文章编号:1004-0609(2011)02-0332-09

Mo对镍基单晶高温合金组织及持久性能的影响

胡聘聘1, 3,陈晶阳1,冯 强1, 2,陈艳辉1,曹腊梅3,李相辉3

(1. 北京科技大学 新金属材料国家重点实验室,北京 100083;

2. 北京科技大学 国家材料服役安全科学中心,北京 100083;

3. 北京航空材料研究院 先进高温结构材料国防科技重点实验室,北京 100095)

摘 要:通过在不含Mo的基础合金USTB-F7中添加1.5%(质量分数)Mo,形成合金USTB-F9,研究Mo对镍基单晶高温合金组织稳定性和持久寿命的影响。1 100 ℃时效与热处理组织的研究分析表明:合金USTB-F7中γ′相形貌介于球形和立方形之间,属中间态形貌;经长期热处理2 000 h后,其形貌保持稳定,仅发生粗化而未产生筏排现象。Mo的添加使γ相中Re、Mo和Cr等元素含量增加,提高了合金USTB-F9的γ/γ′点阵错配度和γ′相的立方度,从而加速长期热处理过程中的筏排化进程,仅200 h就发生明显的筏排现象。同时,Mo强烈促进富含Re、Mo、W和Cr等元素的P相和σ相的析出,使析出时间由合金USTB-F7的700 h提前到合金USTB-F9的 100 h。在1 100 ℃和140 MPa下的持久性能测试表明,尽管Mo的添加提高了γ′相的体积分数和错配度,并促进筏排组织的形成,有利于合金持久性能的提高;但由于Mo促进TCP相的大量析出,从而使合金的持久寿命降低。

关键词:高温合金;Mo;错配度;组织稳定性;持久寿命

中图分类号:TG146.1; TG132.3 文献标志码:A

Effects of Mo on microstructure and stress-rupture property of Ni-based single crystal superalloys

HU Pin-pin1, 3, CHEN Jing-yang1, FENG Qiang1, 2, CHEN Yan-hui1, CAO La-mei3, LI Xiang-hui3

(1. State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing,

Beijing 100083, China;

2. National Center for Materials Service Safety, University of Science and Technology Beijing, Beijing 100083, China;

3. National Key Laboratory of Science and Technology on Advanced High Temperature Structural Materials,

Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The effects of Mo on the microstructural stability and stress-rupture property were investigated in two experimental Ni-based single crystal superalloys when adding 1.5% Mo (mass fraction) into the Mo-free baseline alloy. The heat treatment results indicate that the intermediate γ′ precipitates in the dendrite core of the Mo-free alloy do not change in morphology and only become coarsening after (1 100 ℃, 2 000 h) heat treatment. Mo addition increases the content of Re, Mo and Cr in the γ phase. As a result, the lattice misfit is enlarged and γ′ precipitates become more cuboidal, the time of forming the rafting structure is significantly enhanced and occurs at about 200 h. Meanwhile, the TCP phases precipitate after 700 h in the Mo-free alloy while TCP phases are observed only after 100 h in the Mo-containing alloy. Mo addition promotes the formation of TCP phases significantly, which are identified as the σ and P phases and enriched in Re, W, Cr and Mo. The investigation of stress-rupture properties at 1 100 ℃ and 140 MPa indicates that Mo addition shortens the stress-rupture life of the baseline alloy due to the precipitation of large amount of TCP phases, although Mo addition increases the volume fraction of the γ′ phase and enlarges the lattice misfit with a good rafting microstructure.

Key words: superalloys; Mo; lattice misfit; microstructural stability; stress-rupture life

镍基单晶高温合金是制造高推重比先进航空发动机的关键材料[1]。自VERSNYDER等[2]发明定向凝固技术以来,单晶高温合金的承温能力得到显著提高。自20世纪80年代,出现了以PWA1480和René N4为代表的第一代单晶高温合金;并在此基础上,发现Re的引入可以明显提高合金的高温性能,进而开发出含Re分别为3%和6%(质量分数)的第二、三代高温合金等。但Re成本高,密度高,是有害拓扑密排(TCP)相的形成元素,因而限制其在单晶高温合金中的进一步使用。当前,充分挖掘传统强化元素的潜力,对于合金性能的提高及成本的降低具有重要意义。

