Dependence of characteristics of LaB6 films on DC magnetron sputtering power

XU Jing(徐 静)1, 2, MIN Guang-hui(闵光辉)1, HU Li-jie(胡立杰)1, ZHAO Xiao-hua(赵晓华)1, YU Hua-shun(于化顺)1

1. School of Materials Science and Engineering, Shandong University, Ji’nan 250061, China;

2. Department of Civil Engineering, Shandong Jiaotong University, Ji’nan 250023, China

Received 18 June 2008; accepted 10 March 2009

Abstract: Lanthanum hexaboride(LaB6) thin films were deposited on glass substrate by DC magnetron sputtering technology, and the AFM, XRD and scratch tests were used to characterize the deposited films. Influences of sputtering power on the microstructure and the bonding strength between the film and substrate were investigated. AFM observation proves that the dense films are obtained, and the surface roughness is below 4.3 nm. The LaB6 film shows the crystalline structure with the grain less than 100 nm. The XRD pattern identifies that the crystal structure of the films is in accordance with that of bulk LaB6, and the (100) crystal face is dominated. The average grain size decreases firstly and then increases with increasing power, and reaches the minimum of 40 nm when the sputtering power is 44 W. Moreover, the intensity of peaks in XRD pattern increases firstly and decreases afterward with increasing power. When the sputtering power is 50 W, the peak intensity reaches the maximum, showing an intense relationship between the power and crystal structures. The scratch test shows that interface bonding strength of the film/substrate is higher at the power of 44 W than the others, due to the formation of the nanosized crystals and their improved surface energy.

Key words: LaB6 film; DC magnetron sputtering; microstructure; bonding strength

1 Introduction

LaB6 has many characteristics, such as high melting point, high hardness, good conductivity and high chemical stability. It has much other special functionality [1-2]. The purple color of LaB6 makes it an optical material. LaB6 is widely used for its special characteristic.

The cathode emission speciality of LaB6 film was studied widely, but the research on optical speciality was few. SCHELM and SMITH[3] showed a comprehensive evaluation of the performance of NIR blocking windows, using LaB6 nanoparticle-doped polymer sheets.

The wearing resistance and decorative function of LaB6 films were widely studied[4-6]. The highest hardness value and the most marked visual color impression are obtained at low gas pressures. In contrast to bulk LaB6 cathodes, coated metal filaments seem to be very promising with respect to their simple fabrication, lower operating temperature and thus lower power consumption. Most substrates of the films are metals or crystal materials[7-13].

In this work, in order to further study the optical characteristics, glass was used as the substrate by changing sputtering power; and the formation, morphology and deposition of the films were studied and discussed. The purpose of the study was to investigate the correlation between the characteristic and the sputtering power.

2 Experimental

The pellet LaB6 target with thickness of 3 mm and diameter of 60 mm was hot-pressing sintered. Normal optical glass was used as the substrate. The substrates were precleaned with acetone and alcohol successively in an ultrasonic cleaner, then dried by electric hot air blower. Deposition was carried out in a double room combined systems of high vacuum magnetron sputter and ion beam sputter. During the sputtering, temperature of the substrate was kept at the room temperature. The deposition was carried out in argon (99.999%, purity) at chamber pressure of 1.5 Pa. The distance between the target and the substrate was 50 mm. Flow rate of argon was 25 mL/min. Bias-voltage was -100 V. During the deposition, sputtering power was adjusted from 17.6 to 61.6 W.

The morphology of the films was studied using an atomic force microscope(AFM). The small angle X-ray diffractometer(XRD) was used for structural characterization. The scratch test was used to investigate the bonding strength of the film-substrate. The deposition rate and thickness were determined using a stylus profiler.

3 Results and discussion

Fig.1 shows that surfaces of the films are smooth and compact. There is no obvious defect, but the surfaces of the films obtained at different power are different. The average grain size and roughness of the film obtained at the sputtering power of 44.0 W are the least. The average size of the grains decreases firstly and increases afterward, which is controlled by two factors. Firstly, at the low sputtering power, the time of migration on the substrate is long so that atoms can get to the site of adsorption or be adsorbed by the islet of other adsorption site easily, which makes surface of the film rough and incompact. High sputtering power causes compact and smooth films. Secondly, with the increase of the sputtering power, the scattering of target atoms by argon is increased, resulting in temperature rising. This corresponds to heat treatment on the film. The treatment is continuous on the formation of the films, and causes the growth of the fine grain. The morphology of the films is influenced by the two factors.

