EBSD analysis on aluminum brazing sheet for

automotive heat exchangers

JI Yan-li(纪艳丽)1, GUO Fu-an(郭富安)1, SHEN Jian-sheng(沈健生)2

1. Suzhou Institute for Nonferrous Metals Processing Technology, Suzhou 215026, China;

2. Wuxi Yinbang Aluminum Industry Co, Ltd, Wuxi 214145, China

Received 28 July 2006; accepted 15 September 2006

Abstract: Grain boundary character distribution (GBCD) in the vicinity of clad-core interface in annealed aluminum brazing sheet was investigated by EBSD technique. The results show that, with the increase of annealing temperature, the frequency of special boundaries increases, but the random boundary network can not be fragmented by special boundaries. This means that Si diffusion in annealed sample may not be reduced during brazing. The results also indicate that the modified microstructure of the core, with coarse grains distributed parallel to the rolling direction and broken random boundary network by high frequency of special boundaries,would enhance the brazeability by suppressing the excess Si grain boundary (GB) diffusion from the cladding to core material.

Key words: aluminum brazing sheet; grain boundary character distribution (GBCD); Si diffusion; EBSD

1 Introduction

Aluminum alloys are commonly used for heat exchangers in the automotive industry due to an interesting combination of properties (low density, good thermal conductivity, satisfactory mechanical properties and relatively good corrosion resistance) [1-6]. Since the middle of the 1990s, the trend with automotive heat exchangers is to replace mechanical assembly by brazing of aluminum alloys. The present brazed aluminum sheets consist of multi-layer materials made up of a core composed of a member of the 3××× series clad on one or both sides with an alloy from the 4××× series [1-2, 7]. The brazing process is based on the difference in the melting points of the core and of the cladding. During the brazing process, the excess diffusion of silicon along grain boundaries from the cladding will result in poor thermal fatigue and intergranular attack [2, 8]. But if the key alloying elements and diffusion of Si can be controlled to form a “band of dense precipitates” (BDP) in the core material, which shows lower corrosion potential than center of the core, thereby acting as a sacrificial layer to protect the core against external corrosion [8]. So it is important to research the diffusion of Si for improving the performance of aluminum brazing sheet.

It is well known that grain boundary diffusivity depends on the character of the grain boundary [9]. The random boundary has more structural defects, which are linked to high grain boundary diffusion rate [10], while the coincidence boundaries with low ∑ values maintain a high coherency of atomic configuration in neighboring grains and have low energy [11]. Usually, it has been assumed that “special” grain boundaries are those described by low values (with some arbitrary upper limit) of the reciprocal density of coincident sites, ∑, in the framework of the coincidence site lattice (CSL) model [12]. Special boundaries act more effectively in suppressing the grain boundary embitterment at room and low temperatures [11] and the boundary sliding at high temperatures [11], and show higher resistance to diffusion [9] and corrosion [13] compared to random boundary with high energy. Former study shows that, with the increase of the frequency of special boundaries, the grain boundary diffusion decreases [9]. There exist many researches which focus on the microstructural evolution, the diffusion of Si and the formation of intermetallic compounds in aluminum brazing sheet during brazing process [1-3, 7-8, 14], but there are few investigations on effect of grain boundary character distribution (GBCD), which is a parameter used to quantitatively describe the type and frequency of grain boundaries present in a microstructure, in the core on Si diffusion and performance of clad aluminium sheet.

The main objective of this work is to investigate the GBCD in the vicinity of clad-core interface of annealed aluminum brazing sheet by EBSD technique in order to supply experimental data and method for further study on Si grain boundary (GB) diffusion in clad aluminium sheet during brazing.