Mo是有效的固溶强化元素,能够降低合金层错能,从而提高持久性能[3]。但是,由于Mo对组织稳定性[4]和抗氧化性能不利[5],在传统的合金设计中仅添加少量甚至不引入Mo。近年来,有文献报道[6-7],Mo可以显著提高合金的γ/γ′点阵错配度,促进两相界面位错网的形成,从而提高合金的蠕变性能。基于Mo有效的强化效果,日本NIMS通过合理调整Ru和Mo含量,得到性能优异的第四、五代单晶高温合金[8-9]。HOBBS等[10]也证实Mo能显著提高合金低温高应力下的蠕变性能。而ZHANG等[4]的研究表明:适当添加Mo有利于提高界面位错密度,降低蠕变速率,从而提高合金高温低应力下的蠕变性能;在中温中应力条件下,Mo通过降低堆垛层错能进而提高合金的蠕变性能。但当Mo加入过量时,γ基体中Mo的过饱和程度过大,从而促进脆性μ相的析出,并恶化合金性能。马文有等[4]在其研究的合金体系中也发现类似现象。总之,目前对Mo在单晶高温合金中的作用尚存在争议,有待进一步深入。

本文作者通过两种实验合金的比较分析,研究Mo的添加对镍基单晶高温合金显微组织和持久性能的影响,并初步探讨Mo的加入与合金元素成分分配比、γ/γ′点阵错配度、γ′相形貌、组织稳定性以及持久性能之间的关系。

1 实验

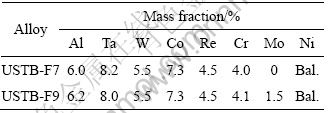

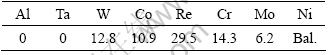

两种实验合金的单晶试棒通过定向凝固技术制备而成,尺寸为d 14 mm×150 mm。随后采用原子吸收分光光度法测定合金成分,如表1所列。其中,合金USTB-F9在不含Mo的合金USTB-F7基础上添加1.5%Mo。

试棒进行(1 320 ℃,8 h)固溶处理后,对一组试样进行1 100 ℃不同时间的组织稳定性(热暴露)实验;对另一组样品进行(1 140 ℃,8 h)+(870 ℃, 16 h)的时效处理,随后进行1 100 ℃,140 MPa条件下的持久性能测试。

表1 实验合金的实测成分

Table 1 Measured compositions of investigated alloys

随后,对合金进行组织分析,金相试样浸蚀剂为1%氢氟酸+33%硝酸+33%醋酸+33%蒸馏水。合金显微组织观察在蔡康4XCE型光学显微镜和ZEISS SUPRA 55型场发射扫描电镜(SEM)下进行。用Image-Pro软件统计γ′相的尺寸,用点分析法统计γ′相的体积分数。

持久性能测试后,利用扫描电镜下的能谱分析模式(EDS)对枝晶干处筏排组织中粗大的γ和γ′相进行成分测定,并计算合金元素的成分分配比(ki)。γ/γ′相成分分配比可用下述公式表示:

(1)

(1)

其中:xiγ和 分别表示合金元素i在γ和γ′相中的摩尔分数。当ki>1时,元素i富集于γ相;而当ki<1时,元素i富集于γ′相。

分别表示合金元素i在γ和γ′相中的摩尔分数。当ki>1时,元素i富集于γ相;而当ki<1时,元素i富集于γ′相。

为了更好地观察TCP相的形貌和空间分布特征并进行相鉴定,对经(1 100 ℃,400 h)热处理后的合金USTB-F9试样进行相萃取实验。相萃取电解液成分为9份甲醇+1份盐酸+1%酒石酸(质量分数),电流密度为0.04 A/cm2,萃取时间为10 h。相萃取结束后收集相萃取产物,并利用Rigaku 2500型X射线衍射仪(XRD)对其进行相鉴定分析。为进一步验证TCP相结构,还通过JEOL-2010型透射电子显微镜(TEM)对析出的TCP相进行相鉴定。

