罐体用3104大铸锭均匀化过程中的组织性能演变

黄瑞银1, 2,尹志民1,徐国富1,黄继武1,廖明顺2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中铝瑞闽铝板带有限公司,福建 福州,350015)

摘要:采用金相、扫描电镜、透射电镜、显微硬度测试等方法对3104合金大尺寸铸锭的均匀化制度进行研究。研究结果表明:在均匀化过程中,晶粒内部析出大量Al(Mn,Si)相和Al(Mn,Fe,Si)相;铸锭表面区域的析出相分布较均匀,而铸锭中部经过580 ℃/(4~12 h)均匀化后的析出相分布不均匀,晶界和晶粒中心存在无析出带,析出相细小;随着温度升高,析出相分布更加均匀,密度降低,粒度长大;铸锭晶粒内部的初始显微硬度不均匀,经过均匀化处理,晶粒边界硬度下降,而晶粒中心硬度上升,显微硬度差别减少;经过600 ℃/(8~12 h)均匀化,显微硬度最低,且最均匀;铸锭均匀化处理对后续的再结晶退火有显著影响,铸锭经过600 ℃/12 h均匀化,与经过450 ℃/12 h相比,后续冷轧产品经过再结晶退火后具有更高的延伸率,晶粒更细小均匀;合适的均匀化处理制度为600 ℃/(8~12 h)。

关键词:3104合金;均匀化;析出相

中图分类号:TG146.21;TG113 文献标志码:A 文章编号:1672-7207(2013)05-1813-09

Evolution of 3104 large slab microstructure and properties in homogenization process

HUANG Ruiyin1, 2, YIN Zhimin1, XU Guofu1, HUAN Jiwu1, LIAO Mingshun2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Chalco Ruimin Co. Ltd., Fuzhou 350015, China)

Abstract: The homogenization processing of 3104 alloy large size slab was studied by OM, SEM, TEM and hardness test. The results show that after homogenization, Al(Mn,Si) and Al(Mn,Fe,Si) particles precipitate at the slab surface area, and the distribution is more even than at the slab center. After 580 ℃/(4-12 h) treatment, the distribution is uneven with no precipitation at the grain boundary and inner, and the precipitation size is small and the density is high. With the increase of temperature, the precipitation distribution becomes more even with lower density and bigger size. The HV hardness is uneven in the primary grain. After homogenization, the HV at the grain boundary decreases and the inner increases. The HV difference reduces to the smallest after 600 ℃/(8-12 h) treatment. The slab has smaller grain size, lower σb, higher δ after recrystallization for the homogenization of 600 ℃/12 h compared with 450 ℃/12 h. The best homogenization is 600 ℃/(8-12 h).

Key words: 3104 alloy; homogenization; precipitation

在工业生产中,3104合金铸造采用大吨位熔炼炉组,铸造速度快,铸锭尺寸大,铸锭中必然存在严重的成分不均匀性和枝晶偏析。3104铝合金罐料的制备工艺包括合金铸造、铸锭均匀化退火、热轧、再结晶退火和最终冷轧。组织不均匀性、枝晶偏析以及铸造应力都会对后续工艺产生不利的影响,因此,均匀化退火是3104铝合金罐料生产中最关键的工艺之一。均匀化退火后的显微组织影响后续工艺的组织状态,进而影响3104铝合金罐料的最终性能。目前,人们对于3104铝合金均匀化制度的研究以及均匀化过程中的组织结构变化均有报道[1-2],但是,对于工业生产中大铸锭均匀化温度和时间的控制以及组织结构的演变过程的研究较少。一般地,均匀化处理过程中会发生以下变化:过饱和固溶体分解析出,非平衡相溶解、熔断,物相转变,枝晶偏析减轻和消除[3-4]。3104铸锭均匀化后,应该使枝晶偏析消除,非平衡相基本熔断,析出相均匀分布且粒度适当,β-(AlMnFe)物相大部分能够转化为α-(AlMnFeSi)相,才能在后续加工中获得最佳的制耳率、内部组织和加工性能[5]。制定均匀化制度要综合考虑这些因素,才能达到最佳效果。为此,本文采用工业生产大铸锭在工业炉中进行均匀化处理,研究均匀化处理过程中析出相的分布、晶粒内部显微硬度变化,结合非平衡相的溶解、熔断的程度,制定合理的均匀化工艺。

