DOI: 10.11817/j.ysxb.1004.0609.2021-39660

Mg的添加及冷却方式对Cu-Cr-Zr合金组织与性能的影响

杨晓红,王澄德,邹军涛,肖 鹏,梁淑华

(西安理工大学 陕西省电工材料与熔(浸)渗技术重点实验室,西安 710048)

摘 要:采用真空感应熔炼制备Cu-Cr-Zr-Mg合金,研究Mg含量及冷却方式对Cu-Cr-Zr-Mg合金组织与性能的影响。结果表明:Cu-Cr-Zr-Mg合金铸态组织为α-Cu相和Cu-Cr共晶相所构成。随着Mg的添加,合金中二次枝晶臂间距明显减小,组织细化。经固溶时效处理后,纳米级CrCu2(ZrMg)相从铜基体中析出,合金的硬度与导电率大幅度提升。当Mg含量为0.3%(质量分数)时,合金的综合性能最佳,硬度为138.3HB,导电率为79.1%IACS。与感应熔炼合金组织相比,采用铜模冷却的合金组织更加细小均匀,偏析少,经固溶时效处理后析出相尺寸明显减小,且析出相数量增多,合金的硬度和导电率分别达到156.8HB和82.8%IACS,合金抗拉强度达到451.8 MPa。

关键词:Cu-Cr-Zr-Mg合金;快速冷却;细晶强化;析出相

文章编号:1004-0609(2021)-02-0342-11 中图分类号:TG146.1 文献标志码:A

引文格式:杨晓红, 王澄德, 邹军涛, 等. Mg的添加及冷却方式对Cu-Cr-Zr合金组织与性能的影响[J]. 中国有色金属学报, 2021, 31(2): 342-352. DOI: 10.11817/j.ysxb.1004.0609.2021-39660

YANG Xiao-hong, WANG Cheng-de, ZOU Jun-tao, et al. Effects of Mg addition and cooling methods on microstructure and properties of Cu-Cr-Zr alloys[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 342-352. DOI: 10.11817/j.ysxb.1004.0609.2021-39660

铜合金因具有较好的综合性能,被广泛应用于各种工业制造领域,比如作为引线框架和接触线材料[1-3]。近年来,随着我国交通、电力、通讯等行业的快速发展,对高强高导铜合金的性能提出了更高的要求[4-7]。由于Cu-Cr-Zr系合金的综合性能更具有应用前景和开发优势,所以大多采用此合金系作为集成电路用的引线框架[2]。SU等[8]通过感应熔炼制备了Cu-0.3Cr-0.15Zr-0.05Mg合金,经固溶时效处理后,导电率和硬度达到80% IACS和109HV。Cu-Cr系合金的强化方式主要以沉淀强化为主,一般通过优化合金成分和热处理工艺,获得理想的析出相形貌和尺寸,改善合金的力学性能[9]。ZHANG等[10]研究发现,元素Ti添加到Cu-Cr合金中,大部分固溶在铜基体中,经时效处理析出大量Cr和Cu4Ti析出相,有效地强化了铜基体。

快速冷凝技术由于冷速快、起始形核过冷度大、生长速率高,可以明显细化晶粒[11]。经时效处理后,铜基体中第二相弥散程度增大,有利于在获得高导电率的同时,显著提高合金的强度[12-14]。PAN等[14]采用喷射沉积技术制备了Cu-Cr-Zr合金,发现Cr和Zr在铜基体中的溶解度增加,经时效处理后大量析出相弥散分布在晶界和铜基体中,Cu-Cr-Zr合金的硬度和导电率分别达到143HV和72%IACS。

由于Cr、Zr和Mg原子在Cu中的固溶度极低,限制了析出强化作用,阻碍了合金综合性能的提高[15-17]。而采用快速凝固可以显著提高溶质原子的平衡固溶度,减少或消除偏析现象,使晶粒细化[18]。

快速冷却引起的细晶强化可显著提高合金强度和塑性[19]。主要原因是由于晶粒细化后,材料变形时,晶界处位错塞积所产生的应力集中可以得到有效分散和缓解,推迟了裂纹的萌生,材料断裂前可实现较大的变形量[20]。本次实验首先采用真空感应熔炼法制备Cu-Cr-Zr-Mg合金,然后浇注入细直径铜模具内,冷却制得合金棒材,研究Mg的添加以及冷却方式对Cu-Cr-Zr-Mg合金组织与性能的影响。

1 实验

实验以工业纯铜(纯度≥99.9%)、铬粒(纯度≥99.9%)、镁块(纯度≥99.9%)以及铜锆中间合金(Cu-40Zr)为原料。合金成分为Cu-1.0Cr-0.25Zr- xMg,其中Mg含量(质量分数)分别为0%,0.15%,0.30%和0.45%。合金熔炼在氩气保护的真空感应熔炼炉中进行,加热到1500 ℃保温20 min后,合金液分别采用坩埚内随炉冷却和浇注入d 13 mm× 130 mm的铜模具中冷却。固溶处理在箱式炉中进行,固溶温度为980 ℃,保温1 h后水淬。随后在氩气保护的管式炉中进行时效处理,时效温度为450 ℃,保温4 h后随炉缓慢冷却。硬度测试选用HB-3000型布氏硬度计,压力载荷2500 N,压头为直径5 mm的淬火钢球,保持加压时间30 s,每个试样测量5次取平均值。导电率的测量采用FQ7501涡流电导仪。选用HT-2402-100kN型电脑伺服材料控制试验机对试样的拉伸性能进行测试,拉伸速率为2 mm/min。金相试样经磨样、抛光和腐蚀,选用腐蚀剂为FeCl3溶液,其成分配比为:5 g FeCl3+15 mL HCl+100 mL H2O。通过光学显微镜(OM)和扫描电子显微镜(SEM)观察不同样品的微观组织。使用Oxford X-Max硅漂移检测器进行EDS相组成分析。借用JEM-2001F透射电子显微镜(TEM)对第二相进行观察与分析,试样经双喷电解减薄处理,温度控制在-20~-40 ℃,减薄电压控制在30~50 V。

