DOI: 10.11817/j.issn.1672-7207.2020.04.011

超高压自能式灭弧室吹弧性能优化

李巧全1,巫世晶1,黎小峰1,李小勇1, 2,赵文强3

(1. 武汉大学 动力与机械学院,湖北 武汉,430072;

2. 武汉大学 苏州研究院,江苏 苏州,215123;

3. 国家电网平高集团有限公司,河南 平顶山,467000)

摘要:为研究超高压自能式灭弧室的结构参数对其吹弧性能的影响,增强断路器开断过程中的吹弧效果,提升断路器的可靠性,首先,建立考虑多物理场耦合的超高压自能式灭弧室仿真模型,计算开断时灭弧室的压力和温度变化,同时,利用压力测量实验验证仿真模型的有效性;然后,通过仿真模型和控制变量法研究喷口喉部直径、喷口喉部长度和膨胀室体积对自能式灭弧室吹弧性能的影响,并以上述3个结构参数作为可控因素,以过零时刻电弧轴线平均温度为噪声因子,采用田口法与方差分析优化吹弧性能。研究结果表明:随着喷口喉部直径增大,电弧轴线整体温度升高;随着喷口喉部长度增加,电弧轴线整体温度升高;随着膨胀室体积增大,电弧轴线整体温度呈现先升高后降低的趋势;喉部直径、喉部长度和膨胀室内径对过零时刻电弧轴线平均温度的显著性分别为0.07,0.01和0.07,优化后喉部直径、喉部长度和膨胀室内径分别为29,75和55 mm;优化后过零时刻电弧轴线平均温度降低9.15%;喷口喉部直径、喷口喉部长度和膨胀室内径对吹弧性能有显著影响,其中喉部长度的影响程度最大。适当选择膨胀室体积、减小喉部直径和喉部长度能有效提高自能式灭弧室的吹弧性能,降低喷口的烧蚀程度。

关键词:超高压断路器;自能式灭弧室;吹弧性能;电弧温度;田口法

中图分类号:TM561;O533 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)04-0962-09

Optimization of arc extinguishing capability of UHV self-energy arc chamber

LI Qiaoquan1, WU Shijing1, LI Xiaofeng1, LI Xiaoyong1, 2, ZHAO Wenqiang3

(1. School of Power and Mechanical Engineering, Wuhan University, Wuhan 430072, China;

2. Suzhou Institute of Wuhan University, Suzhou 215123, China;

3. State Grid Pinggao Group Co. Ltd, Pingdingshan 467000, China)

Abstract: In order to study the influence of the structural parameters of the UHV self-energy arc chamber on its arc blowing performance, increase the arc blowing effect in the process of circuit breaker breaking, and improve the reliability of circuit breaker, the simulation model of the self-energy arc chamber with multi-physical field coupling was firstly established to calculate the pressure and temperature change of the arc chamber during breaking. Meanwhile, the pressure measurement experiment was used to verify the effectiveness of the simulation model. Secondly, the influence of nozzle throat diameter, throat length and expansion chamber volume on the arc blowing performance of self-energy arc chamber was studied by the simulation model and control variable method. Furthermore, taking the above three structural parameters and the average temperature of the arc axis at current zero as controllable factors and the noise factor, the Taguchi method and the variance analysis were adopted to optimize the arc blowing performance. The results show that the overall temperature of arc axis increases with the increases the of diameter of nozzle throat and the length of nozzle throat. As the volume of expansion chamber increases, the overall temperature of arc axis increases firstly and then decreases. In addition, the significance of the diameter of nozzle throat, the length of nozzle throat and the diameter of expansion chamber to the mean temperature of the arc axis at current zero are 0.07, 0.01 and 0.07, respectively. After structural optimization, the diameter of nozzle throat, the length of nozzle throat and the diameter of expansion chamber are 29, 75 and 55 mm, respectively. The optimized mean temperature of the arc axes at currrnt zero reduces by 9.15%. The diameter of nozzle throat, the length of nozzle throat and the diameter of expansion chamber have significant influence on the arc blowing performance, among which the length of nozzle throat has the greatest influence. Proper selection of the volume of expansion chamber and reduction of the diameter and length of nozzle throat can effectively improve the arc blowing performance of self-energy arc chamber and reduce the ablation of nozzle.

