文章编号:1004-0609(2007)01-0156-05

基于遗传算法的铜闪速熔炼过程控制优化

汪金良1, 2 ,卢 宏3,曾青云1, 2,张传福2

(1. 江西理工大学 材料与化学工程学院,赣州 341000;

2. 中南大学 冶金科学与工程学院,长沙 410083;

3. 江西理工大学 信息工程学院,赣州 341000)

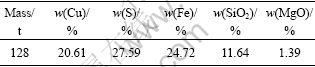

摘 要:基于已建立的铜闪速熔炼神经网络模型,以能耗费用最低为目标,在工艺指标控制范围内,采用遗传算法对铜闪速熔炼过程的工艺参数进行了仿真优化计算。结果表明,当空气、分配风、工艺氧和中央氧的市场价格折合比值分别为0.05、0.1、0.4和0.45,精矿量为128 t,其成分(质量分数)为Cu 20.61%、S 27.59%、Fe 24.72%、SiO2 11.64%和MgO 1.39%时,铜闪速熔炼工艺参数的遗传优化值为空气15 011 m3、分配风1 302 m3、工艺氧17 359 m3、中央氧1 000 m3、熔剂13.6 t;与实践平均值相比,若采用优化工艺参数控制,熔炼能耗费用可降低4.6%。

关键词:铜闪速熔炼;神经网络;遗传算法;控制优化

中图分类号:TF 811; TF 355.2 文献标识码:A

Control optimization of copper flash smelting process based on genetic algorithms

WANG Jin-liang1, 2, LU Hong3, ZENG Qing-yun1, 2, ZHANG Chuan-fu2

(1. Faculty of Material and Chemistry Engineering,Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

3. Faculty of Information Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: Based on the built neural network model, the technological parameters of copper flash smelting process were optimized to make energy consume the lowest by using genetic algorithms when the technological objects ranged in control scope. The simulation results show that the optimizing value of air is 15 011 m3, distribution wind is 1 302 m3, technological oxygen is 17 359 m3, central oxygen is 1 000 m3 and flux is 13.6 t, when the converted ratio of the marketable price of air is 0.05, distribution wind is 0.1, technological oxygen is 0.4, central oxygen is 0.45, and the concentrate mass is 128 t, the mass fractions of components of the concentrate are Cu 20.61%, S 27.59%, Fe 24.72%, SiO2 11.64% and MgO 1.39%, respectively. Compared with the practical average data, the energy consume can be reduced by 4.6% if the smelting process is controlled by adopting the optimizing technological parameters.

Key words: copper flash smelting; neural network; genetic algorithms; control optimization

由于铜闪速炉炉体结构较复杂,炉内物理化学反应迅速,属高温、多相、多组分反应,相关因素多变、不确定,难以用实验手段来模拟熔炼过程,因而借助数学和计算机技术来模拟其过程的方法一直受到冶金工作者的重视和关注[1-4],但关于铜闪速熔炼过程控制优化问题的研究报道很少。

为了实现铜闪速熔炼生产稳定、炉体寿命长、产品优质的目标,关键要控制铜锍温度、铜锍品位及渣含Fe/SiO2在一定的范围,而这3个工艺指标实质上是通过分别控制富化率(总氧量/氧和风的总体积)、吨矿氧量(总氧量/精矿量)及熔剂率(熔剂量/精矿量)来实现的[5]。

在文献[6]中,为了使铜闪速熔炼神经网络模型能直接反映上述控制策略,同时考虑精矿的主要成分 对产物质量的影响,其作者将空气、分配风、工艺氧、中央氧、熔剂量、精矿量及其各成分含量等工艺参数进行了转换处理,得到富化率、吨矿氧量、熔剂率、Cu量、S量、Fe量、SiO2量和MgO量等8个参数,并将其作为神经网络的输入层节点,分别建立了网络结构为8-16-1的铜锍品位模型、8-20-1的铜锍温度模型和8-20-1的渣含Fe/SiO2模型;模型能根据输入参数较正确地预测铜锍品位、铜锍温度及渣含Fe/SiO2值,具有良好的泛化能力和自适应能力,可与其它优化算法相结合,用于铜闪速熔炼过程的控制优化。

本文作者基于已建立的铜闪速熔炼神经网络模型,提出并分析了铜闪速熔炼过程的控制优化问题,即使闪速炉能生产出高质量产品的同时,处理每吨铜精矿的能耗费用最低,之后构造了目标函数和适应度函数,根据实际生产数据及控制目标,确定了优化所需参数值,最后用遗传算法对该优化问题进行了求解,在工艺指标控制范围内搜索能耗最低点,据此确定工艺参数的优化值。

