DOI:10.19476/j.ysxb.1004.0609.2017.10.03

镁合金表面激光熔敷+搅拌摩擦加工Al-Cu涂层的显微组织与性能

刘奋军1,姬 妍1,孟庆森2,李增生1,白艳霞1

(1. 榆林学院能源工程学院 榆林市新材料工程技术研究中心,榆林 719000;

2. 太原理工大学 材料科学与工程学院,太原 030024)

摘 要:采用激光熔敷(Laser cladding, LC)和搅拌摩擦加工(Friction stir processing, FSP)相结合技术在AZ31B镁合金表面制备Al-Cu混合粉末的合金化涂层。采用SEM、EDS、XRD以及电化学腐蚀测试系统对Al-Cu涂层的显微组织特征、相组成以及耐腐蚀性能进行测试。结果表明:LC制备的Al-Cu涂层与基体呈良好的冶金结合,涂层主要由α-Mg、β-Al12Mg17及AlCu4组成;LC制备的Al-Cu涂层经FSP之后,涂层表面宏观成型平整光滑,表层组织均匀细化。电化学腐蚀结果发现经FSP后的Al-Cu涂层耐腐蚀性能得到明显提升,自腐蚀电位达到-0.989 V,比LC涂层的自腐蚀电位(-1.457 V)提高32.1%,比母材的自腐蚀电位(-1.563 V)提高36.7%。

关键词:AZ31B;激光熔敷;搅拌摩擦加工;显微组织;耐腐蚀性能

文章编号:1004-0609(2017)-10-1981-07 中图分类号:TG174.4 文献标志码:A

镁合金具有比强度和比刚度高、电磁屏蔽和减震吸冲性能好以及可回收再利用率高等特点,被广泛应用到交通运输业及航空航天制造领域。镁合金被誉为“21世纪绿色工程材料”[1]。然而镁合金化学活性高,在潮湿空气中极易氧化而最终在其表面形成一层疏松多孔的氢氧化物膜,氧化膜在中性或者碱性环境下对镁合金具有一定的保护作用[2]。然而当氧化膜暴露在含氯离子的潮湿空气中时,氧化膜随即被破坏而最终形成氯化钠,镁合金基体得不到保护而继续被腐蚀[2-3]。镁合金耐腐蚀性能差的特点严重阻碍了镁合金作为结构材料的进一步应用。

激光熔敷作为一种切实可行的表面改性技术,通过在镁合金表面直接重熔或熔敷一层合金粉末涂层来提升镁合金表面性能,已经得到长足的发展。张青来等[4]应用激光对AZ31和AZ91镁合金表面进行冲击强化,电化学腐蚀测试结果发现,镁合金表面经激光冲击强化之后,腐蚀电位和电流均正移,且与冲击表面的形变、钝化膜以及形貌有关。李兴成等[5]对AZ31镁合金进行激光冲击处理,动电位扫描技术测试结果发现,激光冲击后自腐蚀电位提高,腐蚀电流增大,抗腐蚀性能有所下降。PAITAL等[6]在镁合金表面LC铝涂层,最终在AZ31B镁合金表面制备了一层均匀连续且富有Al12Mg17金属间化合物的铝涂层,其耐腐蚀性能得到明显提升。通过在镁合金表面制备铝涂层提升其耐腐蚀性能的类似结果在镁合金表面真空镀铝中也得到验证[7]。利用LC技术在镁合金表面熔覆Al-Cu[8-9]、Al-Si[10-11]、Al-SiC[12]以及Al-Si-Al2O3[13]等混合粉末制备改性层,其表面耐腐蚀和耐磨损性能都得到很好的改善。采用LC在镁合金表面制备Al-Cu涂层之后,由于形成了大量的AlCu4和Al12Mg17等高电位化合物使得表面耐腐蚀性能明显提升[8-9]。然而LC所得的改性层通常会在试样表面出现粗糙度大、成型不美观等缺陷,在改性层内部亦会伴有气孔或微裂纹。因此,利用二次加工或者复合技术在镁合金表面制备一层与基体呈良好冶金结合,且表面成型美观的改性层对工程实际应用意义重大。