Key words: UHV circuit breaker; self-energy interrupter; arc extinguishing performance; arc temperature; Taguchi method

高压断路器是电网最重要的保护和控制设备之一,其可靠性对电力系统的安全稳定运行具有重要意义[1]。高压断路器的可靠性不仅受操动机构的影响,同时取决于灭弧室的吹弧性能,这也是评估断路器优劣的重要指标之一[2-4]。目前压气式断路器因其可靠性高、开断性能好,在高压、超高压和特高压领域得到广泛应用,但其体积大、质量大和操动功高的缺点导致高压断路器的小型化、轻量化、低操动功成为电力系统迫切要解决的问题。自能式断路器为解决此类问题提供了一种有效途径,它通过利用电弧自身能量增压的原理有效地减小了断路器的体积、质量和操动功,在中低压领域已得到应用,但在高压领域尚需进一步研究。试验研究和仿真分析是自能式灭弧室研究的主要手段,试验研究周期长、成本高,很难满足工程实际需求[5-8],而仿真分析成本低、方便快捷的优点导致其成为研究灭弧室的重要途径。断路器开断大电流过程是一个涉及气流场、温度场和电磁场的多场耦合问题,为仿真模型的建立带来了较大困难[9],对此,国内外学者致力于建立多场耦合仿真模型,并开展了一系列研究。目前,国内外研究主要涉及灭弧室开断过程的电弧模型构建、基于实际气体状态方程的开断特性、不同气体介质的灭弧室开断能力比较、SF6气体的介质恢复特性、传动机构间隙对断路器动力学性能的影响、灭弧室开断过程中的压力和电场分布等[10-17],而有关灭弧室结构参数对吹弧性能影响机制的研究还较少。吹弧能力差会增加喷口烧蚀程度,影响断路器使用寿命,严重时将导致断路器产生开断故障,造成灾难性电网事故,因此,研究灭弧室结构参数对吹弧性能的影响具有重要意义。此外,目前仿真模型计算复杂多场耦合问题时的求解时间较长,使用中心复合设计等传统优化方法研究进度过慢。考虑上述研究的不足,本文以420 kV自能式灭弧室为研究对象,建立基于真实开断工况的多场耦合仿真模型,探讨喷口喉部直径、喉部长度和膨胀室体积对灭弧室吹弧性能的影响机制,并利用田口法进行试验设计分析,优化灭弧室的吹弧性能,以便为高压自能式断路器的研制及优化提供有效途径。

1 420 kV自能式灭弧室仿真模型

1.1 基本结构及假设

图1所示为420 kV高压自能式断路器灭弧室结构示意图。由图1可见:自能式灭弧室主要包括压气室、膨胀室、动弧触头、喷口和静弧触头,其中膨胀室的作用是依靠电弧周围产生的高温气体增加室内的气体压力,与喷口喉部形成压力差,在电流零区阶段形成强烈气吹熄灭电弧。

图1 420 kV自能式灭弧室基本结构

Fig. 1 Basic structure of 420 kV self-energy arc chamber

为提高仿真模型的计算效率和准确性,需对灭弧室进行如下假设与简化:

1) 电弧及其周围气流场处于局部热力学平衡状态(LTE),并忽略灭弧室内电弧及金属部件的涡流。

2) 圆角、弧面等复杂形状在不影响气体流动和物体接触面积的前提下,简化为直角和斜面,以提高仿真速度和结果准确性。

1.2 数学模型

灭弧室开断过程中的流场处于跨音速、变边界的复杂状态,并伴随着激波、湍流等复杂物理现象,其过程可由Navier-Stokes方程描述。本文基于直角坐标系建立二维仿真模型,其质量守恒方程为

(1)

(1)

式中:t为时间;ρ为气体密度; 和

和 分别为速度矢量

分别为速度矢量 在x和y方向的分量。

在x和y方向的分量。

动量守恒方程表示为

(2)

(2)

式中:κ=κ1+κ2为黏性系数,κ1为层流黏性系数,κ2为湍流黏性系数;i为坐标轴;Vi为速度矢量 在i轴的分量;Si为动量源项在i轴的分量。

在i轴的分量;Si为动量源项在i轴的分量。

(3)

(3)

式中:P为气体压力;Ji和Bi分别为电流密度和磁场强度在i轴方向的分量。

能量守恒方程可以表示为

(4)