2 结果与分析

2.1 Mg的添加对Cu-Cr-Zr合金组织与性能的影响

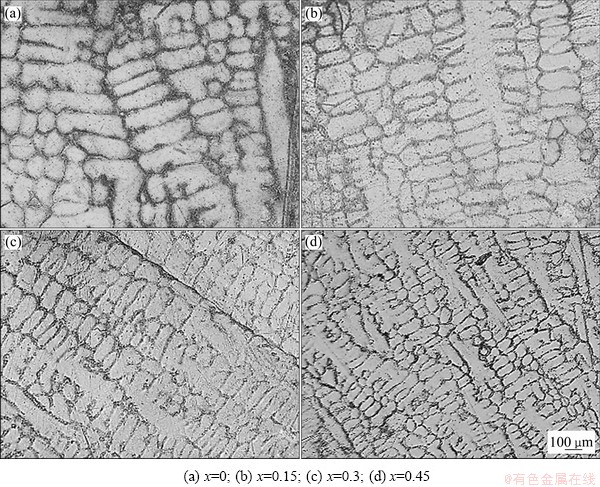

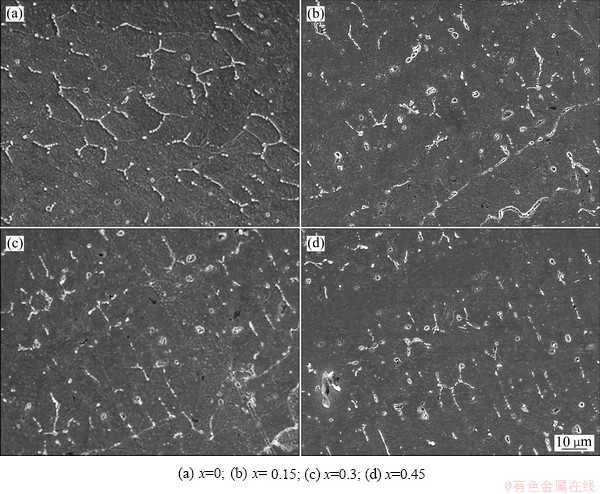

图1所示为感应熔炼坩埚内随炉冷却的Cu-Cr-Zr-Mg合金铸态组织。可以看出,合金组织主要由灰色的初生α-Cu 相和黑色的(α+β)Cu-Cr共晶相所组成,晶粒内部呈树枝晶分布。这符合Cu-Cr-Zr系合金结晶规律[21],杰克逊因子α≤2,属于粗糙界面生长,在负温度梯度下生长,如果界面的某一个局部有凸起,该部位先深入过冷度更大的液体中结晶长大,同时尖端部分的表面积大于其侧面面积,结晶潜热更容易释放,因此沿凸起方向快速生长,形成主干。在主干上还会出现另外一些凸起,并遵循主干的生长原则生长,形成二次枝晶。由图1(a)可知,Cu-Cr-Zr合金铸态组织中分布着粗大的共晶体,铸锭内部出现微观偏析,晶粒内部组织不均匀。同时,从图1(b)至1(d)可以看出,Mg的添加对合金的枝晶组织有明显的细化效果,合金中的Cu-Cr共晶体明显减小,偏析情况也得到改善。

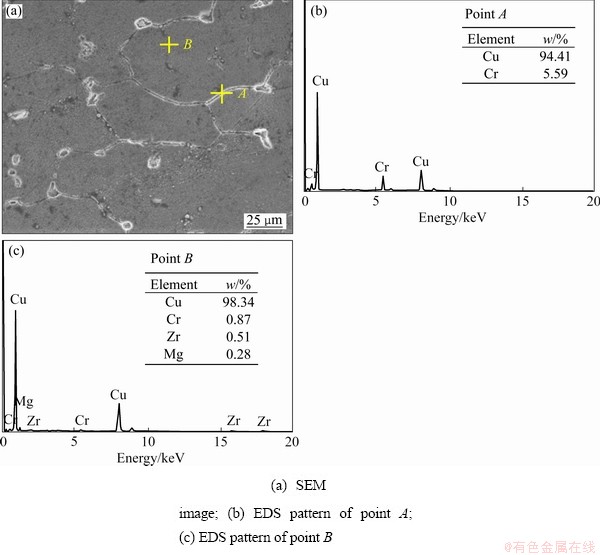

Cu-1.0Cr-0.25Zr-0.45Mg合金铸态组织EDS能谱分析结果如图2所示。由图2可知,A点主要成分为Cu元素和Cr元素,此处组织为Cu与Cr构成的二元共晶相;B处能谱分析结果表明,采用真空感应熔炼制备的Cu-Cr-Zr-Mg合金,在铜基体中均固溶了Cr、Zr、Mg元素。通过对比可以发现,铸态合金组织中Mg元素主要富集于铜基体中。由于Cr在Cu液中的扩散系数较低[22],添加的Mg原子通过阻碍Cu液中Cr元素的扩散,抑制了(α+β) Cu-Cr共晶相的生长。另一方面,高温下Mg在固液两相中的扩散速率远高于其他溶质元素的[23],随着Mg含量的增加,固-液界面前沿液相中Mg元素的浓度不断增大,从而引起成分过冷。随着成分过冷区域的增加,形核速率不断增加,促进了α(Cu)树枝晶的形核与生长;使得枝晶臂间距不断减小,合金组织得到细化,且晶界处偏析物减少。