需要指出的是,由于镍基高温合金成分偏析的影响,枝晶干和枝晶间的显微组织形貌有一定差别。为了便于比较与讨论,本文作者所述显微组织均为合金枝晶干处的组织。

2 结果

2.1 长期热处理的组织稳定性

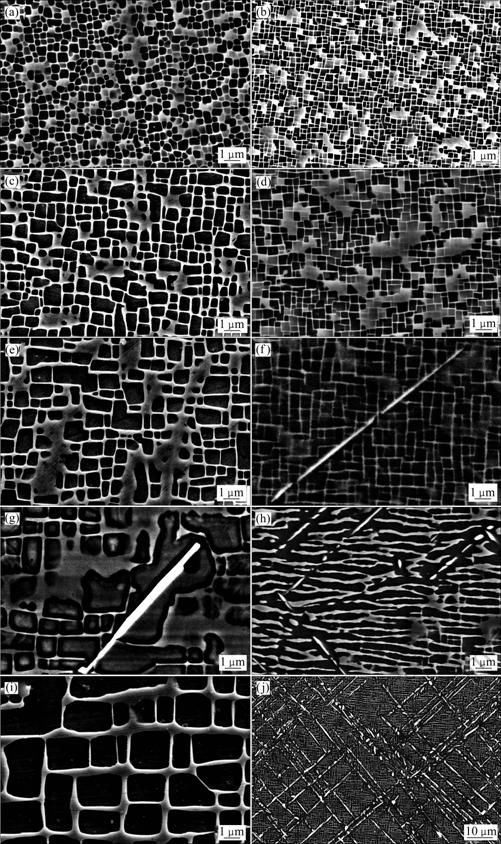

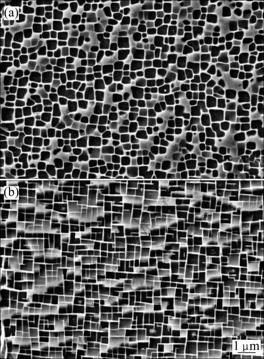

图1所示为两种实验合金经1 100 ℃不同热处理时间后枝晶干处的典型显微组织。由图1可看出,合金经长期热处理后,γ'相的尺寸和形貌均发生了很大的变化。合金USTB-F7在时效之初,形貌介于立方形和球形之间,为中间态形貌,尺寸为0.40 μm(见图1(a));热处理50 h后,γ'相明显长大,为0.73 μm(见图1(c));到200 h后,尺寸进一步长大到1.23 μm(见图1(e));热处理700 h后,γ'相的粗化已经较严重,而形貌没有明显变化,仍为中间态。同时,在枝晶干处已发现针状二次相析出(见图1(g)),能谱分析及后续的相鉴定表明,该二次相为TCP相;直至2 000 h,γ'相的形貌仍未发生明显变化,但已粗化长大至2.12 μm,且未发现筏排现象(见图1(i)),需要指出的是热处理2 000 h后,枝晶干处析出的TCP相与700 h相比显著增加,但是为了突出显示γ′相形貌的变化,图1(i)避开了TCP相。合金USTB-F9时效8 h后,γ'相为立方状,尺寸为0.29 μm(见图1(b));经热处理50 h后,γ'相明显长大,为0.52 μm(见图1(d))。与合金USTB-F7经50 h时效后的组织相比,生长速度较慢;时效100 h后,在枝晶干处析出了TCP相(见图1(f)),能谱分析表明该TCP相富含Re、W、Mo和Cr元素。时效200 h后,TCP相大量析出并长大;伴随着TCP相的析出,γ'相也发生了相互的连接,形成筏排组织(见图1(h));时效350 h后,TCP的析出更为严重,枝晶干处析出的TCP相已长大延伸到枝晶间。同时,筏排粗化现象也更为明显(见图1(j))。

图1 实验合金经1 100 ℃不同热处理时间后枝晶干处典型的显微组织

Fig.1 Typical microstructures in dendrite core of two investigated alloys after heat-treating at 1 100 ℃ for different times: (a) USTB-F7, 8 h; (b) USTB-F9, 8 h; (c) USTB-F7, 50 h; (d) USTB-F9, 50 h; (e) USTB-F7, 200 h; (f) USTB-F9, 100 h; (g) USTB-F7, 700 h; (h) USTB-F9, 200 h; (i) USTB-F7, 2 000 h; (j) USTB-F9, 350 h

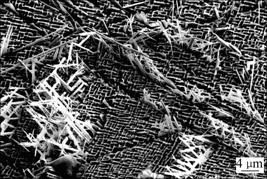

2.2 合金元素成分分配比

表2所列为实验合金持久性能测试后枝晶干处各合金元素的成分分配比。分析表明:Mo元素本身主要分配于γ相,并且Mo的加入显著提高了Re的分配比,同时使Cr的成分分配比增大,而对其他合金元素的成分分配比没有显著影响。

表2 实验合金持久性能测试后枝晶干处γ/γ'相的合金元素成分分配比

Table 2 Elemental partitioning ratio in dendrite core of two investigated alloys after stress-rupture testing