搅拌摩擦加工是一种新型固相加工技术,利用搅拌头和被加工区域材料之间形成的摩擦热以及材料塑性变形产热的共同作用使得该区域材料发生剧烈的塑性变形,热塑性软化材料在搅拌头的热机搅拌作用下发生挤压破碎和动态再结晶,实现材料显微组织结构的细化、均匀化和致密化,从而改善材料的性能[14-17]。FSP技术在镁合金材料表面区域显微组织结构改变中已经开展相关研究,并取得一定成果。DARRAS等[18]用单道FSP技术在镁合金表面获得一层比母材显微组织明显细化和均匀化的改性层。CAVALIERE等[19]研究发现,经FSP后的AZ91镁合金可获得超塑性,在300 ℃和1×10-4 s-1应变速率下伸长率可达到1050%。LIU等[10-20]利用LC和FSP复合技术在AZ31B镁合金表面制备的Al-Si复合涂层,表层组织明显细化、均匀化和致密化,耐腐蚀性能较AZ31B基体和LC涂层明显提升,可见该复合技术应用于镁合金表面改性切实可行。

本文作者采用大功率激光器预先在AZ31B镁合金表面熔覆一层Al-Cu混合粉末涂层,然后利用单道FSP技术对LC层进行加工,研究FSP对涂层表面成型、相组成、显微组织结构特征及耐腐蚀性能的影响机制。

1 实验

本实验中选用AZ31B镁合金板材,尺寸为150 mm×100 mm×10 mm。所选用Al粉和Cu粉的颗粒度和纯度分别为50 μm和99.95%。混合粉末按照质量分数进行配比,比例为85% Al+15% Cu。LC前,首先将AZ31B欲处理表面进行机械抛光至镜面,然后依次用丙酮、乙醇和去离子水清洗抛光表面;用乙二醇将Al-Cu混合粉末搅拌成胶状,均匀涂敷在镁合金抛光表面上,预置厚度达1 mm;接着将试样放置在干燥通风处,自然风干24 h。采用半导体激光器(SISTAN 3000型)进行熔敷,光斑直径15 mm,焦点位于涂覆层表面,熔敷功率和速度分别为2 kW和280 mm/min,高纯氩气作为保护气体。采用FSW-LC2-3012型二维搅拌摩擦焊机对LC层进行单道次FSP,选用无针搅拌头逆时针旋转加工,轴肩开三螺旋线型沟槽,直径18 mm,倾角2.5°,下压0.2 mm,搅拌头转速和加工速度分别为 1500 r/min和100 mm/min。

采用VEGA3 LCU型扫描电子显微镜以及X-Max 20型能谱分析测试仪分别对Al-Cu涂层的显微组织结构特征和元素分布进行观察与测试。采用Bruker S8 TIGER型X射线衍射仪来确定涂层表层的物相。同时,利用辰华电化学工作站对AZ31B镁合金及涂层进行室温动电位极化曲线测试。腐蚀试样用环氧树脂将其余表面密封,仅暴露出涂层表面用于电化学测试,测试表面用SiC水砂纸进行机械磨抛后用无水乙醇清洗并吹干。采用典型的三电极腐蚀测试系统将试样浸泡在5%(质量分数)NaCl水溶液中,试样暴露面积为1 mm2,且试样作为工作电极,铂电极为辅助电极,饱和银电极为参比电极,扫描速率1 mV/S。

2 结果与讨论

2.1 涂层表面宏观形貌

图1所示为AZ31B表面经LC和LC+FSP之后Al-Cu改性层宏观成型形貌。由图1可见,LC层表面粗糙度较大,飞溅物较多,整体宏观成型较差;LC的Al-Cu涂层经FSP之后,改性层表面光滑平整,加工区无沟槽和微裂纹,成型美观。这是由于FSP过程中,LC的Al-Cu涂层高度软化,热塑性软化材料在搅拌头轴肩的旋转摩擦和挤压成型作用下而最终形成平整光滑的表面。