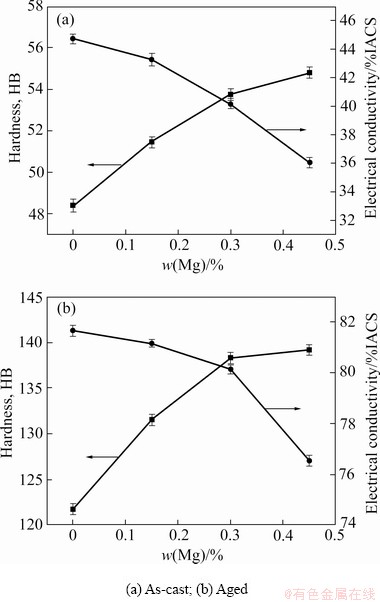

图3所示为不同状态下Cu-Cr-Zr-Mg 合金性能的变化曲线。图3(a)所示为坩埚内随炉冷却条件下不同成分合金的铸态性能曲线,可以看出,随着Mg含量的增加,合金的硬度不断上升,而导电率呈下降趋势。Mg的添加细化了晶粒,增加了晶界和相界面的数量,阻碍了位错的运动。由于细晶强化作用,合金的硬度不断提升,而合金的导电率则随着Mg的添加而急剧下降。

由Cu-Mg二元相图可知,Mg在Cu中的极限固溶度为3.3%,常温下Cu基体中Mg的固溶度不到1%。随着Mg含量的增加,固溶于Cu基体中的Mg原子不断增加,引起铜基体的晶格畸变,增大了对自由电子的散射作用,使得合金的导电率不断下降。另一方面,由于Mg的添加所引起的组织细化,增加了晶界以及相界面数量,进一步加剧了电子散射作用,降低了导电率。当Mg含量为0.3%时,铸态Cu-Cr-Zr-Mg合金在保持良好硬度的同时,兼具了较好的导电性能。

图1 不同Mg含量的Cu-1.2Cr-0.25Zr-xMg合金的铸态组织

Fig. 1 As-cast microstructures of Cu-1.2Cr-0.25 Zr-xMg alloys with different Mg contents

图2 Cu-1.2Cr-0.25Zr-0.45Mg合金的SEM像及EDS分析结果

Fig. 2 SEM image and EDS analysis results of Cu-1.2Cr-0.25Zr-0.45Mg alloy under cast condition:

图3 不同Mg含量Cu-1.2Cr-0.25Zr-xMg合金性能

Fig. 3 Properties of Cu-1.2Cr-0.25Zr-xMg alloys with different Mg contents

对感应熔炼坩埚内随炉冷却的不同成分合金进行固溶时效处理,得到如图3(b)所示的合金硬度与导电率的变化曲线。与图3(a)中的铸态合金性能相比,时效态Cu-Cr-Zr-Mg合金的性能显著提高。当Mg含量为0.3%时,合金的导电率和硬度分别达到79.2%IACS和138.3HB。经时效处理后,铜基体中的溶质原子均以第二相的形式析出,弥散分布的第二相对铜基体的沉淀强化作用增强,使合金的硬度大幅提高。根据Mathiessen理论[24],合金的电阻率可以用式(1)来表示:

(1)

(1)

式中: 为基体中固溶原子产生的电阻;C为溶质原子的摩尔浓度;

为基体中固溶原子产生的电阻;C为溶质原子的摩尔浓度; 为1%溶质原子引起的附加电阻率;K是与温度和溶质浓度有关的偏离参数。其中铜基体中的溶质原子对合金的导电性影响最大。时效处理过程中伴随着过饱和固溶体的脱溶,合金元素大量析出,使得基体的晶格畸变减小,此时

为1%溶质原子引起的附加电阻率;K是与温度和溶质浓度有关的偏离参数。其中铜基体中的溶质原子对合金的导电性影响最大。时效处理过程中伴随着过饱和固溶体的脱溶,合金元素大量析出,使得基体的晶格畸变减小,此时 与

与 这两项的值大为降低,使得合金导电率大幅增加。此外,热处理还消除了合金内残留的内应力,减少位错和空位等缺陷,进一步减弱对电子散射效果,在一定程度上也提高了合金导电率[25]。综上所述,经时效处理,基体中的合金元素以第二相的形式析出,晶格畸变减小,电子散射现象减弱,合金的导电率大幅提升。

这两项的值大为降低,使得合金导电率大幅增加。此外,热处理还消除了合金内残留的内应力,减少位错和空位等缺陷,进一步减弱对电子散射效果,在一定程度上也提高了合金导电率[25]。综上所述,经时效处理,基体中的合金元素以第二相的形式析出,晶格畸变减小,电子散射现象减弱,合金的导电率大幅提升。

2.2 冷却方式对Cu-Cr-Zr-Mg合金组织与性能的影响

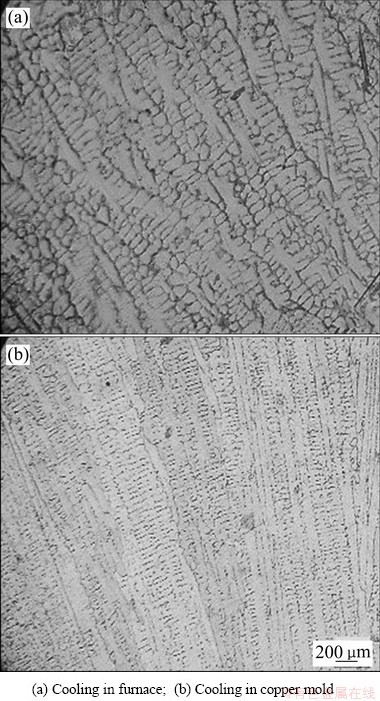

图4所示为不同冷却方式下Cu-Cr-Zr-Mg合金的铸态组织照片。与图4(a)中随炉冷却的合金组织相比,图4(b)所示的铜模冷却合金组织中一次枝晶臂间距明显减小,二次枝晶臂间距明显细化。由于采用铜模冷却时合金的冷却速度大,先形核的晶粒的生长受到了抑制,组织的不均匀性得到改善。同时冷却速度提高使结晶驱动力增大,形核率提升,大量的形核引起枝晶的明显细化。另一方面,较高的冷却速度引起大的过冷度和高的固-液界面推移速度,使合金组织更加细小[26]。

