文章编号:1004-0609(2010)S1-s0021-04

添加返回炉料TA15钛合金材料的基础研究

丁长勤,高 博,魏寿庸,何书林,陈战乾,马 英,刘艳荣

(宝钛集团有限公司,宝鸡 721014)

摘 要:对工业化条件下添加返回炉料生产TA15钛合金加工材进行基础研究。将屑状、块状返回炉料进行净化处理后添加于TA15合金,经熔炼、锻造后制备不同规格棒材(d20~120 mm)。对棒材进行显微组织、力学性能分析,并同未添加返回炉料棒材进行对比以考察添加返回炉料后棒材综合性能。结果表明:添加返回炉料生产的TA15合金棒材完全满足标准要求;除强度略高外,组织、力学性能与未添加返回炉料的棒材基本相当,但需对返回炉料进行净化处理及加工材杂质元素进行控制。

关键词:TA15钛合金;返回炉料;基础研究;显微组织;力学性能

中图分类号:TG 146.2+3 文献标志码:A

Basic research for TA15 titanium alloy with return charge

DING Chang-qin, GAO Bo, WEI Shou-yong, HE Shu-lin, CHEN Zhan-qian, MA Ying, LIU Yan-rong

(Baoti Group Co., Ltd., Baoji 721014, China)

Abstract: Basic research for TA15 titanium alloy working was performed under the conditions of industrialized production with return charge. The dust-like and massive return charge was added for TA15 titanium alloy after cleaning treatment. The bars with different diameters from 20 mm to 120 mm were prepared after melting and forging. The microstructure and mechanical properties of the bar were analyzed, and the comparative test was performed with the bars without return charge in order to study the comprehensive performance of the bars with return charge. The results show that the bars with return charge meet the standard requirements completely. The microstructure and mechanical properties are roughly equal with the bars without return charge except that the strength is slightly higher. But futher study is required for the pure processing of return charge and impurity control of the working material.

Key words: TA15 titanium alloy; return charge; basic research; microstructure; mechanical properties

TA15合金是一种综合性能优良的中强钛合金,焊接性能良好,具有较好的加工性能,可用于生产薄板、厚板、型材、棒材、锻件、模锻件和线材等产品[1]。该合金还具有良好的热稳定性能,也适于制作在450 ℃ (6 000 h)和500 ℃(3 000 h)时长时间工作的构件。目前,国内在航空、航天和舰船等武器装备上钛合金用量不断增加,而对成本控制的要求也日益明确,因而降低钛合金原材料成本的技术将有广阔的应用前景。本文作者对TA15钛合金添加返回炉料进行基础研究工作,对添加返回炉料生产的棒材进行性能、组织、热处理测试和实验。通过研究,实现TA15钛合金添加返回料生产加工材,为降低钛合金生产成本和提高TA15钛合金产业化生产水平提供理论支持。

1 实验

针对加入返回炉料的TA15合金铸锭,在单相区开坯锻造,两相区中间及成品锻造,分别制备d120 mm、d80 mm、d47 mm和d20 mm棒材,并进行性能检测,与未添加返回炉料的TA15合金棒材进行对比。同时,对d20 mm棒材选取不同的热处理工艺进行组织和性能检测。

2 结果与讨论

2.1 显微组织

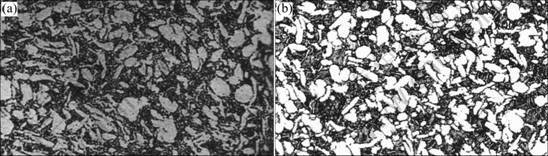

图1(a)所示为没有添加返回炉料的TA15合金小棒的显微组织,图1(b)所示为加入返回炉料的TA15合金小棒的显微组织。对于加入返回炉料的TA15合金,所生产的棒材的显微组织满足相关标准的要求,其组织形貌与未添加返回炉料的棒材的显微组织基本一致。

2.2 力学性能

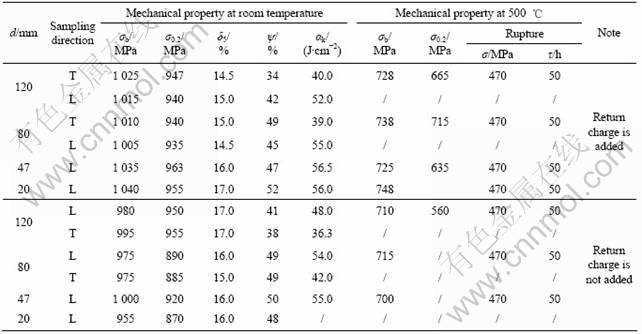

添加返回炉料的棒材及与未添加返回炉料的棒材的力学性能测试结果如表1所列。从表1可以看出,添加返回炉料的TA15合金棒材的性能经过坯料的充分变形,其各项性能指标均达到技术标准的要求。与未加返回炉料的棒材相比,由于杂质元素偏高,室温强度稍高,塑性水平稍低,高温强度略高。