图1 镁合金表面LC和LC + FSP加工的Al-Cu涂层宏观形貌

Fig. 1 Macromorphology of Al-Cu coating prepared by LC and LC + FSP

2.2 涂层微观结构

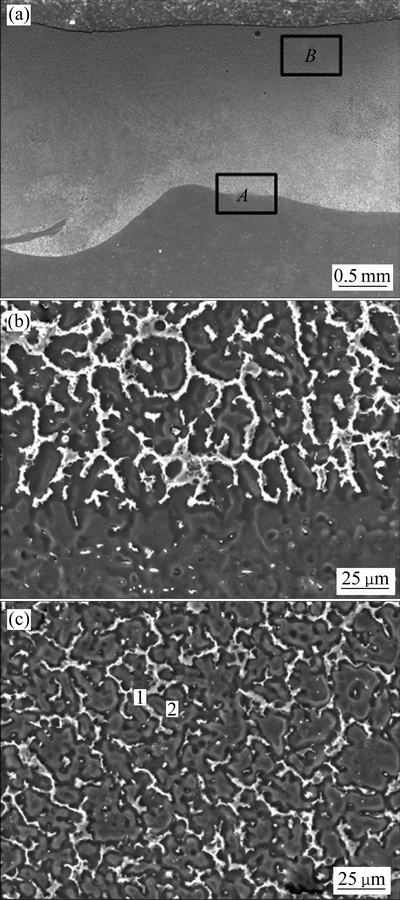

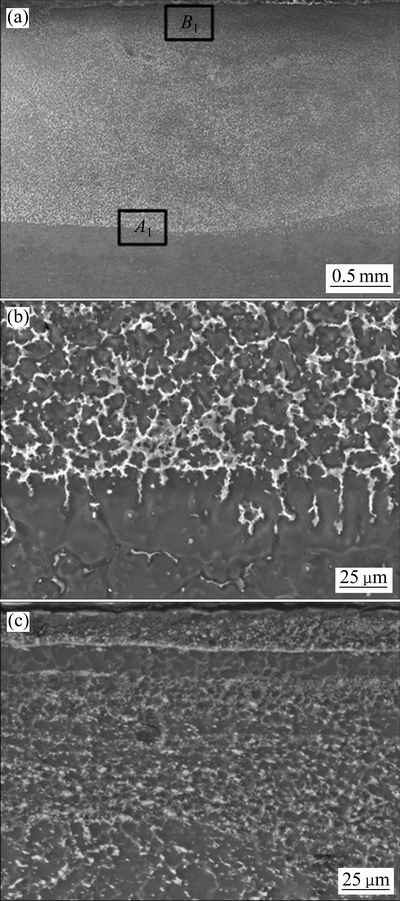

图2所示为经LC后的Al-Cu涂层显微组织形貌。由图2(a)可见,LC的Al-Cu涂层厚度不均匀,涂层厚度约为1.5~2.0 mm,明显大于预置厚度。涂层与母材基体之间存在明显的冶金结合界面,结合界面呈波浪形,且结合界面处无气孔、微裂纹等缺陷(见图2(b)),这对于改善涂层与基体之间的结合强度有一定的积极作用。涂层主要由白色相和灰色相两种物相组成,白色相呈不连续网状结构分布在灰色相的晶内和晶界处(见图2(c))。LC涂层经FSP后的显微组织形貌如图3所示。涂层与基体材料之间良好的冶金结合界面未受到FSP的影响,仅在FSP过程中受搅拌头向下的挤压作用而逐渐平直(见图3(a))。然而经FSP之后,涂层的最外层微观结构发生明显变化,白色相尺寸明显细化,颗粒明显增多且弥散分布在灰色相中。Al-Cu涂层变得均匀致密(见图3(c))。

图2 LC的Al-Cu涂层的显微组织

Fig. 2 Macrostructure of AZ31B modified surface layer with Al-Cu powder by LC(a) and microstructures of bonding interface (area A)(b) and coating (area B)(c)

LC过程中,激光束照射在预置的Al-Cu涂层时,光子能量转变成热量快速向涂层内部传导[21]。当热量聚集到一定程度且能够使得试样温度达到Al-Cu涂层材料和AZ31B镁合金基体材料的熔点时,在涂层内部或者涂层与基体接触界面附近就形成熔池。液态金属通过不断溶解涂层或基体材料使得液相金属逐渐增多,熔池逐渐增大。液态金属经随后的冷却凝固而最终形成一层厚度大于预置层厚度的Al-Cu改性层。由于LC涂层表面成型较差,采用新型固相FSP技术对LC层进行二次加工以期获得表面成型美观且均匀致密的改性层。根据FSP时的热输入公式:

