文章编号: 1004-0609(2005)12-1933-05

2D Cf/SiC-Cu复合材料的制备和性能

简 科, 陈朝辉, 胡海峰, 王其坤, 马青松

(国防科技大学 航天与材料工程学院, 国防科技重点实验室, 长沙 410073)

摘 要: 针对固体火箭发动机喉衬的使用工况, 提出并采用先驱体转化法制备了一种新型的复合材料, 2D Cf/SiC-Cu材料(其中Cu作为发汗剂), 对其力学性能和烧蚀性能进行了考察。 结果表明: 采用先驱体转化法可以制备出力学性能较好的2D Cf/SiC-Cu材料, 弯曲强度、 剪切强度和断裂韧性分别达到263MPa, 27.7MPa和15.7MPa·m1/2。 材料密度为2.24g/cm3, 在氧乙炔焰中烧蚀60s后, 材料结构保持完整, 力学性能仍能满足喉衬材料的使用要求, 质量损失为0.124g。 因此, 2D Cf/SiC-Cu材料具有较低的密度、 良好的力学性能和较好的抗烧蚀性能, 是一种有希望的固体火箭发动机喉衬备选材料。

关键词: 2D Cf/SiC-Cu材料; 先驱体转化; 烧蚀性能; 力学性能 中图分类号: TB323

文献标识码: A

2D Cf/SiC-Cu composites fabricated by precursor pyrolysis

JIAN Ke, CHEN Zhao-hui, HU Hai-feng, WANG Qi-kun, MA Qing-song

(Key Laboratory of Advanced Ceramic Fibers and Composites,

College of Aerospace and Materials Engineering,

National University of Defense Technology, Changsha 410073, China)

Abstract: Based on the working environments of the solid rocket nozzle throat, a proposal to improve anti-ablative property of 2D C/SiC composites by introduction of Cu into C/SiC composites and decreasement of surface temperature through Cu transpiration was presented. 2D C/SiC-Cu composites were prepared by precursor infiltration and pyrolysis. The mechanical properties and ablative properties were investigated. The flexural strength, shear strength and fracture toughness of the 2D Cf/SiC-Cu composites reach 263MPa, 27.7MPa and 15.7MPa·m1/2, respectively. The desity of the samples is 2.24g/cm3, and the samples mass loss is 0.124g when exposed for 60s in a flowing oxyacetylene torch environment. The mechanical properties of 2D Cf/SiC-Cu composites could still satisfy the requirements of the solid rocket nozzle throat. Compared to other throat materials, 2D Cf/SiC-Cu composites has lower density and better ablative properties.

Key words: 2D Cf/SiC-Cu composites; preceramic polymer pyrolysis; ablative properties; mechanical properties

喉衬是固体火箭发动机的关键部件, 其使用条件恶劣, 目前使用的喉衬材料均存在一些不足, W/Cu材料密度过大[1]; 石墨材料及石墨渗铜强度较差、 烧蚀率大、 热震性能差[2]; C/C材料存在烧蚀率大、 抗冲刷性差等缺点[3]。 解决的方法主要有两种: 第一种方法是对现有的材料体系进行改进。 目前国外在该领域已开展广泛研究, 如俄罗斯采用类似钨渗铜工艺对C/C材料浸渗Cu制成含铜C/C抗烧蚀涂层的喉衬材料, 经燃气温度3800℃、 压力8.0MPa、 工作时间60s的地面点火试验, 烧蚀率较纯C/C材料成倍降低; 美国也在进行该领域的研究, 开发了一种混合涂覆HfB+SiC的炭/炭复合材料, 经试验表现出良好的抗烧蚀性能[4]。 国内也在积极开展这方面的研究, 西安航天43所通过在炭/炭复合材料加入适量难熔金属炭化物来提高材料的抗烧蚀性能, 取得了较好效果; 中南大学通过工艺优化, 所制备的C/C喉衬材料性能达到国际先进水平[3]。

