文章编号:1004-0609(2011)10-2523-11

苑世剑,何祝斌,刘 钢,王小松,韩 聪

(哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:介绍哈尔滨工业大学在内高压成形基础理论、关键技术及工业应用等方面取得的重要进展。在基础理论方面,利用平面应力屈服椭圆描述典型内高压成形过程中应力状态及壁厚变化趋势;揭示变径管内高压成形过程中壁厚分布规律以及多边形截面环向的壁厚分布特点;指明整形阶段圆角充填时存在极限圆角半径;发明了用于测量管材环向力学性能的管材环向拉伸实验方法。在工艺关键技术方面,针对航空航天领域对大直径薄壁复杂管件的需求,发明了Y型薄壁三通管两步成形方法、双层管充液弯曲方法,试制出超薄Y型三通管、整体不锈钢进气道及弯管零件。在工业应用方面,研制了合模力最大达55 MN的工业生产用大型内高压成形机,并成功地用于轿车底盘零件大批量生产。

关键词:内高压成形;液压成形;塑性变形;应力状态;失稳行为

中图分类号:TG306 文献标志码:A

New developments in theory and processes of

internal high pressure forming

YUAN Shi-jian, HE Zhu-bin, LIU Gang, WANG Xiao-song, HAN Cong

(School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: Important progresses and achievements in fundamental theory, key processes and industrial applications of tube hydroforming realized in engineering research center of hydroforming/harbin institute of technology (ERCH/HIT) were introduced. Typical stress states in tube hydroforming process and the corresponding thickness changing tendency were given on the plane stress yield loci. Thickness changes along the axial direction of tubular part with changeable diameters and the hoop direction of tubular part with rectangular cross-section were given. The concept of limited corner radius in calibration process was proposed and analyzed. Ring hoop tension test was proposed to evaluate the mechanical properties of tube along hoop direction. Multi-step method for the forming of thin Y-shaped branch tube, and double-layered hydro-bending method for the forming of thin-walled bent tubular part were proposed. Ultra-thin Y-shaped branch tube, integral stainless steel tube, and bent tubular part for aerospace application were manufactured. Hydroforming machine of 55 MN maximal closing force was developed. Typical parts for automotive industry, such as engine cradle, front beam holder and torsion beam, were manufactured.

Key words: internal high pressure forming (IHPF); hydroforming; plastic forming; stress state; instability behavior

结构轻量化是汽车、飞机运输工具节约燃料、减少废气排放的主要手段之一。对于承受弯扭载荷为主的结构,采用空心变截面构件,既可减轻质量又可充分利用材料强度。内高压成形是以管材为毛坯在内压和轴向补料联合作用下将管材成形为所需形状的先进制造技术。内高压成形件实现以空心替代实心、以变截面取代等截面、以封闭截面取代焊接截面,比冲焊件的质量减少15%~30%,且可大幅提高零件的刚度和疲劳强度。20世纪80年代初,德国和美国的研究机构系统地开展了内高压成形基础理论、工艺及应用研究,并从20世纪90年代中期开始在汽车工业领域大批量应用[1-3]。

内高压成形的本质是封闭薄壳在内压作用下经过各种中间形状变化和塑性变形由圆柱壳变为复杂形状壳体,由于中间形状变化与模具接触顺序受加载路径和摩擦等因素影响,所以,内高压成形过程的塑性变形十分复杂。本文作者根据塑性变形特点,提出将内高压成形分为变径管、弯曲轴线管和多通管3大类零件的成形[4-7]。针对3类零件变形特点,采用物理实验、数值模拟和塑性理论系统地研究了薄壳变形规律和弹塑性失稳机理[8-10]。揭示了缺陷形成机制及加载路径的影响、应力状态和壁厚变化规律以及圆角充填行 为,通过塑性理论证明了存在极限圆角半径,发明了“有益皱纹”和内凹形预制坯降低整形压力等原创性工艺技术,研制出多台大型内高压成形机,并在汽车结构件批量生产中得到了实际应用。目前,国外内高压成形主要用于制造汽车零件,我国已经扩展到航空航天领域,其零件的特点是大尺寸、薄壁和截面形状复杂,最大直径可达500 mm, 径厚比(直径与厚度之比)达到400,而汽车行业所用管材的径厚比不超过100。这类大径厚比超薄零件成形难点是起皱倾向严重。为了攻克起皱的难题,开发了相应的新工艺,并成功地应用于火箭和飞机。本文作者主要介绍近年来哈尔滨工业大学在内高压成形基础理论、工艺(尤其是超薄零件成形工艺)、设备和工业应用方面取得的最新研究进展。

1 内高压成形基础理论

1.1 应力状态与壁厚变化趋势

假设管材为薄壁管,忽略管材内壁压力p,只考虑轴向应力和环向应力,则可认为管材处于平面应力状态。由Mises屈服准则,可得内高压成形的屈服条件为

(1)