(1)

(1)

式中:Q为热输入; 为热输入系数;μ为摩擦因数;p为压力;N为搅拌头转速;R为轴肩半径;v为焊速。选用大直径轴肩,较高的转速和较低的加工速度对LC的Al-Cu涂层进行FSP,确保加工时,搅拌头轴肩与涂层之间的摩擦生热和涂层材料塑性变形产热的共同热作用使得被加工区域处的Al-Cu涂层完全达到热塑性软化状态。这样热塑性软化材料在搅拌头的旋转摩擦剪应力作用下,随搅拌头由前进侧经后退侧绕流回填时发生动态再结晶和形变而形成均匀细小的晶粒。此外,改性层热塑性金属在搅拌头下压力的作用下发生强烈的挤压变形而充分致密化。与此同时,搅拌头轴肩所存在的三螺旋线型沟槽在旋转运动过程中本身对热塑性软化材料有热机破碎和挤压作用,也会使得改性层金属细化和致密化。因此,LC的Al-Cu涂层经FSP之后,在搅拌头后方形成一层组织细化、晶粒尺寸大小不一的均匀化和致密化的改性涂层。

为热输入系数;μ为摩擦因数;p为压力;N为搅拌头转速;R为轴肩半径;v为焊速。选用大直径轴肩,较高的转速和较低的加工速度对LC的Al-Cu涂层进行FSP,确保加工时,搅拌头轴肩与涂层之间的摩擦生热和涂层材料塑性变形产热的共同热作用使得被加工区域处的Al-Cu涂层完全达到热塑性软化状态。这样热塑性软化材料在搅拌头的旋转摩擦剪应力作用下,随搅拌头由前进侧经后退侧绕流回填时发生动态再结晶和形变而形成均匀细小的晶粒。此外,改性层热塑性金属在搅拌头下压力的作用下发生强烈的挤压变形而充分致密化。与此同时,搅拌头轴肩所存在的三螺旋线型沟槽在旋转运动过程中本身对热塑性软化材料有热机破碎和挤压作用,也会使得改性层金属细化和致密化。因此,LC的Al-Cu涂层经FSP之后,在搅拌头后方形成一层组织细化、晶粒尺寸大小不一的均匀化和致密化的改性涂层。

图3 LC的Al-Cu涂层经FSP后显微组织

Fig. 3 Microstructure of AZ31B modified surface layer with Al-Cu powder by LC+FSP(a) and microstructures of bonding interface (area A1)(b) and coating (area B1)(c)