第二种方法是开发密度较小、 烧蚀性能优异的新型喉衬材料。 关于这方面的文献报道较少。 而Cf/SiC体系具有良好的耐高温、 抗氧化和抗热震等优点, 是目前研究最为深入的高温热结构材料之一。 但SiC基体的分解温度为2700℃、 软化点约2000℃, 不能满足火箭发动机喉衬等部件大于3000℃的使用要求。 本文作者提出并采用先驱体转化法制备了一种新型的材料体系, 即在Cf/SiC复合材料中引入铜, 以期在保持Cf/SiC复合材料优良性能的同时通过材料基体中铜的气化带走大量热量, 为材料提供良好的冷却效果, 降低材料的表面温度和烧蚀率, 从而满足使用要求。

1 实验

1.1 原料

碳纤维布: 吉林碳素厂生产的粗纱平纹布, 丝束3K, 厚度0.24mm, 碳纤维单丝强度3.57GPa。

先驱体聚碳硅烷由国防科技大学新型陶瓷纤维及其复合材料国防科技重点实验室合成, 淡黄色固体, 软化点为217~227℃。

二乙烯基苯(DVB): 株洲化工厂生产, 工业纯, 淡黄色透明液体, 作为PCS的交联剂。

α-SiC(粒度1.0μm): 郑州第二砂轮厂生产, 密度3.2g/cm3, 作为惰性填料。

铜粉(粒度150μm): 中南大学生产, 密度8.9g/cm3, 作为填料。

1.2 试样制备

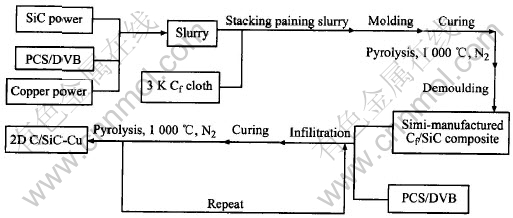

将一定配比的PCS、 DVB、 Xylene、 SiC微粉、 Cu粉配成浆料。 将碳纤维布裁成一定形状, 铺入模具中, 均匀、 适量地涂刷含铜浆料, 然后模压成坯体, 交联后裂解, 脱模得到层压板预成型体。 再经过反复先驱体(PCS/DVB)浸渍—交联—裂解过程来使预成形体致密化, 制得致密的含铜碳纤维布增强碳化硅复合材料。 工艺路线如图1所示。

1.3 测试方法

采用体积法测试试样密度。

采用CSS-1101系列电子万能试验机测试试样的室温力学性能。 采用三点弯曲法测试材料的弯曲强度, 跨高比为15, 加载速率0.5mm/min。 采用单边切口梁法测试材料的断裂韧性, 加载速率0.05mm/min。 采用短梁法测试材料的剪切强度, 跨高比为5, 加载速率0.5mm/min。

材料的抗烧蚀性能测试参照GJB 323A—96标准, 采用质量烧蚀率来表征材料的抗烧蚀性能。

采用330万像素的数码相机观测材料的宏观形貌, 采用JSM-5600LV扫描电镜(SEM)观察试样断口及纤维拔出情况。

2 结果与讨论

2.1 2D Cf/SiC-Cu材料的力学性能

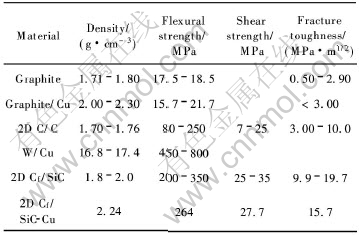

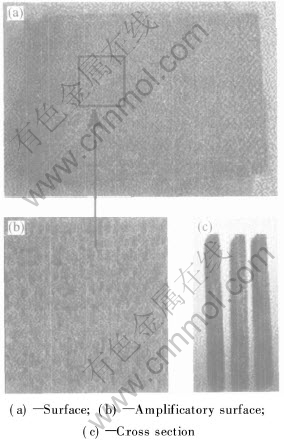

经过9个浸渍—交联—裂解周期后, 2D Cf/SiC-Cu材料的密度达到2.24g/cm3, 材料的力学性能见表1。 可以看出, 与目前使用的几种喉衬材料相比, 2D Cf/SiC-Cu材料具有较低的密度和较好的力学性能。 图2所示为2D Cf/SiC-Cu材料的宏观形貌, 可以看出, 铜在材料中分布比较均匀(图2(b)中浅色部分为铜)。