(1)

式中: 为环向应力;

为环向应力; 为轴向应力;

为轴向应力; 为材料的屈服强度。

为材料的屈服强度。

根据Levy-Mises增量本构方程,厚度变化量与应力状态的关系如下:

(2)

(2)

式中: 为厚度瞬时增量,大于0表示增厚,小于0表示减薄;

为厚度瞬时增量,大于0表示增厚,小于0表示减薄; 为等效应变增量;

为等效应变增量; 为等效应力。

为等效应力。

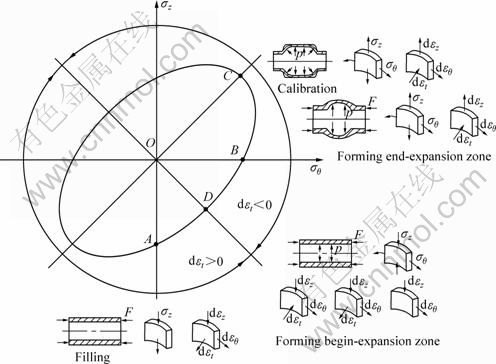

内高压成形过程中,某一时刻管材上不同点以及同一点在不同时刻的应力状态都将有很大差别,根据式(1)和(2),可以给出在平面应力屈服轨迹所有可能的应力状态(从A点到B点直至C点之间的曲线上)与壁厚变化的关系,如图1所示[8]。

图1 内高压成形应力状态与壁厚变化趋势[8]

Fig.1 Typical stress states during IHPF on plane stress yield loci[8]

在充填阶段,两端冲头向模具型腔移动并与管端接触而实现密封。整个管材处于轴向受压的单向应力状态(A点),对应的应变状态为轴向压缩、环向伸长和厚度增加,但变形量都很小。在此阶段,如果管材长度较长,当轴向压应力过大时管材整体会产生屈曲。

在成形阶段,送料区和成形区的应力及应变状态均不同。在送料区,环向应力为零,应力状态对应于A点。因受到模具约束,环向应变也为零,因此,处于平面应变状态,轴向缩短,厚度增加,且管端处增厚最为严重。成形区的应力状态在成形初期为环向受拉、轴向受压,随环向应力与轴向应力比值的不同,可出现壁厚增加(A点与D点之间)、减薄(D点与B点之间)及不变(D点)3种情况:

1) 当 >

> ,位于图1中屈服轨迹的B点和D点之间,有

,位于图1中屈服轨迹的B点和D点之间,有 <0,壁厚减薄;

<0,壁厚减薄;

2) 当 <

< ,位于图1中屈服轨迹的D点和A点之间,有

,位于图1中屈服轨迹的D点和A点之间,有 >0,壁厚增加;

>0,壁厚增加;

3) 当 ,位于图1中屈服轨迹的D点,此时

,位于图1中屈服轨迹的D点,此时 ,

, ,壁厚不变。

,壁厚不变。

成形后期,变为双向受拉应力状态(B点与C点之间),环向和轴向伸长,壁厚减薄。减薄程度取决于轴向应力与环向应力的大小。需要指出的是, 与

与 的比值还与变形区的相对长度有关。

的比值还与变形区的相对长度有关。

在整形阶段, 成形区管材已与模具接触,只有送料区与成形区的过渡区域尚未完全贴模。整形就是通过增加内压使过渡圆角贴模。过渡区域受力相当于内压作用下的圆环壳,在环向、切向都发生拉伸变形,壁厚减薄(B点与C点之间)。

1.2 壁厚分布规律

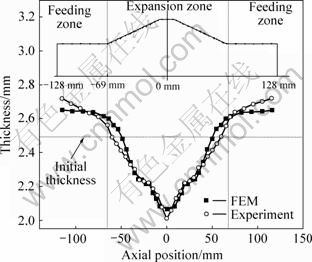

变径管具有轴对称特点,沿环向壁厚分布均匀,而沿轴向壁厚将发生变化,一般表现为成形区壁厚减薄,送料区壁厚增加,在两区之间存在壁厚不变的厚度分界圆。图2所示为双锥变径管壁厚分布。管材原始壁厚2.5 mm,成形区最小壁厚2 mm,最大减薄率达20%;送料区最大壁厚2.7 mm,最大增厚率8.8%。

根据受力平衡条件和全量塑性本构方程,建立厚度分界圆距离管端位置的理论模型[11]。

(3)

(3)

式中:Lc为厚度分界圆的相对距离;li为厚度分界圆到管端的距离;d为管材原始外径; 为送料区长度;

为送料区长度; 为摩擦因数;D为成形区直径;

为摩擦因数;D为成形区直径; 为过渡半锥角;t为管坯初始壁厚;