2.3 涂层表面物相组成

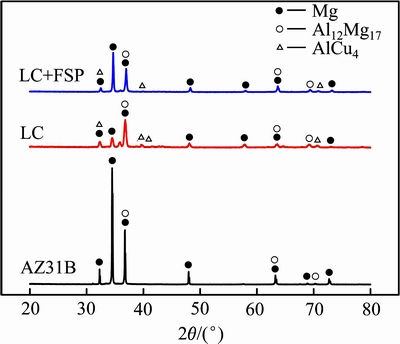

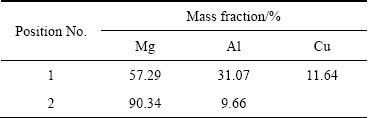

图4所示为AZ31B镁合金基体表面及经LC和LC+FSP之后Al-Cu涂层上表面区域的XRD谱。由图4可见,添加Al-Cu混合粉末的涂层,经LC之后形成了新的金属间化合物AlCu4,同时涂层中还存在大量的α-Mg固溶体和Al12Mg17金属间化合物。而LC的Al-Cu涂层经FSP之后,涂层的相组成与LC一致,表明FSP过程中并未形成新的物相。这是由于FSP过程中,加工温度处于固相线温度之下,加工区域的塑性金属在搅拌头旋转摩擦作用下只发生了再结晶、破碎及混合,而未出现金属熔融现象,因此未发生冶金反应及相转变而形成新的物相,仅仅使得涂层组织结构明显细化和致密化。对涂层中的白色相和灰色相(见图2(c)中点1与点2)进行EDS成分分析可知(见表1),白色相中Mg、Al、Cu的质量分数分别为57.29%,31.07%和11.64%。根据Mg-Al二元平衡相图可知[22],Al在α-Mg中的最大固溶度为12.7%,且Al含量越大越向Al12Mg17金属间化合物形成区域靠近。白色相中Al的质量分数为31.07%,远大于12.7%,表明白色相可能为Mg-Al金属间化合物。与此同时,Cu在Al中的最大固溶度为5.65%,因此白色相也可能为Al-Cu金属间化合物。结合Al-Cu表面区域XRD分析测试结果可知,白色相为Al12Mg17和AlCu4金属间化合物。而灰色相EDS成分分析结果可知,Al的质量分数为9.66%,这小于Al在α-Mg中的最大固溶度,因此,灰色相为α-Mg固溶体。细小化合物在Al-Cu涂层中均匀化分布势必会对涂层耐腐蚀性能产生一定影响。

图4 Al-Cu涂层表面的XRD谱

Fig. 4 XRD patterns of AZ31B and modified layers with Al-Cu powders

表1 图2所示各点的EDS成分分析结果

Table 1 Concentration analysis results of positions show in Fig. 2

2.4 涂层耐腐蚀性能

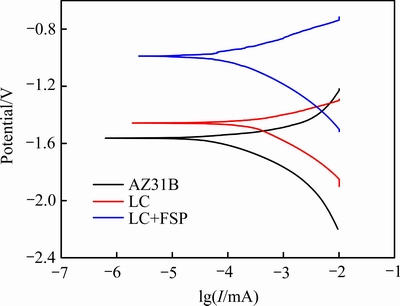

图5所示为AZ31B镁合金基体及其表面经LC和LC+FSP改性之后获得的Al-Cu涂层动电位极化曲线。由图5可见,添加Al-Cu金属混合粉末的涂层经LC之后,耐腐蚀性能较基体得到一定程度的提高,自腐蚀电位由母材基体的-1.563 V提升到-1.457 V,提升6.8%。然而,LC的Al-Cu涂层经FSP之后,耐腐蚀性能较母材基体及LC涂层又得到明显提升,自腐蚀电位高达-0.989 V,比母材基体的自腐蚀电位提升36.7%,比激光熔敷涂层的自腐蚀电位提升32.1%。表明由Al-Cu金属粉末形成的合金化涂层在NaCl溶液中具有良好的耐氯离子腐蚀性能。涂层中的Al12Mg17、AlCu4等金属间化合物经搅拌摩擦加工之后,重新分布,更加均匀化和致密化,很好地抑制了镁合金在NaCl溶液中的溶解程度,从而进一步提升了镁合金的耐腐蚀性能。

