J. Cent. South Univ. Technol. (2011) 18: 1638-1645

DOI: 10.1007/s11771-011-0883-3

Effect of geogrid reinforcement on soft and medium dense soils

JEON Sang-Soo

Department of Civil Engineering, Construction Technology Research Center,

INJE University, Obang-dong 607, Kimhae, Kyungsangnam-Do #621-749, South Korea

? Central South University Press and Springer-Verlag Berlin Heidelberg 2011

Abstract: The field tests were carried out to examine the reinforcement effect of a geogrid on various conditions of embankment height, the number of passages of vibratory roller, the number of reinforced layer of geogrid, and soil properties. The test results of the dynamic earth pressure indicate that the soil reinforced by geogrid is very effective to increase the stiffness of soil, especially in soft soil. The dynamic earth pressure ratio, which is defined as the ratio of dynamic earth pressure to self weight of soils, exponentially decreases as the embankment height increases. The dynamic earth pressure ratio increases up to 80% for soft soils reinforced by both one layer of geogrid in place of no reinforced soils and two layers in place of a single layer of geogrid.

Key words: dynamic earth pressure; geogrid; reinforced soils; repetitive loading

1 Introduction

The practice of soil reinforcement using geogrid is well established and geogrid is being increasingly used as reinforcement for railway and roadway foundations, earth retaining walls, bridge abutments and the other applicable areas [1-4]. Analytical and model studies to examine reinforcement effects of geotextile were carried out in soft clay [5]. The reinforced soils generally provide the denser and stiffer soils and the peak strength of reinforced soils increases as the number of geotextile sheets and confining pressure increase [6-8].

The shear strength of sand under static load was substantially increased by the reinforced fiber and especially two layers of geotextile are optimal to reinforce unpaved road [9-10]. HAERI et al [7] derived the analytical solution for the effects of embankment heights of the soft ground reinforced by geogrid. HOLTZ and SIVAKUGAN [11] developed the design sheet reflecting the specification of the embankment height based on this analytical solution. The lateral and vertical deformations of the foundation were substantially reduced by the reinforcement during embankment construction [12].

WEBSTER and ALFORD [13] established a chart giving the thickness of aggregate layer as a function of number of passages and California Bearing Ratio (CBR) of subgrade soil, for a standard axle load of 80 kN. The stiffness, stress, and strain in geosynthetic-reinforced soils subjected to the repeated loadings were evaluated by analytical and numerical models and lab tests for a single layer and multiple [14-18]. However, the dynamic earth pressure in embankment soils subjected to the dynamic loadings induced by vibratory roller has not been evaluated by field tests for geogrid layers.

In this study, the geogrid reinforcement effect has been examined at two roadway sites in fields. The lab test was carried out to examine the characteristics of soils and the strength of soils as a reference. Vibratory roller was applied to the ground surface of the embankment soils reinforced by a single or multilayer of geogrid. The dynamic earth pressures were measured in two test sites: soft soils and medium dense soils. The soil stiffness due to geogrid-reinforcement was examined by measuring the dynamic earth pressure associated with embankment heights, the number of passages of the vibratory roller, the number of reinforced layer of geogrid, and the soil properties.

2 Laboratory tests

2.1 Properties of soils and geogrid

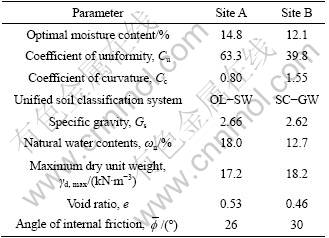

The laboratory tests were performed to examine the characteristics of soils sampled from two field test sites, A and B. Table 1 lists the index and mechanical properties of soils obtained from the laboratory tests. The soils at site A have the coefficient of uniformity, Cu, of 63.3 and the coefficient of curvature, Cc, of 0.8. This indicates that the soils at site A are well-graded and have very smooth surface of grains. The maximum grain diameter is 30 mm and approximately 20%-40% and 60%-90% grains pass the No. 200 and the No. 4, respectively. The natural water content is about 18.0% and is higher than the optimum water content of 14.8%. The maximum dry unit weight of soil is 17.2 kN/m3. The soils at site B have the coefficient of uniformity, Cu, of 39.8 and the coefficient of curvature, Cc, of 1.5. This indicates that the soils at site B are well-graded and have smooth surface of grains. Approximately 30% and 65% grains pass the No. 200 and the No.4, respectively. The natural water content is about 12.7% and is very similar to the optimum water content of 12.1%. The maximum dry unit weight of soil is 18.2 kN/m3.