为过渡半锥角;t为管坯初始壁厚; 为轴向应力与内压之比。

为轴向应力与内压之比。

图2 双锥变径管件的壁厚分布

Fig.2 Thickness distribution of double-coned part with changeable diameter

该模型表明,当管坯相对厚度、送料区长度及过渡锥角等参数一定时,随摩擦因数的增大,厚度分界圆与管端的距离减小,即成形区壁厚减薄的区域增大;膨胀率越大,成形区壁厚减薄的区域也会增大。

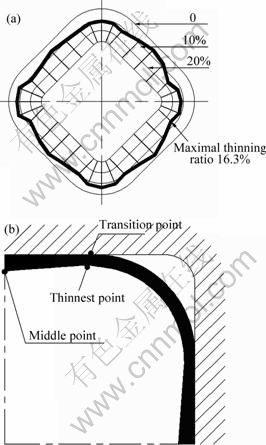

多边形截面(包括正方形、矩形及梯形等)的壁厚,从直边中点到圆角过渡区壁厚逐渐减薄,最薄点位于过渡区,最厚点位于直边中点。图3所示为弯曲轴线管成形后的正方形截面壁厚分布。直边中点最大厚度1.46 mm,减薄率2.5%;过渡区最小厚度1.26 mm,减薄率16.3%。矩形截面构件的壁厚分布与正方形截面的类似。过渡区减薄严重是正方形和矩形等多边形截面构件成形后壁厚分布的一个特点,且减薄程度随膨胀量和摩擦因数的增加而增加。控制过渡区的减薄量是弯曲轴线管异型截面内高压成形的关键技术 之一[12-14]。

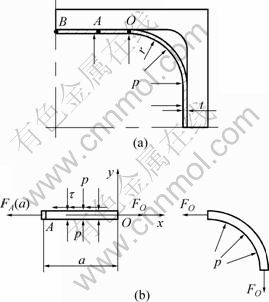

1.3 极限圆角半径

通常认为,随内压的增加,圆角半径将减小。然而,通过大量实验发现,当圆角半径达到一定值后将不再随内压的增加而减小。定义整形过程中破裂前可获得的最小圆角半径为极限圆角半径,以rlim表示。图4中过渡点O处的应变增量可表示为[15]

(4)

(4)

式中:t和r分别为圆角处的瞬时壁厚和半径;a为矩形截面的边长;p为内压; 为管材和模具之间的摩擦因数。

为管材和模具之间的摩擦因数。

当 时,极限圆角半径可表示为

时,极限圆角半径可表示为

(5)

(5)

图3 正方形截面壁厚分布

Fig.3 Thickness distribution of section with square shape: (a) Experimental results; (b) Position with minimal thickness

图4 圆角充填过程的受力分析

Fig.4 Force analysis of corner filling process: (a) Shape of corner; (b) Force analysis

可见,极限圆角半径由摩擦因数、截面边长和管材厚度决定。

通过实验测定了不同润滑条件下的极限圆角半径,如表1所列。可以看出,当润滑条件改善时,圆角充填能力强,可以获得更小的圆角半径。

表1 不同润滑条件下的极限圆角半径

Table 1 Limited corner radius with different lubricants

1.4 管材环向力学性能测试方法

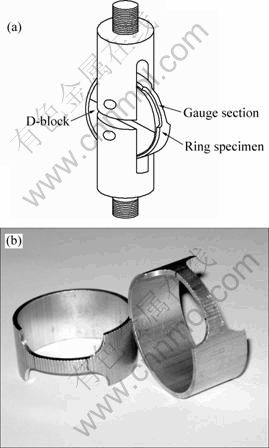

管材的环向力学性能通常可沿管材环向切取试样展平后进行单向拉伸获得,但展平过程中管材将发生加工硬化而使测量结果不可靠,对于小直径管材尤为明显。为此,提出一种直接测试管材环向力学性能的方法,即管材环向拉伸方法,其原理如图5所示[16-17]。在环形试样的中部放置两D形块,D形块的直径与环形试样内径相同,其宽度大于试样的宽度。向两个相反方向拉动D形块,通过D形块传递载荷而使环形试样发生拉伸变形。拉伸过程中,试样内表面始终与D形块接触,所以,其将基本保持原始的弧形,可以避免试样发生展平而对测试结果产生影响。

图5 管材环状试样拉伸实验示意图

Fig.5 Schematic diagram of ring hoop tension test (RHTT): (a) Principle of RHTT; (b) Ring specimen

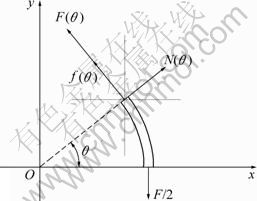

当环形试样拉伸时,由于受到D形块的摩擦力作用,试样各处所受环向力并不均匀。环向力的不均匀分布必将导致试样的不均匀变形,从而对拉伸结果的测量和分析带来很大影响。图6所示为等宽环状试样的受力分析图。试样上位于 位置的点将受到径向正压力