(4)

式中:h为能量焓;cp为比定压热容;λ=λ1+λ2,为导热系数,λ1为层流导热系数,λ2为湍流导热系数;Sh为能量源项。

(5)

(5)

式中:μ为电导率;E为电场强度;Q为电弧辐射散热能量。

由自由带电粒子构成的电弧等离子体类似于导体,在电流通过时会产生复杂的电磁过程,必须求解电磁场得到电流密度和磁通密度分布才能求得影响气流场、温度场的焦耳热和电磁力。电场强度、电流密度和磁场强度可由麦克斯韦方程表示为

(6)

(6)

(7)

(7)

(8)

(8)

式中: 为电场强度;

为电场强度; 为磁场强度;

为磁场强度; 为电流密度;φ为电位;

为电流密度;φ为电位; 为磁矢势。

为磁矢势。

电弧散热主要有热传递和辐射散热2种方式。对流散热可由导热系数计算;辐射散热较复杂,其辐射能量可采用静辐射系数εnec计算[18]。相关研究表明,灭弧室开断过程中的流场为湍流,为了与断路器实际开断工况一致,引入Prandtl混合长度湍流模型,该模型经验证可以描述开关电弧的湍流现象[19-20]。Prandtl湍流模型的计算公式为

(9)

(9)

式中:c为湍流常数;R为电弧半径。湍流黏性系数和湍流导热系数的关系可通过湍流Pt表达为

(10)

(10)

1.3 求解设置

本文使用PHOENICS求解式(1)~(10),为提高计算效率和保证结果准确性,在喷口计算域划分较密的网格,单元尺寸约为0.5 mm,其他区域划分为疏网格,单元尺寸约为1.5 mm。仿真模型均采用四边形单元,共包含约1.9×105个单元和1.6×105个节点。仿真模型考虑了SF6、喷口、动弧触头和静弧触头等元件的材料属性。其中,喷口材料的电导率为1.0×10-3 S/m,动弧触头和静弧触头材料的电导率为1.0×105 S/m。计算域内气体初始压力为0.62 MPa,初始温度为300 K,开断电流为63 kA,燃弧时间为10 ms,触头行程为280 mm。模型两端设置为出口,并始终保持为初始压力。

在模型求解时,空载工况计算时间步长取为0.01 ms,负载工况计算时采用事件控制确定时间步长:在0~16 ms,压气室、膨胀室和喷口区域均处于压缩阶段,步长取为0.003 ms;在16~20 ms内,电流进入零区阶段,为研究过零时刻电弧温度,步长取为0.000 1 ms;其后阶段,步长恢复至0.003 ms。仿真过程中收敛条件设置为压力残差小于0.005 MPa,速度残差小于0.008 m/s,焓残差小于0.03 J/g。

2 仿真计算

2.1 空载仿真结果

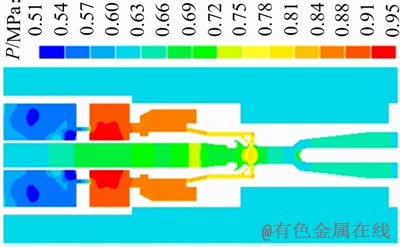

在空载工况下,利用仿真模型对超高压自能式灭弧室进行仿真计算,得到分闸过程中的压力分布云图,如图2所示。从图2可见:在断路器空载动作中,压力最大位置位于压气室和膨胀室内,此时由于活塞作用,压气室和膨胀室均被压缩,静弧触头处于脱离喷口的临界位置,膨胀室与喷口间的压差达到最大值0.35 MPa。在静弧触头脱离喷口后,压气室和膨胀室内的高压气体吹出,在喉部区域形成强烈的气吹。