2 Experimental

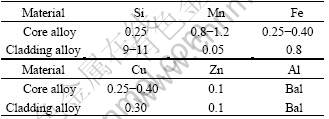

Samples used in this work were cut from hot and cold-rolled AA3017 aluminum alloy (core alloy, 1 200 μm thick) clad on both sides with AA4045 aluminum alloy (180 μm thick). The compositions of the core and filler alloys are listed in Table 1. The samples were annealed at 423 and 643 K for 3 h and 45 min respectively. Annealed samples were electro-polished for EBSD analysis. Electropolishing was performed in a solution of 90% ethyl alcohol-10% perchloric acid. The optical microstructures of as-received samples were investigated using a Nikon Epiphot 200 optical microscope after etching in Keller’s solution. The data sets for determining GBCD of annealed samples were obtained from analysis of electron backscattered diffraction (EBSD) and automated orientation imaging microscopy (OIM) on a LEO1450 scanning electron microscope (SEM) with HKL EBSD detector and Channel 4 system. Grain boundaries were characterized in terms of the CSL model using Brandon’s criterion [15].

Table 1 Compositions of AA3017 core alloy and AA4045 cladding material(mass fraction, %)

3 Results and discussion

3.1 Microstructure

Fig.1 shows the optical microstructures of the studied sample. It can be seen from Fig.1(a) that, the sample consists of three-layers: the core alloy and the cladding layers on both sides. These three layers play different roles in the brazing process. During the brazing, the clad sheet is heated for a short duration at a temperature between the melting temperatures of the cladding and core alloys. Owing to the low melting point, the clad layer is brazed with the extruded multi-port Al tube, and the core layer keeps its strength in order to avoid the collapse of the assembly. Therefore, the clad material should have good brazeability, and the core material should have suitable microstructure and chemical composition to avoid excessive Si diffusion from clad layer, which will result in poor strength of the core layer and decrease Si content in cladding layers. From Fig.1(b), it can be observed that, in the cladding layer, Si particles are homogenously dispersed (as indicated by arrow), and in the core layer, the light grey particles are Al6(Mn,Fe) phase [16]. Owing to the low nominal silicon level of alloy AA3017, Si bearing intermetallic precipitates are not expected in the core.

Fig.1 OM images of as-received sample by different magnifications

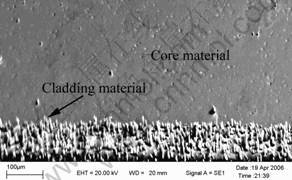

Fig.2 shows a SEM image of the as-received sample. Attempts for achieving electron backscattered patterns in the cladding layer were unsuccessful because of its high volume fraction of Si particles, as shown in the bottom of Fig.3(b). Only electron backscattered patterns near to the clad/core boundaries were obtained.

Fig.2 SEM image of as-received sample

3.2 EBSD analysis

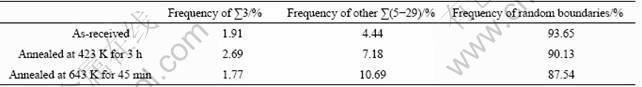

Fig.3 shows some typical EBSD grain boundary maps for as-received and annealed samples, and Table 2 lists the corresponding frequencies of low ∑CSL (up to 29) type grain boundaries and random grain boundaries. As shown in Fig.3, special boundaries exist in the annealed samples. And with the increase of annealing temperature, the grains are refined, as shown in Fig.3(c). It can be observed from Table 2 that, the frequency of ∑3 boundaries has little variation with the increase of annealing temperature, but the frequency of other low ∑ boundaries (∑5-∑29) increases significantly, and the total frequency of low ∑ boundaries increases with the increase of annealing temperature. This indicates that, with the increase of annealing temperature, the studied material maybe have stronger resistance to Si diffusion, and decrease the intergranular attack for the increase of low energy special boundaries frequency. But Connectivity of boundaries is more important than the absolute volume fraction of special boundaries [17]. There are two main ways with which grain boundary connectivity is quantified by GBCD investigations; one is to analyze the constitution of triple junctions, the other is percolation dynamics and cluster mass analysis [17]. The former was employed to analyze connectivity of boundaries in this study. The rationale is that, in a two dimensional microstructure, if a triple junction comprises at least two CSL boundaries, it will fragment the random boundary network [17]. As shown in Fig.3, pathways of connected random boundaries in the microstructures are not broken up by special boundaries, and random boundaries in the vicinity of clad-core interface still have a high frequency. And with the increase of temperature, the grains of the core are refined. In Yoon’s study [2], the core with coarsen grains will have excellent resistance to Si diffusion. Considering described above, Si diffusion along grain boundary from cladding to the core in annealed material will not be reduced during brazing cycle and/or in high temperature.