1 实验材料和方法

1.1 样品制备

采用75 t熔炼炉组,经过熔炼、调配成分后转到保温炉,经过除气、过滤、添加晶粒细化剂后,使用低液位结晶器进行铸造。铸造速度为70 mm/min,铸造温度为690 ℃。3104合金铸锭的长×宽×高为560 mm×1 600 mm×7 500 mm。

1.2 实验方法

铸锭在电阻炉中均匀化处理,均匀化温度范围为450~620 ℃,均匀化时间选择4~12 h。铸锭均匀化后从中心部位取样。样品取自离浇注口200 mm的横截面的阴影部分,如图1所示。

图1 取样部位

Fig.1 Position of sample

经过STUER金相抛光机制样,在ZEISS图像分析仪上观察样品的金相组织;采用三酸浸蚀,在ZEISS图像分析仪上计算晶粒粒度;采用THVS-30显微硬度计测量显微硬度;采用Sirion 200场发射扫描电子显微镜和TecnaiG2 20透射电镜观察显微组织。

2 实验结果

2.1 均匀化处理对铸锭组织的影响

图2所示为距离铸锭表面10 mm的试样经过均匀化处理的金相观察结果。从图2可见:经过均匀化处理后,铸锭表面的晶粒粒度未发生变化,但是,晶粒内部出现了云团状的物质。在不同均匀化制度下的析出相分布较均匀,随着温度上升,析出相逐渐长大,密度下降。

图3所示为铸锭中部试样的均匀化实验结果。从图3可见:经过均匀化处理后,晶粒内部出现了云团状的物质;在580 ℃/(4~12 h)均匀化后(图3(c),(d)和(e)),云团状物质不均匀,在靠近晶界边部区域出现,而在晶界和晶粒中心并不存在;在600 ℃以上处理后,云团状物质逐渐在晶内均匀分布,并且其中的个体粒度增加,密度降低。于620 ℃/12 h出现了过烧现象。