图2 空载压力云图

Fig. 2 No-load pressure contour

2.2 负载仿真结果

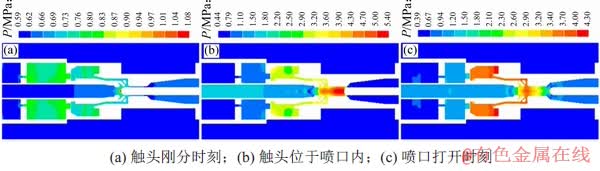

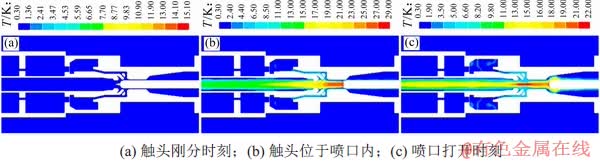

图3和图4所示分别为不同时刻下灭弧室开断大电流的压力云图和温度云图。由图3(a)和图4(a)可见:动弧触头和静弧触头分离之前为单纯的气缸压缩过程,弧触头和喷口均处于堵塞状态,没有形成有效的气吹通道与电弧,灭弧室内温度基本不变,仅压气缸压力不断上升。由图3(b)和图4(b)可见:静弧触头与动弧触头分离后进入喷口喉部,触头间产生电弧,周围气体温度急剧升高,由电弧造成的高温气体进入膨胀室后导致膨胀室压力快速增加。在该过程中,动弧触头空心腔内的流道打开,气体从空心腔流出并在触头间形成较大的压差,有利于小电流、短燃弧的熄灭。由图3(c)和图4(c)可见:静弧触头离开喷口时,膨胀室压力达到最高4.3 MPa,并在喷口喉部形成稳定流道。此时,电流接近零点,膨胀室气体在压差作用下迅速释放,在喷口喉部形成强烈气吹,带走电弧能量,电弧周围的气体温度急剧下降,从而熄灭电弧。

图3 负载压力云图

Fig. 3 Contour of load pressure

图4 负载温度云图

Fig. 4 Contour of load temperature

3 压气测量实验

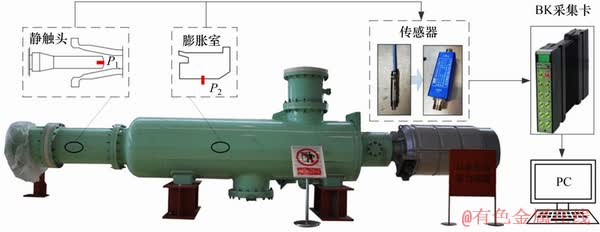

为验证仿真模型的计算准确性,搭建了图5所示的420 kV灭弧室压力测量系统。实验测量灭弧室空载开断中的压力变化,测点位置分别布置在静弧触头端部和膨胀室(见图5的P1和P2)。选用WMS-53高频微型压力传感器,实验数据的采集与处理采用BK公司生产的具有较高精度的LAN-XI信号采集系统。

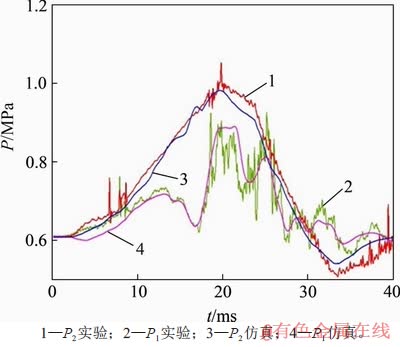

图6所示为灭弧室空载开断压力测量曲线。由图6可见:灭弧室的开断时间约为35 ms,喷口喉部气吹约在20 ms时形成,仿真和实验曲线的压力变化趋势基本吻合。膨胀室压力变化分为上升和下降2个阶段,仿真计算和实验测量的膨胀室最高压力分别为0.95 MPa和0.98 MPa,仿真与实验的最高压力误差为3.1 %。静弧触头端部压力在开断历程上变化较为剧烈,因为静触头历经动静触头分离和喷口打开等过程,其压力同时具有了动弧触头空心腔、喷口上游、喷口喉部和喷口下游压力变化的部分特征,导致压力出现复杂变化。静弧触头端部压力的仿真和实验结果在开断末期剧烈波动,此现象为静触头处于喷口内,气体在喷口壁面不断反射造成气压波动。此外,在开断结束时,气室内出现短暂的负压变化,这与其他工作的气压研究结果基本相符合[4-6]。

