文章编号:1004-0609(2015)12-3488-09

铅锌混合硫化精矿的低温熔盐还原固硫熔炼

胡宇杰1, 2,唐朝波1,陈永明1,唐谟堂1,杨声海1,杨建广1,何 静1

(1. 中南大学 冶金科学与工程学院,长沙 410083;

2. 湖南工业大学 冶金工程学院,株洲 412007)

摘 要:针对铅锌混合硫化精矿烧结-密闭鼓风炉还原熔炼工艺(ISP)熔炼温度高、能耗大和大气污染严重等弊端,提出一种低温熔盐炼铅分离铅锌的新工艺。采用单因素实验法研究固硫剂ZnO和碳酸钠的用量、熔炼温度及熔炼时间等工艺参数对铅的直收率及ZnO固硫率的影响。结果表明:确定最佳条件为ZnO扩大实验的结果良好和精矿的质量比为0.36:1,碳酸钠和精矿的质量比为3.2:1,熔炼温度为880 ℃和熔炼时间为60 min。在此优化条件下扩大实验的结果良好:铅直收率为97.15%,粗铅品位为98.52%,ZnO固硫率为95.42%,水浸渣含Zn 55.80%(质量分数)。XRD物相分析表明:硫主要被固定在ZnS中,Na2CO3熔盐的物相未发生改变,可循环使用。

关键词:硫化精矿;碳酸钠熔盐;固硫;熔炼

中图分类号:TF803 文献标志码:A

Reductive sulfur-fixation smelting of lead and zinc sulfide mixed concentrate in soda molten salt at low temperature

HU Yu-jie1, 2, TANG Chao-bo1, CHEN Yong-ming1, TANG Mo-tang1, YANG Sheng-hai1, YANG Jian-guang1, HE Jing1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. School of Metallurgy Engineering, Hunan University of Technology, Zhuzhou 412007, China)

Abstract: In view of serious shortcomings, such as high smelting temperature, large energy consumption and atmospheric contamination, existed in the imperial smelting process (ISP), a low-temperature molten salt smelting process to directly produce lead from the lead and zinc mixed sulfide concentrates was proposed. The influencing factors, including the smelting temperature, reaction time and dosage of ZnO and salt, were investigated in detail using single-factor experiments. The results show that the optimum conditions are determined as follows: mass ratio of ZnO and concentrate is 0.36:1, mass ratio of Na2CO3 and concentrate is 3.2:1; smelting temperature is 880 ℃ and smelting time is 60 min. Under above-mentioned optimum conditions, some encouraging results are obtained as follows: the direct recovery rate of lead reaches 97.15%, the grade of crude lead reaches 98.52%, the sulfur-fixing rate for ZnO reaches 95.42%, the mass fraction of zinc in the leaching slag is 55.80% (mass fraction). The XRD results indicate that sulfur is mainly fixed in the form of ZnS, whereas, the Na2CO3 molten salt does not react with other components, serving only as a reaction medium.

Key words: sulfide concentrate; soda molten salt; sulfur-fixing; smelting

随着硫化铅、锌矿物资源的日益贫乏和复杂,将紧密共生的铅锌混合矿石分选得到单一铅精矿和锌精矿的难度越来越大[1-2],因此,大部分选矿厂将难以分选的铅锌矿石按照硫化矿全浮选工艺流程生产铅锌混合硫化精矿,以提高资源综合利用率和经济技术指标[3-4]。当前,ISP工艺仍然是工业上处理铅锌混合硫化精矿、分离铅锌的主要方法。该法反应速度快,能够从混合精矿中同时提取金属铅、锌,简化了锌生产流程,节约了生产成本[5],但由于存在烧结过程和熔炼温度过高(>1200 ℃),ISP法存在着能耗大,铅和铊的蒸气及粉尘大量外逸,低浓度SO2烟气排空,环境污染严重等缺点[6-7]。