2.3 TCP相鉴定

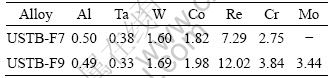

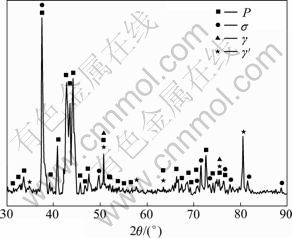

图2所示为合金USTB-F9经(1 100 ℃,400 h)热处理试样相萃取后TCP相残留在合金基体上的三维形貌。由图2可看出,TCP相呈典型的“网络编篮状”分布,且沿某些特定的晶体取向析出。相萃取后对TCP相的能谱分析表明,TCP相富集Re、Mo、W和Cr等合金元素,分别为实测合金成分的19.7、6.2、6.7和3.0倍;但几乎不含Al和Ta,如表3所列。图3所示为合金USTB-F9相萃取产物的XRD谱。XRD分析表明,该合金中析出的TCP相为σ相和P相。同时,XRD谱中也出现了γ′(γ)相的峰,这说明相萃取的TCP产物中也含有少量γ′(γ)相。

图2 合金USTB-F9经(1 100 ℃,400 h)热处理试样相萃取后TCP相的典型形貌

Fig.2 Typical morphology of phase-extracted residues of USTB-F9 alloy after heat-treating at 1 100 ℃ for 400 h

表3 合金USTB-F9相萃取后TCP相的EDS结果

Table 3 EDS results of extracted TCP precipitates of alloy USTB-F9 (mole fraction, %)

图3 合金USTB-F9经(1 100 ℃,400 h)热处理后相萃取产物的XRD谱

Fig.3 XRD pattern of extracted precipitates in USTB-F9 alloy after heat-treating at 1 100 ℃ for 400 h

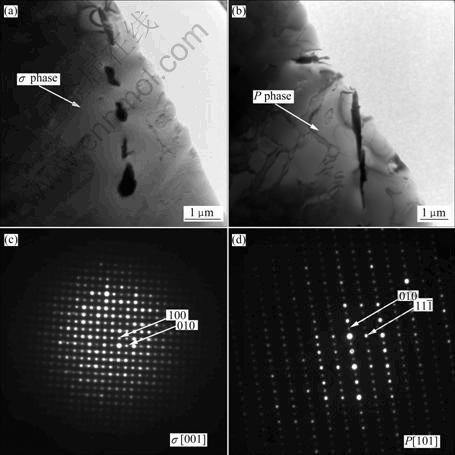

为进一步分析TCP相,对合金USTB-F9经 (1 100 ℃,400 h)时效后析出的TCP相进行了TEM鉴定。图4(a)和(b)为TCP相的TEM像。TCP相的电子衍射谱分析表明:该合金中析出的TCP相为σ相或P相;其中,图4(c)为σ相的[001]电子衍射谱,图4(d)则是P相的[101]电子衍射谱。这与XRD分析结果是相吻合的。

图4 合金USTB-F9经(1 100 ℃,400 h)时效后析出TCP相的TEM像及相应的SAD谱

Fig.4 TEM images(a, b) and indexed SAD patterns(c, d) of TCP phases in USTB-F9 alloy after heat-treating at 1 100 ℃ for 400 h: (a), (c) σ phase; (b), (d) P phase

2.4 持久性能

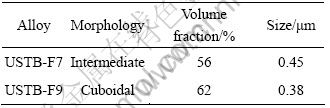

图5所示为实验合金经(1 140 ℃, 8 h)+(870 ℃, 16 h)时效后枝晶干处典型显微组织。由图5可看出,与(1 100 ℃,8 h)时效处理后的组织(图1(a)和(b))相比,本次热处理后两种合金γ′相的形貌保持不变,但尺寸增加,说明高温(1 140 ℃)加速了γ′相的长大。将两种实验合金γ′相的形貌、体积分数和尺寸大小等组织特征进行统计,其结果如表4所列。对比两种合金再次表明(见图5(a)和(b)),Mo的添加对镍基单晶高温合金的时效组织有显著影响。不含Mo的合金USTB-F7中γ′相的形貌介于球形和立方形之间,为中间态形貌,而含Mo合金USTB-F9中γ′相呈典型的立方形。同时,合金USTB-F9中γ′相的平均尺寸为0.38 μm,小于合金USTB-F7中γ′相的平均尺寸(0.45 μm),但其体积分数较高。需要指出的是,γ′相体积分数统计的部位为枝晶干中心处,是合金中γ′相体积分数最低的部位,实际的平均体积分数应高于此值。

表5所列为两种实验合金在1 100 ℃,140 MPa条件下的持久寿命。合金USTB-F7和USTB-F9的最短持久寿命分别为72 h和61 h,说明Mo的加入使合金的持久寿命略有降低。图6所示为两种实验合金经持久性能测试后离断口15 mm处其纵截面(010)面SEM背散射(BSE)模式下的组织形貌。由图6可看出,合金USTB-F7和USTB-F9在持久性能测试后均析出了富集Re、W、Mo和Cr的TCP相,而含Mo合金中TCP的含量明显高于基础合金USTB-F7的。