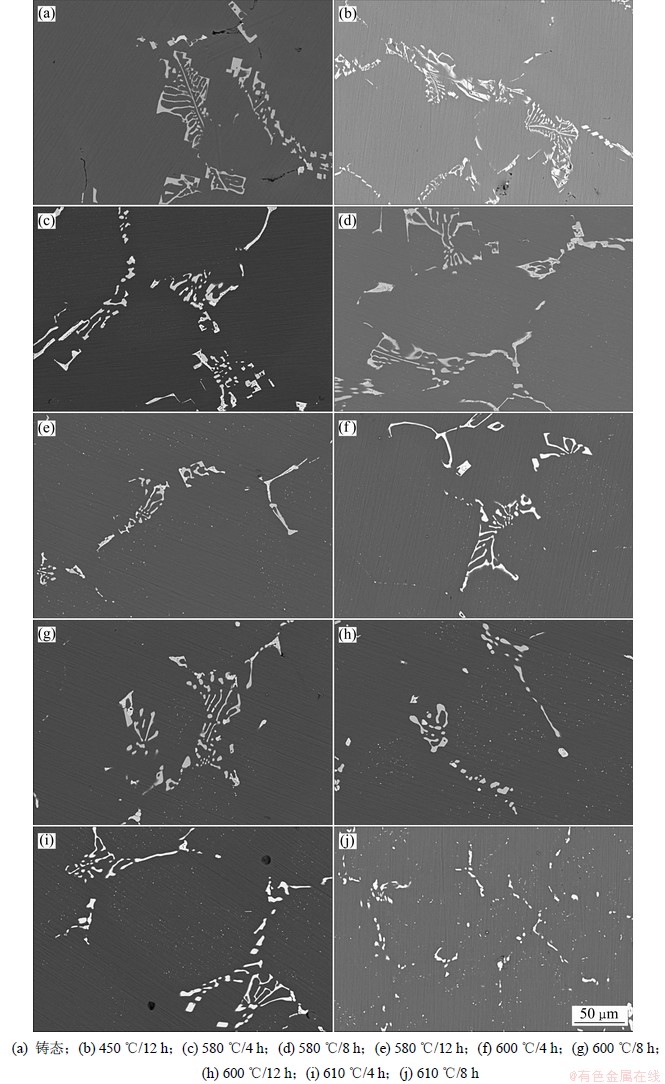

3104合金铸锭中部不同均匀化处理条件下的SEM二次电子像见图4。

从图4可以看出铸锭中部组织在均匀化过程中出现了以下几种变化:

(1) 晶粒边界化合物随着温度升高和时间延长,出现了组织熔断,在600 ℃/8 h后熔断较明显,在610 ℃/8 h后熔断较彻底。

(2) 均匀化后出现了析出相。在580 ℃/(4~12 h)均匀化后,析出相分布不均匀,且析出相粒度小;而在600 ℃/8 h以上均匀化后析出相分布较均匀,而且析出相粒度增大,这与图3中云团状物质相对应。可以认为:云团状物质是析出相在金相图片中的宏观显示[6]。

2.2 均匀化处理过程中铝固溶体中相的析出

为了进一步研究均匀化过程的物相析出行为,进行了透射电镜分析,如图5所示。

从图5可以看出:铸态合金中的第二相并不明显(图5(a)和(b));于450 ℃/12 h均匀化,从固溶体中析出大量棒状相和块状相(图5(c)和(d))。微区成分分析表明块状析出相是Al(Mn,Si)相,棒状析出相为Al(Mn,Fe,Si)相,见表1。于600 ℃/12 h均匀化,析出物的密度降低,粒度变大(图5(e)和(f)),这与金相分析和SEM的观察结果相对应。

图2 不同均匀化处理条件下3104铝合金铸锭的金相组织(距离铸锭表面10 mm)

Fig.2 OM observation of 3104 Al alloy at different homogenization conditions(10 mm distance from slab surface)

图3 不同均匀化处理条件下3104铝合金铸锭的金相组织(铸锭中部)

Fig.3 OM observation of 3104 Al alloy at different homogenization conditions in slab center

图4 铸锭中部不同均匀化处理条件下的铸锭组织SEM观察

Fig.4 SEM observation of 3104 Al alloy of slab center at different homogenization conditions

图5 不同均匀化处理条件下的铸锭组织TEM观察

Fig.5 TEM observation of 3104 Al alloy at different homogenization conditions

表1 析出相能谱微区成分分析结果(原子数分数)

Table 1 Atomic percentage of precipitated phases %

2.3 均匀化处理对晶粒内部显微硬度的影响

取铸锭中部试样,经过不同均匀化处理,经过抛光后,分别在1个晶粒的晶界处、晶粒直径的1/4处和晶粒中心位置进行显微硬度分析,分析位置如图6所示。

均匀化条件与显微硬度的关系见图7。从图7可知:在原始铸锭的晶粒之内,由于晶界处存在第二相,且成分存在微观偏析,因此,硬度很不均匀,晶界处硬度最大,往晶粒中心,硬度逐渐下降。在晶界处与晶粒中心,硬度差别达到30.7,在1/4处与晶粒中间位置,硬度最大差别达到11.5;随着均火温度增大和时间延长,从580 ℃/8 h后晶粒1/4直径处与晶粒内部硬度基本一致;在600 ℃/8 h晶粒中心硬度达到最低,且晶粒内部的硬度均匀性最好;随着时间延长,硬度反而增大。这可能是析出的化合物重新溶解,导致基体内Mn固溶度升高。