图1 2D Cf/SiC-Cu材料的制备

Fig.1 Fabrication of 2D Cf/SiC-Cu composite

表1 几种喉衬材料的密度与力学性能[3-12]

Table 1 Density and mechanical properties of several throat materials[3-12]

图2 2D Cf/SiC-Cu材料的宏观形貌

Fig.2 Macrophotos of 2D Cf/SiC-Cu composites

图3 2D Cf/SiC-Cu材料的载荷—位移曲线

Fig.3 Load—displacement curves of 2D Cf/SiC-Cu composites

图4 2D Cf/SiC-Cu 材料断口的SEM形貌

Fig.4 SEM morphology of fracture surfaces of 2D Cf/SiC-Cu composites

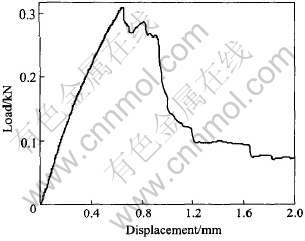

图3所示为材料的载荷位移曲线。 可以看出, 材料的断裂过程明显可分为线性和非线性两个阶段, 当载荷达到最大值后材料仍然具有一定的承载能力, 表现出典型的韧性断裂模式[10]。 图4所示为2D Cf/SiC-Cu材料的断口形貌。 可以看出, 材料断裂时有纤维脱粘现象和较多的纤维拔出, 拔出长度也较长, 表明纤维与基体间界面结合较弱。 从载荷位移曲线和材料的断口形貌分析可知, 2D Cf/SiC-Cu材料中碳纤维起到了较好的增韧作用[12]。

2.2 2D Cf/SiC-Cu材料的抗烧蚀性能

参照GJB 323A—96标准, 采用氧乙炔焰烧蚀质量损失率来表征材料的抗烧蚀性能。 在烧蚀过程中火焰颜色呈绿色并有轻烟逸出, 材料在烧蚀的过程中存在铜的气化过程, 同时带走大量热量。 烧蚀实验完成后材料如图5所示, 材料结构保持完整, 没有出现明显的破坏与分层, 在火焰中心区(A区)由于温度高, 热流量很大, 材料烧蚀较为严重, 在材料表面形成一个凹坑。 在靠近中心处有一个面积较大的环状区(B区)。 最外层由于离火焰中心区较远, 材料烧蚀不明显, 只有部分碳化硅基体氧化, 在表面形成白色二氧化硅膜。

图5 2D Cf/SiC-Cu材料烧蚀60s后的光学照片

Fig.5 Optic photo of 2D Cf/SiC-Cu composites exposed for 60s in flowing

oxyacetylene torch environment

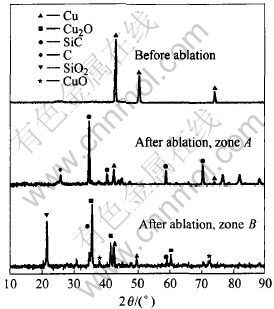

图6 2D Cf/SiC-Cu复合材料表面的X射线衍射谱

Fig.6 XRD patterns of paralysis products of 2D Cf/SiC-Cu composites

为了分析材料烧蚀后表面物质组分与结构, 对烧蚀后材料表面进行X射线衍射分析, 结果如图7所示。 可以看出, 材料烧蚀前材料中铜峰很强, SiC峰和C峰被掩盖; 烧蚀实验后, 火焰中心区铜的含量大大下降, 以SiC基体、 碳和残余铜为主, 而SiC基体氧化生成的SiO2在高温和气流的作用下向周边扩散, 因此, 在火焰中心区的SiO2峰不明显, 而在B区SiO2峰较强。 高温下SiO2膜的形成有助于提高材料的抗氧化性能, 而SiO2的流动能够弥补一部分微孔, 有助于保持材料烧蚀后的结构完整性[11]。 同时X射线衍射分析还表明, B区表面以Cu2O为主, 同时还存在少量的CuO。