Grain boundaries are known to contribute to faster diffusion than in the bulk by providing an easy path for matter transport, because atoms can easily squeeze their way through the disordered grain boundary, and the activation energy is low [18]. The GB is described by two physical parameters: the GB width δ, and the GB diffusion coefficient Db. It is assumed that Db>D, where D is the volume diffusion coefficient [18].

It is well known that the GB diffusion coefficient depends on temperature, as described by the following Arrhenius equation [18]:

Db=Db0exp(-Eb/RT) (1)

where Eb is the activation energy of GB diffusion; Db0 is the pre-exponential factor; R is the gas constant.

Fig.3 EBSD grain boundary maps from samples as-received (a) and annealed at 423 K for 3 h(b) and at 643 K for 45 min(c)

Table 2 Measurement results of grain boundary characters distribution of samples as processed

The diffusion model for describing the diffusion in the volume and along the grain boundary can be written in form of two coupled partial differential equations as follows [14, 18]:

(2)

(2)

(3)

(3)

where c, cb, D, Db, δ, t, x, and y represent concentration of silicon in the bulk aluminum core alloy, concentration of silicon along the aluminum grain boundary, volume diffusion coefficient of silicon in aluminum, grain boundary diffusion coefficient of silicon in aluminum, grain boundary thickness, time, and Cartesian coordinates, respectively.

The experimental results confirm that the grain boundary diffusivity is closely associated with its structure [19]. Low ∑CSL type grain boundaries show higher activation energy than random boundaries, therefore special boundaries have lower Db than that of random boundaries. Consequently, special boundaries show lower diffusivity than random boundaries.

The grain size, its shape and distribution also influence Si GB diffusion. The microstructures with coarse grains distributed parallel to the rolling direction have good resistance to Si GB diffusion [2, 20-21].

Therefore, during brazing cycle, Si diffusion occurs easily through grain boundary in the vicinity of clad-core interface from the clad to the core, then the diffusion maybe accelerate phase transformation of Al6(Mn,Fe) to α-Al(Mn, Fe)Si [1, 16], thus, a BDP is formed in the core. But if random boundaries network in the core has been fragmented by high frequency of special boundaries and the grains in the core is large for decreasing the whole length of diffusivity path and distribute with the rolling direction, excess Si diffusion maybe has been controlled and reduced. Therefore, the brazing aluminum sheet will exhibit excellent brazeability with suppressed erosion owing to modified microstructures. These modified microstructures can be achieved by controlling the parameters of thermomechanical treatments and annealing [2, 20-21].

From the above discussion, we can make an assumption that the macrostructures of the core, with coarse grains distributed parallel to the rolling direction, would hinder the excess Si diffusion from the clad to the core, and consequently, advance the formation of BDP.

4 Conclusions

1) EBSD technique is a powerful tool to gain GBCD of the core material, and investigate structure- dependence of Si GB diffusion from the clad to the core in aluminium brazing sheet during brazing.

2) With the increase of annealing temperature, frequency of special boundaries increases, but random boundaries network isn’t broken up by special boundaries in the vicinity of clad-core interface in aluminium brazing sheet.

3) The modified microstructure of the core, with coarse grains distributed parallel to the rolling direction and broken random boundary network by high frequency of special boundaries,would enhance the brazeability by suppressing the excess Si GB diffusion from the cladding to core material.

References

[1] LACAZE J, TIERCE S, LAFONT M C, THEBAULT Y, P?B?RE N, MANKOWSKI G, BLANC C, ROBIDOU H, VAUMOUSSE D, DALOZ D. Study of the microstructure resulting from brazed aluminium materials used in heat exchangers [J]. Mater Sci & Eng A, 2005, A413-414: 317-321.

[2] YOON J S, LEE S H, KIM M S. Fabrication and brazeability of a three-layer 4343/3003/4343 aluminum clad sheet by rolling [J]. Journal of Materials Processing Technology, 2001, 111: 85-89.