Fig.1 AFM morphologies of LaB6 films obtained at various powers: (a)17.6 W; (b) 26.4 W; (c) 35.2 W; (d) 44.0 W; (e) 52.8 W; (f) 61.6 W

We also studied the relationship between sputtering power and roughness. Fig.2 shows the transformation trend of average roughness. The average roughness of the films arranged from 4.26 to 140 nm. The roughness of films is also influenced by the same factors. So the film with the minimum roughness is obtained at 44.0 W. The result is in accordance with the minimum grain size.

Fig.2 Influence of sputtering power on average roughness

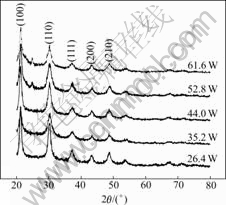

The film deposited at 17.6 W is so thin that diffraction peak cannot be observed. The results of XRD of other films show that they are of crystal structure. Fig.3 shows that the predominant face of the films is (100), and this is different from the bulk LaB6. This result is in accordance with the report of MITTERER[6]. The diffraction intensity and the crystallinity are influenced by the sputtering power. The relative intensity of (110) increases firstly and decreases afterward with the increase of sputtering power. The diffraction peaks of the film obtained under 35.2 W show that the ratio is 90.13%. When the sputtering power exceeds 35.2 W, the ratio changes little, and the value is in the range of 50%-60%.

Fig.3 XRD patterns of LaB6 films sputtered under various power

Crystal nucleuses on the surface of the substrate exhibit different crystal orientations. Growth conditions of different orientations are different. The predominant crystal face orientation lies on the growth condition. When the sputtering is 35.2 W, the growth condition is favorable for plane (110).

The collision of atoms on the substrate will increase the temperature of the substrate, which is in favor of the transformation from amorphous structure to crystal. The crystallinity will be improved with the increase of the sputtering power.

At the low sputtering power, the time of migration on the substrate is long, so the crystal nucleus forms and grows easily. But few atoms will get to the substrate, so the continuous growth is difficult. To increase the sputtering, the number of atoms that get to the substrate should be increased. In addition, more crystal nucleuses formed at the same time result in fine crystal grains. The crystallization of the film is governed by a competition between the two factors.

Fig.4 shows that the bonding strength of the film/substrate increases firstly and decreases afterward with the increase of sputtering power. The maximum strength appears at the power of 44 W. Collision of atoms on the substrate increases the temperature of the substrate. The phenomenon becomes obvious with the increase of sputtering power. High temperature of the substrate leads to the diffusion between the substrate and the film, which accelerates chemical reaction, so the bonding strength increases. If the temperature becomes too high, the crystal grain will coarsen and the thermal stress will be influenced.

Fig.4 Influence of power on bonding strength

In addition, the incidence of atoms increases with the increase of sputtering power, and the incidence of the oxygen molecule in remaining atmosphere reduces. The oxide interlayer reduces, so the bonding strength reduces. At the same time, the films deposited at high speed have loose structure and internal stress, which will lead to the decline of the bonding strength. In general, the change of the bonding strength is the reflection of the two reasons.

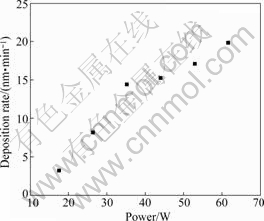

Fig.5 shows the deposition rate of the films. The average deposition rate increases with the increase of power, but the increment of deposition rate is not average with the increase of sputtering power. The deposition rate of the film increases quickly first, and then increases slowly after the sputtering power is up to 35.2 W. The number of ions increases with the increase of sputtering power. The bombardment of these ions induces more atoms to leave the target, so the deposition rate increases with increasing the power, but the deposition rate does not increase at the same rate. There are two reasons for the phenomena. Firstly, the energy of the argon ions is so high that some of them enter the inside of the crystal lattice, and bomdardment of these ions cannot induce any atom to leave the target. Secondly, the capture area is small, so the condensing is slow or part condense. The condensing rate depends on the number of the atoms that get and stay on the substrate. Atoms condensed quickly with the increase of the sputtering power, which leads to increase of the density of the crystal nucleus. If the distance of two neighboring crystal nucleuses is so small that they overlap each other, new crystal nucleus will not form. That means the deposition rate does not increase with increasing the power if the power exceeds a given value.