表4 实验合金经(1 140 ℃, 8 h)+(870 ℃, 16 h)时效处理后枝晶干处γ′相的特征

Table 4 Characteristic of γ′ precipitates in dendrite core of investigated alloys after aging treatment at (1 140 ℃, 8 h)+ (870 ℃, 16 h)

图5 实验合金经(1 140 ℃, 8 h)+(870 ℃, 16 h)时效处理后枝晶干处的典型显微组织

Fig.5 Typical microstructures in dendrite core of USTB-F7 (a) and USTB-F9 (b) alloys after aging treatment at (1 140 ℃, 8 h)+(870 ℃, 16 h)

表5 实验合金在(1 100 ℃,140 MPa)条件下的持久寿命

Table 5 Stress-rupture life of investigated alloys at 1 100 ℃, 140 MPa

3 分析与讨论

γ/γ′点阵错配度(δ)与γ′相形貌[11]、合金的力学性 能[12]和组织稳定性[13]密切相关。较大的错配度能提高合金的筏排化程度,促进γ/γ′界面位错网的形成,从而提高合金高温低应力条件下的蠕变性能。γ/γ′点阵错配度( )由公式(2)表示[14]:

)由公式(2)表示[14]:

(2)

(2)

式中: 和

和 分别为γ′相和γ相的点阵常数。

分别为γ′相和γ相的点阵常数。

图6 实验合金经持久性能测试后在离断口15 mm处沿纵截面(010)面的组织形貌

Fig.6 Sectional microstructures of (010) plane at 15 mm away from fracture surface of USTB-F7 (a) and USTB-F9 (b) alloys after stress-rupture testing

F?HRMANN等[11]研究表明:γ′相形貌受错配度正负和大小的影响。当错配度接近于零时,γ′相的形貌为球形;随着错配度绝对值变大,γ′相的形貌逐渐向立方形转变。此外,γ相和γ′相点阵常数的大小取决于γ相和γ′相中固溶的原子大小及其数量,也即受合金元素成分分配比的影响。CARON[15]分析γ相和γ′相成分与错配度的关系,γ相和γ′相的点阵常数与合金元素在两相中成分之间的关系由公式(3)和(4)表示:

(3)

(3)

(4)

(4)

式中: 和

和 分别为纯Ni和纯Ni3Al的点阵常数;xi和

分别为纯Ni和纯Ni3Al的点阵常数;xi和 分别为合金元素i在γ和γ′相中的摩尔分数;Vi和

分别为合金元素i在γ和γ′相中的摩尔分数;Vi和 分别为合金元素i在纯Ni和纯Ni3Al中的Vegard系数。综上所述,γ相和γ′相的成分决定了合金元素成分分配比,影响了点阵错配度的正负及其大小,最终影响了γ′相的形貌。在本研究中,由图1(a)和(b)及图5(a)和(b)可见,Mo的添加促进了γ′相形貌由中间态向立方形转变。这是因为Mo元素的添加改变了合金元素在γ相和γ′相中的分配比和错配度。参考合金元素的成分分配比可知(见表2),Mo本身富集于γ相,并且Mo的添加使Re的分配比明显增大,从而使γ及γ′相点阵常数的差值变大,进而使γ/γ′点阵错配度绝对值变大,最终提高含Mo合金中γ′相的立方度。

分别为合金元素i在纯Ni和纯Ni3Al中的Vegard系数。综上所述,γ相和γ′相的成分决定了合金元素成分分配比,影响了点阵错配度的正负及其大小,最终影响了γ′相的形貌。在本研究中,由图1(a)和(b)及图5(a)和(b)可见,Mo的添加促进了γ′相形貌由中间态向立方形转变。这是因为Mo元素的添加改变了合金元素在γ相和γ′相中的分配比和错配度。参考合金元素的成分分配比可知(见表2),Mo本身富集于γ相,并且Mo的添加使Re的分配比明显增大,从而使γ及γ′相点阵常数的差值变大,进而使γ/γ′点阵错配度绝对值变大,最终提高含Mo合金中γ′相的立方度。

