文章编号: 1004-0609(2006)09-1558-05

硬质粒子扰动对电铸铜微观结构与性能的影响

朱增伟, 朱荻

(南京航空航天大学 机电工程学院, 南京 210016)

摘要: 在铜的电铸过程中, 通过陶瓷微珠等硬质粒子摩擦和扰动电铸层表面来改善电铸层的质量。 对所制备的铜电铸层的表面形貌、 织构等微观结构和显微硬度、 抗腐蚀等性能进行测试和分析, 并与传统方法所制备的铜电铸层相比较。 结果表明: 硬质粒子在电铸过程中对电铸层表面的摩擦和扰动具有显著的除瘤和整平作用, 使所制备的铜电铸层外观光亮平整, 显著改变其微观结构和性能; 铜电铸层各晶面的衍射强度降低, (200)晶面的择优程度减小, (111)晶面的择优程度增大; 显微硬度值由HV156增至HV221; 抗腐蚀性能显著提高, 在NaCl溶液中的腐蚀速率降低了20%。

关键词: 铜; 硬质粒子; 电铸; 电沉积; 结构; 性能 中图分类号: TQ153.44

文献标识码: A

Effect of hard particle perturbation on microstructure and property of electroformed copper

ZHU Zeng-wei, ZHU Di

(School of Mechanical and Electrical Engineering, Nanjing University of Aeronaustics and Astronaustics, Nanjing 210016, China)

Abstract: During the electroforming process of copper, the quality of electrodes was improved through polishing and perturbation of hard particles. The morphology and texture of the deposits were studied in contrast with that of the deposits obtained by traditional methods. The values of microhardness and corrosion rate in NaCl solution were also measured. The results show that the polishing of hard particles can effectively remove nodules and level the deposit, which leads to a brightening and smoothing deposition. Due to the perturbing of hard particles, the microstructure and property significantly change. The intensity of X-ray diffraction reduces, the degree of (200) preferential orientation decreases and that of (111) preferential orientation increases. The microhardness evidently increases from HV156 to HV221 and the corrosion resistance is improved by 20% in NaCl solution.

Key words: copper; hard particle; electroformation; electrodeposition; structure; property

电铸技术作为一种具有很高复制精度和重复精度的精密特种加工方法[1, 2], 在现代工业中得到越来越广泛的应用。 铜是电铸工业中常用的金属之一, 已被成功应用于电子器件、 微波器件、 破甲药型罩、 火箭发动机部件以及电加工电极等的制造[2-7]。 由于上述零件属于精密、 微细和异型零件, 对材料的使用性能有着某些特殊的要求。 因此, 如何进一步改善铸层质量是电铸工艺中的关键问题。

在电铸过程中有诸多因素会影响电铸层的质量[2-4], 如由于尖端放电效应和杂质的影响, 随着电铸层厚度的增加, 表面容易产生积瘤、 枝晶等缺陷, 造成铸层均匀性差, 整体沉积速度下降; 随着金属离子的沉积, 会有氢气等气体从阴极表面析出, 并以气泡的形式滞留在阴极表面, 阻碍金属沉积, 造成铸件表面出现麻点和针孔等缺陷; 电铸层内普遍存在的内应力会造成电铸层起泡、 开裂, 还可能增大电铸层的脆性, 从而影响电铸层的物理及力学性能等。

传统的电铸工艺常通过在电铸液中加入添加剂的方法来细化晶粒, 减小应力, 以改善电铸层的表面形貌和性能[3, 8, 9]。 但在长时间的电铸过程中, 许多添加剂均会有不同程度的消耗, 从而导致电解液成分的稳定性变差, 最终直接影响电铸层的质量[10, 11]。 由此可见, 在电铸工艺中, 如何最大限度地改善电铸层质量, 以制备出满足零件性能要求的电铸层具有重要的现实意义。