位置的点将受到径向正压力 、环向力

、环向力 以及切向摩擦力

以及切向摩擦力 的作用,F为D形块的拉力。

的作用,F为D形块的拉力。

图6 环状试样受力分析

Fig.6 Force analysis of ring specimen

图7 摩擦因数对环向力分布的影响

Fig.7 Effect of friction factor on distribution of radial normal force

假设在[0, 90°]范围内 为线性分布,即

为线性分布,即 ,其中,k为

,其中,k为 随

随 变化的斜率;

变化的斜率; 为

为 0°时的正压力。经推导,可得到环向力

0°时的正压力。经推导,可得到环向力 的计算公式为

的计算公式为

(6)

(6)

式中: 。

。

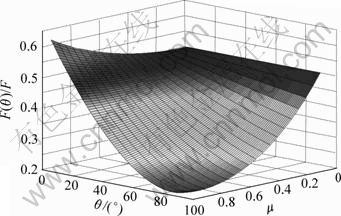

从式(6)可知,环向力 随角度

随角度 和摩擦因数

和摩擦因数 的变化而变化,如图7所示。可以看出,在环形试样拉伸过程中,当摩擦因数较小时,环向力

的变化而变化,如图7所示。可以看出,在环形试样拉伸过程中,当摩擦因数较小时,环向力 的分布较均匀,接近F/2,对测试结果影响小;当摩擦因数较大时,环向力分布很不均匀,从水平位置

的分布较均匀,接近F/2,对测试结果影响小;当摩擦因数较大时,环向力分布很不均匀,从水平位置 =0°时接近0.6F迅速减小到正上方

=0°时接近0.6F迅速减小到正上方 =90°位置的0.2F。因此,环向拉伸时需尽量减小试样与D形块之间的摩擦,以使标距段的变形均匀,从而便于对标距段的变形进行测量和分析。

=90°位置的0.2F。因此,环向拉伸时需尽量减小试样与D形块之间的摩擦,以使标距段的变形均匀,从而便于对标距段的变形进行测量和分析。

2 内高压成形工艺关键技术

2.1 薄壁Y型三通内高压成形

Y型三通管因结构非对称,所以,相比T型三通管其成形更为困难。对于薄壁、支管直径小的情况,其成形难度更大。在成形过程中,若内压、左右两端轴向进给量及中间冲头的后退量匹配不合理,将出现主管起皱及支管顶部破裂等缺陷。

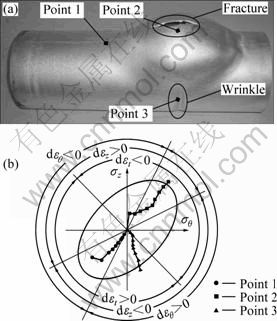

图8所示为一步成形Y型三通管的破裂缺陷及应力轨迹。可以看出,在支管顶部和主管下部分别出现了开裂和起皱缺陷。从图8(b)所示的应力轨迹可知,支管顶部的2点始终处于环向应力( )和轴向应力(

)和轴向应力( )双向受拉的应力状态,壁厚减薄严重,因此出现破裂缺陷。而主管下部的3点处于轴向受压、环向受拉应力状态,当轴向应力大于临界应力时,出现起皱现象。过渡区1点也为一拉一压应力状态,由式(2)可知,当

)双向受拉的应力状态,壁厚减薄严重,因此出现破裂缺陷。而主管下部的3点处于轴向受压、环向受拉应力状态,当轴向应力大于临界应力时,出现起皱现象。过渡区1点也为一拉一压应力状态,由式(2)可知,当 >

> 时,

时, >0,出现增厚现象。

>0,出现增厚现象。

图8 Y型三通管成形时的破裂缺陷及应力轨迹

Fig.8 Failures and stress loci at different points in Y-shaped tubular part forming: (a) Typical failures; (b) Stress loci at typical points

为改善支管顶部的应力状态及壁厚分布,提出分步成形方法,即在成形过程中采用带有不同斜度的反向冲头[18-19]。采用该成形方案,支管部分将一直受到反向冲头的约束作用,应力状态和变形条件得到改善,支管顶部的局部减薄将得到有效缓解。

采用分步成形方法,对5A03铝合金Y型三通管的成形进行实验。主管外径为100 mm,支管外径为90 mm,支管端面与主管轴线夹角为28°,原始管坯壁厚为2.5 mm。图9所示为5A03铝合金Y型三通管的分步成形结果。

图9 5A03铝合金Y型三通管分步成形结果

Fig.9 Multi-step forming results of 5A03 Y-shaped tubular part: (a) The first step part; (b) The second step part; (c) Final part