1 铜闪速熔炼的控制优化问题

铜闪速熔炼过程的能耗控制优化,就是当投入一定量和一定成分的精矿时,寻找一个优化点,使得工艺指标(包括铜锍品位、铜锍温度和渣含Fe/SiO2)和工艺参数(包括空气、分配风、工艺氧、中央氧和熔剂)都在一定的范围,且能耗费用E最小。这个优化问题属于一个非线性约束下的单目标优化问题,可归纳如下:

(1)

(1)

式中 E为能耗函数,也是优化目标,将其定义为

(2)

(2)

式中 αi(i=1, 2, 3, 4)分别为空气、分配风、工艺氧和中央氧的实际价格的折合比值,单位为元/单位体积;ci(i=1, 2, 3, 4)分别代表空气、分配风、工艺风和中央氧的实际投入体积数,c5对应于熔剂实际投入量,但由于它的量变化较小,所以没有将其纳入能耗函数; 和

和 分别为它们的取值最小值和最大值。φj(j=1, 2, 3)分别为代表工艺指标铜锍品位、铜锍温度和渣含Fe/SiO2的实际值,它们是具有非线性关系的工艺参数,用所建立的铜闪速熔炼神经网络表达。

分别为它们的取值最小值和最大值。φj(j=1, 2, 3)分别为代表工艺指标铜锍品位、铜锍温度和渣含Fe/SiO2的实际值,它们是具有非线性关系的工艺参数,用所建立的铜闪速熔炼神经网络表达。 和

和 分别为它们的取值最小值和最大值,也即工艺指标的控制范围。

分别为它们的取值最小值和最大值,也即工艺指标的控制范围。

铜闪速熔炼过程的控制优化实质上就是用有效的优化算法对式(1)进行求解。

2 遗传控制优化流程

遗传算法基于生物进化的思想,将优化计算中的迭代过程模拟成物种进化过程[7],目前已被成功地应用于多个领域[8-11]。因为其解的多样性和计算的并行性,遗传算法较好地解决了传统算法易于陷入局部最优的问题,其另一个显著特点就是对于所解的优化问题没有太多的数学要求,可以处理任意形式的目标函数和约束,特别适合处理传统搜索方法所不能解决的复杂问题和非线性问题[12]。

铜闪速熔炼过程遗传控制优化的主要过程如下:

1) 编码 将决策变量,也即工艺参数ci (i=1, 2, 3, 4, 5)进行二进制编码[13]。

2) 初始化群体 随机产生一系列的染色体,每个染色体代表一个个体(包括所有工艺参数的编码),一定数量的个体组成原始群体。

3) 解码 将各工艺参数的二进制编码变成十进制数,得到真正的工艺参数值,这里隐含了条件 的满足。

的满足。

4) 预处理和归一化处理 预处理是将空气、分配风、工艺氧、中央氧、熔剂量、精矿量及其各成分含量等工艺参数值进行转换处理,得到富化率、吨矿氧量、熔剂率、Cu量、S量、Fe量、SiO2量和MgO量等8个输入参数值[6]。归一化处理是将输入参数值转换到0~1之间。

5) 适应度的计算 主要包括取训练好的神经网络模型(包括网络拓扑结构、网络权值、阈值等),并以归一化处理后的8个输入参数值为输入,进行网络前向计算;根据得到的输出值φj(j=1, 2, 3)以及优化目标函数E、适应度函数F,得到相应的适应度。其中适应度函数构造为

(3)

(3)

该函数的含义为:当工艺指标在控制范围内 时,适应度Fitness与优化目标函数值E成反比,否则为0。常数9 000是为了使适应度不会太小而设立的。

6) 满足终止条件就退出,打印出优化结果;否则进入下一步。

7) 对工艺参数编码进行选择、交叉和变异等操作[14-15],得到新的编码群体,返回步骤3。

3 遗传控制优化的实现

铜闪速熔炼过程的控制优化是基于一定量和一定成分的精矿量的,于是首先应该给定精矿量及其主要成分含量。根据某厂实际生产数据,取其数据列于表1。

表1 铜精矿量及其成分

Table 1 Mass and composition of copper concentrate

要进行优化还要进行以下设置。

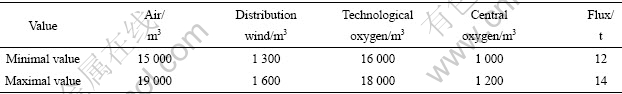

1) 工艺参数和工艺指标的范围设置

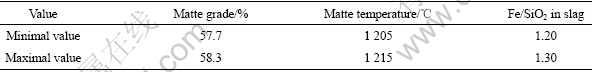

工艺指标一般在一定时期都相对固定,而工艺参数的波动范围相对较大,当然它们都可以由决策者和操作者确定。本文作者根据采集样本时的工艺指标和工艺参数值,将它们的值确定为如表2、表3所列。