熔盐由于具有良好的热稳定性和热溶解性[8],在材料制备[9]、太阳能电池[10]以及去除金属表面污渍[11]等方面得到了广泛应用。近年来,研究者在碱法冶金的基础上[12-17],提出在低温熔盐中提取重金属的新冶金方法[18-21],将Na2CO3、Na2CO3-NaCl、Na2CO3-NaOH等一元或二元低温熔盐体系应用于处理硫化锑精矿[22-25]、硫化铋精矿[26-28]和再生铅、含铅烟灰等二次物料[29-32],均获得了较为理想的技术指标,缩短了工艺流程,提高了有价金属的综合回收率。低温熔盐冶金工艺可将熔炼温度由传统火法冶金的1200 ℃以上降低至900 ℃以下,可大幅降低生产能耗和铅、铊等有毒金属的挥发率,避免了有毒有害金属对周边环境和土地的污染。此外,该工艺还以我国丰富价廉且难以回收的高氟氯次氧化锌资源作为固硫剂,将原料中的绝大部分硫以ZnS的形式固定,有效解决了SO2等有害气体排放所引发的环境污染问题和高氟氯氧化锌的高效处理和升值问题。

综合上述研究,本文作者提出一种在碳酸钠熔盐中低温还原熔炼铅锌混合硫化精矿一步炼制粗铅的新方法,即在800~900 ℃的温度及还原气氛下,以高氟氯次氧化锌为固硫剂,将铅锌混合硫化精矿中的PbS及次氧化锌中的PbO还原成金属铅,PbS中的负二价硫被次氧化锌中的ZnO固定生成ZnS,与混合精矿中的ZnS加合在一起,从而获得高品位的硫化锌精矿,而作为熔盐主成分的Na2CO3在反应前后物相保持不变,大部分熔盐以热态返回,循环利用,少部分被固态物粘附形成固态渣。这种固态渣经湿法处理再生Na2CO3,并获得以ZnS为主要组分、符合锌精矿要求(w(Zn)>50%)的水浸渣。该工艺除了具有低温、清洁和低碳等优点外,还解决了混合精矿中铅锌分离的难题,直接产出粗铅和锌精矿,同时可以实现高氟氯次氧化锌烟灰中铅、锌的回收和增值,因此,对促进铅锌混合硫化精矿及铅锌物料的清洁高效冶炼具有重要意义。

1 实验

1.1 实验材料

实验所用铅锌混合硫化精矿和次氧化锌烟灰均为株洲冶炼集团提供,其化学成分如表1和2所列。

表1 铅锌混合硫化精矿主要化学组成

Table 1 Chemical composition of lead and zinc mixed sulfide concentrates (mass fraction,%)

表2 次ZnO烟灰主要化学组成

Table 2 Chemical composition of secondary ZnO dusts (mass fraction,%)

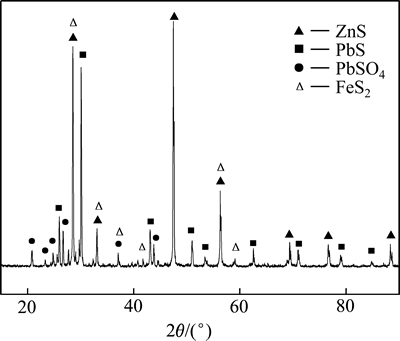

由表1可知,铅锌混合硫化精矿中的主要有价金属为Pb和Zn,其物相主要为硫化物(见图1)。此外,精矿中Au、Ag、In等贵金属含量也较高,具有较高的综合回收和利用价值。次氧化锌烟灰中的主要有价金属为Zn、Pb和In等。

图1 硫化铅锌混合精矿的XRD谱

Fig. 1 XRD pattern of lead and zinc sulfide concentrates

1.2 工艺流程

苏打熔盐低温还原固硫熔炼铅锌混合硫化精矿一步炼铅新工艺的原则流程如图2所示。

由图2可以看出,该工艺流程闭路循环,具有低温、低碳和清洁生产等优点。按照该流程,重点研究铅锌混合硫化精矿的还原固硫熔炼过程,由于试验规模较小,没有进行熔盐与固态物的热态分离,只是将冷却后的熔盐与固态物的混合物(熔盐渣) 进行水浸处理。

图2 铅锌混合硫化精矿低温还原固硫熔炼原则工艺流程

Fig. 2 Flow diagram of lead extraction from lead and zinc mixed sulfide concentrate using low-temperature smelting process

1.3 实验方法

单因素条件试验每次称取100 g铅锌混合硫化精矿,按一定比例配入不同量的苏打、次氧化锌烟灰和焦粉等辅料后,研磨混匀并装入反应器中。待电阻炉内温度达到预设值后,将盛有反应物料的石墨坩埚置于6 kW的电阻炉中并开始计时。达到设定的反应时间后,从电阻炉中快速取出坩埚,倒出熔体并在空气中自然冷却,分离金属铅和熔盐渣。将熔盐渣在常温下用2倍于精矿量的自来水浸出后过滤并烘干,分别取样称量、分析,计算铅的直收率( )和ZnO的固硫率(