Fig.5 Influence of sputtering power on deposition rate

4 Conclusions

1) The surface morphology of films is smooth and compact with the average roughness value below 4.26 nm and the minimum of 1.40 nm.

2) All the films are crystalline and the predominant face of the films is (100) face.

3) The average deposition rate increases with increasing the power, but the increment of deposition rate is not in concordance with the increasing power.

4) The bonding strength increases firstly and decreases afterward. The characteristics of film obtained at 44.0 W are the best.

References

[1] YANG Li-xia, MIN Guang-hui, YU Hua-shan, HAN Jian-de, WANG Wei-ti. Development of research of CaB6 ceramic [J]. Chinese Ceramic Society, 2003, 31(7): 687-691. (in Chinese)

[2] ZHENG Shu-qi, MIN Guang-hui, YU Hua-shan, HAN Jian-de, WANG Wei-ti, ZHANG Shu-yu. Present status of research on LaB6 functional ceramic materials [J]. Mater Rev, 2000, 14(3): 50-51. (in Chinese)

[3] SCHELM S, SMITH G B. Tuning the surface-plasmon resonance in nanoparticles for glazing applications [J]. J Appl Phys, 2005, 97(10): 124314.

[4] KAFADARYAN E A, PETROSYAN S I, BADALYAN G R, HARUTYUNYAN S R, KUZANYAN A S. Optical characteristics of (La,Ce)B6 films deposited on silicon substrates by e-beam evaporation process [J]. The Solid Films, 2004, 416: 218-223.

[5] WALDHAUSER W, MITTERER C, LAIMER J, STORI H. Structure and electron emission characteristics of sputtered lanthanum hexaboride films [J]. Surface and Coatings Tech, 1995, 74/75: 890-896.

[6] MITTERER C, OTT H M, STALLMAIER J K, SCHMOLZ, P WERNER W S W, STORI H. Sputtered decorative hard coatings within the system LaB6-ZrB2 [J]. Alloys and Comp, 1996, 239: 183-192.

[7] LATE D J, MORE M A, MISRA P, SINGH B N, KUKREJA L M, JOAG D S. Field emission studies of pulsed laser deposited LaB6 films on W and Re [J]. Ultramicroscopy, 2007, 107(9): 825-832.

[8] CRACIUN V, CRACIUN D. Pulsed laser deposition of crystalline LaB6 thin films [J]. Applied Surface Science, 2005, 247(1/4): 384-389.

[9] LI Jian-jun, LIN Zu-lun, SHI Qing-xuan, WANG Xiao-ju. Study of the emission characteristics of LaBx thin film [J]. Vacuum Electronics, 2006, 6: 31-34.

[10] SHI Qing-xuan, LIN Zu-lun, LI Jian-jun, CHEN Ze-xiang. LaB6 thin films prepared by electron beam evaporation and its property [J]. Chinese Journal of Electron Device, 2007, 30(3): 745-747. (in Chinese)

[11] YUTANI A, KOBAYASHI A, KINBARA A. Work functions of thin LaB6 films [J]. Applied Surface Science, 1993, 70/71(2): 737-741.

[12] WALDHAUSER W, MITTERER C, LAIMER J, ST?RI H. Sputtered thermionic hexaboride coatings [J]. Surface and Coatings Tech, 1998, 98(1/3): 1315-1323.

[13] KHER S S, SPENCER J T. Chemical vapor deposition of metal borides: 7. The relatively low temperature formation of crystalline lanthanum hexaboride thin films from boron hydride cluster compounds by chemical vapor deposition [J]. Journal of Physics and Chemistry of Solids, 1998, 59(8): 1343-1351.

Corresponding author: MIN Guang-hui; Tel: +86-531-88392412; Fax: +86-531-88395639; E-mail: ghmin@sdu.edu.cn

DOI: 10.1016/S1003-6326(08)60384-2

(Edited by YANG Hua)