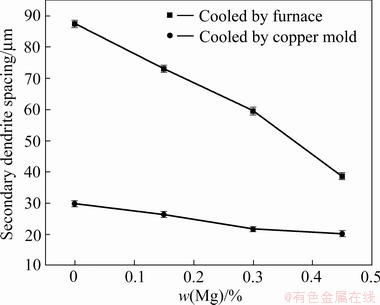

图5所示为不同冷却方式下合金的二次枝晶臂间距(SDAS)变化曲线。与随炉冷却的合金相比,可以看出,铜模冷却铸态下合金的SDAS值大幅减小。以Cu-1.0Cr-0.25Zr-0.3Mg为例,采用铜模冷却得到的合金二次枝晶臂间距减少了44.7%,细晶强化效果明显。同时,随着Mg含量的不断增加,合金的二次枝晶臂间距不断减小。

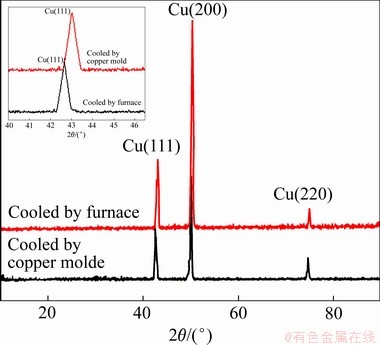

图6所示为不同冷却方式下Cu-1.2Cr-0.25Zr- 0.3Mg合金的XRD谱。从图6以看出,3个明显的衍射峰分别对应着Cu的(111)、(200)和(220)的三个晶面。由于合金元素的添加量较少,XRD图谱中未出现其他物相的衍射峰。但仔细观察发现,相比于随炉冷却合金,铜模冷却的铸态合金中铜的衍射峰向左偏移,根据布拉格方程:

(2)

(2)

图4 不同冷却方式下Cu-1.2Cr-0.25Zr-0.3Mg合金的金相组织

Fig. 4 Optical microstructures of Cu-1.2Cr-0.25Zr-0.3Mg alloy with different cooling methods

图5 不同冷却方式下Cu-Cr-Zr-Mg合金二次枝晶臂间距

Fig. 5 Secondary dendrite arm spacing of Cu-Cr-Zr-Mg alloy by different cooling methods

此时θ值减小, 值随之减小,所以铜基体的晶面间距d值增大,表明铜基体产生晶格畸变。即更多的合金元素固溶到铜基体中,可见采用铜模冷却法制备Cu-Cr-Zr-Mg合金能够显著地提高铜基体中合金元素的固溶度。

值随之减小,所以铜基体的晶面间距d值增大,表明铜基体产生晶格畸变。即更多的合金元素固溶到铜基体中,可见采用铜模冷却法制备Cu-Cr-Zr-Mg合金能够显著地提高铜基体中合金元素的固溶度。

图6 不同冷却方式下Cu-1.2Cr-0.25Zr-0.3Mg合金的XRD谱

Fig. 6 XRD patterns of Cu-1.2Cr-0.25Zr-0.3Mg alloy by different cooling methods

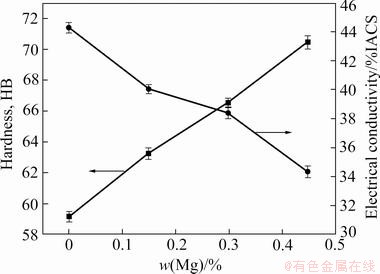

图7 铜模冷却下不同Mg含量的Cu-1.2Cr-0.25Zr-xMg合金铸态性能

Fig. 7 As-cast properties of Cu-1.2Cr-0.25Zr-xMg alloys with different Mg content cooling in copper mold

图7所示为铜模冷却下不同Mg含量Cu-Cr-Zr- Mg铸态合金的导电率与硬度。与图3中感应熔炼坩埚内随炉冷却的合金性能相比,发现采用铜模冷却法制得的合金导电率较低,但其硬度大幅度提高。当Mg含量为0.3%时,合金硬度及导电率分别达到66.5HB和38.4%IACS,其中硬度提升了28.5%。随着Mg的添加,合金的二次枝晶臂间距不断减小,硬度不断提升。同时,快速冷却提高了合金元素在铜基体中的固溶度,促使大量合金元素固溶进铜基体中,在细晶强化和固溶强化的综合作用下,合金硬度得到大幅度的提升。另一方面,基体中溶质原子的数量增多,产生的晶格畸变提高了电子散射的几率;同时,晶粒的细化增加了晶界以及相界面,阻碍了电子的运动。在这两方面作用下,合金导电率有所降低。