2.3 添加返回炉料棒材的热处理工艺

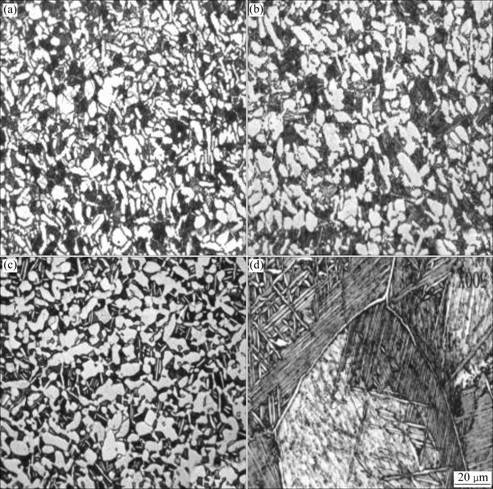

TA15钛合金是一种近α钛合金,不可以热处理强化,一般只采用普通退火。为了充分了解热处理工艺对加入返回炉料的TA15钛合金组织和性能的影响,进一步优化工艺,提高产品的组织性能,本试验重点研究退火温度对合金显微组织及拉伸性能的影响,表2所列为不同退火制度下的力学性能。图2所示为不同热处理制度下的显微组织。

图1 添加返回炉料棒材及未添加返回炉料棒材的显微组织

Fig.1 Microstructures of bars without (a) and with return charge (b)

表1 添加返回炉料与未加返回炉料的棒材性能对比

Table 1 Comparison of properties between bars with and without return charge

图2 不同工艺热处理的棒材的显微组织

Fig.2 Microstructures of bars under different heat treatments: (a) 700 ℃, 1 h, AC; (b) 800 ℃, 1 h, AC; (c) 900 ℃, 1 h, AC, (d) 1 010 ℃, 1 h, AC

表2 不同退火制度下棒材的力学性能

Table 2 Mechanical properties of bars under different annealing treatments

从表2可以看出,除热处理温度超过TA15合金的相变温度之后塑性急剧下降外,其余强度和塑性的指标差异不大,强度随着温度的升高略有降低,塑性变化不大,但整体强度水平略高于没有加入返回炉料TA15合金小棒的。由此可以看出,塑性水平与没有加入返回炉料的TA15合金小棒的相当。

在相变点(Tβ)以下加热时,空冷后均形成α+β双态组织,组织中初生α相含量基本相同,为20%~30%。转变的β组织,其形貌也比较接近,故各温度处理后的拉伸性能差异不大,σb值均在1 020~1 090 MPa的范围内。在1 010 ℃加热时,因已进入β相区,故空冷后形成魏氏组织,存在明显的晶界,造成屈服强度较低,塑性也较差。

3 结论

1) 添加返回炉料的TA15合金棒材力学性能和组织均满足技术标准要求。

2) 由于添加返回炉料后铸锭杂质元素含量总体偏高,造成添加返回炉料铸锭生产的TA15棒材与未添加返回炉料的棒材相比,强度略高,塑性略低。

3) 不同热处理温度下棒材的拉伸性能差异不大,经β热处理后,形成魏氏组织,存在明显的晶界,屈服强度较低,塑性也较差。

4) 添加返回炉料可能带来夹杂以及杂质元素增加的风险,需在返回炉料处理过程以及添加过程中以防范。

REFERENCES

[1] 王永强, 陶海林, 冯永琦, 张永强, 魏寿庸. 加热温度计冷却速度对BT20钛合金组织与性能的影响[J]. 金属学报, 2002, 38(s): 81-88.

WANG Yong-qiang, TAO Hai-lin, FENG Yong-qi, ZHANG Yong-qiang, WEI Shou-yong. Effects of heating temperature and cooling rate on the microstructure and properties of BT20 alloy [J]. Acta Metallurgica Sinica, 2002, 38(s): 81-88.

(编辑 杨 华)

通信作者:丁长勤; 电话:0917-3382252;E-mail: dingding.73@163.com