表2 工艺参数的波动范围

Table 2 Wave scope of technological parameters

表3 工艺指标的控制范围

Table 3 Control scope of technological objects

2) αi(i=1, 2, 3, 4)的确定

根据市场行情不同它们会有所波动,本研究取空气、分配风、工艺氧和中央氧的实际价格折合比值分

别为0.05,0.1,0.4和0.45 yuan/m3。

3) 遗传算法参数的确定

①编码长度取决于工艺参数的编码精度,由表2数据可知,变化范围最大的工艺参数是空气量(变化量为4 000),当编码长度取10时,其精度为3.91,满足生产要求,故编码长度取10即可。

②当群体小于某个数时,网络很难进化;但随群体的增大,训练时间也相应加长,经训练发现群体大小取20时较好。

③交叉概率决定随机配对的两个染色体是否进行基因链的交换,从而产生新的染色体,对遗传进化起到全局支配的作用。交叉概率小了起不到全局搜索作用,大了进化又慢,效果反而不好。通过训练发现取0.75时较好。

④当变异概率太大时,容易将种群中优良的染色体破坏,而太小时因得不到足够的变异而使进化停 滞,经训练发现变异概率取0.05时较好。

⑤适应度指数变换系数取1.5;终止条件使用最大迭代次数,取值为1 000。

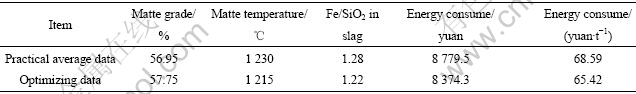

经以上设置后,就可按上述遗传控制优化流程进行优化求解了。优化开始对各工艺参数的10位数的编码进行初始化处理,得到20个染色体组成的初始群体,然后解码,得到空气、分配风、工艺氧、中央 氧、熔剂量的实际值。再根据设置的精矿量及其成 分,进行预处理和归一化处理,得到20组输入样本(每组包括富化率、吨矿氧量、熔剂率、Cu量、S量、Fe量、SiO2量和MgO量等8个输入参数值),将其分别输入铜锍品位神经网络模型、铜锍温度神经网络模型及渣含Fe/SiO2神经网络模型,分别得到20组输出 值(每组包括铜锍品位、铜锍温度和渣含Fe/SiO2的值),然后根据适应度函数F求出各染色体的适应度,再进行选择、交叉和变异操作,生成下一代群体。就这样周而复始,直到遗传代数达到1 000次,取迄今适应度最高的染色体,进行解码,即得到工艺参数的优化值,分别是空气15 011 m3、分配风1 302 m3、工艺氧17 359 m3、中央氧1 000 m3、熔剂13.6 t,而此染色体所对应的各网络输出,即为优化工艺参数条件下的工艺指标值,如表4所列。

表4 精矿量及其成分相同时优化值与某厂实际值的比较

Table 4 Comparison between optimizing data and practical data under the same condition of mass and composition of concentrate

由表4可知,与实践平均值相比,采用优化工艺参数控制时,总能耗降低405.2元,吨矿能耗降低3.17元,若以1年为300个工作日、日处理铜精矿量为2 000 t来计算,优化控制每年能节约的能耗费用为1 902 000元;相应的工艺指标值比实际生产值更能达到控制要求。

4 结论

1) 遗传算法与神经网络技术的结合在铜闪速熔炼过程的控制优化中应用是可行的,能有效解决铜闪速熔炼过程高温、炉型及反应复杂、因素多变而不确定、难以建立工业在线控制机理模型的问题。

2) 对某厂实际操作数据仿真优化计算结果表明,若采用以能耗最低为目标的遗传优化工艺参数进行控制,铜闪速熔炼平均可降低能耗费用4.6%。

3)结合实时的生产数据和具体的控制要求,该建模与控制优化方法可应用于辅助决策铜闪速熔炼过程的优化控制,同时还可推广应用于其它难以用传统的数学方法及冶金机理建立控制模型的火法冶金过程。

REFERENCES

[1] 张传福, 谭鹏夫, 李作刚, 曾德文,吴翠云. 第ⅤA族元素在铜熔炼过程中分配行为的数学模型[J]. 中南工业大学学报, 1995, 26(3): 343-348.

ZHANG Chuan-fu, TAN Peng-fu, LI Zuo-gang, ZENG De-wen, WU Cui-yun. Mathematical model of distribution behaviors of the ⅤA elements in copper smelting[J]. Journal of Center South University of Technology, 1995, 26(3): 343-348.

[2] 谭鹏夫, 张传福, 李作刚, 曾德文,吴翠云. 在铜熔炼过程中第ⅤA族元素分配行为的计算机模型[J]. 中南工业大学学报, 1996, 26(4): 479-483.