Table 1 Mechanical properties of soils at field test sites

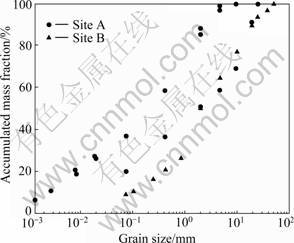

Figure 1 shows the grain size distributions of soils sampled from the field test sites and the soils are classified using Unified Soil Classification System (USCS). The soil at site A is classified from OL to SW consisting of fine particles such as clay, silt and sand. The soil at site B is classified from SC to GW consisting of coarse particles such as sand and gravel.

Fig.1 Grain size distribution

Table 2 lists the properties of biaxial geogrid used in the field tests. The aperture shape of geogrid used as reinforcement of the field tests is biaxial and has a maximum tensile strength of 58.8 kN associated with a maximum strain of 10.8%. The geogrid has interwoven structures made of high-modulus polyester yarns, covered by an additional protective layer of PVC. The nominal thickness and their aperture size are 1.1 mm and 17 mm × 19 mm, respectively.

Table 2 Engineering properties of geogrid used in field tests

2.2 Compressive strength and strain characteristics of soils

Figure 2 shows the effective and total stress path with the critical state line (CSL) obtained from conventional undrained triaxial compression test associated with various confining pressures. As shown in Fig.2, the effective stress paths for the soft soils at site A and for the medium dense soils at site B indicate lightly overconsolidated soils and normally consolidated soils, respectively.

Fig.2 Effective and total stress path in conventional undrained triaxial compression test: (a) Soft soils (site A); (b) Medium dense soils (site B)

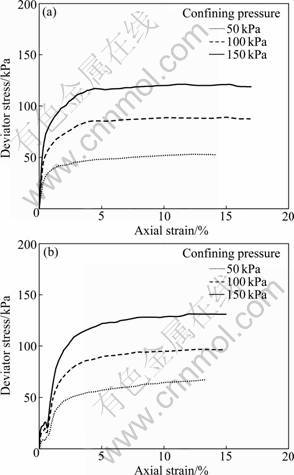

Figure 3 compares the deviator stress-strain response of the soft soil from site A and medium dense soil from site B, under the confining pressures of 50, 100 and 150 kPa. As shown in Fig. 3, the overall soil behavior is influenced by confining pressure. Both soil specimens result in hardening behavior in triaxial compression tests. It is observed that the peak strengths and initial stiffness of both soils remain similar but the axial strain at failure for medium dense soils from site B is a little larger than that of soft soils from site A under the same confining condition.

Fig.3 Deviator stress-strain curves with confining pressure: (a) Soft soils (site A); (b) Medium dense soils (site B)

3 Field test procedures

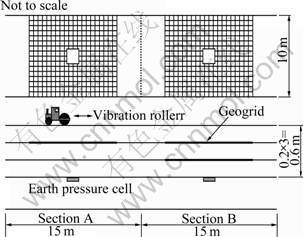

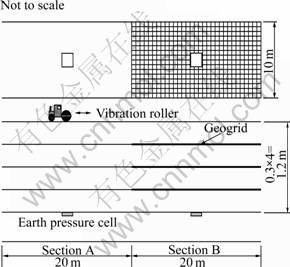

Figures 4 and 5 show the configurations of the field test associated with the geogrid reinforced in embankment, earth pressure cell, and applied dynamic loading to ground surface at sites A and B, respectively. The embankment height of a single soil layer was 0.2 m and 0.3 m at sites A and B, respectively. Embankment height of each layer was measured using an electro- optical distance meter and then the field test was performed.

Fig.4 Schematic view of embankment configuration in soft soils at site A

Fig.5 Schematic view of embankment configuration in medium dense soils at site B

The vibratory compaction roller of a weight of 117.6 kN and the frequency of 40 Hz (2 400 r/min) was applied to the ground surface of each layer to generate dynamic loading. The dynamic compaction using a vibratory roller was performed. It was usually operated for four to eight passages to satisfy the required density, compaction ratio, and bearing capacity. The degree of compaction and K30 (kN/m3), the coefficient of subgrade reaction, were estimated at each layer. As each layer satisfies the required compaction, a dynamic loading of a vibratory roller was applied to ground surface and the dynamic earth pressures with respect to time were measured using the earth pressure cell at each layer.