)和ZnO的固硫率( ),计算公式为

),计算公式为

(1)

(1)

(2)

(2)

式中:m1、m 2和m 3分别代表精矿、粗铅和浸出渣的质量,g;w1和w2分别代表精矿和粗铅中铅的质量分数;w3和w4分别代表精矿和浸出渣中硫的质量分数。

2 实验原理

在以Na2CO3为熔盐介质、ZnO为固硫剂和焦粉为还原剂的熔炼体系中,铅锌混合硫化精矿中的PbS组分可能发生如式(3)~(9)反应:

PbS+3ZnO+3C=Pb+3ZnS+3CO(g) (3)

PbS+ZnO+CO(g)=Pb+ ZnS+3CO2(g) (4)

2PbS+2ZnO+C=2Pb+2ZnS+CO2(g) (5)

PbS+Na2CO3+2C=Pb+Na2S+3CO(g) (6)

PbS+Na2CO3+ CO(g)=Pb+Na2S+2CO2(g) (7)

2PbS+2Na2CO3+C=2Pb+2Na2S+3CO2(g) (8)

Na2S+ZnO+CO2(g)=Na2CO3+ZnS (9)

此外,精矿中的Fe、Cu、Sb等金属硫化物也可能按式(10)~(15)参与反应:

2FeS2+4Na2CO3+C=4Na2S+2FeO+5CO2(g) (10)

2FeS2+4ZnO+C=2FeO+4ZnS+CO2(g) (11)

2Sb2S3+6ZnO+3C=4Sb+6ZnS+3CO2(g) (12)

2Sb2S3+6Na2CO3+3C=4Sb+6Na2S+9CO2(g) (13)

2CuS+2Na2CO3+C=2Cu+2Na2S+3CO2(g) (14)

2CuS+2ZnO+C=2Cu+2ZnS+CO2(g) (15)

对以上反应,文献[23, 32 ]中已经进行了详细的热力学计算,其 与温度的关系如图3所示。

与温度的关系如图3所示。

从图3(a)可以看出:反应(3)~(5)在温度大于700 K时, 值均小于0,说明在有C或CO存在的还原气氛条件下,PbS和ZnO可发生还原固硫反应,产出液体铅和固态ZnS;在温度大于1080 K时,反应(6)中的

值均小于0,说明在有C或CO存在的还原气氛条件下,PbS和ZnO可发生还原固硫反应,产出液体铅和固态ZnS;在温度大于1080 K时,反应(6)中的 值也小于0,说明还原气氛条件下,PbS也可与Na2CO3发生还原固硫反应,产出液体铅和硫化钠。由于反应(9)在整个温度区间的

值也小于0,说明还原气氛条件下,PbS也可与Na2CO3发生还原固硫反应,产出液体铅和硫化钠。由于反应(9)在整个温度区间的 值均小于0,因此,Na2S又会和ZnO及CO2发生反应(9)生成Na2CO3和ZnS。由此可知:在一定温度下,铅锌混合硫化精矿在碳酸钠熔盐中可发生还原固硫反应产出液体铅和固态ZnS,熔盐的主成分Na2CO3在反应前后保持不变。

值均小于0,因此,Na2S又会和ZnO及CO2发生反应(9)生成Na2CO3和ZnS。由此可知:在一定温度下,铅锌混合硫化精矿在碳酸钠熔盐中可发生还原固硫反应产出液体铅和固态ZnS,熔盐的主成分Na2CO3在反应前后保持不变。

由图3(b)可知,在还原气氛条件下,锑、铜、铁的硫化物在反应温度大于1000 K时均可与ZnO发生还原固硫反应,硫以ZnS的形式固定,锑和铜被还原成单质进入粗铅,而FeS2中的铁转化为FeO。

此处要特别指出的是,以上绝大部分反应都产生CO或CO2气体,这对搅动熔体、强化传热传质, 加速熔炼过程的进行是非常有利的。

图3 不同反应的 与温度关系图

与温度关系图

Fig. 3  -T graphs of different reactions

-T graphs of different reactions

3 结果与讨论

采用单因素实验法分别进行了次ZnO及苏打用量、熔炼温度及时间等因素的条件试验,因采用石墨坩埚作为反应器,还原焦粉用量可能考察不准确,因此不作具体试验,其它因素试验中均固定焦粉用量为2倍理论量。