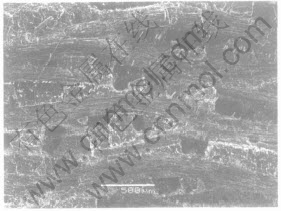

图7 2D Cf/SiC-Cu材料烧蚀实验后的SEM像

Fig.7 SEM image of 2D Cf/SiC-Cu composites after ablation test

材料在烧蚀实验后力学性能有一定程度的下降, 在靠近火焰中心区(A区), 材料的弯曲强度只有80.7MPa, 强度保留率仅为30.6%。 在B区, 材料的弯曲强度为124.2MPa, 强度保留率为47.1%。 材料烧蚀后强度下降的主要原因在于以下几个方面: 首先, 在烧蚀过程中基体中铜消耗后在材料中留下大量孔隙(断口形貌如图7所示), 这些孔隙既不利于纤维与基体间载荷的传递, 又形成了应力集中源, 导致了材料性能的下降[12]; 其次, 在高温过程中碳纤维的氧化导致了纤维强度的下降, 也造成了材料性能的下降。 虽然材料烧蚀后材料的力学性能有较大下降, 但仍远高于石墨材料和石墨渗铜材料, 可以满足固体火箭喉衬材料的使用要求。

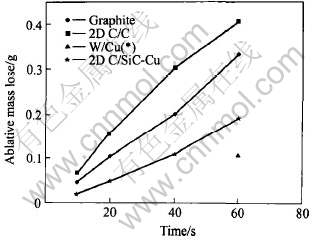

2D Cf/SiC-Cu材料与其余几种典型高温材料的质量烧蚀率对比如图8所示(其中, W/Cu数据来自文献[13])。 烧蚀60s后, 2D Cf/SiC-Cu材料的质量损失明显小于2D C/C材料和石墨材料, 略大于W/Cu材料。 然而, W/Cu材料具有很高的密度, 约为17.0g/cm3, 将近是2D Cf/SiC-Cu材料的8倍。 因此, 与传统的喉衬材料相比, 2D Cf/SiC-Cu材料具有较低的密度和良好的抗烧蚀性能, 极具应用前景。

图8 几种喉衬材料的氧乙炔焰质量烧蚀率

Fig.8 Mass loss of several throat materials

in oxygen-acethylene flame

REFERENCES

[1]宋桂明, 周玉, 王玉金, 等. 固体火箭发动机喉衬材料[J]. 固体火箭技术, 1998, 21(2): 51-55.

SONG Gui-ming, ZHOU Yu, WANG Yu-jin, et al. Throat materials for solid rocket motors[J]. J Solid Rocket Technology, 1998, 21(2): 51-55.

[2]陈伟, 邝用庚, 周武平, 等. 中国高温用钨铜复合材料的研究现状[J]. 稀有金属材料与工程, 2004, 33(1): 11-14.

CHEN Wei, KUANG Yong-geng, ZHOU Wu-ping, et al. Current research status of W-Cu composites for high temperature in China[J]. Rare metal materials and Engineering, 2004, 33(1): 11-14.

[3]苏君明, 陈林泉, 王书贤, 等. 石墨渗铜喉衬的烧蚀特性[J]. 固体火箭技术, 2004, 27(1): 69-72.

SU Jun-ming, CHEN Lin-quan, WANG Shu-xian, et al. The erosive property of copper-infiltrated graphite throat insert[J]. J Solid Rocket Technology, 2004, 27(1): 69-72.