2.3 时效态Cu-Cr-Zr-Mg合金组织与性能

为了进一步提升合金性能,对铜模冷却的铸态Cu-Cr-Zr-Mg合金进行了固溶时效处理。图8所示为时效态Cu-Cr-Zr-Mg合金的SEM像。从图8以看出,合金组织由亮白色的(α+β) Cu-Cr共晶相和灰色铜基体组成。经固溶时效处理后,杆状的共晶相逐渐熔断成为点粒状;且随着Mg含量的增加,共晶相的点粒化趋势越来越明显,网状共晶相被破坏,且共晶区域有所减少。固溶阶段,共晶组织发生部分回溶、分断,共晶相中的部分Cr元素重新回溶进铜基体中,为后续的时效析出提供了动力。经450 ℃保温4 h的时效处理,合金元素以纳米级的析出相弥散分布在基体中,对合金性能提升起到了重要的作用。

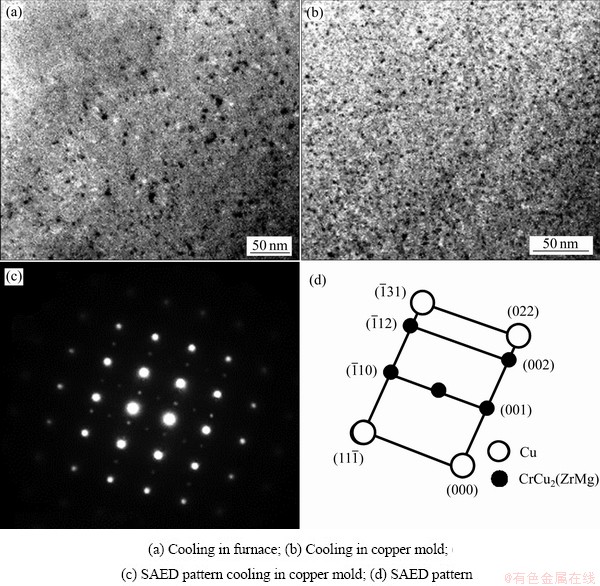

图9所示为合金时效后析出相的TEM明场像形貌。图9(a)所示为感应熔炼随炉冷却合金的析出相形貌,点粒状的析出相弥散分布在铜基体中,直径约为5~8 nm。图9(b)所示为铜模冷却合金的析出相形貌,析出相直径约为2~4 nm。图9(c)所示为图9(b)中的选区电子衍射花样,图中显示有两套衍射斑点,通过图9(d)中的标定结果可知,其主斑点为Cu的衍射斑,围绕其周围的是第二相CrCu2(ZrMg)的衍射斑,其晶格常数为a=0.3388 nm,这是一种超点阵结构分布的金属间化合物。在基体中弥散分布,起到了弥散强化的作用,使得时效处理后的合金硬度与导电率均大幅提升。

图8 铜模冷却不同Mg含量的Cu-1.2Cr-0.25Zr-xMg合金时效态组织

Fig. 8 Microstructures of Cu-1.2Cr-0.25Zr-xMg alloys with different Mg contents cooled in copper mold

图9 不同冷却方式下Cu-1.0Cr-0.25Zr-0.3Mg合金的时效处理后TEM像和衍射谱

Fig. 9 TEM images((a), (b)) and SAED pattern((c), (d)) of aged Cu-1.0Cr-0.25Zr-0.3Mg alloy cooled by different methods

从以上实验结果分析可以看出,随着冷却速度的增加,合金组织中的时效析出相明显细化,且析出数量增加。BATAWI[27]认为快速凝固得到的Cu-Cr合金的时效强化符合Orowan强化机制,根据Orowan强化机制公式[28-29]

(3)

(3)

式中:G是基体的剪切模量;b是位错的柏氏矢量;r是第二相粒子的平均半径;R是位错核心半径;λ为两个第二相粒子的间距。由式(3)可知,Orowan应力 主要由第二相粒子半径r与第二相粒子间距λ决定。采用铜模具冷却获得时效析出相颗粒半径r明显减小,同时析出相数量的提升导致第二相粒子间距λ的降低。纳米级沉淀相的大量析出,对位错的阻碍作用增强,从而提高了合金的强度。

主要由第二相粒子半径r与第二相粒子间距λ决定。采用铜模具冷却获得时效析出相颗粒半径r明显减小,同时析出相数量的提升导致第二相粒子间距λ的降低。纳米级沉淀相的大量析出,对位错的阻碍作用增强,从而提高了合金的强度。

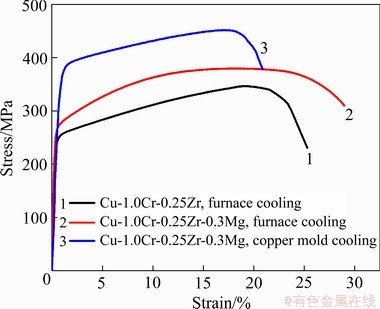

图10所示为不同成分及冷却方式下时效态Cu-Cr-Zr-Mg合金的应力-应变曲线。测试结果表明,感应熔炼随炉冷却Cu-1.0Cr-0.25Zr合金经固溶时效处理后抗拉强度仅为347.3 MPa,添加 0.3%Mg的合金强度达到374.2 MPa。相比随炉冷却,铜模冷却的Cu-1.0Cr-0.25Zr-0.3Mg合金抗拉强度提升20.7%,达到451.8 MPa。

由前面的分析可知,Mg添加到Cu-Cr-Zr合金中,显著减小合金二次枝晶臂间距,起到了细晶强化作用。经时效处理后纳米级的CrCu2(ZrMg)相从基体中析出,作为增强相弥散分布在基体中,强化了铜基体,使合金的硬度、强度均有所增加。而采用铜模冷却合金进一步细化了Cu-Cr-Zr-Mg合金的组织,增加了析出相的体积分数,使单位体积内晶界的面积增加,进一步阻碍了位错的运动,从而使合金力学性能提高。合金在常温下的屈服强度和晶粒尺寸之间的关系符合Hall-Petch公式[30]。

(4)