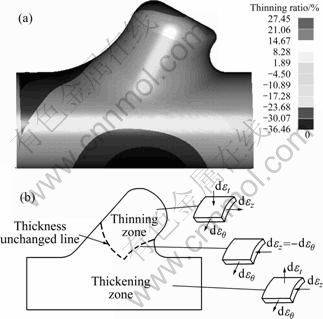

图10所示为Y型三通管的壁厚减薄率分布。在所成形零件上,减薄主要发生在支管顶部,增厚集中在主管上。在减薄区域和增厚区域之间,存在一个呈V型的壁厚不变线,位于支管下部,如图10(b)所示。在壁厚不变线上各点,环向应变增量与轴向应变增量的绝对值相等,符号相反,因此,厚向应变增量为0。而在壁厚不变线两侧,厚向应变增量符号相反,分别对应壁厚减薄和壁厚增加。

图10 铝合金Y型三通管壁厚分布

Fig.10 Thickness distribution of 5A03 Y-shaped tubular part: (a) Distribution of thinning ratio; (b) Thickness distribution

2.2 超薄复杂截面构件内高压成形

图11所示为整体不锈钢进气道内高压成形件。该零件具有弯曲轴线、复杂多边形截面且超薄厚度的特点, 径厚比(直径与厚度之比)达400。采用传统的冲压焊接工艺,需要8个冲压零件。而采用内高压成形方法,可顺利一次成形该零件。与传统的分段或分片先成形后焊接工艺相比,大大减少了焊缝数量,避免了严重的焊接变形问题。同时,通过模具内高压整形,大大提高了零件的几何精度。

图11 复杂截面进气道

Fig.11 Stainless steel inlet with complex sections

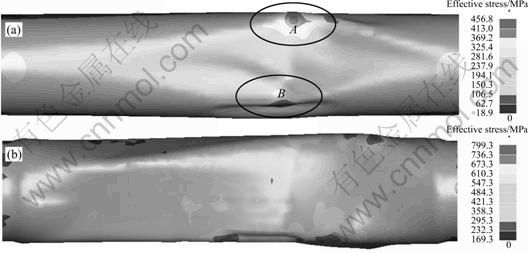

图12所示为进气道内高压成形过程中的等效应力分布及塑性区发展规律。进气道材料为不锈钢0Cr18Ni9Ti,屈服强度为320 MPa。从图12可以看出,在成形初期模具闭合的过程中,管坯和模具接触一侧的区域(图12中区域A和B)首先发生屈服而开始塑性变形。随着模具的闭合,模具接触的管坯在中心和端部交界区域开始屈服,继续扩展到端部区域。在成形阶段,当压力较低时,塑性区主要位于弯曲部位和截面过渡圆角区,随着内压增加,除管端和最后贴模的局部区域外,进气道绝大部分区域发生塑性变形,加工硬化明显,最大等效应力约800 MPa,位于最早进入屈服的区域A和B。

2.3 超薄管件充液弯曲成形

采用CNC弯曲或内部充填物弯曲,仅能实现相对弯曲半径小于100的弯管成形。随着大型飞机等飞行器的研制需要相对弯曲半径大于180的整体弯管(无纵向焊缝),现有的弯曲工艺均存在内侧起皱缺陷。为了解决该难题,本文作者发明了双层管充液弯曲方法,可有效避免弯曲起皱问题,其原理如图13所示。内层管为要获得的薄壁管零件,外层管为工艺辅助套,通常为低碳钢厚壁管。先把内、外层管套装成整体双层管毛坯,采用特殊的管端结构密封,在管内充满液体介质并增压到所需支撑内压(见图13(a)),在模具内弯曲得到双层弯管(见图13(b)),切除管端并去除外层管(见图13(c))即可得到超薄弯管零件[20]。

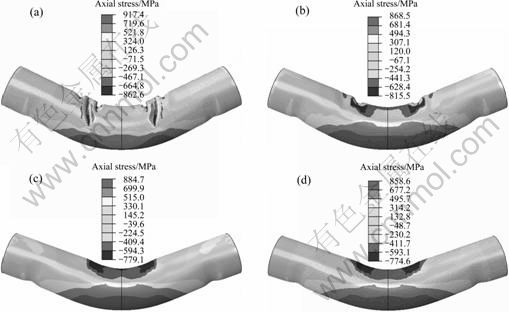

当采用双层管充液弯曲时,通过管端部内、外层管的连接可在弯曲时对内管产生一定的轴向拉应力,降低了内管的内侧压应力,从而有助于避免弯曲时内管起皱。图14所示为采用不同厚度外管进行弯曲后内管的轴向应力分布。由图14可以看出,当外管的壁厚从2 mm增加至10 mm时,内管的轴向应力拉、压分界线明显向弯曲内侧移动,即内管的轴向压应力作用区域和数值都明显减小。当轴向压应力小于临界失稳应力时,即可消除内管内侧的起皱。

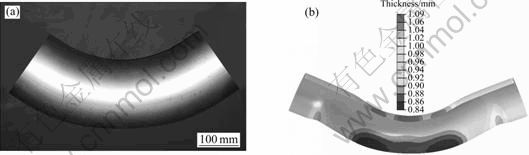

采用双层管充液弯曲方法,成形了如图15所示的薄壁弯头。该弯头直径为180 mm,壁厚为1 mm,径厚比为D/l=180。沿轴向的壁厚分布如图15(b),最大减薄率为14%,最大椭圆度为3%。

