journal of Non-crystallization Solids, 2002, 312/314: 581-584.

[14] MIZUBAYASHI H, OKUDA S. Structural relaxation induced by passing electric current in amorphous Cu50Ti50 at low temperatures [J]. Physical Review B, 1989, 40: 8057-8060.

[15] SPRECHER A F, MANNAN S L, CONRAD H. On the mechanism for the electroplastic effect in metals [J]. Acta Metall, 1986, 34(7): 1145-1162.

[16] OVCHINNIKOV I V. Determination of plasticity resource under the action of current [J]. Problems of Strength, 1993(6): 54-59. (in Russian)

[17] ZHOU Y Z, QIN R S, XIAO S H. Reversing effect of electropulsing on damage of 1045 steel [J]. J Mater Res, 2000, 15(5): 1056-1061.

[18] PARISHAV K A, KORAVIN U I, XUPIRMAN V A. The change of microstructure around a hole and an impurity under the action of current [J]. Physics and Chemistry for Materials Working, 1980(4): 12-15. (in Russian)

[19] ZHANG W, ZHAO W S, LI D X, SUI M L. Martensitic transformation from α-Ti to β-Ti on rapid heating [J]. Applied Physics Letters, 2004, 84(24): 4872-4874.

[20] Editorial Committee of Engineering Materials Handbook. Handbook of Engineering Materials (Book 3)—Aluminum Alloy, Magnesium Alloy and Titanium Alloy [M]. Beijing: Publisher of Standard of China, 1989. 589-593. (in Chinese)

[21] WANG Jin-you, GE Zhi-ming, ZHOU Yan-bang. Titanium Alloys in Aviation Applications [M]. Shanghai: Shanghai Scientific and Technical Publishers, 1985. 167. (in Chinese)

Corresponding author: WANG Zhong-jin; Tel: +86-451-86418643; E-mail: wangzj@hit.edu.cn

(Edited by YUAN Sai-qian)