(4)

式中: 是屈服极限;

是屈服极限; 是移动单个位错时产生的晶格摩擦阻力;k是强化系数(材料特有常数);d是晶粒平均尺寸。当外力一定时,晶粒越细小,晶界处所引起的应力集中越小,必须施加更大的外加载荷才能使滑移从先塑性变形的晶粒转移到相邻晶粒中,使合金产生屈服,即晶粒尺寸d值越小,合金的强度越高。

是移动单个位错时产生的晶格摩擦阻力;k是强化系数(材料特有常数);d是晶粒平均尺寸。当外力一定时,晶粒越细小,晶界处所引起的应力集中越小,必须施加更大的外加载荷才能使滑移从先塑性变形的晶粒转移到相邻晶粒中,使合金产生屈服,即晶粒尺寸d值越小,合金的强度越高。

图10 不同成分及冷却方式下时效态合金的应力-应变曲线

Fig. 10 Stress-strain curves of aged alloy with different components and cooling methods

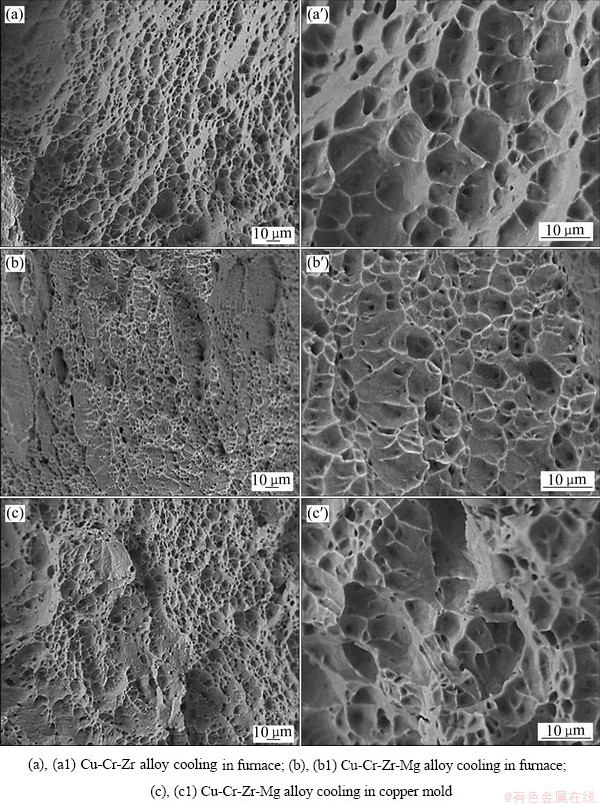

图11 不同成分及处理方式下合金的断口形貌

Fig. 11 Fracture morphologies of alloys with different compositions and cooling methods

图11所示为不同Cu-Cr-Zr-Mg合金的拉伸断口形貌。图11(a)和(a1) 所示为感应熔炼随炉冷却条件下时效态Cu-1.0Cr-0.25Zr合金的断口SEM像。图11(b)和(b1)所示为该条件下时效态Cu-1.0Cr- 0.25Zr-0.3Mg合金的断口形貌。图11(c)和(c1)所示为铜模冷却时效态Cu-1.0Cr-0.25Zr-0.3Mg合金断口形貌。可以看出,Cu-Cr-Zr-Mg合金以塑性断裂为主。合金断口主要由韧窝区和撕裂区组成,韧窝区主要为等轴状韧窝,部分韧窝内还有尺寸不规则的塑孔和细小的颗粒相。韧窝是断裂过程中微孔分离所留下的痕迹。Cu-Cr-Zr合金断口存在大量韧窝,表明合金具有韧性断裂特征。合金的强度随着断口组织中韧窝数量的增多而增大。随着Mg元素的添加,韧窝的尺寸减小,数量有所增加。而采用铜模快速冷却制备的Cu-Cr-Zr-Mg合金,韧窝分布均匀,尺寸细小,且数量明显增加,因此合金的抗拉强度有了较为明显的提升。

3 结论

1) 采用感应熔炼坩埚内随炉冷却法制备的Cu-Cr-Zr-Mg合金,随着Mg含量的增加,合金的二次枝晶臂间距减小,硬度不断提升而导电率下降。当Mg含量为0.3%时,合金的综合性能较好。经固溶和时效处理后,Cu-Cr-Zr-Mg合金的导电率和硬度显著提高,分别达到79.2%IACS和138.3HB。

2) 与感应熔炼炉内冷却相比,采用铜模冷却制备的Cu-Cr-Zr-Mg合金组织中枝晶细小均匀,SDAS值降低了一半以上,共晶相明显减少。合金元素在铜基体中的固溶度显著提升。铸态时合金硬度相较随炉冷却提升了28.5%,导电率有所下降。

3) 采用铜模冷却制备的Cu-Cr-Zr-Mg合金经固溶时效处理后,杆状的共晶相转变为点粒状,大量细小的CrCu2(ZrMg)相从基体中析出,且弥散分布。合金的拉伸性能明显提升,韧窝尺寸减小。与感应熔炼随炉冷却合金相比,合金抗拉强度提高了20.7%,达到451.8 MPa。

REFERENCES

[1] 王庆娟, 徐长征, 郑茂盛, 等. 高强高导电铜合金的研究现状[J]. 西安建筑科技大学学报(自然科学版), 2006, 38(5): 731-734.

WANG Qing-juan, XU Chang-zheng, ZHENG Mao-sheng, et al. Prospect of research on high-strength and high- conductivity copper alloys[J]. J Xi’an Univ of Arch & Tech (Natural Science Edition), 2006, 38(5): 731-734.