3.1 条件实验

3.1.1 次氧化锌用量的影响

取3倍精矿量的Na2CO3,在温度860 ℃下熔炼60 min,改变反应体系中次ZnO的加入量,实验结果如图4所示。

由图4可以看出,次ZnO加入量对固硫率的影响较为显著,固硫率随着次ZnO添加量的增加而增大。

图4 次ZnO加入量对产出铅和固硫率的影响

Fig. 4 Effects of secondary ZnO dosage on lead extraction rate and sulfur-fixing rate

当次ZnO添加量从精矿用量的0.29倍增加到0.36倍时,固硫率从85.51%急剧增大到94.73%,之后,继续增加次ZnO用量,固硫率增加较为缓慢,其最大峰值可以达到95.16%。增加次ZnO用量能促进固硫向正反应方向进行,因而有利于固硫率的提高,次ZnO用量太少,则原料中的硫可能和Na2CO3反应生成Na2S,造成熔盐损失和固硫率下降。与之相反,铅的直收率随着次ZnO添加量的增加而降低,当次ZnO添加量从精矿用量的0.29倍增加到0.43倍时,铅直收率从96.02%逐渐下降至95.16%,这主要是由于次ZnO的熔点较高,熔体的黏度会随着次ZnO添加量的增加而增大,过多加入次ZnO,粗铅和熔盐渣的澄清及分离将变得困难。综合考虑,本实验最适宜的次ZnO用量为精矿用量的0.36倍,即ZnO和精矿的质量比为0.36:1。

3.1.2 Na2CO3用量的影响

取0.36倍精矿量的次ZnO,在温度860℃下熔炼60 min,改变反应体系中Na2CO3的加入量,实验结果如图5所示。

由图5可以看出,当Na2CO3用量从2.5倍增加到3.0倍精矿量时,铅的直收率和固硫率分别从93.07%和92.31%快速增大到95.68%和94.73%,之后,继续增加Na2CO3用量,铅直收率和固硫率的增加速度均较缓慢,且当Na2CO3用量增加至3.2倍精矿量时,铅直收率和固硫率均达到其最大值,分别为96.08%和94.95%。Na2CO3量与精矿量之比,实际上相当于湿法冶金过程中的液固比,对冶金过程的影响非常明显。因此,增加熔盐量就是增大液固比,这样有利于降低熔体的黏度,提高其流动性,从而改善熔炼过程的传质、传热和产物的分离效果,降低金属铅在渣中的机械夹杂。然而过量的加入熔盐相当于稀释了反应物的浓度,会降低生产效率。综合考虑,本实验最适宜的熔盐用量为3.2倍精矿量,即碳酸钠和精矿的质量比为3.2:1。

图5 Na2CO3用量对产出铅和固硫的影响

Fig. 5 Effects of dosage of Na2CO3 on lead extraction rate and sulfur-fixing rate

3.1.3 熔炼温度的影响

取0.36倍精矿量的次ZnO、3.2倍精矿量的Na2CO3,熔炼时间为60 min时,改变反应体系的熔炼温度,其实验结果如图6所示。

图6 熔炼温度对产出铅和固硫的影响

Fig. 6 Effects of smelting temperature on lead extraction rate and sulfur-fixing rate

提高熔炼温度不仅可加快反应速度,而且可以降低熔盐黏度、增强熔体的流动性以及改善熔炼过程的传质、传热和产物澄清,分离效果好。由图6可以看出,熔炼温度越高,铅的产出和ZnO的固硫效果越好,当熔炼温度从800 ℃升至880 ℃时,铅直收率和固硫率分别从65.24%和56.43%急剧增加至97.26%和96.27%;之后,继续升高温度,铅的产出和ZnO的固硫效果变化不大,因此,从节能和降低熔盐挥发率的角度综合考虑,本实验最适宜的熔炼温度为880 ℃。

3.1.4 熔炼时间的影响

取0.36倍精矿用量的次ZnO、3.2倍精矿量的Na2CO3,在温度880℃下分别熔炼30、45、60、80和100 min,实验结果如图7所示。

图7 熔炼时间对产出铅和固硫的影响

Fig. 7 Effects of smelting time on lead extraction rate and sulfur-fixing rate

延长熔炼时间可使还原固硫反应进行更加充分,接近其平衡状态,也可使生成的金属铅有足够时间在熔盐中汇聚和分层,减少铅在渣中的损失。由图7可知,当熔炼时间达到60 min时,铅的直收率和固硫率分别达到97.26%和96.27%,继续延长熔炼时间,铅的产出和ZnO的固硫效果无明显变化。考虑到熔炼时间越长,能耗越大,生产效率越低,因此,本实验最适宜的熔炼时间为60 min。