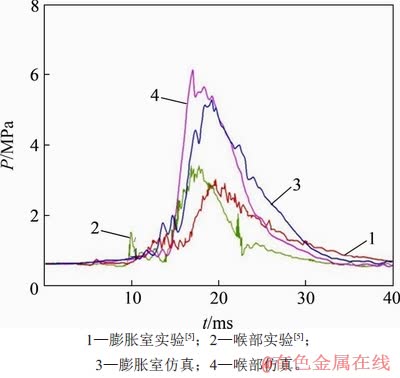

断路器开断大电流时,灭弧室内部的高温、高压、强电磁干扰导致暂态压力测量较困难,受测量条件限制,未进行负载开断测量,因此,采用文献[5]中实验数据进一步验证仿真模型的准确性,如图7所示。文献[5]中暂态压力测量对象为252 kV自能式灭弧室,灭弧室结构与本文研究对象基本相同,压力实验数据能够用来校验本文仿真模型的准确性。

从图7可见:喷口喉部和膨胀室的仿真曲线与实验曲线在整体波形趋势上基本一致。与图6所示的空载实验和仿真结果对比发现:开断强电流时的喷口喉部压力、膨胀室压力与空载差异显著,空载时膨胀室压力大于喷口喉部压力,压力上升速度小于压力下降速度,而负载时膨胀室压力小于喷口喉部压力,压力上升速度大于压力下降速度,这是因为负载时,喷口喉部由于电弧影响产生了高温气体并流入膨胀室,导致喷口喉部和膨胀室压力急剧升高。以上结果表明:本文的仿真模型能够较好地反映灭弧室的开断过程,验证了模型的准确性。

4 吹弧性能影响因素

断路器开断大电流时,熄弧阶段电弧温度过高会导致电弧熄灭困难或烧穿喷口,直接影响断路器的可靠性,因此,研究熄弧过程的灭弧室结构参数对电弧温度的影响具有重要作用。

4.1 喉部直径

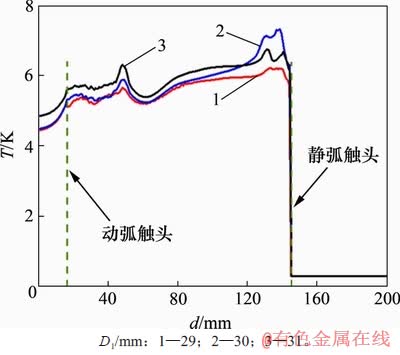

在电流过零阶段,电弧轴线温度会受到通过喷口的气体质量流影响,而喷口结构是影响质量流的关键因素,因此,分析喷口喉部直径、喉部长度对过零时刻电弧轴线温度的影响十分必要。设定喷口喉部直径D1分别为29,30和31 mm,图8所示为过零时刻不同喉部直径的电弧轴线温度。从图8可见:随着喉部直径增加,电弧轴线整体温度升高。在实际工况中,喷口喉部直径增加会引起气吹通道截面积增大,导致气体质量流在熄弧阶段减小,降低电弧温度的散热速度,表现为过零时刻电弧轴线温度升高。

图5 420 kV压力实验测量系统

Fig. 5 Pressure measurement system with 420kV

图6 空载实验和仿真压力曲线

Fig. 6 Pressure curves of no-load experiment and simulation

图7 负载实验和仿真压力曲线

Fig. 7 Pressure curves of load experiment and simulation

图8 不同喉部直径的电弧轴线温度

Fig. 8 Arc axis temperature of different nozzle diameter

4.2 喉部长度

保持喷口喉部直径不变,分析喷口喉部长度对过零时刻电弧轴线温度的影响。设定喷口喉部长度L分别为75,83和90 mm,图9所示为过零时刻不同喉部长度的电弧轴线温度分布情况。从图9可见:随着喷口喉部长度增加,电弧轴线整体温度升高。在实际工况中,喷口喉部长度增加会增加气吹通道长度,降低熄弧阶段的气吹作用,削弱电弧温度的传热效率,这是过零时刻电弧轴线温度升高的重要原因之一。