两种实验合金在长期热暴露过程中γ′相均发生了粗化。其中,合金USTB-F9出现了非加载下的筏排化现象(见图1(h))。γ′相的粗化和长大是按照Ostwald熟化方式发生的扩散长大,而非加载下的筏排化则是Ostwald熟化机制与γ/γ′相界面的错配应力共同作用的结果。在热暴露早期,γ′相长大的主要驱动力为界面能的降低,长大过程主要受扩散控制。加Mo合金中Re的分配比较高,阻止了合金元素的扩散,进而抑制了该合金中γ′相的长大。随着热暴露时间的延长,由γ/γ′两相点阵错配度引起的弹性共格应力对粗化过程将产生显著的影响[16-17]。对于错配度较大、γ′相立方度较高的合金,γ与γ′两相共格界面存在较高的错配应力。受其影响,合金元素发生定向扩散,γ′相优先沿 方向长大。同时,在γ/γ′两相共格界面的位错网协调了两相的共格错配应力,改变了γ′相原有的弹性应力场,使γ′相中心至边缘的弹性应力梯度消失,从而导致非加载下的三向筏排化现象。合金USTB-F7经2 000 h热暴露后组织依然保持稳定,没有发生筏排化(见图1(i)),而加Mo合金仅经过200 h热暴露,其组织即被明显破坏,发生了筏排化(见图1(h))。原因在于合金USTB-F9中Re和Mo等元素的分配比较高(见表2),合金的错配度增大,共格应变能增加,为长期热暴露过程中的筏排化行为提供了足够的驱动力,因此,加Mo合金出现了非加载下的筏排化现象。这与本课题组前期的研究结果[13]是相符的。

方向长大。同时,在γ/γ′两相共格界面的位错网协调了两相的共格错配应力,改变了γ′相原有的弹性应力场,使γ′相中心至边缘的弹性应力梯度消失,从而导致非加载下的三向筏排化现象。合金USTB-F7经2 000 h热暴露后组织依然保持稳定,没有发生筏排化(见图1(i)),而加Mo合金仅经过200 h热暴露,其组织即被明显破坏,发生了筏排化(见图1(h))。原因在于合金USTB-F9中Re和Mo等元素的分配比较高(见表2),合金的错配度增大,共格应变能增加,为长期热暴露过程中的筏排化行为提供了足够的驱动力,因此,加Mo合金出现了非加载下的筏排化现象。这与本课题组前期的研究结果[13]是相符的。

对比合金USTB-F7与USTB-F9长期时效过程中的TCP相析出情况可以发现,合金USTB-F7开始析出TCP相的时间为700 h(见图1(g)),而合金USTB-F9开始析出TCP相的时间为100 h(见图1(f)),这说明Mo强烈促进TCP相的析出。结合合金元素的分配比分析,表明Mo作为一种TCP相的强形成元素,其本身富集于γ相;同时,Mo的加入显著促进了Re向γ相中的分配,也使Cr的成分分配比略有提高,从而提高了TCP相形成元素在γ相中的过饱和度,因而促进了TCP相的析出。需要指出的是,在持久性能测试后的组织中,分别在72 h和61 h就发现合金USTB-F7和USTB-F9中有TCP相析出(见图6(a)和(b))。这说明无论是在含Mo合金还是不含Mo合金中,应力均显著促进了TCP相的析出。这与本课题组的前期工作[18]也是相符的。

从强化原理上讲,单晶高温合金中的主要强化相为γ′相,其体积分数、尺寸及形貌对合金的力学性能起重要作用。MURAKUMO等[19]的研究表明,合金的持久性能随γ′相体积分数的增加先提高后降低,存在一定的峰值,一般在70%左右达到最佳效果。对照合金USTB-F7和USTB-F9可见,Mo的引入使枝晶干处γ′相最小体积分数由56%增加到62%,因而有利于合金持久性能的提高。

从γ′相的形貌看,CARROLL等[20-21]及课题组前期研究[22]表明:错配度为零和γ′相呈球形的合金,其蠕变性能最差,错配度较小和γ′相形貌处于中间态的合金蠕变性能次之,而具有较高错配度并且γ′相为立方形的合金蠕变性能最好。本研究中,随着Mo的加入,γ′相的形貌由中间态转变为立方形,应该提高合金的持久寿命。此外,具有高立方度γ′相和较大错配度的合金易于促进筏排化的进程,根据NATHAL和EBERT[23]以及CARON等[24]的报道,筏排组织的形成对高温低应力条件下持久性能的提高是有利的。因 此,从γ′相的形貌特征上看,Mo的引入有利于合金持久性能的提高。然而,实验结果表明,含Mo合金USTB-F9的持久性能比USTB-F7的略有下降。其主要原因在于高温加载促进了TCP相的析出,它一方面降低了基体中强化元素的含量,弱化了强化效果;另一方面,由于TCP相为脆硬相,易于产生应力集中,成为裂纹源及裂纹扩展的快速通道,因而使合金的持久性能下降。综上所述,从对强化相的影响看,Mo的添加提高了γ′相的体积分数,增加了强化相数量。同时,使γ′相立方度和错配度提高,并有利于筏排组织的形成,从而提高合金高温低应力下的持久性能;而从TCP相的析出看,Mo强烈促进TCP相析出,不仅使析出时间提前,而且使其体积分数明显提高。在两个因素的综合作用下,由于TCP相的析出成为影响合金性能的重要因素,因而合金USTB-F9的持久性能有所降低。