3.2 综合扩大实验

3.2.1 实验产物

根据条件试验结果,确定最优条件为:ZnO和精矿的质量比为0.36:1,Na2CO3和精矿的质量比为3.2:1,焦粉为2倍理论用量,熔炼温度为880 ℃和熔炼时间为60 min。在最优条件下进行规模为400 g硫化铅锌混合精矿/次的综合扩大试验,冶炼产物粗铅、熔盐渣及水浸渣的质量及化学组成列于表3。

由表3可以看出,粗铅品位大于98.50%,杂质较少,计算得金属铅直收率为97.15%,金属铅总回收率(按渣含铅计算)为97.64%。水浸渣含锌55.8%,符合锌精矿的标准,可直接出售。同时,熔盐渣中金、银等贵金属含量难以检测出,说明它们均富集于粗铅中。

3.2.2 金属平衡

综合扩大试验中主要元素的平衡情况如表4所列。

表3 最优条件下主要产物的产出量及其化学成分

Table 3 Mass of product and its chemical composition in integrated experiments

表4 熔炼过程中主要元素的平衡情况

Table 4 Input-output balance of main elements in the process

由表4可知,熔炼过程中主金属和硫的平衡情况良好:精矿和次氧化锌烟灰中的铅几乎全部进入粗铅;Zn、S和In主要进入浸出渣;Sb和Cu大部分进入粗铅,这与前面的理论分析结果相符合;Au和Ag等贵金属几乎100%被粗铅捕集。因此,可考虑将高银锌精矿与铅精矿合炼,这对回收贵金属十分有利。

3.2.3 熔炼渣物相分析

将熔盐渣和浸出后的固态渣研磨到74 μm以下,分别取样进行了XRD分析,其结果如图8所示。

由图8(a)可知,熔盐渣的主要成分仍是Na2CO3,说明反应前后熔盐的化学形态未发生改变,可大部分热态返回再用,少部分用湿法再生,循环使用。由图8(b)可知,硫绝大部分以ZnS的形式被固定在固态渣中,ZnO固硫率为95.42%。

3.2.4 与ISP工艺的对比

表5所列为新工艺和ISP法处理铅锌混合硫化精矿生产粗铅的主要技术指标。由表5可以看出,和ISP工艺相比,该方法在降低熔炼温度、节能降耗、提高金属回收率和保护环境等方面具有明显的优势。

图8 熔盐渣和浸出渣XRD谱

Fig. 8 XRD patterns of smelting slag(a) and leach residue(b)

表5 本工艺与ISP工艺主要技术指标对比

Table 5 Comparisons between new process and ISP process

4 结论

1) 低温苏打熔盐还原固硫熔炼是清洁高效冶炼铅锌混合硫化精矿和高氟氯次氧化锌的理想工艺。

2) 铅锌混合硫化精矿低温苏打熔盐还原固硫熔炼一步炼铅的最佳工艺条件:ZnO和精矿的质量比为0.36:1,Na2CO3和精矿的质量比为3.2:1,熔炼温度为880 ℃,熔炼时间为60 min。

3) 在优化条件下,获得良好技术指标:铅直收率为97.15%,粗铅品位大于98.50%,氧化锌固硫率为95.42%。

4) 硫几乎全部转化为ZnS成为水浸渣的主要成分,水浸渣中w(Zn)>50%,是一种标准的硫化锌精矿。

5) 还原固硫熔炼过程中Na2CO3物相不变,可大部分热态返回,少部分用于湿法再生,实现循环利用。

REFERENCES

[1] LI Cun-xiong, WEI Chang, DENG Zhi-gan, LI Xing-bin, LI Min-ting, XU Hong-sheng. Hydrothermal sulfidation and flotation of oxidized zinc-lead ore[J]. Materials Transactions B, 2014, 45(3): 833-838.

[2] 黄彦强. 复杂铜铅锌混合精矿的冶炼分离研究[J]. 湖南有色金属, 2014, 30(1): 22-25.