本文作者利用一种新型硬质粒子摩擦法电铸技术进行了电铸铜的实验, 并对所制备铸层的微观结构和性能进行了测试和分析。

1 实验原理及装置

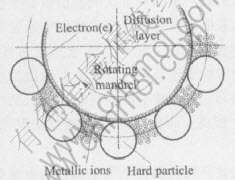

硬质粒子摩擦法电铸技术是针对零件的精密电铸成形而提出的一种新的工艺方法, 其原理如图1所示。 在传统电铸工艺的基础上, 在阴、 阳极之间放置诸如陶瓷球以及玻璃微珠等硬质粒子。 当阴极旋转时, 就会带动这些硬质粒子不停地运动, 摩擦和撞击阴极表面。 运动着的硬质粒子通过紧贴芯模表面摩擦和撞击, 可以阻止氢气泡和杂质在阴极表面长期滞留, 从而避免在铸层表面形成凹坑、 针孔、 麻点和积瘤等缺陷。 通过对已经形成的积瘤等微观突起的机械磨削和抛光作用, 可以抑制积瘤继续长大, 从而实现表面整平的效果。 通过扰动电沉积的结晶过程以影响电铸层的组织结构, 从而改善电铸层的表面质量和性能。

图1 实验原理示意图

Fig.1 Schematic diagram of experimental principle

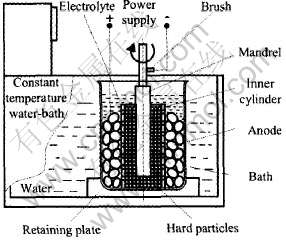

实验装置示意图如图2所示。 在电铸过程中, 电机带动圆柱形芯模在镂空的内筒中旋转, 内筒外壁和底部均用涤纶布密封。 在内筒和芯模间的硬质粒子完全覆盖芯模表面。 将颗粒状阳极围绕内筒放置, 并与内筒一起置于实验所用电铸槽中。 电铸槽置于恒温水浴槽内, 以保持电铸液温度恒定。

图2 实验装置示意图

Fig.2 Schematic diagram of experimental apparatus

2 实验过程

实验分别在不添加和添加硬质粒子两种条件下进行。 采用常规的焦磷酸盐电铸液, 其配方为: Cu2P2O7 65g/L, K4P2O7·3H2O 300g/L, (NH4)2HC6H5O7 22g/L, pH为8.2~8.8, 温度为45℃。 阳极为含磷0.04%~0.06%的磷铜颗粒, 用涤纶布包覆, 以防止阳极泥的渗出。 阴极采用不锈钢圆柱芯模, 沉积面积0.3dm2。 硬质粒子选用d1.5~2mm的陶瓷球, 使用前用蒸馏水反复清洗, 以去除杂质。 实施电铸前, 芯模表面依次经过抛光、 除油和弱浸蚀等处理, 并用蒸馏水冲洗后即刻入槽, 以增强电铸层和基体的结合力。 芯模以设定的转速旋转几分钟后, 接通电源进行电铸, 电流密度为3A/dm2, 时间为2h。 电铸结束后, 取出芯模, 经过冲洗、 干燥后, 进行显微硬度的测试。 脱模后, 再进行SEM和XRD的测试和分析。

电铸层的表面形貌测试采用LEO-1530VP型场发射扫描电子显微镜(FEG-SEM)。 电铸层的微观结构测试用BRUKER D8 ADVANCE型X射线衍射仪。

晶面择优取向的程度用晶面(hkl)织构系数TC(hkl)来表征

的(hkl)晶面的X射线衍射相对强度; n为衍射峰个数。

电铸层的显微硬度测试用HXS-1000A型数字式智能显微硬度计。 载荷为0.245N, 保荷时间10s, 每个样品均测定6个点, 取其平均值。

将所制备的铜电铸层切割成30mm×20mm 的试片, 在常温下于0.1mol/L NaCl溶液中进行静态浸泡实验, 时间为250h。 采用失重法测定电铸层的平均腐蚀速率。