4 结论

1) Mo的添加显著促进了Re在γ相中的富集,也使Cr的分配比增加,而对Al、Ta、W和Co的分配比没有显著影响。同时,Mo主要分布在γ相中,Mo的添加促进了γ′相立方度和错配度的提高。

2) 在1 100 ℃长期热暴露实验中,不含Mo合金中呈中间态的γ′相形貌稳定,只出现粗化,2 000 h后也未发生筏排。随着Mo的加入,含Mo合金仅200 h热处理后,就出现了筏排化。同时,Mo的加入显著促进富集Re、Mo、W和Cr等元素的TCP(σ和P)相的析出,使其析出时间由USTB-F7合金的700 h提前到USTB-F9合金的100 h。

3) Mo的加入促进了γ′相体积分数的提高、形貌的立方化和筏排化进程,有利于持久性能的提高;但同时Mo也显著促进了TCP相的析出,破坏合金的持久性能。在两种因素的综合作用下,含Mo合金的持久寿命有所降低。

REFERENCES

[1] POLLOCK T M, TIN S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure, and properties[J]. Journal of Propulsion and Power, 2006, 22(2): 361-374.

[2] VERSNYDER F I, SHANK M E. The development of columnar grain and single crystal high temperature materials through direction solidification[J]. Materials Science and Engineering, 1970, 6(4): 213-247.

[3] ZHANG J, LI J, JIN T, SUN X, HU Z. Effect of Mo concentration on creep properties of a single crystal nickel-base superalloy[J]. Materials Science and Engineering A, 2010, 527(13/14): 3051-3056.

[4] 马文有, 韩雅芳, 李树索, 郑运荣, 宫声凯. Mo含量对一种镍基单晶高温合金显微组织和持久性能的影响[J].金属学报, 2006, 42(11): 1191-1196.

MA Wen-you, HAN Ya-fang, LI Shu-suo, ZHENG Yun-rong, GONG Sheng-kai. Effect of Mo content on the microstructure and stress rupture of a Ni base single crystal superalloy[J]. Acta Metallurgica Sinica, 2006, 42(11): 1191-1196.

[5] 黄乾尧, 李汉康, 陈国良, 郭建亭. 高温合金[M]. 北京: 冶金工业出版社, 2000: 2-9.

HUANG Qian-yao, LI Han-kang, CHEN Guo-liang, GUO Jian-ting. Superalloys[M]. Beijing: Metallurgical Industry Press, 2000: 2-9.

[6] ZHANG J X, MURAKUMO T, HARADA H, KOIZUMI Y. Dependence of creep strength on the interfacial dislocations in a fourth generation SC superalloy TMS-138[J]. Scripta Materialia, 2003, 48(3): 287-293.

[7] ZHANG J X, WANG J C, HARADA H, KOIZUMI Y. The effect of lattice misfit on the dislocation motion in superalloys during high-temperature low-stress creep[J]. Acta Materialia, 2005, 53(17): 4623-4633.

[8] KOIZUMI Y, KOBAYASHI T, YOKOKAWA T, ZHANG J X, OSAWA M, HARADA H, AOKI Y, ARAI M. Development of next-generation Ni-base single crystal superalloys[C]// GREEN K A, POLLOCK T M, HARADA H, HOWSON T E, REED R C, SCHIRRA J J, WALSTON S. Superalloys 2004. Champion PA: TMS, 2004: 35-43.

[9] SATO A, HARADA H, YEH A C, KAWAGISHI K, KOBAYASHI T, KOIZUMI Y, YOKOKAWA T, ZHANG J X. A 5th generation SC superalloy with balanced high temperature properties and processability[C]// REED R C, GREEN K A, CARON P, GABB T P, FAHRMANN M G, HURON E S, WOODARD S A. Superalloys 2008. Champion PA: TMS, 2008: 131-138.