HUANG Yan-qiang. Study on smelting separation of complex copper lead zinc mixed concentrate[J]. Hunan Nonferrous Metals, 2014, 30(1): 22-25.

[3] 徐 斌, 钟 宏, 王魁珽, 姜 涛. 复杂铜铅锌银混合精矿两段逆流氧压浸出工艺[J]. 中国有色金属学报, 2011, 21(4): 901-907.

XU Bin, ZHONG Hong, WANG Kui-ting, JIANG Tao. Two stage adverse current oxygen pressure acid leaching of complex Cu-Pb-Zn-Ag bulk concentrate[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 901-907.

[4] 张向阳, 王吉坤, 巨 佳, 徐 静, 杨大锦, 贺山明. 一种高铁低品位硫化铅锌混合精矿综合利用工艺探讨[J]. 矿冶, 2010, 19(3): 78-80.

ZHANG Xiang-yang, WANG Ji-kun, JU Jia, XU Jing, YANG Da-jin, HE Shan-ming. Utilization process of a high-iron low-grade bulk concentration of lead and zinc[J]. Mining and Metallurgy, 2010, 19(3): 78-80.

[5] 王 华, 田海军. 密闭鼓风炉炼锌工艺实践[J]. 有色冶金设计与研究, 2009, 30(5): 24-26.

WANG Hua, TIAN Hai-jun. Practice in zinc smelting in imperial smelting furnace[J]. Nonferrous Metals Engineering and Research, 2009, 30(5): 24-26.

[6] 马红周, 王成军, 刘 勇, 冯 涛. ISP冶炼厂含铅污染物排放工艺环节分析[J]. 有色金属(冶炼部分), 2014(7): 60-64.

MA Hong-zhou, WANG Cheng-jun, LIU Yong, FENG Tao. Analysis of emission technology of lead-bearing pollutants in ISP melting process[J]. Nonferrous Metals(Metallurgy Section), 2014(7): 60-64.

[7] GUO Xue-yi, XIAO Song-wen, XIAO Xiao, LI Qi-hou, RYOICHI Y.LCA case study for lead and zinc production by an imperial smelting process in China-A brief presentation[J]. International Journal of Life Cycle Assessment, 2002, 7(5): 276-276.

[8] YE Long-gang, TANG Chao-bo, CHEN Yong-ming, TANG Mo-tang, ZHANG Wen-hai. The thermal physical properties an stability of the eutectic composition in a Na2CO3-NaCl binary system[J]. Thermochimica Acta, 2014, 596: 14-18.

[9] CHEN Z, FRAY D, FARTHING T. Direct electrochemical reduction of titanium dioxide to titanium in molten calcium chloride[J]. Nature, 2000, 407: 361-364.

[10] ZHOU Dao, ZHAO Chang-ying, TIAN Ye. Review on thermal energy storage with phase change materials (PCMs) in building applications[J]. Applied Energy, 2012, 92: 593-605.

[11] LONG Yang-yang, LI Jian-zhi, TIMMER D H, JONES R E, GONZALEZ M A. Modeling and optimization of the molten salt cleaning process[J]. Journal of Cleaner Production, 2014, 68: 243-251.

[12] 肖剑飞, 唐朝波, 唐谟堂, 陈永明. 硫化铋精矿低温碱性熔炼新工艺研究[J]. 矿冶工程, 2009, 29(5): 82-85.

XIAO Jian-fei, TANG Chao-bo, TANG Mo-tang, CHEN Yong-ming. Study on a new process for alkaline smelting bismuth sulfide concentrate at low temperature[J]. Mining and Metallurgical Engineering, 2009, 29(5): 82-85.

[13] 郭学益, 刘静欣, 田庆华, 李 栋. 有色金属复杂资源低温碱性熔炼原理与方法[J]. 有色金属科学与工程, 2013, 4(2): 8-13.

GUO Xue-yi, LIU Jing-xin, TIAN Qing-hua, LI Dong. Principle and method of low temperature alkaline smelting in non-ferrous metallurgy complicated resources[J]. Nonferrous Metals Science and Engineering, 2013, 4(2): 8-13.

[14] 郭学益, 李 菲, 田庆华, 计 坤. 二次铝灰低温碱性熔炼研究[J]. 中南大学学报(自然科学版), 2012, 43(3): 809-812.

GUO Xue-yi, LI Fei, TIAN Qing-hua, JI Kun. Recovery of aluminium from secondary aluminum dross using low-temperature alkaline smelting[J]. Journal of Central South University (Science and Technology), 2012, 43(3): 809-812.