As shown in Fig.4, the dynamic loading was applied to the surface at embankment height of 0.4 m with no reinforced geogrid at section A and a single layer of geogrid at section B, respectively (in soft soils at site A). And then the dynamic loading was applied to the surface at embankment height of 0.6 m with a single layer of geogrid at section A and two layers of geogrid at section B, respectively. The dynamic earth pressures were recorded with respect to time using the earth pressure cell as the dynamic loading was applied.

As shown in Fig.5, the dynamic loading was applied to the ground surface at 0.3 m of embankment height with no reinforced geogrid and a single layer of geogrid at section A and section B, respectively, in medium dense soils at site B. And then, the dynamic loading was applied to the ground surface at 0.6, 0.9 and 1.2 m of embankment height with no reinforced geogrid and a single to three layers of geogrid at section A and section B, respectively. The dynamic earth pressures were measured as the dynamic loading was applied to the ground surface at each layer.

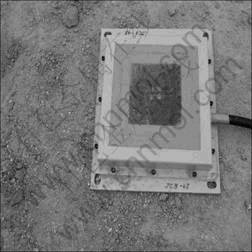

As shown in Fig.6, the earth pressure cell mainly consists of the hydrostatic pressure cell, resisting force plate, and the cable is an electric resisting system and measures the pressure by strain gage acting on the hydrostatic pressure plate. The data logger is EDX-1500 with 32 channels. Each channel is able to measure high frequency of 10 kHz. The vibratory roller operates along the path during three to five passages above the buried earth pressure cell with speed of 1.1-2.5 m/s. The soil should be excavated with the soil depth of 50 mm in consideration of the thickness of the sensor and the thin layer of the sand adjusting the bottom layer to make a horizontal balance and the level of the installed earth pressure cell has been measured using TPS-system 1800.

Fig.6 Photograph of earth pressure cell device

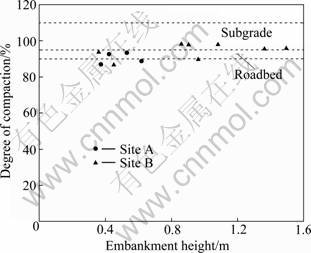

The degree of compaction for subgrade and roadbed satisfying the specification of expressway construction should be above 95% and 90%, respectively, as plotted in Fig.7. A field density test was performed by the sand cone method and the degree of compaction was estimated. It appears that the degree of compaction for subgrade and roadbed is in the range from 90% to 95% for both of test sites. The degree of compaction for medium dense soils at site B is slightly higher than that for soft soils at site A.

Fig.7 Degree of compaction estimated at each layer of soils

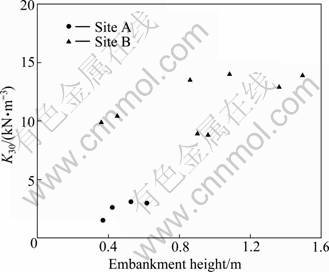

The plate bearing test (PBT) was carried out to determine the bearing capacity of each layer of soils compacted by dynamic loading of vibratory roller. Figure 8 shows the estimated K30 (kN/m3) at sites A and B. It is shown that K30 at sites A and B is in the range of 2- 4 kN/m2/m and 8-15 kN/m2/m, respectively. The subgrade reaction in medium dense soils at site B is four times stiffer than that in soft soils at site A.