3 内高压成形工业应用

3.1 大型内高压成形设备

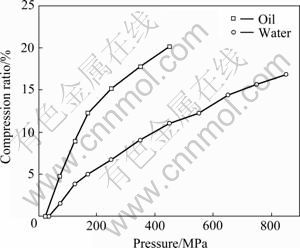

内高压成形机由合模压力机、高压源、水平缸(水平压力机)、液压系统、水压系统和计算机控制系统6大部分组成。内高压成形机需完成的工作过程包括如下10个步骤:1) 闭合模具;2) 施加合模力;3) 快速填充成形介质;4) 管端密封;5) 施加内压和轴向进给;6) 增压整形;7) 卸压;8) 卸载合模力;9) 退回冲头;10) 开模。经过近10年的努力,攻克了超高压建立及高压水介质传输、超高压与多轴位移闭环实时控制、数控系统软件等设备关键技术难题,其中,超高压建立与介质选择最为关键。超高压建立是采用增压器,通过大面积活塞推动小面积活塞,在小面积腔体端建立高压。定义大活塞面积与小活塞面积之比为增压比,当增压比为25时,低压腔25 MPa的液压油在高压腔增压为400 MPa。由于水在超高压下的压缩量小于油的压缩量(见图 16),高压腔介质一般选用水作为传力介质,而且水介质对工件及环境无污染。

图12 进气道内高压成形过程等效应力分布与塑性区发展规律

Fig.12 Effective stress distribution and deformation development in hydroforming of inlet: (a) Die closing; (b) After calibration

图13 双层管充液弯曲原理

Fig.13 Principle of hydro-bending process of double-layered tube: (a) Pre-filling and pressurized; (b) Hydro-bending; (c) Removing of outer tube

图14 采用不同厚度(l)外管弯曲时内管的轴向应力分布

Fig.14 Axial stress distribution of inner tube hydro-bent with out tube of different thicknesses: (a) l=2 mm; (b) l=4 mm; (c) l=6 mm; (d) l=10 mm

图15 双层管充液弯曲成形的超薄弯管及壁厚分布

Fig.15 Ultra thin-walled elbow manufactured by double-layered tube hydro-bending: (a) Elbow tube; (b) Thickness distribution

图16 油与水压缩量比较

Fig.16 Comparison of compression ratio of oil and water

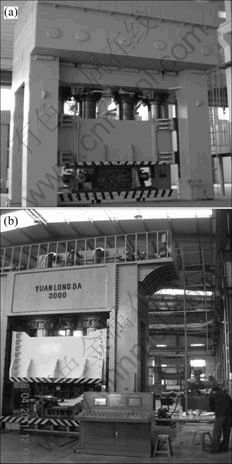

在获得了设备关键技术的基础上,为国内汽车主机厂及零部件厂研制了多台生产用大型内高压成形机,替代进口设备,用于汽车底盘等关键零件大批量生产,生产效率为每件40~60 s。图17所示为哈尔滨工业大学为国内汽车行业开发的大吨位内高压成形机,最大合模力达到55 MN。

图17 汽车行业用大吨位内高压成形机

Fig.17 Large hydroforming press for automotive industry: (a) Closing force of 55 MN; (b) Closing force of 30 MN

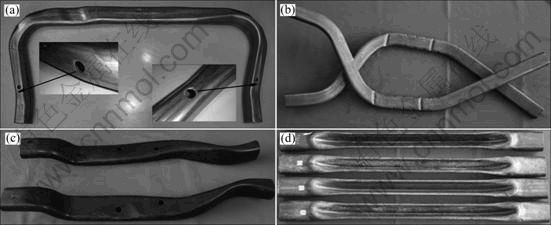

3.2 内高压成形典型汽车零件

近年来,工艺关键技术的创新和大型生产用设备的研制,为自主品牌轿车底盘和车身内高压成形件制造提供了设备与模具,促进了自主品牌轿车整车竞争力的提升。图18(a)所示为一汽奔腾轿车用副车架。该副车架具有三维轴线、18个不同的异型截面。为成形该零件,通过设计多个花瓣状预成形截面,有效降低了最终的成形压力,壁厚更加均匀,该零件于2011年实现批量生产。图18(b)所示为SUV车型的前支梁。该零件同样具有三维弯曲轴线及变化的矩形截面,所用材料为440 MPa级高强钢。通过数控弯曲、预成形及液压成形3道工序实现该零件成形。图18(c)所示为汽车底盘零件,所用材料为440 MPa级高强钢管。该零件成形的最大难点在于存在一个局部小弯曲半径,通过传统方法难以顺利成形。图18(d)所示为液压成形扭力梁,该零件截面为V型。