图9 不同喉部长度的电弧轴线温度

Fig. 9 Arc axis temperature of different nozzle length

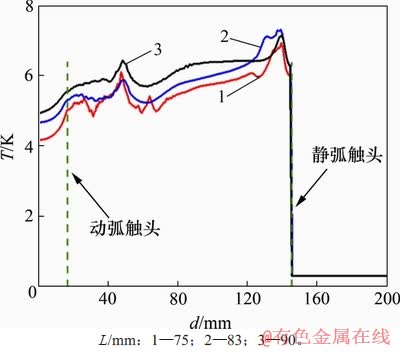

4.3 膨胀室体积影响

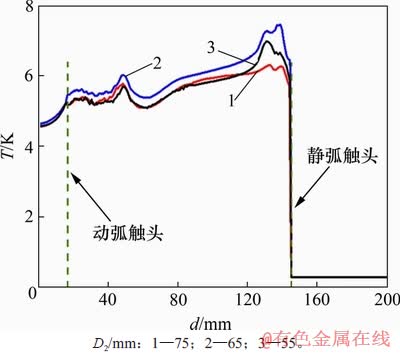

为了研究膨胀室体积对过零时刻电弧轴线温度的影响,考虑膨胀室长度与外径不变,设定膨胀室内径D2分别为75,65和55 mm,图10所示为过零时刻不同膨胀室内径的电弧轴线温度分布。从图10可见:内径为65 mm时电弧轴线整体温度最高,而内径为75 mm和55 mm的电弧轴线整体温度较低,且比较接近。这是因为膨胀室体积同时影响着向喷口吹出气体的温度和压力,体积增大会引起膨胀室温度降低和气体压力减小;当温度降低影响小于气体压力降低影响时,表现为电弧轴线整体温度升高;当温度降低影响大于气体压力降低影响时,表现为电弧轴线整体温度降低。

图10 不同膨胀室内径的电弧轴线温度

Fig. 10 Arc axis temperature of different expansion chamber inside diameter

5 吹弧性能优化

5.1 田口法分析

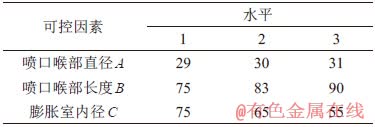

田口法可以有效地减少试验次数,有利于工程参数的优化设计。由于灭弧室结构设计尺寸的约束,选择喷口喉部直径为29~31 mm,喷口喉部长度为75~90 mm,膨胀室内径为55~75 mm。可控因素水平的选择如表1所示。此外,选择电流过零时刻电弧轴线平均温度为噪声因子。根据可控因素的个数和水平,采用L9(34)正交实验表,如表2所示,其中D代表田口法未考虑的可控因素。

表1 可控因素水平表

Table 1 Levels of controllable factors mm

表2 正交实验结果

Table 2 Result of orthogonal array experiment

田口法使用信噪比表征最优过程,本研究对象的评价指标具有望小特性,其信噪比计算模型表达式为

(11)

(11)

式中:SN为因素水平的信噪比;yi为第i次试验的观测数据;n为试验次数。

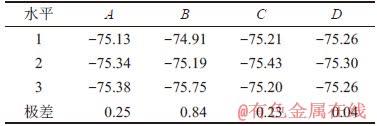

可控因子各水平下的信噪比计算结果如表3所示。从表3可见:B因子对过零时刻电弧轴线平均温度 影响最大,A因子和C因子较小,各因子的最优水平分别为A1,B1和C3。

影响最大,A因子和C因子较小,各因子的最优水平分别为A1,B1和C3。

表3 因素水平信噪比

Table 3 Signal/Noise ratio of factor level

为检验喷口喉部长度、喉部直径和膨胀室内径对过零时刻电弧轴线平均温度的显著性,采用方差分析计算上述3个参数对优化目标的F分位数,其结果如表4所示。从表4可知:喉部直径、喉部长度与膨胀室内径对过零时刻电弧轴线平均温度的显著性分别为0.07,0.01和0.07;3个因素对电弧平均温度 均有显著影响,其中,喉部长度的显著性最大,表明本次研究已经考虑到最重要因素,最优结构参数选择方案为A1B1C3。

