Study on the method of recovering and separating indium from residue containing indium

来源期刊:中南大学学报(英文版)2002年第2期

论文作者:曾冬铭 胡爱平 舒万艮 刘又年 雷存喜

文章页码:104 - 106

Key words:residue containing indium; indium; iron; recovery

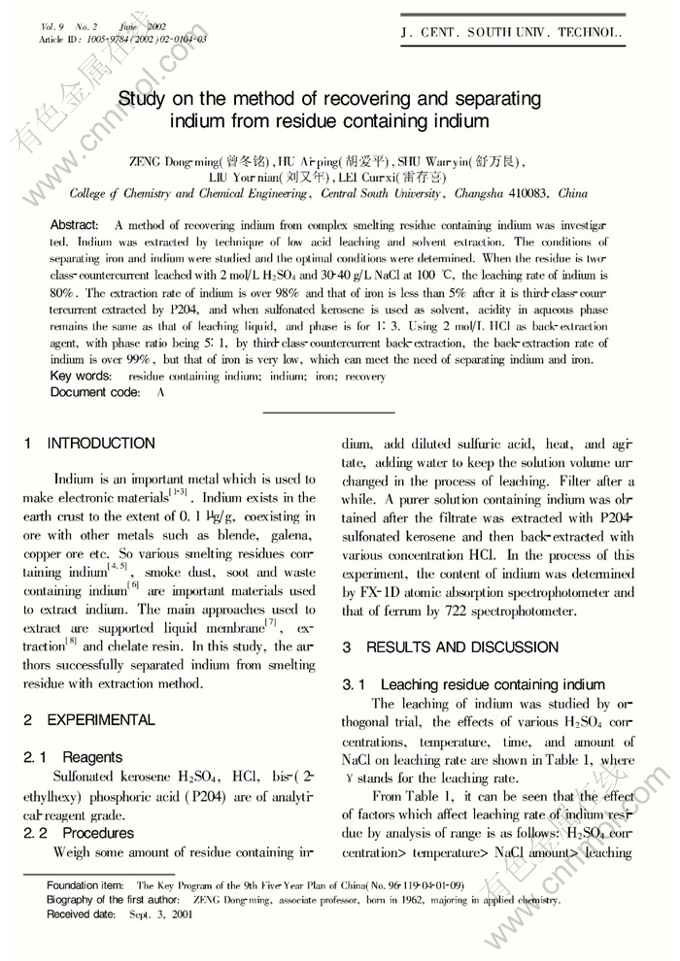

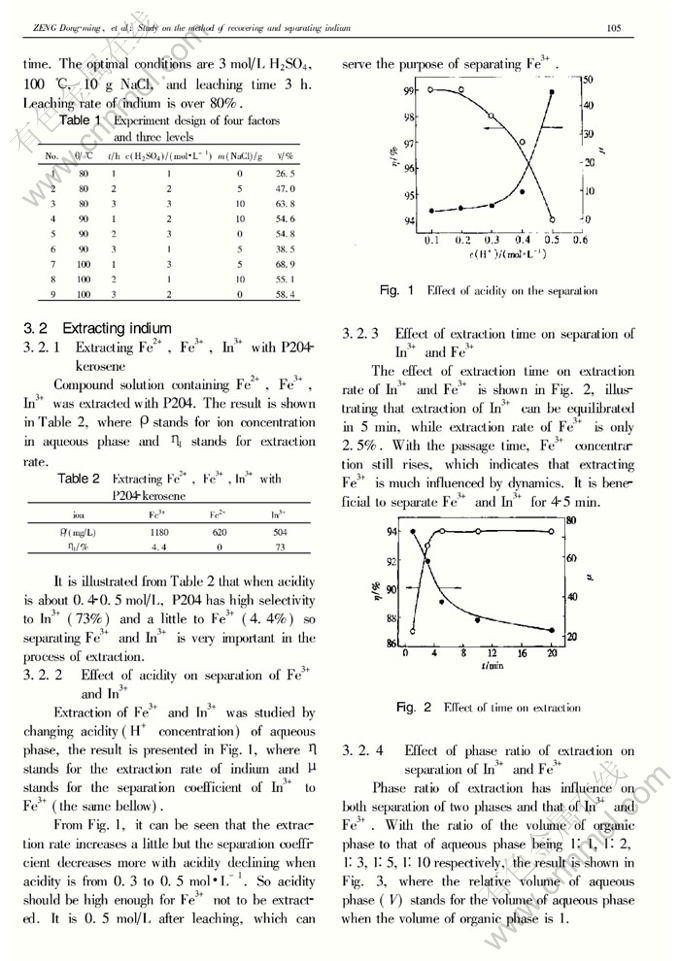

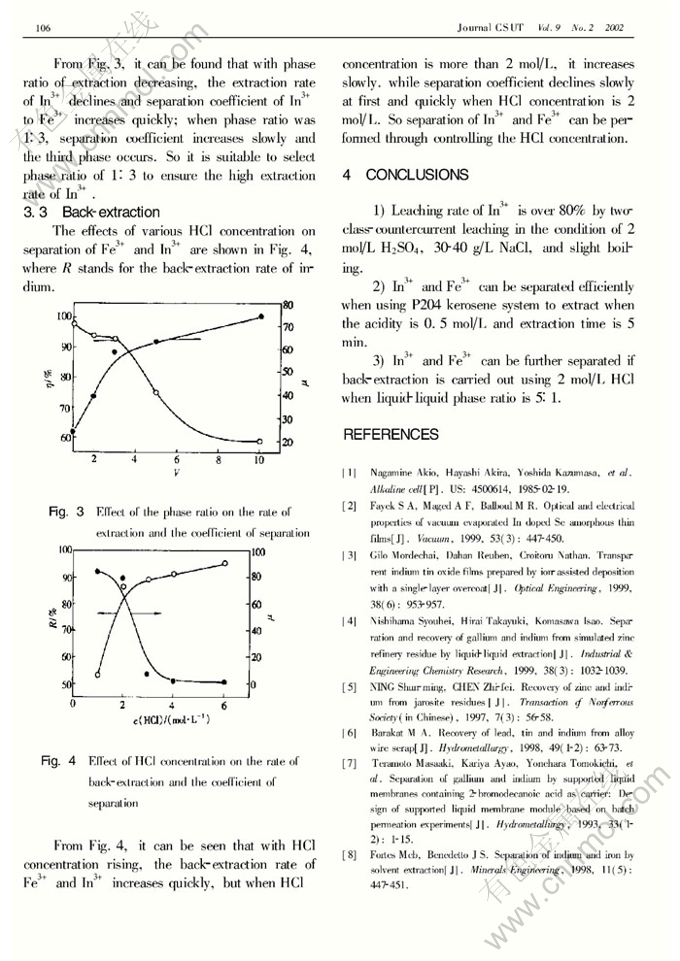

Abstract: A method of recovering indium from complex smelting residue containing indium was investigated. Indium was extracted by technique of low acid leaching and solvent extraction. The conditions of separating iron and indiumwere studied and the optimal conditionswere determined. When the residue is two-class-countercurrent leached with 2 mol/LH2SO4and 30-40 g/LNaCl at100℃, the leachingrate of indium is 80%. The extraction rate of indium is over 98% and that of iron is less than 5% after it is third-class-coun-tercurrent extracted by P204, and when sulfonated kerosene is used as solvent, acidity in aqueous phase remains the same as that of leaching liquid, and phase is for 1∶3. Using 2 mol/L HCl as back-extraction agent, with phase ratio being 5∶1, by third-class-countercurrent back-extraction, the back-extraction rate of indium is over 99%, but that of iron is very low, which can meet the need of separating indium and iron.