[15] 田庆华, 程利振, 袁廷刚, 辛云涛, 郭学益. NaOH-Na2S熔盐法处理分银渣[J]. 中南大学学报(自然科学版), 2014, 45(8): 2553-2557.

TIAN Qing-hua, CHEN Li-zhen, YUAN Ting-gang, XIN Yun-tao, GUO Xue-yi. Processing of silver separated residue by NaOH-Na2S molten salt method[J]. Journal of Central South University (Science and Technology), 2014, 45(8): 2553-2557.

[16] 郭学益, 刘静欣, 田庆华. 废弃电路板多金属粉末低温碱性熔炼过程的元素行为[J]. 中国有色金属学报, 2013, 23(6): 1757-1762.

GUO Xue-yi, LIU Jing-xin, TIAN Qing-hua. Elemental behavior of multi-component metal powders from waste printed circuit board during low-temperature alkaline smelting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1757-1762.

[17] 刘静欣, 郭学益, 刘 旸. 废弃电路板多金属粉末碱性熔炼产物分形浸出动力学[J]. 中国有色金属学报, 2015, 25(2): 545-552.

LIU Jing-xin, GUO Xue-yi, LIU Yang. Fractal leaching kinetics of alkaline smelting product with metal enrichment from waste printed circuit boards[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 545-552.

[18] 唐谟堂, 唐朝波, 陈永明, 杨建广, 杨声海, 何 静, 欧 召. 一种很有前途的低碳清洁冶金-重金属低温熔盐冶金[J]. 中国有色冶金, 2010(4): 49-53.

TANG Mo-tang, TANG Chao-bo, CHEN Yong-ming, YANG Jian-guang, YANG Sheng-hai, HE Jing, OU Zhao. A promising low carbon clean metallurgical method-low-temperature molten salt metallurgy of heavy metal[J]. China Nonferrous Metallurgy, 2010(4): 49-53.

[19] 唐谟堂, 陈永明, 唐朝波, 杨建广, 杨声海, 何 静, 邵国军. 一种锑的低温熔盐清洁冶金方法: 中国, CN101914693A[P]. 2010-12-15.

TANG Mo-tang, CHEN Yong-ming, TANG Chao-bo, YANG Jian-guang, YANG Sheng-hai, HE Jing, SHAO Guo-jun. A process for clean metallurgy of antimony in a molten salt at low-temperature: China, CN101914693A[P]. 2010-12-15.

[20] 唐谟堂, 杨建广, 唐朝波, 陈永明, 杨声海, 何 静. 一种铋的低温熔盐清洁冶金方法: 中国, CN101956084A[P]. 2011-01-26.

TANG Mo-tang, YANG Jian-guang, TANG Chao-bo, CHEN Yong-ming, YANG Sheng-hai, HE Jing. A process for clean metallurgy of bismuth in a molten salt at low-temperature: China, CN101956084A[P]. 2011-01-26.

[21] 唐谟堂, 杨建广, 唐朝波, 何 静, 陈永明, 杨声海, 叶龙刚. 一种锡的低温熔盐清洁冶金方法: 中国, CN102102154A[P]. 2011-06-22.

TANG Mo-tang, YANG Jian-guang, TANG Chao-bo, HE Jing, CHEN Yong-ming, YANG Sheng-hai, YE Long-gang. A Process for clean metallurgy of stannum in a molten salt at low-temperature: China, CN102102154A[P]. 2011-06-22.

[22] YANG Jian-guang, TANG Chao-bo, CHEN Yong-ming, TANG Mo-tang. Separation of antimony from a stibnite concentrate through a low-temperature smelting process to eliminate SO2 emission[J]. Metall Mater Trans B, 2011, 42(1): 30-36.

[23] 叶龙刚, 唐朝波, 唐谟堂, 杨建广, 陈永明, 杨声海, 何 静. 硫化锑精矿低温熔炼新工艺[J]. 中南大学学报(自然科学版), 2012, 43(9): 3338-3342.

YE Long-gang, TANG Chao-bo, TANG Mo-tang, YANG Jian-guang, CHEN Yong-ming, YANG Sheng-hai, HE Jing. Seperation antimony from stibnite concentrate through a low temperature smelting[J]. Journal of Central South University (Science and Technology), 2012, 43(9): 3338-3342.