均有显著影响,其中,喉部长度的显著性最大,表明本次研究已经考虑到最重要因素,最优结构参数选择方案为A1B1C3。

5.2 优化效果

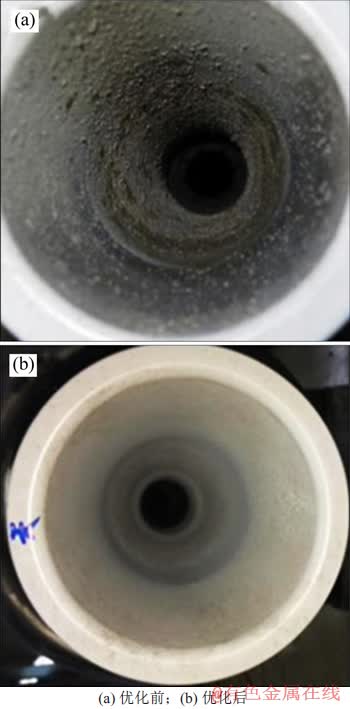

根据优化方案A1B1C3进行仿真模型参数设置,计算得到过零时刻电弧轴线平均温度为5 360 K,与原方案A2B2C2对比,使过零时刻电弧轴线平均温度降低了9.15%。图11所示为优化前后的喷口烧蚀情况。从图11可见:优化前的喷口产生严重的烧蚀,喉部直径由30 mm烧蚀至35 mm;优化后的喷口内表面仅有轻微烧蚀,喉部直径由30 mm烧蚀至32 mm,优化方案设计的灭弧室的吹弧性能得到了有效提高。

图11 喷口烧蚀状态

Fig. 11 Conditions of nozzle ablation

表4 方差分析结果

Table 4 Result of variance analysis

6 结论

1) 建立了超高压自能式灭弧室的多物理场耦合的仿真模型,仿真计算结果与压气测量实验数据具有较好的一致性,验证了仿真模型的有效性。

2) 随着喷口喉部直径和喷口喉部长度增加,电弧轴线整体温度升高,而膨胀室体积增大,电弧轴线整体温度呈现先升高后降低的趋势。田口法优化得到的结构参数方案A1B1C3(喉部直径、喉部长度和膨胀室内径分别为29,75和55 mm)使过零时刻电弧轴线平均温度降低了9.15%。

3) 灭弧室的喉部长度对吹弧性能影响最大,其次是喉部直径和膨胀室体积。适当选择膨胀室体积,减小喉部直径和喉部长度能有效降低电流过零时刻电弧轴线平均温度,减轻喷口的烧蚀程度。

参考文献:

[1] 徐国政, 张节容, 钱家骊, 等. 高压断路器原理和应用[M]. 北京: 清华大学出版社, 2000: 1-11.

XU Guozheng, ZHANG Jierong, QIAN Jiali, et al. Principle and application of high voltage circuit breaker[M]. Bejing: Tsinghua University Press, 2000: 1-11.

[2] MENG Fangang, WU Shijing, ZHANG Fan, et al. Numerical modeling and experimental verification for high-speed and heavy load planar mechanism with multiple clearances[J]. Mathematical Problem in Engineering, 2015, 180312.

[3] 孟凡刚, 巫世晶, 张增磊, 等. 特高压断路器传动机构动态特性分析[J]. 中南大学学报(自然科学版), 2016, 47(5): 1519-1526.

MENG Fangang, WU Shijing, ZHANG Zenglei, et al. Dynamic characteristic analysis of transmission mechanism of ultra-high voltage circuit breaker[J]. Journal of Central South University(Science and Technology), 2016, 47(5): 1519-1526

[4] 巫世晶, 赵文强, 王振, 等. 基于操动机构配合工差的断路器灭弧性能研究[J]. 华中科技大学学报(自然科学版), 2017, 45(11): 109-114.

WU Shijing, ZHAO Wenqiang, WANG Zhen, et al. Study on influence of fit tolerance of transmission mechanism on arc-extinguishing characteristics of circuit breaker[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2017, 45(11): 109-114.

[5] 刘卫东, 吴俊勇, 黄瑜珑, 等. SF6断路器强电流开断喷管内压力测量[J]. 中国电机工程学报, 2010, 30(7): 131-136.

LIU Weidong, WU Junyong, HUANG Yulong, et al. Pressure measurement in SF6 circuit breaker’s nozzle in heavy current interruption[J]. Proceedings of the Chinese Society of Electrical Engineering, 2010, 30(7): 131-136.

[6] 刘新航, 刘卫东, 何嘉希, 等. 引压导管对SF6断路器灭弧室暂态压力测量影响的消除方法研究[J]. 高压电器, 2016, 52(6): 55-60.

LIU Xinhang, LIU Weidong, HE Jiaxi, et al. Research on methods of eliminating the interference of the tube structure on transient pressure measurement in SF6 circuit breaker[J]. High Voltage Apparatus. 2016, 52(6): 55-60.