[3] CAO Xiu-li, WANG Cheng-zhi, LI Ya-jiang. Microstructure analysis of aluminum alloy vacuum brazing joints [J]. Transactions of Shenyang Ligong University, 2005, 24: 10-14.

[4] YIN Xao-hui, CHEN Xin-min. Study on combined hot rolling process for aluminum alloy brazing sheet(Foil) [J]. Aluminium Fabrication, 2005, 3: 22-26.

[5] WANG Ning, LI Yi, YU Jiu-min. Processing techniques for composite brazing aluminum stripe used in automotive heat exchanger [J]. Automobile Technology & Material, 2004, 9: 37-40.

[6] FENG Tao, LOU Song-nian, YANG Shang-lei, LI Ya-jian. Mechanical property and microstructure of aluminum radiator vacuum brazing joint [J].Pressure Vessel Technology, 2004, 21(12): 12-16.

[7] PAN Chun-xu, DUSAN P. Microstructural characteristics of AA4343/AA3003 Al-alloy sheet brazed joints [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 481-485.(in Chinese)

[8] MARSHALL G J, BOLINGBROKE R K. Microstructural control in an aluminum core alloy for brazing sheet applications [J]. Metallurgical and Materials Transactions A, 1993, A24(9): 1935-1942.

[9] NITTA H, IIJIMA Y, TANAKA K, et al. Grain boundary self-diffusion in directionally solidified equiatomic Fe-Co alloy [J]. Materials Science and Engineering A, 2004, A382: 250-256.

[10] HAYAKAWA Y, KUROSAWA M. Orientation relationship between primary and secondary recrystallized texture in electrical steel [J]. Acta Materialia, 2002, 50: 4527-4534.

[11] MATSUMOTO K, SHIBAYANAGI T, UMAKOSHI Y. On the role of grain boundary character distribution in grain growth of Al-Mg alloys [J]. Acta Materialia, 1997, 45: 439-451.

[12] GERTSMAN V Y, BRUEMMER S M. Study of grain boundary character along intergranular stress corrosion crack paths in austenitic alloys [J]. Acta Materialia 2001, 49: 1589-1598.

[13] KIM S H, ERB U, AUST K T, PALUMBO G. Grain boundary character distribution and intergranular corrosion behavior in high purity aluminum [J]. Scripta Materialia, 2001, 44: 835-839.

[14] FENG Gao, ZHAO Hui, SEKULIC D P, QIAN Y, WALKER L. Solid state Si diffusion and joint formation involving aluminum brazing sheet [J]. Materials Science and Engineering A, 2002, A337: 228-235.

[15] BRANDON D G. The structure of high-angle grain boundaries [J]. Acta Metallurgica, 1966, 14: 1479-1984.

[16] LI Y J, ARNBERG L. Evolution of eutectic intermetallic particles in DC-cast AA3003 alloy during heating and homogenization [J]. Materials Science and Engineering A, 2003, A347: 130-135.

[17] RANDLE V. Twinning-related grain boundary engineering [J]. Acta Materialia, 2004, 52: 4067-4081.

[18] MISHIN Y, HERZIG C. Grain boundary diffusion: recent progress and future research [J]. Materials Science and Engineering A, 1999, A260: 55-71.

[19] GARBACZ A, WYRZYKOWSKI W. Correlation between diffusitity of grain boundaries and distribution of coincidence site lattice boundaries in polycrystals [J]. Materials Science and Engineering A, 1993, A172: 137-144.

[20] LEE S H, KIM M S, JUNG D S, HAN J W, YOU B D. Fabrication and sagging behavior of three-layer Al-Si/Al-Mn-Zn/Al-Si clad sheets for automotive heat exchanger [J]. Materials Science Forum, 2003, 439: 221-226.

[21] FUKUMOTO A, DOKO T. Control of erosion in brazing sheet produced by continuous annealing process [J]. Materials Forum, 2004, 28: 319-325.

(CHEN Ai-hua)

Corresponding author: JI Yan-li; Tel: +86-512-62585996; E-mail:jxm0319@yahoo.com.cn