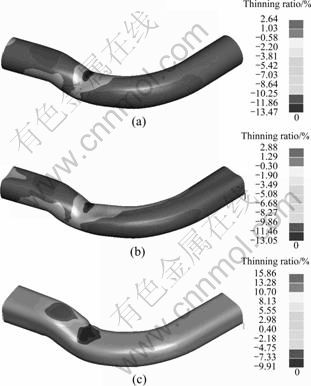

为了减轻质量及适应空间布置的要求,底盘零件大多设计为空间弯曲轴线的空心变截面构件,截面形状以矩形、梯形和长椭圆形为主,且沿零件轴线截面周长变化。对于弯曲轴线变截面件,需通过弯曲、预成形和内高压成形3个工序完成。图19所示为采用 多步法数值模拟给出的克莱斯勒300C底盘前梁内高压成形全过程减薄率分布规律。其中,减薄率为负值表示增厚。弯曲后弯曲段外侧减薄,最大减薄率出现在小弯的外侧,为2.6%;弯曲段内侧增厚,最大增厚率出现在小弯的内侧,为13.5%。预成形过程壁厚变化不明显。内高压成形后的壁厚分布规律如下:沿轴线方向,最小壁厚位于曲率半径较小位置处的弯角外侧;沿截面方向,最小壁厚位于截面圆角和直边的过渡区域。最大增厚率仍处于小弯内侧,为10%;最大减薄率仍处于小弯外侧,为16%。C级轿车汽车底盘零件要求减薄率小于20%,所以满足要求。

图18 内高压成形典型汽车零件

Fig.18 Typical automotive parts manufactured by hydroforming: (a) Engine cradle; (b) Front beam holder; (c) Chassis part; (d) Torsion beam

图19 底盘前梁内高压成形过程及减薄率分布

Fig.19 Hydroforming process of front beam of chassis and thinning ratio distribution: (a) Bending; (b) Preforming; (c) Hydroforming

4 结论

1) 内高压成形过程中,所有可能的应力状态都位于平面应力屈服椭圆(屈服轨迹)上从A点到B点直至C点之间的曲线上。在平面应力状态下,变形区壁厚变化取决于轴向应力与环向应力之和。

2) 在变径管轴线方向,成形区壁厚减薄,送料区壁厚增加,在两区之间存在壁厚不变的厚度分界圆。沿多边形截面管的环向,从直边中点到圆角过渡区壁厚逐渐减薄,最薄点位于过渡区,最厚点位于直边 中点。

3) 在整形阶段存在极限圆角半径,其主要由摩擦因数、截面边长和管材厚度决定,而与内压无关。采用管材环向拉伸试验方法,可以直接测试管材的环向力学性能,但试验过程中应尽量减小管材与D型块之间的摩擦。

4) Y型薄壁三通管成形时,采用带斜面的反向冲头经两步成形,可改善支管部位的壁厚分布,从而获得大径厚比的超薄三通管件。采用双层管充液弯曲方法,可防止出现薄壁管弯曲过程中的内侧起皱的问题,实现径厚比达180的超薄弯管成形。

5) 攻克了生产用内高压成形设备的关键技术难题,成功地研制了合模力达到55 MN的大型内高压成形机,并应用于汽车底盘零件大批量生产。

REFERENCES

[1] DOHMANN F, HARTL C. Hydroforming—A method to manufacture lightweight parts[J]. Journal of Materials Processing Technology, 1996, 60: 669-676.

[2] VOLLERTSEN F, PRANGE T, SANDER M. Hydroforming: Needs, developments and perspective[C]//Proceedings of the 6th International Conference on Technology of Plasticity. Heidelberg: Springer-Verlag, 1999: 1197-1210.

[3] KOC M, ALTAN T. An overall review of the tube hydroforming(THF) technology[J]. Journal of Materials Processing Technology, 2001, 108: 384-393.

[4] YUAN S J, LIU G, HUANG X R. Hydroforming of typical hollow components[J]. Journal of Materials Processing Technology, 2004, 151: 203-207.

[5] YUAN S J, LIU G, WANG X S. Development and applications of tube hydroforming in China[C]//Proceedings of TUBEHYDRO 2007. Harbin: Harbin Institute of Technology Press, 2007: 27-38.

[6] YUAN S J. Innovative processes in tube hydroforming and applications[C]//Proceedings of the 2nd ICNFT. Bremen, 2007: 1-13.

[7] 苑世剑. 现代液压成形技术[M]. 北京: 国防工业出版社, 2009: 14-18.

YUAN Shi-jian. Modern hydroforming technology[M]. Beijing: National Defence Industry Press, 2009: 14-18.

[8] 苑世剑, 刘 钢, 何祝斌, 王小松, 韩 聪, 滕步刚, 徐永超. 内高压成形机理与关键技术[J]. 数字制造技术, 2008, 6(4): 1-34.