[7] GUAN Yonggang, LIU Weidong, WU Junhui, et al. Pressure measurement and characteristic analysis on a 252-kV Puffer-Type SF6 Circuit Breaker[J]. IEEE Transactions on Power Delivery, 2013, 28(4): 2616-2622.

[8] KOTSUJI H, URAI H, SAKUYAMA T, et al. Measurement of gas temperature in self-blast chamber of model gas circuit breaker at high current interruption[J]. IEEJ Transactions on Electrical and Electronic Engineering, 2018, 13(10): 1440-1445.

[9] 刘国勇. 流体力学数值方法[M]. 北京:冶金工业出版社, 2016: 3-12.

LIU Guoyong. Numerical methods of fluid mechanics[M]. Beijing: Metallurgical Industry Press, 2016: 3-12.

[10] LIN Xin, WANG Feiming, XU Jianyuan, et al. Study on the mathematical model of dielectric recovery characteristics in high voltage SF6 circuit breaker[J]. Plasma Science and Technology, 2016, 18(3): 223-229.

[11] ZHONG Jianying,GUO Yujing,ZHANG Hao. Research of arc chamber optimization techniques based on flow field and arc joint simulation[J]. Plasma Science and Technology, 2016, 18(3): 319-324.

[12] PEI Y, ZHONG J, ZHANG J, et al. A comparative study of arc behavior in an auto-expansion circuit breaker with different arc durations[J]. Journal of Physics D: Applied Physics, 2014, 47(33): 335201.

[13] ZHANG Q, YAN J D, FANG M T C. Current zero behavior of an SF6 nozzle arc under shock conditions[J]. Journal of Physics D Applied Physics, 2013, 46: 165203.

[14] KIM Y J, LEE J C. SF6 arc plasma simulation and breakdown performance prediction using computational fluid dynamics and arc modeling[J]. Thin Solid Films, 2012, 521: 206-211.

[15] 郭煜敬, 张豪, 张权, 等. N2, CO2和SF6喷口电弧电流开断能力的比较分析[J]. 高压电器, 2016, 52(12):31-40.

GUO Yujing, ZHANG Hao, ZHANG Quan, et al. Comparative study of the interruption capability of N2, CO2, and SF6 nozzle arcs[J]. High Voltage Apparatus. 2016, 52(12): 31-40.

[16] 林莘, 苏安, 李学斌, 等. 基于实际气体Redlich-Kwong方程的SF6断路器开断特性[J]. 高电压技术, 2018, 44(3): 704-710.

LIN Xin, SU An, LI Xuebin, et al. Interruption features in SF6 circuit breaker based on real gas Redlich-kwong equation[J]. High Voltage Engineering, 2018, 44(3): 704-710.

[17] 黎小峰, 巫世晶, 李小勇, 等. 高压断路器操动机构动力学特性联合仿真研究[J]. 华中科技大学学报(自然科学版), 2019, 47(2): 70-75.

LI Xiaofeng, WU Shijing, LI Xiaoyong, et al. Study on dynamic characteristic of operating mechanism of high voltage circuit breaker based on co-simulation[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2019, 47(2): 70-75.

[18] ZHANG J F, FANG M T C, NEWLAND D B. Theoretical investigation of a 2 kA DC Nitrogen arc in a supersonic nozzle[J]. Journal of Physics D Applied Physics, 2000, 20(3): 368-379.

[19] YAN J , FANG M. Modelling of SF6 arc in a supersonic nozzle. Part I: Cold flow features and DC arc characteristics[J]. Journal of Physics D Applied Physics, 2014, 47(21): 747-759.

[20] ZHANG Q, LIU J, YAN J D, et al. The modelling of an SF6 arc in a supersonic nozzle. Part II. Current zero behaviour of the nozzle arc[J]. Journal of Physics D: Applied Physics, 2016, 49(33): 335501.

(编辑 秦明阳)

收稿日期: 2019 -05 -27; 修回日期: 2019 -08 -10

基金项目(Foundation item):国家自然科学基金资助项目(51375350);国家电网公司科技项目(5211DS16002L) (Project(51375350) supported by the National Natural Science Foundation of China, Project(5211DS16002L) supported by State Grid Corporation of China)

通信作者:巫世晶,博士,教授,从事机械电子工程研究;E-mail:wsj@whu.edu.cn