图6 显微硬度分析位置

Fig.6 Analyzing position of micro-hardness

图7 均匀化条件与显微硬度的关系

Fig.7 Relationship between homogenization and micro-hardness

2.4 均匀化处理对后续加工材性能的影响

选择600 ℃/12 h(1号试样)与450 ℃/12 h(2号试样)2种均匀化处理后的样品,热轧到4.0 mm,再冷轧到1.0 mm,最后分别在230,250,260,270,280,300,320和340 ℃时退火2 h,试样的抗拉强度(σb),屈服强度(σ0.2)和伸长率(δ5)见表2。

表2 温度对3104合金后续性能的影响

Table 2 Effect of temperature on properties of 3104 alloys

从表2可见:经过后续加工后的2号试样σb与σ0.2均比1号试样的高,而2号试样的初始伸长率比1号试样的低。但是,经过再结晶退火后(退火温度高于280 ℃),1号试样的伸长率比2号试样的高。

3 分析与讨论

在3104铝合金铸锭中,Si,Mg和Cu的溶解度较大,主要是以固溶体的形式存在,均匀化退火后不会从Al基体中析出;Fe在Al中的固溶度很小,绝大部分以金属间化合物的形式存在;Mn在铝中的溶解度不大,铸锭中主要以过饱和固溶体的形式存在,均匀化退火过程中析出。因此,在均匀化过程中,Mn在该合金中的溶解析出行为起主要作用[7-10]。在均匀化退火过程中,过饱和固溶体分解析出第二相粒子,是一个形核长大的过程,其析出速率取决于形核速率和长大速率,受温度控制,满足[11]:

(1)

(1)

其中: 为形核率;N为单位体积基体中的原子数;

为形核率;N为单位体积基体中的原子数; 为原子振动频率;

为原子振动频率; 为形核功;

为形核功; 为扩散激活能;

为扩散激活能;  为波尔兹曼常数;T为热力学温度。形核功

为波尔兹曼常数;T为热力学温度。形核功 与温度正相关,温度越高,过饱和度越小,驱动力越小,形核功越大;扩散激活能

与温度正相关,温度越高,过饱和度越小,驱动力越小,形核功越大;扩散激活能 与温度负相关,温度越高,原子越容易扩散运动,扩散激活能越小。在较低温度下进行均匀化退火时,虽然过饱和度大,析出驱动力大,但是,由于扩散系数很小,Mn原子难以扩散,析出困难,导致析出速率小,析出相少,也难以长大。在较高温度下进行均匀化退火时,尽管扩散系数大,Mn原子容易扩散,但由于过饱和度小,析出驱动力小,析出速率也较小,析出相不多。

与温度负相关,温度越高,原子越容易扩散运动,扩散激活能越小。在较低温度下进行均匀化退火时,虽然过饱和度大,析出驱动力大,但是,由于扩散系数很小,Mn原子难以扩散,析出困难,导致析出速率小,析出相少,也难以长大。在较高温度下进行均匀化退火时,尽管扩散系数大,Mn原子容易扩散,但由于过饱和度小,析出驱动力小,析出速率也较小,析出相不多。

根据合金能量学[12],3104铝合金组织中不可避免地存在不同粒径的粒子,在小粒子与大粒子之间存在1个从高到低的溶质浓度梯度,小粒子周围的溶质具有向大粒子周围扩散的趋势。随着加热温度的升高,加速扩散进程,破坏体系的亚稳定状态,使小粒子周围的溶质浓度小于亚稳平衡时的溶质浓度,因而发生溶解;当溶质原子扩散到大粒子周围并超过其自身的溶解度时发生沉淀,使大粒子长大。而根据Li等[13]的解释,随着温度升高,Mn的扩散速率增加,有可能进行远距离扩散,晶粒粗化逐渐变成主导过程。晶粒粗化不但在粒子间进行,而且在富Mn析出相与富Fe初生相之间进行,从而引起晶界及晶界附近第二相溶解。