[10] HOBBS R A, BREWSTER G J, RAE C M F, TIN S. Evaluation of ruthenium-bearing single crystal superalloys—A design of experiments[C]// REED R C, GREEN K A, CARON P, GABB T P, FAHRMANN M G, HURON E S, WOODARD S A. Superalloys 2008. Champion PA: TMS, 2008: 171-180.

[11] F?HRMANN M, FRATZL P, PARIS O, F?HRMANN E, JOHNSON W C. Influence of coherency stress on microstructural evolution in model Ni-Al-Mo alloys[J]. Acta Metallurgica et Materialia, 1995, 43(3): 1007-1022.

[12] ZHANG J X, HARADA H, KOIZUMI Y, KOBAYASHI T. Dislocation motion in the early stages of high-temperature low-stress creep in a single-crystal superalloy with a small lattice misfit[J]. Journal of Materials Science, 2010, 45(2): 523-532.

[13] 陈晶阳, 赵 宾, 冯 强, 曹腊梅, 孙祖庆. Ru和Cr对镍基单晶高温合金γ/γ'热处理组织演变的影响[J]. 金属学报, 2010, 46(8): 897-906.

CHEN Jing-yang, ZHAO Bin, FENG Qiang, CAO La-mei, SUN Zu-qing. Effects of Ru and Cr on γ/γ' microstructural evolution of Ni-based single crystal superalloys during heat treatment[J]. Acta Metallurgica Sinica, 2010, 46(8): 897-906.

[14] NATHAL M V, MACKAY R A, GARLICK R G. Temperature dependence of γ-γ' lattice mismatch in nickel-base superalloys[J]. Materials Science and Engineering A, 1985, 75(1/2): 195-205.

[15] CARON P. High γ' solvus new generation nickel-based superalloys for single crystal turbine blade applications[C]// POLLOCK T M, KISSINGER R D, BOWMAN R R, GREEN K A, MCLEAN M, OLSON S L, SCHIRRA J J. Superalloys 2000. Champion PA: TMS, 2000: 737-746.

[16] SOCRATE S, PARKS D M. Numerical determination of the elastic driving force for directional coarsening in Ni-superalloys[J]. Acta Metallurgica et Materialia, 1993, 41(7): 2185-2209.

[17] NATHAL M V, MACKAY R A. The stability of lamellar γ-γ' structures[J]. Materials Science and Engineering A, 1987, 85: 127-138.

[18] 陈晶阳, 曹腊梅, 冯 强. 应力对一种含Ru镍基单晶高温合金组织稳定性的影响[J]. 材料科学与工艺, 2008, 16(S1): 80-85.

CHEN Jing-yang, CAO La-mei, FENG Qiang. Effect of stress on the microstructural stability of a Ru-containing Ni-base single crystal superalloy[J]. Materials Science and Technology, 2008, 16(S1): 80-85.

[19] MURAKUMO T, KOBAYASHI T, KOIZUMI Y, HARADA H. Creep behaviour of Ni-base single-crystal superalloys with various γ' volume fraction[J]. Acta Materialia, 2004, 52(12): 3737-3744.

[20] CARROLL L J, FENG Q, POLLOCK T M. Interfacial dislocation networks and creep in directional coarsened Ru-containing nickel-base single-crystal superalloys[J]. Metallurgical and Materials Transactions A, 2008, 39(6): 1290-1307.

[21] CARROLL L J, FENG Q, MANSFIELD J F, POLLOCK T M. High refractory, low misfit Ru-containing single-crystal superalloys[J]. Metallurgical and Materials Transactions A, 2006, 37(10): 2927-2938.

[22] CHEN J Y, ZHAO B, FENG Q, CAO L M. Effects of Cr on the stress rupture of Ni-based single crystal superalloys[C]// JOSEPH R, OMER D, DONNA B, SHIELA W. Warrendale PA: TMS, 2009: 233-240.

[23] NATHAL M, EBERT L. Elevated temperature creep-rupture behavior of the single crystal nickel-base superalloy NASAIR 100[J]. Metallurgical and Materials Transactions A, 1985, 16(3): 427-439.

[24] CARON P, HENDERSON P J, KHAN T, MCLEAN M. On the effects of heat treatments on the creep behaviour of a single crystal superalloy[J]. Scripta Metallurgica, 1986, 20(6): 875-880.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2007AA03A225);国家重点基础研究发展计划资助项目(2010CB631201);国家自然科学基金资助项目(50671015);教育部“新世纪优秀人才支持计划”资助项目(NCET-06-0079)

收稿日期:2010-03-09;修订日期:2010-06-18

通信作者:冯 强,教授,博士;电话:010-82375850;E-mail: qfeng@skl.ustb.edu.cn