[4]左劲旅, 张红波, 熊翔, 等. 喉衬用炭/炭复合材料研究进展[J]. 炭素, 2003, 114(2): 7-10.

ZUO Jin-lü, ZHANG Hong-bo, XIONG Xiang, et al. Evovle of a research of C/C composites used for nozzle throat[J]. Carbon, 2003, 114(2): 7-10.

[5]冉宏星, 崔红, 郝志彪, 等. 几种喉衬材料断裂韧性的比较[J]. 新型炭材料, 2002, 17(1): 30-35.

RAN Hong-xing, CUI Hong, HAO Zhi-biao, et al. The fracture toughness of several rocket nozzle throat materials[J]. New Carbon Materials, 2002, 17(1): 30-35.

[6]Levine S R, Opila E J, Halbig M C, et al. Evaluation of ultra-high temperature ceramics for aeropropulsion use[J]. J European Ceramic Soc, 2002, 22(2): 2757-2767.

[7]苏君明, 陈林泉, 王书贤, 等. 石墨渗铜喉衬材料的微观结构与抗热震性能[J]. 固体火箭技术, 2003, 26(3): 58-61.

SU Jun-ming, CHEN Lin-quan, WANG Shu-xian, et al. The microscopic structure and thermal shock resistance of copper-impregnated graphite throat insert material[J]. J Solid Rocket Technology, 2003, 26(3): 58-61.

[8]简科, 陈国民, 陈朝辉, 等. SiC微粉含量对先驱体转化制备碳纤维布增强碳化硅复合材料性能的影响[J]. 材料工程, 2003, 12: 23-26.

JIAN Ke, CHEN Guo-min, CHEN Zhao-hui, et al. Effect of SiC powder content on the mechanical properties of carbon fiber cloth reinforced SiC composites fabricated via precursor pyrolysis[J]. Journal of Materials Engineering, 2003, 12: 23-26.

[9]JIAN Ke, CHEN Zhao-hui, MA Qing-song, et al. Effects of pyrolysis processes on the microstructures and mechanical properties of Cf/SiC composites using polycarbosilane[J]. Mater Sci Eng A, 2005, A390(1-2): 154-158.

[10]MA Qing-song, CHEN Zhao-hui, ZHENG Wen-wei, et al. Mechanical properties of Cf/Si-O-C composites prepared by hot-pressing assisted pyrolysis of polysiloxane[J]. Trans Nonferrous Met Soc China, 2004, 14(3): 480-484.

[11]徐永东, 成来飞, 张立同, 等. 连续纤维增韧碳化硅陶瓷基复合材料研究[J]. 硅酸盐学报, 2002, 30(2): 184-188.

XU Yong-dong, CHENG Lai-fei, ZHANG Li-tong, et al. Research on continuous fiber reinforced silicon carbide composites[J]. J Chinese Ceramic Society , 2002, 30(2): 184-188.

[12]MA Qing-song, CHEN Zhao-hui, ZHENG Wen-wei. Microstructures and mechanical properties of three-dimensional Cf/Si-O-C composites fabricated by polysiloxane pyrolysis[J]. Journal of Materials Science, 2004, 39(11): 3809-3812.

[13]崔红, 苏君明, 李瑞珍, 等. 添加难熔碳化物提高炭/炭复合材料抗烧蚀性能的研究[J]. 西北工业大学学报, 2000, 18(4): 669-673.

CUI Hong, SU Jun-ming, LI Rui-zhen, et al. On improving anti-ablation property of multi-matrix C/C withstand 3700K[J]. Journal of Northwestern Polytechnical University, 2000, 18(4): 669-673.

基金项目: 国防预研基金资助项目(51488030105ZS9504)

收稿日期: 2005-01-26; 修订日期: 2005-09-06

作者简介: 简 科(1979-), 男, 博士研究生

通讯作者: 简 科, 电话: 0731-4576441; 传真: 0731-4573165; E-mail: jianke_nudt@sina.com

(编辑陈爱华)