[2] 占国星, 李明茂. 高强高导Cu-Cr-Zr系合金的研究与应用进展[J]. 有色金属科学与工程, 2012, 3(1): 13-17.

ZHAN Guo-xing, LI Ming-mao. Research and application progress of high-strength and high-conductivity Cu-Cr-Zr alloys[J]. Nonferrous Metals Science and Engineering, 2012, 3(1): 13-17.

[3] 方善锋, 汪明朴, 程建奕, 等. 高强高导Cu-Cr-Zr系合金材料的研究进展[J]. 材料导报, 2003, 17(9): 21-24.

FANG Shan-feng, WANG Ming-pu, CHENG Jian-yi, et al. Recent development in high strength and high conductivity Cu-Cr-Zr system alloys[J]. Materials Reports, 2003, 17(9): 21-24.

[4] 丁宗业, 贾淑果, 宁向梅, 等. 高强高导Cu-Cr-Zr合金时效性能[J]. 中国有色金属学报, 2017, 27(12): 2420-2425.

DING Zong-ye, JIA Shu-guo, NING Xiang-mei, et al. Aging properties of high-strength and high-conductivity Cu-Cr-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2420-2425.

[5] 谢水生, 吴予才, 黄国杰. 浅谈高速列车接触导线的研究开发[J]. 有色金属加工, 2011, 40(7): 11-14.

XIE Shui-sheng, WU Yu-cai, HUANG Guo-jie. Development study on high conductivity wire for high speed train[J]. Nonferrous Metals Processing, 2011, 40(7): 11-14.

[6] 朱承程, 马爱斌, 江静华, 等. 高强高导铜合金的研究现状与发展趋势[J]. 热加工工艺, 2013, 42(2): 15-23.

ZHU Cheng-cheng, MA Ai-bin, JIANG Jing-hua, et al. Research status and development tendency of high-strength and high-conductivity copper alloy[J]. Hot Working Technology, 2013, 42(2): 15-23.

[7] 李银华, 刘 平, 田保红, 等. 集成电路用铜基引线框架材料的发展与展望[J]. 材料导报, 2007, 21(7): 24-26.

LI Yin-hua, LIU Ping, TIAN Bao-hong, et al. Development and expectation of copper-based lead frame material used in intergrated circuit[J]. Materials Reports, 2007, 21(7): 24-26.

[8] SU Juan-hua, DONG Qi-ming, LIU Ping, et al. Research on aging precipitation in a Cu-Cr-Zr-Mg alloy[J]. Materials Science & Engineering A, 2005, 392(1): 422-426.

[9] 刘林贤, 汪明朴, 陈 伟, 等. 新型Cu-Zn-Cr合金的形变热处理及对性能的影响[J]. 金属热处理, 2015, 40(6): 80-85.

LIU Lin-xian, WANG Ming-pu, CHEN Wei, et al. Thermomechanical treatment of a novel Cu-Zn-Cr alloy and its effect on properties[J]. Heat Treatment of Metals, 2015, 40(6): 80-85.

[10] ZHANG Peng-chao, JIE Jin-chuan, GAO Yun, et al. Influence of cold deformation and Ti element on the microstructure and properties of Cu-Cr system alloys[J]. Journal of Materials Research, 2015, 30: 2073-2080.

[11] FORWALD K R, ARNBERG L. Microstructural development in rapidly solidified silicon-rich alloys[J]. Materials Science & Engineering A (Structural Materials: Properties, Microstructure and Processing), 2001, 304/306: 125-128.

[12] XIE Ming, LIU Jian-liang, LU Xian-yong, et al. Investigation on the Cu-Cr-RE alloys by rapid solidification[J]. Materials Science and Engineering A, 2001, 304(1): 529-533.

[13] SU Juan-hua, DONG Qi-ming, LIU Ping, et al. Establishing the knowledge repository of rapidly solidified aging Cu-Cr-Zr alloy on the artificial neural-network[J]. Rare Metals, 2004, 23(2): 171-175.

[14] PAN Zhen-ya, CHEN Jiang-biao, ZHOU Wei, et al. Microstructure and properties of rapidly solidified Cu-0.81Cr-0.12Zr alloy[J]. Materials Transactions, 2013, 54(8): 1403-1407.

[15] 刘 平, 康布熙, 曹兴国, 等. 快速凝固Cu-Cr-Zr-Mg合金的时效析出与再结晶[J]. 中国有色金属学报, 1999, 9(2): 241-246.

LIU Ping, KANG Bu-xi, CAO Xing-guo, et al. Aging precipitation and recrystallization of rapidly solidified Cu-Cr-Zr-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 241-246.

[16] 沈 斌. Cu-Cr-Zr-Mg合金中的固态相变及微结构研究[D]. 南昌: 南昌大学, 2015.

SHEN Bin. Solid phase transformation and microstructure in Cu-Cr-Zr-Mg alloy[D]. Nanchang: Nanchang University, 2015.

[17] 赵志方, 孙 伟. 高强度高导电铜合金的强化机制[J]. 热加工工艺, 2017(6): 27-30.

ZHAO Zhi-fang, SUN Wei. Strengthening mechanism of high strength and high conductivity copper alloy[J]. Hot Working Technology, 2017(6): 27-30.

[18] 李 圣, 刘 峰, 杨 伟. 不同热流模式下快速凝固Cu-Co不混溶合金枝晶-分相结构的转变[J]. 中国有色金属学报, 2017, 27(1): 227-233.

LI Sheng, LIU Feng, YANG Wei. Comparison of dendrite and dispersive structure in rapidly solidified Cu-Co immiscible alloy with different heat flow models[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1): 227-233.

[19] VINOGRADOV A, ISHIDA T, KITAGAWA K, et al. Effect of strain path on structure and mechanical behavior of ultra-fine grain Cu-Cr alloy produced by equal-channel angular pressing[J]. Acta Materialia, 2005, 53(8): 2181-2192.