距离铸锭表面很近的区域均匀化后,析出相较为均匀,且温度升高,析出相粗化,密度下降;而铸锭中部580 ℃均匀化时,析出相分布不均匀,晶界和晶粒中心存在无析出带;温度在600 ℃以上均匀化时,析出相分布较均匀,密度降低,且析出相粗化(图2~4)。这是由于在铸锭表面区域,由于晶粒细小,枝晶偏析小,晶界区域的化合物相也较小,均匀化后析出相分布较均匀;而在铸锭中部,晶粒较大,枝晶偏析大,在晶界区,存在大量的粗大初生化合物,因此,在均匀化过程中,细小的析出相向粗大化合物聚集,导致细小析出相消失,晶界附近存在无析出带。而对于晶粒中心,在580 ℃以下均匀化时,偏析元素的扩散尚不充分,晶粒中心合金元素的固溶度较低,析出的驱动力较小,因此,晶粒中心存在无析出带;而在600 ℃以上均匀化时,偏析元素的扩散较均匀,因此,晶粒中心也出现了析出相,析出相的分布更均匀[14]。显微硬度的变化也说明了这一点。未均匀化时,晶粒内部和晶界处的硬度差别很大,晶粒内部也不均匀;均匀化处理后,富集在晶界附近的偏析元素向晶粒中心扩散,导致晶粒中心的合金元素固溶度上升,显微硬度上升,而晶界附近的合金元素固溶度下降,显微硬度下降;在600 ℃/8 h以上处理后,合金元素的扩散较均匀,晶内显微硬度基本一致(图7)。

研究结果表明:第二相粒子对再结晶动力学、最终晶粒尺寸以及织构都有强烈影响[15]。第二相质点对再结晶温度的影响与它们的数量及弥散度有关。第二相粒子数量不多且弥散度不大,当粒度超过1 μm时,变形时金属流动更紊乱,同时,在质点周围形成位错塞积,有可能使再结晶温度降低,可作为再结晶形核点而促进再结晶形核(PSN)。但细小弥散分布的第二相对大角晶界及小角晶界都有很强的钉扎作用(Ze-ner阻力),从而抑制再结晶过程。本文用的样品经过450 ℃均匀化处理后,合金中晶内和晶界处析出大量细小第二相,经热轧后这些第二相依然存在,到再结晶退火时,这些细小第二相会钉扎晶界,阻碍晶粒的形核,造成形核率低,故晶粒粗大。经高温均匀化(如600 ℃/(8~12 h)后合金中沉淀析出第二相粒径较大,合金中Mn固溶度较高;再结晶退火时,这些析出的第二相对再结晶存在阻碍作用力小,形核率高;同时,过饱和固溶体再结晶时会发生析出与再结晶的交互作用,进行再结晶退火时,一般先完成再结晶,然后,在再结晶基体发生第二相的析出。再结晶过程析出的第二相阻碍晶粒长大,所以,得到细小的等轴的晶粒组织(图8)。

图8 均匀化制度对晶粒的影响

Fig.8 Effect of homogenization on grain size

4 结论

(1) 在均匀化过程中,晶粒内部析出大量Al(MnSi)相和Al(MnFeSi)相。铸锭表面区域的析出相分布较均匀,而铸锭中部经过580 ℃/(4~12 h)均匀化后的析出相分布不均匀,晶界和晶粒中心存在无析出带,析出相细小。随着温度升高,析出相分布更加均匀,密度降低,粒度增大。在600 ℃/8 h以上均匀化后,析出相分布较均匀。

(2) 在均匀化处理过程中,晶粒边界上化合物逐步熔断和球化,至600 ℃/8 h基本熔断,620 ℃均匀化出现过烧。

(3) 铸锭中部晶粒内部的初始显微硬度不均匀,经过均匀化处理,晶粒边界硬度下降,而晶粒中心硬度上升,显微硬度差别减少。经过600 ℃/(8~12 h)均匀化,显微硬度最低,且最均匀。

(4) 铸锭均匀化处理对后续的再结晶退火有显著影响,铸锭经过600 ℃/12 h均匀化,与经过450 ℃/12 h相比,后续冷轧产品经过再结晶退火后的伸长率更高,晶粒更细小、均匀。

(5) 合适的均匀化处理制度为600 ℃/(8~12 h)。

参考文献:

[1] 孙东立, 姜石峰, 高兴锡. 均匀化处理对3004铝合金显微组织的影响[J]. 中国有色金属学报, 1999, 9(3): 556-560.