[24] YE Long-gang, TANG Chao-bo, CHEN Yong-ming, T ANG Mo-tang, ZHANG Wen-hai. Reaction behavior of sulfides associated with stibnite in low temperature molten salt smelting process without reductant[C]// TMS 5th international symposium on high-temperature metallurgical process. Sandiego: TMS Annual Meeting Committee, 2014: 99-103.

[25] 刘小文, 杨建广, 伍永田, 李 静, 唐朝波, 陈永明, 唐谟堂. 由辉锑矿低温固硫熔炼制取粗锑[J]. 中国有色金属学报, 2012, 22(10): 2896-2901.

LIU Xiao-wen, YANG Jian-guang, WU Yong-tian, LI Jing, TANG Chao-bo, CHEN Yong-ming, TANG Mong-tang. Separation of needle antimony from stibnite through low- temperature sulfur-fixing smelting process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2896-2901.

[26] HE De-wen, YANG Jian-guang, TANG Chao-bo, CHEN Yong-ming, TANG Mo-tang. Separation of bismuth from a bismuth glance concentrate through a low-temperature smelting process[J]. Miner Process Extr M, 2013, (34): 73-77.

[27] YANG Jian-guang, HE De-wen, TANG Chao-bo, CHEN Yong-ming, SUN Ya-hui, TANG Mo-tang. Thermodynamics calculation and experimental study on separation of bismuth from a bismuth glance concentrate through a low-temperature molten salt smelting process[J]. Metallurgical and Materials Transactions B, 2011, 42(4): 730-735.

[28] 刘小文, 杨建广, 李 静, 陈永明, 孙亚辉, 唐谟堂. Bi2S3-ZnO-Na2CO3体系热力学分析及应用[J]. 中国有色金属学报, 2012, 22(1): 310-314.

LIU Xiao-wen, YANG Jian-guang, LI Jing, CHEN Yong-ming, SUN Ya-hui, TANG Mong-tang. Thermodynamic analysis of Bi2S3-ZnO-Na2CO3 and its application[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 310-314.

[29] 唐谟堂, 唐朝波, 陈永明, 杨建广, 杨声海, 何 静, 王一霖. 一种铅的低温熔盐清洁冶金方法: 中国, CN101864522A[P]. 2010-10-20.

TANG Mo-tang, TANG Chao-bo, CHEN Yong-ming, YANG Jian-guang, YANG Sheng-hai, HE Jing, WANG Yi-lin. A Process for clean metallurgy of lead in a molten salt at low-temperature: China, CN 101864522A[P]. 2010-10-20.

[30] HU Yu-jie, TANG Chao-bo, TANG Mo-tang, CHEN Yong-ming. Reductive smelting of spent lead-acid battery colloid sludge in a molten Na2CO3 salt[J]. International Journal of Minerals Metallurgy and Materials, 2015, 22(8): 798-803.

[31] 胡宇杰, 唐朝波, 唐谟堂, 杨建广, 陈永明, 杨声海, 何 静. 一种再生铅低温清洁冶金的绿色工艺[J]. 有色金属(冶炼部分), 2013(8): 1-4.

HU Yu-jie, TANG Chao-bo, TANG Mo-tang, YANG Jian-guang, CHEN Yong-ming, YANG Sheng-hai, HE Jing. A clean and green process of low temperature for smelting of secondary lead[J]. Nonferrous Metals(Metallurgy Section), 2013(8): 1-4.

[32] 胡宇杰, 唐朝波, 唐谟堂, 陈永明, 杨建广, 杨声海, 何 静. 废铅酸蓄电池胶泥低温钠熔盐还原熔炼新工艺[J]. 中国有色冶金, 2014(1): 75-78.

HU Yu-jie, TANG Chao-bo, TANG Mo-tang, CHEN Yong-ming, YANG Jian-guang, YANG Sheng-hai, HE Jing. Reductive smelting of spent lead-acid battery colloid sludge in molten salt of sodium at low temperature[J]. China Nonferrous Metallurgy, 2014(1): 75-78.

(编辑 李艳红)

基金项目:国家重点自然科学基金资助项目(51234009);湖南省自然科学基金资助项目(13JJ5035);湖南省教育厅科学研究项目基金资助项目(14C0349)

收稿日期:2015-03-03;修订日期:2015-04-22

通信作者:唐朝波,副教授,博士;电话:0731-88830470;E-mail: tangchaobo9043@163.com