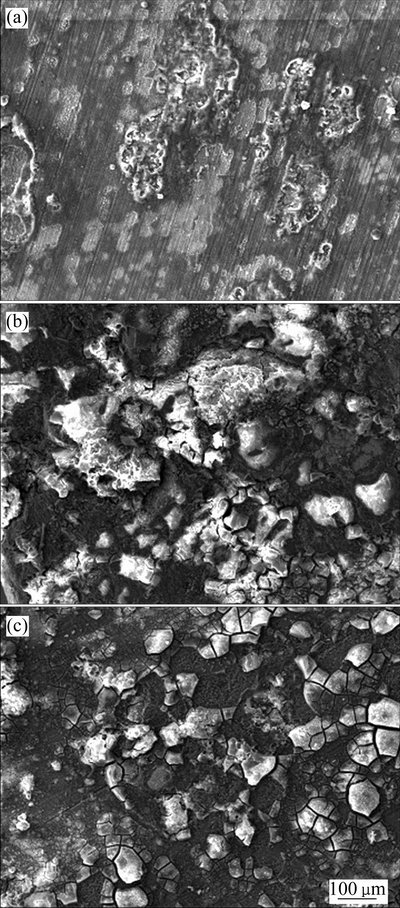

AZ31B镁合金基体中,第二相主要是Al12Mg17相。Al12Mg17既可以作为阴极,与α-Mg固溶体形成微电池,加速α-Mg的溶解,又可以阻碍阳极反应,抑制腐蚀发生,这与Al12Mg17相的分布密切相关[4]。Al12Mg17相颗粒在AZ31B基体中主要分布在晶内或晶界上,作为阴极与α-Mg形成许多腐蚀微电池,从而加速基体的腐蚀,腐蚀主要为离散型分布的点蚀,且点蚀属于孔蚀,孔蚀发生的原因是晶界处的析氢以及沿晶界处的基体优先腐蚀脱落(见图6(a))。镁合金表面改性时,由于添加的Al-Cu混合粉末中Al的含量为85%,远大于Al在镁合金基体中的最大溶解度,因此,涂层中可以生成大量的、连续网状分布的Al12Mg17金属间化合物。金属间化合物的腐蚀电流密度远小于α-Mg,表明Al12Mg17在NaCl溶液中相对稳定有利于阻止腐蚀行为的发生,从而提高镁合金耐腐蚀性能[23]。涂层中添加Cu粉时,Cu在镁合金中的固溶量小,容易析出,而且析氢过电位都较小,腐蚀发生时常常会作为阴极而加快镁合金腐蚀速率。然而在Al-Cu涂层中添加的Cu粉主要形成AlCu4金属间化合物,且涂层中还存在Al12Mg17金属间化合物,化合物相对于α-Mg均成高电势,从整体上提高了镁合金的腐蚀电势,这是添加Cu粉后提升镁合金耐氯离子腐蚀的主要原因[24],也是LC处理的Al-Cu涂层耐腐蚀性能提升的主要原因之一,腐蚀还是以点蚀为主(见图6(b))。然而,LC的Al-Cu涂层经FSP之后,涂层晶粒变得均匀细小和致密化,这大大减少了组成电偶腐蚀的α-Mg和Al12Mg17等金属间化合物的有效接触面积,从而抑制了腐蚀电流的增大;对耐蚀性能提高起到了很好的作用,试样表面的点蚀现象明显轻于母材基体和LC层的,如图6(c)所示。表明FSP技术通过改善涂层表层的微观组织结构可显著改善镁合金基体的耐腐蚀性能。

图5 AZ31B镁合金及涂层动电位极化曲线

Fig. 5 Potentiodynamic polarization curves of modified layer and matrix AZ31B

图6 AZ31B镁合金及涂层腐蚀后的SEM像

Fig. 6 Surface SEM images of electrochemical corrosion specimens of AZ31B magnesium alloy(a) and coatings prepared by LC(b) and FSP(c)

3 结论

1) 采用激光熔敷和搅拌摩擦加工相结合的技术在AZ31B镁合金基体表面成功制备了一层与母材基体呈良好的冶金结合的Al-Cu涂层。涂层主要由α-Mg、Al12Mg17和AlCu4金属间化合物组成,且涂层表面成型平整光滑,组织均匀细小。

2) 激光熔敷Al-Cu涂层经搅拌摩擦加工之后,Al-Cu涂层的耐腐蚀性能明显提升,自腐蚀电位达-0.989 V,较激光熔敷涂层的自腐蚀电位提升32.1%,较母材基体的自腐蚀电位提升36.7%。表明搅拌摩擦加工技术可通过改善镁合金表面改性层的显微组织结构特征对镁合金表面耐腐蚀性能起到积极的作用。

REFERENCES

[1] FRIEDRICH H, SCHUMANN S. Research for a new age of magnesium in the automotive industry[J] Journal of Materials Processing Technology, 2001, 117: 276-281.

[2] SONG G L, ATRENS A. Corrosion mechanisms of magnesium alloys[J]. Advanced Engineering Materials, 1999, 1: 11-33.

[3] PARDO A, MERINO M C, COY A E, ARRABAL R, VIEJO F, MATYKINA E. Corrosion behaviour of magnesium/aluminium alloys in 3.5wt% NaCl[J]. Corrosion Science, 2008, 50 (3): 823-834.

[4] 张青来, 鲍士喜, 王 荣, 钱 阳, 张永康, 李兴成. 激光冲击强化对AZ31和AZ91镁合金表面形貌和电化学腐蚀性能的影响[J]. 中国有色金属学报, 2014, 24(10): 2455-2473.