Fig.8 K30 estimated at each layer of soils

4 Results of field tests

4.1 Dynamic earth pressure

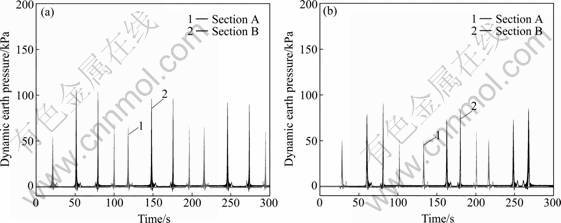

Figure 9 shows the dynamic earth pressure generated by the dynamic loadings applied to the ground surface with respect to embankment height in soft soils at site A. As shown in Fig.9(a), the dynamic earth pressures with no reinforced soils at section A and one layer of geogrid at section B are in the range of 60-70 kPa and 90-100 kPa, respectively. The dynamic earth pressure of the soils reinforced by one layer of geogrid is one and half times larger than that of no reinforcement soils. As shown in Fig.9(b), the dynamic earth pressures of the soils reinforced by one layer at section A and two layers of geogrid at section B are in the range of 50-60 kPa and 75-85 kPa, respectively. The dynamic earth pressure of the soils reinforced by two layers of geogrid at section B is one and half times larger than that reinforced by one layer of geogrid at section A.

Figure 10 shows the dynamic earth pressure with respect to embankment height in medium dense soils at site B. As shown in Fig.10(a), the dynamic earth pressures with no reinforcement soils at section A and one geogrid layer at section B are in the range of 75- 100 kPa and 110-150 kPa, respectively. The dynamic earth pressure of the soils reinforced by one geogrid layer at section B is one and half times larger than that of no reinforcement soils at section A. As shown in Fig.10(b), the dynamic earth pressures with no reinforcement soils at section A and two layers of geogrid at section B are about 90 kPa and 100 kPa, respectively. There is 10% higher dynamic earth pressure as embankment is reinforced by geogrid. Figures 10(c) and 10(d) show the dynamic earth pressures at embankment height of 0.9 m and 1.2 m, respectively. As shown in Figs.10(c) and 10(d), the dynamic earth pressures with no reinforcement soils and three layers of geogrid are about 40-60 kPa, respectively. As shown in Figs.10(c) and 10(d), at both sections A and B, the dynamic earth pressures become similar disregarding to the application of geogrid at site B. Since the dynamic loading is not enough in magnitude to mobilize the shear strength at the interface between geogrid and soil, the dynamic earth pressure is dominantly governed by the self weight of soils as embankment height increases.

Fig.9 Dynamic earth pressures associated with embankment height in soft soils at site A: (a) Embankment height of 0.4 m; (b) Embankment height of 0.6 m

Fig.10 Dynamic earth pressures associated with embankment height in medium dense soils at site B: (a) Embankment height of 0.3 m; (b) Embankment height of 0.6 m; (c) Embankment height of 0.9 m; (d) Embankment height of 1.2 m

4.2 Maximum dynamic earth pressure

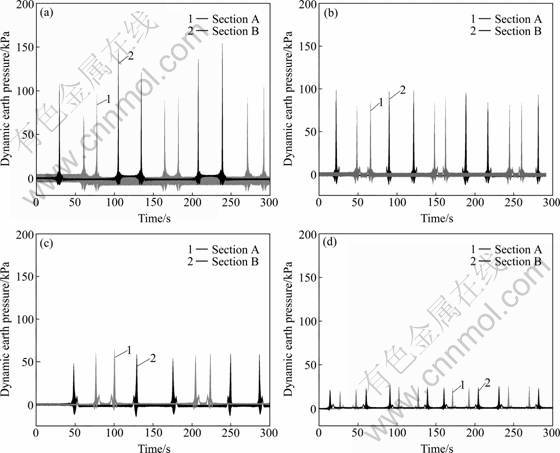

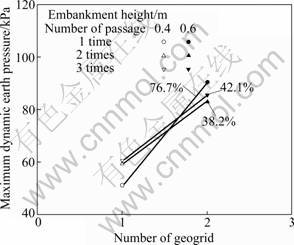

The maximum value chosen from dynamic earth pressure is defined as a maximum dynamic earth pressure. As shown in Fig.11, the maximum dynamic earth pressure at section A is in the range of 50-60 kPa as one layer of geogrid is reinforced for the embankment height of 0.4 m. The maximum dynamic earth pressure at section B is in the range of 80-90 kPa as two layers of geogrid are reinforced for the embankment height of 0.6 m. The increased earth pressure is due to the reinforcement of one additional layer of geogrid and the self weight of soils. Figure 11 shows that the maximum dynamic earth pressure of the soft soils reinforced by one additional layer of geogrid increases by 38%-77%. The results indicate that the reinforced geogrid increases the stiffness of soft soils. However, since the soils at site B are very densely compacted, the maximum dynamic earth pressure of the medium dense soils has very small increase.