[20] 韩启强. Zr对7020铝合金铸轧板裂纹及均匀化的研究[D]. 辽宁: 辽宁科技大学, 2018.

HAN Qi-qiang. Effect of Zr on cracking of 7020 aluminum alloy casting and rolling plate and its homogenization treatment[D]. Liaoning: University of Science and Technology Liaoning, 2018.

[21] VINOGRADOV A, SUZUKI Y, PATLAN V, et al. Structure, properties and thermal stability of ultra-fine grained Cu-Cr-Zr alloy[J]. Journal of Chemical Information and Modeling, 2013, 53(9): 1689-1699.

[22] 黄忠平. 新型Cu-Ni-Cr纳米复合镀层的制备及氧化性能研究[D]. 沈阳: 沈阳金属研究所, 2006: 25-35.

HUANG Zhong-ping. Preparation and oxidation properties of novel Cu-Ni-Cr nanocomposite coatings[D]. Shenyang: Institute of Metal Research, 2006: 25-35.

[23] 赵柏森. Cu/Mg连接界面扩散行为研究[J]. 电焊机, 2013, 43(8): 71-73.

ZHAO Bai-sen. Investigation of diffusion behavior of interfacial bonded copper and magnesium[J]. Electric Welding Machine, 2013, 43(8): 71-73.

[24] 陈树川. 材料物理性能[M]. 上海: 上海交通大学出版社, 1999: 40-65.

CHEN Shu-chuan. Physical properties of materials[M]. Shanghai: Shanghai Jiao Tong University Press, 1999: 40-65

[25] 陆晓培. 合金元素和热处理对Cu-Ag-Cr合金显微组织与性能的影响[D]. 浙江: 浙江大学, 2014.

LU Xiao-pei. Effects of alloy elements and heat treatment on microsturcture and properties of Cu-Ag-Cr alloy[D]. Zhejiang: Zhejiang University, 2014.

[26] 王 勇, 郭喜平. 凝固速率对Nb-Ti-Si基合金整体定向凝固组织及固/液界面形态的影响[J]. 金属学报, 2010, 46(4): 506-512.

WANG Yong, GUO Xi-ping. Effect of solidifying rate on integrally directionally solidified microstructure and solid/liquid interface morphology of an Nb-Ti-Si base alloy[J]. Acta Metallurgica Sinica, 2010, 46(4): 506-512.

[27] BATAWI E, MORRIS D G, MORRIS M A. Effect of small alloying additions on behavior of rapidly solidified Cu-Cr alloy[J]. Materials Science and Technology, 1990, 6(9): 892-899.

[28] JIA S G, ZHENG M S, LIU P, et al. Aging properties studies in a Cu-Ag-Cr alloy[J]. Materials Science & Engineering A, 2006, 419(1/2): 8-11.

[29] WANG Wei, LI Ren-geng, ZOU Cun-lei, et al. Effect of direct current pulses on mechanical and electrical properties of aged Cu-Cr-Zr alloys[J]. Materials & Design, 2016, 92: 135-142.

[30] MOROZOVA A, KAIBYSHEV R. Grain refinement and strengthening of a Cu-0.1Cr-0.06Zr alloy subjected to equal channel angular pressing[J]. Philosophical Magazine, 2017: 1-24.

Effects of Mg addition and cooling methods on microstructure and properties of Cu-Cr-Zr alloys

YANG Xiao-hong, WANG Cheng-de, ZOU Jun-tao, XIAO Peng, LIANG Shu-hua

(Shaanxi Province Key Laboratory of Electrical Materials and Infiltration Technology, Xi’an University of Technology, Xi’an 710048, China)

Abstract: Cu-Cr-Zr-Mg alloys were prepared by vacuum induction melting method. The effects of Mg contents and cooling method on the microstructure and properties of Cu-Cr-Zr-Mg alloy were studied. The results show that the microstructure of as-cast Cu-Cr-Zr-Mg alloy is α-Cu phase and Cu-Cr eutectic structure. With the addition of Mg, the secondary dendrite arm spacing of the alloy decreases significantly and the microstructure is refined. After solution treatment and aging treatment, the nano-sized CrCu2 (ZrMg) phase precipitates from the matrix, and the hardness and electrical conductivity of the alloy are greatly improved. When the Mg content is 0.3% (mass fraction), the alloy obtains the best overall performance, with the hardness of 138.3HB and the electrical conductivity of 79.1%IACS. Compared with the furnace cooling alloy, the structure of the alloy cooling in the copper mold is finer and more uniform, and the segregation is less. After the solution treatment, the precipitated phase size obviously decreases, and the number of precipitated phases increases. The hardness and electrical conductivity reach 156.8HB and 82.8%IACS, respectively, and the tensile strength reaches 451.8 MPa.

Key words: Cu-Cr-Zr-Mg alloy; rapid cooling; fine grain strengthening; precipitation phase

Foundation item: Project(51834009) supported by the National Natural Science Foundation of China; Project (2014SZS08-K02) supported by the Science and Technique Innovation Program of Shaanxi Province for Key Laboratory, China

Received date: 2020-01-20; Accepted date: 2020-12-10

Corresponding author: YANG Xiao-hong; Tel: +86-29-82312185; E-mail: yangxh2000@126.com

(编辑 龙怀中)

基金项目:国家自然基金重点资助项目(51834009);陕西省科技统筹创新工程重点实验室项目(2014SZS08K02)

收稿日期:2020-01-20;修订日期:2020-12-10

通信作者:杨晓红,副教授,博士;电话:029-82312185;E-mail:yangxh2000@126.com