ZHANG Qing-lai, BAO Shi-xi, WANG Rong, QIAN Yang, ZHANG Yong-kang, LI Xing-cheng. Effect of laser shock processing on surface morphology and electrochemical corrosion resistance of AZ31 and AZ91 alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2455-2473.

[5] 李兴成, 张永康, 卢雅琳, 陈菊芳, 周金宇. 激光冲击AZ31镁合金抗腐蚀性能研究[J]. 中国激光, 2014, 41(4): 1-6.

LI Xing-cheng, ZHANG Yong-kang, LU Ya-lin, CHEN Ju-fang, ZHOU Jin-yu. Research of corrosion resistance for AZ31 magnesium alloy by laser shock processing[J]. Chinese Journal of Laser, 2014, 41(4): 1-6.

[6] PAITAL S R, BHATTACHARYA A, MONCAYO M, HO Y H, MAHDAK K, NAG S, BANERJEE R, DAHOTRE N B. Improved corrosion and wear resistance of Mg alloys via laser surface modification of Al on AZ31B[J]. Surface & Coatings Technology, 2012, 206: 2308-2315.

[7] LIU Fen-jun, MENG Qing-sen, LI Zeng-sheng. Microstructure and properties of alloying coating on AZ31B magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 2347-2354.

[8] GAO Ya-li, WANG Cun-shan, PANG Hong-jie, LIU Hong-bin, YAO Man. Broad-beam laser cladding of Al-Cu coating on AZ91HP magnesium alloy[J]. Applied Surface Science, 2007, 253: 4917-4922.

[9] ZHU Run-dong, LI Zhi-yong, LI Xiao-xi, SUN Qi. Microstructure and properties of the low-power-laser clad coatings on magnesium alloy with different amount of rare earth addition[J]. Applied Surface Science, 2015, 353: 405-413.

[10] LIU Fen-jun, JI Yan, MENG Qing-sen, LI Zeng-sheng. Microstructure and corrosion resistance of laser cladding and friction stir processing hybrid modification Al-Si coatings on AZ31B[J]. Vacuum, 2016, 133: 31-37.

[11] CHEN Er-lei, ZHANG Ke-min, ZOU Jian-xin. Laser cladding of a Mg based Mg-Gd-Y-Zr alloy with Al-Si powders [J]. Applied Surface Science, 2016, 367: 11-18.

[12] ZHENG B J, CHEN X M, LIAN J S. Microstructure and wear property of laser cladding Al+SiC powders on AZ91D magnesium alloy[J]. Optics and Laser in Engineering, 2010, 48: 526-532.

[13] QIAN Jian-gang, YIN Ying, LI Tie-jun, HU Xiao-tian, WANG Chun, LI Shu-qing. Structure, micro-hardness and corrosion behaviour of the Al-Si/Al2O3 coatings prepared by laser plasma hybrid spraying on magnesium alloy[J]. Vacuum, 2015, 117: 55-59.

[14] ZHANG Da-tong, XIONG Feng, ZHANG Wei-wen, QIU Cheng, ZHANG Wen. Superplasticity of AZ31 magnesium alloy prepared by friction stir processing[J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 1911-1916.

[15] SATHISKUMAR R, DINAHARAN I, MURUGAN N, VIJAY S J. Influence of tool rotational speed on microstructure and sliding wear behavior of Cu/B4C surface composite synthesized by friction stir processing[J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 95-102.

[16] 黄春平, 柯黎明, 邢 丽, 刘鸽平. 搅拌摩擦加工研究进展及前景展望[J]. 稀有金属材料与工程, 2011, 40(1): 183-188.

HUANG Chun-ping, KE Li-ming, XING Li, LIU Ge-ping. Research progress and prospect of friction stir processing[J]. Rare Metal Materials and Engineering, 2011, 40(1): 183-188.

[17] 王快社, 王 文, 郭 韡, 王文礼, 武佳蕾. 搅拌摩擦加工铸态AZ31镁合金组织与性能研究[J]. 稀有金属材料与工程, 2010, 39(7): 1275-1278.

WANG Kuai-she, WANG Wen, GUO Wei, WANG Wen-li, WU Jia-lei. Microstructure and properties of friction stir processed cast AZ31 magnesium alloy[J], 2010, 39(7): 1275-1278.