Fig.11 Effects of number of reinforced geogrid on maximum dynamic earth pressure in soft soils at site A

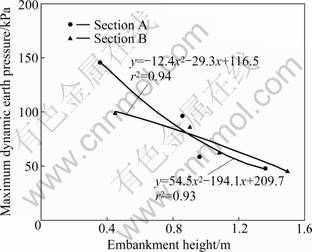

The maximum dynamic earth pressure associated with embankment height in medium dense soils at site B is evaluated in Fig.12. As shown in Fig.12, the maximum dynamic earth pressure in medium dense soils substantially decreases especially for no reinforcement soil as embankment height increases. The regressions for the maximum dynamic earth pressure associated with embankment height show good fits as indicated by high r2.

Fig.12 Maximum dynamic earth pressure associated with embankment height in medium dense soils at site B

4.3 Dynamic earth pressure ratio

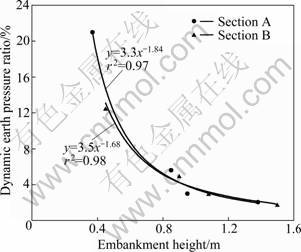

Figure 13 shows the dynamic earth pressure ratio, a maximum dynamic earth pressure normalized by a static earth pressure, which is calculated from the self weight of soils, with respect to embankment height. As shown in Fig.13, the dynamic earth pressure ratio exponentially decreases as the embankment height increases. The fitting results appear to have high r2.

Fig.13 Dynamic earth pressure ratio associated with embankment height in medium dense soils at site B

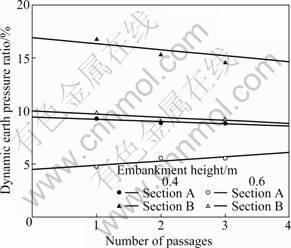

Figures 14 and 15 show that the dynamic earth pressure ratio substantially decreases with the increased embankment height and reinforced layers of geogrid. The dynamic earth pressure ratio is shown to be independent of the number of passages.

Fig.14 Dynamic earth pressure ratio vs number of passages in soft soils at site A

Fig.15 Dynamic earth pressure ratio vs number of passages in medium dense soils at site B: (a) Section A; (b) Section B

As shown in Fig.14, the dynamic earth pressure ratios associated with no reinforced geogrid and one layer of geogrid in soft soils are 9% and 16%, respectively, for the embankment height of 0.4 m. The dynamic earth pressure ratios associated with one layer and two layers of geogrid are 5% and 9%, respectively, for the embankment height of 0.6 m. The dynamic earth pressure ratio of 80% increases as both one geogrid layer in place of no reinforced soils and two layers of geogrid in place of a single layer of geogrid are reinforced.

As shown in Fig.15(a), the dynamic earth pressure ratios associated with the embankment height of 0.3, 0.6, 0.9 and 1.2 m are about 20%, 5%, 3% and 2%, respectively. As shown in Fig.15(b), the dynamic earth pressure ratios associated with the embankment height of 0.3, 0.6, 0.9 and 1.2 m are about 12%, 5%, 3% and 2%, respectively. This shows that the dynamic earth pressure ratio substantially decreases especially for no reinforced soils as the embankment height increases from 0.3 to 0.6 m but is independent of the number of passages of a vibratory roller.

5 Conclusions

1) The dynamic earth pressure is not increased by reinforced geogrid layers as the embankment height increases. It is explained by the fact that the dynamic loading is not enough in magnitude to mobilize the shear strength at the interface between geogrid and soil. Hence, the dynamic earth pressure is dominantly governed by the self weight of soils.

2) The maximum dynamic earth pressure of the soft soils reinforced by geogrid significantly increases. This indicates that the reinforced geogrid increases the stiffness of soft soils. The regressions for the maximum dynamic earth pressure associated with embankment height show good fits as indicated by high r2.

3) The dynamic earth pressure ratio defined as a maximum dynamic earth pressure normalized by a static earth pressure substantially decreases with increasing the embankment height and reinforced layers of geogrid. The dynamic earth pressure ratio in soft soils significantly increases as a geogrid is reinforced but is independent of the number of passages.