YUAN Shi-jian, LIU Gang, HE Zhu-bin, WANG Xiao-song, HAN Cong, TENG Bu-gang, XU Yong-chao. Mechanism of internal high pressure forming and its key technologies[J]. Digital Manufacture Science, 2008, 6(4): 1-34.

[9] YUAN S J, YUAN W J, WANG X S. Effect of wrinkling behavior on formability and thickness distribution in tube hydroforming[J]. Journal of Materials Processing Technology, 2006, 177: 668-671.

[10] YUAN S J, WANG X S, LIU G. Control and use of wrinkles in tube hydroforming[J]. Journal of Materials Processing Technology, 2007, 182: 6-12.

[11] 苑文婧, 王小松, 苑世剑. 变径管内高压成形的厚度分界圆[J]. 材料科学与工艺, 2008, 16(2): 196-199.

YUAN Wen-jing, WANG Xiao-song, YUAN Shi-jian. Thickness dividing circle in hydroforming of variable diameter tubes[J]. Material Science and Technology, 2008, 16(2): 196-199.

[12] LIU G, YUAN S J, TENG B G. Analysis of thinning at the transition corner in tube hydroforming[J]. Journal of Materials Processing Technology, 2006, 177: 688-691.

[13] YUAN S J, HAN C, WANG X S. Hydroforming of automotive structural components with rectangular-sections[J]. International Journal of Machine Tools and Manufacture, 2006, 46(11): 1201-1206.

[14] HAN C, YUAN S J. Reduction of friction and calibration pressure by section preform during hydroforming of tubular automotive structural components[J]. Advanced Materials Research, 2008, 44/46: 143-150.

[15] SONG P, WANG X S, HAN C, XU Y C, YUAN S J. Filling behavior of transition corner in hydroforming of aluminum alloy rectangular section tube[J]. Journal of Mechanical Engineering, 2010, 46(12): 59-64.

[16] 何祝斌, 苑世剑, 查微微, 梁迎春. 管材环状试样拉伸变形的受力和变形分析[J]. 金属学报, 2008, 44(4): 423-427.

HE Zhu-bin, YUAN Shi-jian, CHA Wei-wei, LIANG Ying-chun. Force and deformation analysis of tube ring specimen during hoop tension test[J]. Acta Metallurgica Sinica, 2008, 44(4): 423-427.

[17] HE Z B, YUAN S J, LIU G, CHA W W. Formability testing of AZ31B magnesium alloy tube at elevated temperature[J]. Journal of Materials Processing Technology, 2010, 210: 877-884.

[18] LIU G, PENG J Y, CHU G N, ZHU S Q, XIAO H T, YUAN S J. Deformation patterns in hydroforming of thin-walled Y-shaped tube[J]. Steel Research International, 2010, 81(9): 536-539.

[19] LIU G, PENG J Y, WANG X S, ZHU S Q, YUAN S J. Effects of preform on thickness distribution of hydroformed Y-shaped tube[J]. Advanced Materials Research, 2011, 189/193: 2796-2800.

[20] TENG B G, YUAN S J. Deformation behavior of thin-walled tubes bending with internal pressure[C]//Proceedings of the 6th International Conference on Physical and Numerical Simulation of Materials Processing. Guilin: Trans Tech Press, 2010: 16-19.

(编辑 陈卫萍)

基金项目:国家杰出青年科学基金资助项目(50525516);国家自然科学基金资助项目(59975021, 50375036, 50575051)

收稿日期:2011-05-22;修订日期:2011-07-29

通信作者:苑世剑,教授,博士;电话:0451-86418776;E-mail: syuan@hit.edu.cn

苑世剑教授简介

苑世剑,博士,教授、博士生导师、长江学者特聘教授、国家杰出青年基金获得者,首批国防科技创新团队带头人。现任哈尔滨工业大学材料科学与工程学院院长、金属精密热加工国防科技重点实验室主任。主要研究方向包括内高压成形、板材热成形和塑性加工理论。主要学术贡献如下:对内高压成形技术进行了开创性研究,发展了内高压成形基础理论,形成了具有自主知识产权的工艺和设备关键技术,研究成果已经在自主品牌轿车关键零件的批量生产和国防型号重要零件的研制中得到大量应用,突破了国外对内高压成形工艺和设备的封锁。学术兼职如下:国际塑性加工会议(ICTP)常务理事,中国塑性工程学会副理事长,中国汽车工程学会理事,高温结构材料国家级重点实验室学术委员会委员,金属精密热加工国家级重点实验室学术委员会委员,《材料科学与工艺》主编,《塑性工程学报》副主编。发表论文120余篇,其中SCI收录60余篇;出版专著2本;授权专利20项;国际会议大会报告3次,担任第三届内高压成形国际会议主席。获国家科技进步二等奖2项,省技术发明奖一等奖1项,省部级二等奖5项。