3 结果与讨论

3.1 表面形貌

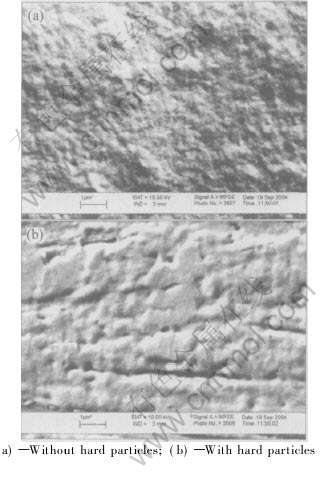

与传统电铸工艺相比, 使用硬质粒子摩擦法所得电铸层表面更加光亮平整, 但略呈雾状。 图3和4所示分别为两种条件下所得电铸层表面的放大照片和SEM像。

图3 不同条件下所得电铸层的放大照片

Fig.3 Magnified photos of electroformed copper under different conditions

图4 不同条件下所得电铸层的SEM像

Fig.4 SEM images of electroformed copper under different conditions

通过对比两种电铸层的放大照片(图3(a)和(b)), 可以看出不加硬质粒子所得电铸层表面布满积瘤、 凹坑和气孔等缺陷; 添加硬质粒子后, 上述缺陷几乎完全消失, 所得电铸层表面只有微小的沟痕。 这说明硬质粒子在铜的电沉积过程中具有显著的除瘤和阻氢作用。

两种电铸层的显微形貌也有显著的变化(图4(a)和(b))。 不加硬质粒子所得电铸层表面凹凸不平; 添加硬质粒子后所得电铸层的表面具有明显的微小平面和缝隙, 且缝隙之间是平整的带状沉积层。 众多的微小平面和带状沉积层组成平整的宏观表面。 这表明硬质粒子在沉积过程中通过对电铸层表面的摩擦和撞击, 起到了机械抛光和挤压作用。 同时, 硬质粒子还会在一定程度上细化晶粒和影响晶粒的排布, 从而减小电铸层表面的凹凸度, 导致其光亮度提高, 而狭缝的存在则造成其表面呈雾状[14]。

通过计算两种条件下铜电沉积的电流效率, 即电铸层质量与根据法拉第定律计算所得理论沉积量的比值, 发现添加硬质粒子条件下的电流效率比不加硬质粒子条件下的电流效率有所降低, 从99.2%降至94.7%。 这进一步说明了硬质粒子对沉积层起了除瘤作用和机械抛光作用。

3.2 微观结构

图5和表1所示分别为两种条件下所得铜电铸层的X射线衍射谱和各晶面的织构系数。

图5 不添加或添加硬质粒子所得电铸层的X射线衍射谱

Fig.5 XRD patterns of electroformed copper without(a) and with(b) hard particles

表1 不同条件下所得电铸层晶面的织构系数TC(hkl)

Table 1 Texture coefficient of (hkl) planes of electroformed copper under different conditions

通过将图谱与PDF卡(04-0836)对照发现, 各衍射峰所对应的晶面依次为(111)、 (200)、 (220)、 (311)及(111)面的平行面(222), 其结构为面心立方结构。 与没有添加硬质粒子时所得电铸层相比, 添加硬质粒子所得电铸层的各晶面衍射强度均有明显的降低。 由表1可知, 两种电铸层各晶面的择优程度都不高。 添加硬质粒子时, 所得电铸层(200)面的择优程度减小, 由择优取向面变为非择优取向面; 而(111)面的择优程度增大, 由非择优取向面变为择优取向面。

根据择优取向的几何选择理论[13, 14], 当加入硬质粒子时, 硬质粒子对铸层表面的摩擦和撞击作用会在一定程度上影响晶体的生长方式, 使各晶面的相对生长速率差别变小, 造成衍射强度降低; 同时(111)面的生长速度变慢, 而(200)面的生长速度变快, 从而使前者择优程度增大, 后者择优程度减小。

3.3 性能

与没有添加硬质粒子时所得电铸层相比, 添加硬质粒子后所制备电铸层的显微硬度值明显提高, 从HV156增至HV221; 在NaCl溶液中, 平均腐蚀速率由4.48mg/dm2降至3.56mg/dm2, 抗腐蚀性能提高了约20%。

通常金属材料的硬度满足传统的Hall-Petch关系[15]: HV∝d-1/2或σ∝d-1/2, 即材料的硬度HV和应力σ随晶粒尺寸d的减小而提高。 金属材料的抗腐蚀性能与金属表面钝化膜的稳定性密切相关[16], 即钝化膜越稳定, 金属的抗腐蚀性越高。 在硬质粒子摩擦法电铸技术中, 由于硬质粒子的摩擦和扰动, 所制备的电铸层组织均匀致密, 其晶粒在一定程度上被细化, 显微硬度得到提高; 硬质粒子的摩擦和扰动能有效去除沉积层表面吸附的杂质, 减少表面均匀性的缺陷, 如夹杂物、 位错等, 从而提高电铸层表面钝化膜在腐蚀溶液中的稳定性, 进而提高其抗腐蚀性能。