[18] DARRAS B M, KHRAISHEH M K, ABU-FARHA F K, OMAR M A. Friction stir processing of commercial AZ31 magnesium alloy[J]. Journal of Materials Processing Technology, 2007, 191: 77-81.

[19] CAVALIERE P, DE MARCO P P. Superplastic behavior of friction stir processes AZ91 magnesium alloy produced by high pressure die cast[J]. Journal of Materials Processing Technology, 2007, 184: 77-83.

[20] 刘奋军, 孟庆森, 李增生. AZ31B 镁合金表面激光熔敷+搅拌摩擦加工改性层结构与性能[J]. 稀有金属材料与工程, 2016, 45 (9): 2419-2423.

LIU Fen-jun, MENG Qing-sen, LI Zeng-sheng. Microstructure and properties of modified layers for AZ31B magnesium alloys by laser cladding+friction stir processing[J]. Rare Metal Materials and Engineering, 2016, 45 (9): 2419-2423.

[21] ZHENG B J, CHEN X M, LIAN J S. Microstructure and wear property of laser cladding Al+SiC powders on AZ91D magnesium alloy[J]. Optics and Lasers in Engineering, 2010, 48: 526-532.

[22] MASSALSKI T B, OKAMOTO H, SUBRAMAMIAN P R, KACPRZAK L. Binary alloy phase diagrams[M]. 2nd ed. Metals Park, OH: ASM International. 1990: 170.

[23] SONG G L, ATRENS A, WU X L, ZHANG B. Corrosion behaviour of AZ21, AZ501 and AZ91 in sodium chloride[J]. Corrosion Science, 1998, 40(10): 1769-1791.

[24] 崔泽琴, 吴宏亮, 王文先, 许并社. AZ31镁合金表面激光熔敷Cu-Ni合金层[J]. 中国有色金属学报, 2010, 20(9): 1665-1670.

CUI Ze-qin, WU Hong-liang, WANG Wen-xian, XU Bing-she. Laser cladding Cu-Ni alloy layer on AZ31B magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1665-1670.

Microstructure and properties of Al-Cu coating on magnesium alloys prepared by laser cladding+friction stir processing

LIU Fen-jun1, JI Yan1, MENG Qing-sen2, LI Zeng-sheng1, BAI Yan-xia1

(1. College of Energy Engineering, Yulin Engineering Technology Research Center for Frontier Materials, Yulin University, Yulin 719000, China;

2. College of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China)

Abstract: Al-Cu powders were prepared on the surface of AZ31B magnesium alloy by a method of combining laser cladding and friction stir processing. The microstructure feature, phase component and corrosion resistance of the modified layer were studied by scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), X-ray diffractometry (XRD) and electrochemical workstation. The composite modified layers with Al-Cu powders are composed of α-Mg, Al12Mg17 and AlCu4. Both modified layers show very good bonding with the magnesium alloy substrate. The corrosion resistance of the Al-Cu coating is higher than that of the substrate. Compared with the matrix and laser cladding, the maximum self-corrosion potential (-0.989 V) with Al-Cu powders prepared by friction stir processing increases by 36.7% and 32.1%, respectively.

Key words: AZ31B magnesium alloy; laser cladding; friction stir processing; microstructure; corrosion resistance

Foundation item: Project (2016KTZDGY04-03) supported by the Science and Technology Coordinate Major Project of Shaanxi Province, China; Projects(2015GY167, 2016GY-027) supported by the Science and Technology Department of Shaanxi Province, China; Project(2015sf261) supported by the Key Social Science and Technique Projects of the Science and Technology Department of Shaanxi Province, China

Received date: 2016-05-26; Accepted date: 2017-05-28

Corresponding author: LIU Fen-jun; Tel: +86-18091231515; E-mail: lfjxcmg@126.com

(编辑 龙怀中)

基金项目:陕西省科技统筹重大项目(2016KTZDGY04-03);陕西省科技厅工业科技攻关项目(2015GY167,2016GY-027);陕西省科技厅社会发展科技攻关项目(2015sf261)

收稿日期:2016-05-26;修订日期:2017-05-08

通信作者:刘奋军,讲师,博士;电话:18091231515;E-mail: lfjxcmg@126.com