TAN Peng-fu, ZHANG Chuan-fu, LI Zuo-gang, ZENG De-wen, WU Cui-yun. Computer model of distribution behaviors of the ⅤA elements in copper smelting[J]. Journal of Center South University of Technology, 1996, 26(4): 479-483.

[3] 黎书华, 黄克雄, 梅显芝. 贵溪闪速炉铜锍熔炼过程热力学模型[J]. 中南工业大学学报, 1995, 26(5): 627-631.

LI Shu-hua, HUANG Ke-xiong, MEI Xian-zhi. Thermodynamic model of Guixi flash furnace process for copper matte smelting[J]. Journal of Center South University of Technology, 1995, 26(5): 627-631.

[4] 黄克雄, 黎书华, 尹爱君, 梅显芝. 贵溪闪速炉造锍熔炼过程计算机模拟[J]. 中南工业大学学报, 1996, 27(2): 173-176.

HUANG Ke-xiong, LI Shu-hua, YIN Ai-jun, MEI Xian-zhi. Computer simulation of Guixi flash furnace process for copper matte smelting[J]. Journal of Center South University of Technology, 1996, 27(2): 173-176.

[5] Davenport W G, Partelpoeg E H. Flash Smelting Analysis, Control and Optimization[M]. New York: Pergamon Press, 1987.

[6] 曾青云, 汪金良. 铜闪速熔炼神经网络模型的建立[J]. 南方冶金学院学报, 2003, 24(5): 15-18.

ZENG Qing-yun, WANG Jin-liang. Building of the copper flash smelting model based on neural network[J]. Journal of Southern Institute of Metallurgy, 2003, 24(5): 15-18.

[7] Holland J H. Adaptation in Natural and Artificial Systems[M]. Cambridge: MIT Press, 1975: 26-42.

[8] Deb K, Goyal M. A robust optimization procedure for mechanical component design based on genetic adaptive search[J]. Journal of Mechanical Design, 1998, 120(2): 162-164.

[9] 姚俊峰, 梅 炽, 彭小奇. 改进的混沌遗传算法及其在炼铜转炉操作优化中的应用[J]. 中国有色金属学报, 2001, 11(5): 920-924.

YAO Jun-feng, MEI Chi, PENG Xiao-qi. Modified chaos genetic algorithm and its application on operation-optimization of copper smelting converter[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 920-924.

[10] 李 劼, 刘代飞, 秦庆伟. 基于GA-BP的NiFe2O4基金属陶瓷阳极优化设计[J]. 中国有色金属学报, 2006, 16(2): 351-356.

LI Jie, LIU Dai-fei, QIN Qing-wei. Optimization designs of NiFe2O4 cermet inert anodes based on GA-BP hybrid neural network[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 351-356.

[11] 李 萍, 薛克敏. 基于人工智能的钛合金热变形工艺参数优化[J]. 中国有色金属学报, 2006, 16(7): 1202-1206.

LI Ping, XUE Ke-min. Optimization of hot deformation process for titanium based on artificial intelligence[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1202-1206.

[12] 陈霁威, 乐慧丰, 黄 道. 基于神经网络和遗传算法的在线优化软件设计与实现[J]. 华东理工大学学报, 2002, 28(4): 419-422.

CHEN Ji-wei, LE Hui-feng, HUANG Dao. Design and implementation of online optimization software based on neural networks and genetic algorithms[J]. Journal of East China University of Science and Technology, 2002, 28(4): 419-422.

[13] 陶海红, 王 伶, 廖桂生. 基于遗传算法的最优参差码搜索[J]. 系统工程与电子技术, 2004, 26(6): 711-713.

TAO Hai-hong, WANG Ling, LIAO Gui-sheng. Optimal selection of nonuniform code of radar using the genetic algorithm[J]. Systems Engineering and Electronics, 2004, 26(6): 711-713.

[14] 陈国良, 王熙法, 庄镇泉, 王东生. 遗传算法及其应用[M]. 北京: 北京邮电出版社, 1996. 59-122.

CHEN Guo-liang, WANG Xi-fa, ZHUANG Zhen-quan, WANG Dong-sheng. Genetic algorithms and application[M]. Beijing: Posts and Telecom Press, 1996. 59-122.

[15] 靖稳峰, 魏 红, 段惠娣. 遗传算法及其发展现状[J]. 西安工业学院学报, 2000, 20(3): 230-235.

JING Wen-feng, WEI Hong, DUAN Hui-di. Overview of genetic algorithms and their present development[J]. Journal of Xi’an Institute of Technology, 2000, 20(3): 230-235.

基金项目:国家自然科学基金资助项目(50364004);江西省自然科学基金资助项目(0250026)

收稿日期:2006-06-16;修订日期:2006-11-12

通讯作者:曾青云,教授;电话:0797-8312361;E-mail:zengqy3906@sina.com

(编辑 何学锋)