SUN Dongli, JIANG Shifeng, GAO Xingxi. Influence of homogenization on microstructure of 3004 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(3): 556-560.

[2] Marshall G J. Microstructural control during processing of aluminum canning alloys[J]. Materials Science Forum, 1996, 8(6): 217-222.

[3] 朱清洋. 3104铝合金化学成分优化及织构研究[D]. 重庆: 重庆大学材料科学与工程学院, 2006: 18-32.

ZHU Qingyang. Study on chemical component's optimization and texture of 3104 aluminum alloy[D]. Chongqing: Chongqing University. College of Materials Science and Engineering, 2006: 18-32.

[4] 李飞庆. 双级均匀化对3104铝合金组织和再结晶行为的影响[D]. 长沙: 中南大学材料学院, 2009: 20-29.

LI Feiqing. Influence of twin-stage homogenization on microstructure and recrystallization of 3104 aluminum alloy[D]. Changsha: Central South University. College of Materials Science and Engineering, 2009: 20-29.

[5] 卢敬华. 均匀化温度、热轧道次对3104制罐板化合物形貌的影响[J]. 铝加工, 2003, 26(6): 25-28.

LU Jinghua. Effect of homogenization temperature and hot rolling pass on morphology of compound in 3104 sheet[J]. Aluminum Processing, 2003, 26(6): 25-28.

[6] 金相图谱编写组. 变形铝合金金相图谱[M]. 北京: 冶金工业出版社, 1975: 73-74.

Compiling Group of Metallographic. The metal graph atlas of wrought aluminum alloy[M]. Beijing: Metallurgical Industry Press, 1975: 73-74.

[7] Altenpohl D. Aluminium and aluminiumlegierungen[M]. Berlin: Springer Verlag, 1965: 117-119.

[8] Li Y J, Arnberg L. Evolution of eutectic intermetallic particles in DC-cast AA3003 alloy during heating and homogenization[J]. Materials Science and Engineering A, 2003(347): 130-135.

[9] Alexander D T L, Greer A L. Solid-state intermetallic phase transformations in 3××× aluminium alloys[J]. Acta Materialia, 2002, 50(10): 2571-2583.

[10] Watanabe H, Ohori K, Takeuchi Y. Phase change in 3004 base alloys at elevated temperatures[J]. Light Metals, 1983(33): 149-156.

[11] Porter D A, Easterling K E. Phase transformation in metals and alloy[M]. Oxford: Alden Press, 1981: 112-113.

[12] 肖纪美. 合金相与相变[M]. 北京: 冶金工业出版社, 1987: 465-466.

XIAO Jimei. Alloy phase and phase transformation[M]. Beijing: Metallurgical Industry Press, 1987: 465-466.

[13] Li Y J, Arnberg L. Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization[J]. Acta Materialia, 2003, 51(12): 3415-3428.

[14] 佟长清. 3004合金铸锭锰偏析及均匀化处理[J]. 轻合金加工技术, 1997, 25(1): 31-36.

TONG Changqing. The Mn segregation and homogenization for 3004 alloy slab[J]. Light Alloy Fabrication Technology, 1997, 25(1): 31-36.

[15] Humphreys F J, Hatherly M. Recrystallization and related annealing phenomena[M]. Qxford: ELsevier Science Ltd, 1995: 474-475.

(编辑 陈灿华)

收稿日期:2012-06-27;修回日期:2012-08-29

基金项目:中铝科技基金资助项目(ZB2010CCDBJ1)

通信作者:黄继武(1963-),男,湖南宁乡人,副教授,从事铝合金材料研究;电话:0731-88836426;E-mail: huangjw@csu.edu.cn