4) As the applied loading of vibratory roller acts on the ground surface, the large strain of ground occurs in soft ground and the shear strength is well mobilized at the interface between geogrid and soil.

Acknowledgements

This work was supported by Grant from INJE University, 2008. The financial support is gratefully acknowledged.

References

[1] CHAN F, BARKSDALE R D, BROWN S F. Aggregate base reinforcement of surfaced pavements [J]. Geotextiles and Geomembranes, 1989, 8(3): 165-189.

[2] GIROUD J P, NOIRAY L. Geotextile-reinforced unpaved road design [J]. Journal of Geotechnical Engineering, ASCE, 1981, 107(9): 1233-1254.

[3] KOERNER R M, SOONG T Y. Geosynthetic reinforced segmental retaining walls [J]. Geotextiles and Geomembranes, 2001, 19(6): 359-386.

[4] LING H I, LIU Z. Performance of geosynthetic-reinforced asphalt pavements [J]. Journal of Geotechnical and Geoenvironmental Engineering, ASCE, 2001, 127(2): 177-184.

[5] LOVE J P, BURD H J, MILLIGAN W E, HOULSBY G T. Analytical and model studies of reinforcement of a layer of granular fill on a soft clay subgrade [J]. Canadian Geotechnical Journal, London, 1987, 24(4): 611-622.

[6] ALAWAJI H A. Settlement and bearing capacity of geogrid-reinforced sand over collapsible soil [J]. Geotextiles and Geomembranes, 2001, 19(2): 75-88.

[7] HAERI S M, NOORZAD R, OSKOOROUCHI A M. Effect of geotextile reinforcement on the mechanical behavior of sand [J]. Geotextiles and Geomembranes, 2000, 18(6): 385-402.

[8] MAHER M H, HO Y C. Behavior of fiber-reinforced cemented sand under static and cyclic loads [J]. Geotechnical Testing Journal, ASCE, 1993, 16(3): 330-338.

[9] GRAY D H, PHASHI H. Mechanics of fiber reinforcement in sand [J]. Journal of Geotechnical Engineering, ASCE, 1983, 109(3): 335-353.

[10] DELMAS P H, MATICHARD Y, GOURE J P, RIONDY G. Unsurfaced roads reinforced by geotextiles—A seven years experiment [C]// Proc 3rd Int Conf on Geotextiles. Vienna, 1986: 141-146

[11] HOLTZ R D, SIVAKUGAN K. Design charts for roads with geotextiles [J]. Geotextiles and Geomembranes, 1987, 5(3): 191-200.

[12] ROWE R K, LI A L. Reinforced embankments over soft foundations under undrained and partially drained conditions [J]. Geotextiles and Geomembranes, 1999, 17(3): 129-146.

[13] WEBSTER S L, ALFORD S J. Investigation of construction concepts for pavements across soft ground [R]. United States Army Engineer Waterways Experiment Station, Vicksburg, Miss. 1978. S-78-6.

[14] ASHMAWY A K, BOURDEAU P L. Geosynthetic-reinforced soils under repeated loading: A review and comparative design study [J]. Geosynthetics International. 1995, 2(4): 643-678.

[15] ASHMAWY A K, BOURDEAU P L. Testing and analysis of geotextile-reinforced soil under cyclic loading [C]// Proc Conf Geosynthetics. Long Beach, California, USA. 1997: 663-674.

[16] ASHMAWY A K, BOURDEAU P L, DRNEVICH V P, DYSLI M. Cyclic response of geotextile-reinforced soil [J]. Soils and Foundations. 1999, 39(1): 43-52.

[17] DOUGLAS R A. Parametric study of the stiffness of unbound geosynthetic-built roads on compressible subgrades [C]// Proc 44th Canadian Geotech Conf. Calgary, Alberta, Canada, 1991: 80-1-80- 7.

[18] UNNIKRISHNAN N, RAJAGOPAL L, KRISHNASWAMY N R. Behavior of reinforced clay under monotonic and cyclic loading [J]. Geotextiles and Geomembranes, 2002, 20(2): 117-133.

(Edited by YANG Bing)

Received date: 2011-01-04; Accepted date: 2011-03-11

Corresponding author: JEON Sang-Soo, Assistant Professor, PhD; Tel: +82-55-320-3651; Fax: +82-55-321-3410; E-mail: ssj@inje.ac.kr