4 结论

1) 与传统的电铸工艺相比, 硬质粒子摩擦法电铸技术具有显著的除瘤和整平效果, 不需要任何添加剂, 就能获得表面光亮平整、 组织致密的铜电铸层。

2) 硬质粒子的扰动能影响电沉积的结晶过程, 进而影响铜电铸层的微观组织结构。

3) 用硬质粒子摩擦法所制备的铜电铸层的显微硬度和抗腐蚀性能均明显提高。

REFERENCES

[1]Zhu D, Qu N S, Chan K C. Development of joint electroforming[J]. Technology Journal of Materials Processing Technology, 1997, 63: 44-847.

[2]McGeough J A, Leu M C, Rajurkar K P, et al. Electroforming process and application to micro/macro manufacturing[J]. Annals of the CIRP, 2001, 50(2): 499-514.

[3]Silaimani S M, John S. Review on recent advances in electroforming during the last decade[J]. Bulletin of Electrochemistry, 2001, 17 (12): 553-560.

[4]Hart T, Watson A. Electroforming[J]. Metal Finishing, 2000, 98(1): 388-399.

[5]Sole M J, Szendrei T. Electroformed copper shaped charge liners[A]. Proceedings of the 78th Annual International Technical Conference[C]. Toronto: ASEF Preess, 1991: 423-47.

[6]Thangavelu P, Veeramani P, Srinivasan K N, et al. Copper electroforming of cryogenic upper stage main engine[J]. Bulletin of Electrochemistry, 2000, 16(11): 493-496.

[7]Tajiri K, Kabeya Z, Saito Y. A new copper electroforming for vacuum components and comparison with conventional processes[J]. Journal of the Vacuum Society of Japan, 2001, 44(9): 831-836.

[8]Bonou L, Eyraud M, Denoyel R, et al. Influence of additives on Cu electrodeposition mechanisms in acid solution: direct current study supported by non-electrochemical measurements[J]. Electrochimica Acta, 2002, 47: 4139-4148.

[9]Veilleux B, Lafront A M, Ghali E. Influence of Gelatin on deposit morphology during copper electrorefining using scaled industrial cells[J]. Canadian Metallurgical Quarterly, 2002, 41(1): 47-61.

[10]Hu C C, Wu C M. Effects of deposition modes on the microstructure of copper deposits from an acidic sulfate bath[J]. Surface and Coatings Technology, 2003, 176: 75-83.

[11]Wong K P, Chan K C, Yue T M. A study of surface finishing in pulse current electroforming of nickel by utilizing different shaped waveforms[J]. Surface and Coatings Technology, 1999, 115: 132-139.

[12]许书楷, 杨防祖, 周绍民. 电沉积条件对锌镀层织构的影响[J]. 电化学, 1995, 1(4): 408-414.

XU Shu-kai, YANG Fang-zu, ZHOU Shao-min. Effect of deposition conditions on the texture of zinc deposition[J]. Electrochemistry, 1995, 1(4): 408-414.

[13]Ye X P, Bonte M De, Celis J P, et al. Role of overpotential on texture, morphology and ductility of electrodeposited copper foils for printed circuit board applications[J]. J Electrochem Soc, 1992, 139(6): 592-1600.

[14]周绍民. 金属电沉积——原理与研究方法[M]. 上海: 上海科学技术出版社, 1987: 242-305.

ZHOU Shao-min. Electrodeposition of Metal—Principle and Methods[M]. Shanghai: Shanghai Press of Science and Technology, 1987: 242-305.

[15]Alfantazi A M, Erb U. Microhardness and thermal stability of pulse-plated Zn-Ni alloy coatings[J]. Mater Sci Eng A, 1996, 212: 123-129.

[16]Cicileo G P, Rosales B M, Varela F E, et al. Inhibitory action of 8-hydroxyquinoline on the copper corrosion process[J]. Corrosion Science, 1998, 40(11): 1915-1926.

基金项目: 江苏省自然科学基金重点资助项目(BK2004005)

收稿日期: 2006-02-26; 修订日期: 2006-06-13

通讯作者: 朱增伟; 电话: 025-84892349; E-mail: zwei_z@163.com

(编辑李艳红)