J. Cent. South Univ. Technol. (2007)02-0225-05

DOI: 10.1007/s11771-007-0045-9

Deposit 3D modeling and application

LUO Zhou-quan(罗周全), LIU Xiao-ming(刘晓明), SU Jia-hong(苏家红),

WU Ya-bin(吴亚斌), LIU Wang-ping(刘望平)

(School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: By the aid of the international mining software SURPAC, a geologic database for a multi-metal mine was established, 3D models of the surface, geologic fault, ore body, cavity and the underground openings were built, and the volume of the cavity of the mine based on the cavity 3D model was calculated. In order to compute the reserves, a grade block model was built and each metal element grade was estimated using Ordinary Kriging. Then, the reserve of each metal element and every sublevel of the mine was worked out. Finally, the calculated result of each metal reserve to its actual prospecting reserve was compared, and the results show that they are all almost equal to each other. The absolute errors of Sn, Pb, and Zn reserves are only 1.45%, 1.59% and 1.62%, respectively. Obviously, the built models are reliable and the calculated results of reserves are correct. They can be used to assist the geologic and mining engineers of the mine to do research work of reserves estimation, mining design, plan making and so on.

Key words: geologic database; deposit model; cavity; reserves; SURPAC software

1 Introduction

The deposit three-dimensional model is the numeric token of the deposit. Some international mining corporations, such as Canadian VOISEYS Nickel International and BHP-BILLITON Mining Mult- inational Corporation, applied the mining software to build the 3D deposit model to realize the dynamic management of the production and the reasonable using of the resources, reduce the cost of resource exploration and mining, and improve the benefit of the company[1-4]. Surpac Version is a kind of large-scale mining engineering software produced by Australian Surpac software International Pty Ltd. The software has been licensed to 4 000 users in more than 91 countries, and widely used in exploration, survey, mining design and reclamation[5-6]. In this paper, the Surpac software was used to establish a geologic database for a multi-metal mine, the 3D models of the digging surface, geologic fault, ore body, cavity and underground openings were built, the volume of the mining cavity was calculated. As well, a grade block model was constructed and the Ordinary Kriging was used to estimate the metal element grade, the reserves of the mine were worked out according to each metal element and every sublevel respectively. Finally, the calculated reserves to the actual prospecting reserves of the mine were compared.

2 Establishment of geologic database

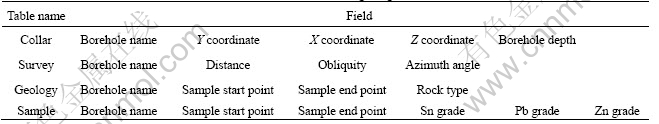

In order to establish the geologic database, we collected almost all the prospecting data of the mine, and chose the main elements, including Sn, Pb and Zn, as the territorial variables. Then, we used the Surpac Version 5.0-K and the collected data to establish the mine’s geologic database. The datasheet structure of the geologic database is shown in Table1.

Geologic database is the foundation of 3D modeling. It is necessary for building 3D model of ore body, analyzing the borehole data, estimating the metal element grade and calculating reserves[7-10]. The geologic database has powerful post-processing functions, which can be used to edit, inquire, update, analyze and display the data visually. Fig.1 shows the 3D displaying of the spatial location of the boreholes.

Fig.1 3D displaying of spatial location of boreholes

Table 1 Datasheet structure of geologic database

3 3D modeling

3.1 Surface 3D model

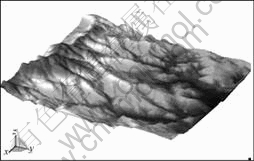

Building the surface 3D model is to figure clearly the spatial location relationship between the surface and other spatial bodies, such as ore body and underground openings. 3D model of the surface generated from the mine surface contour map is shown in Fig.2.

Fig.2 3D model of surface

3.2 Fault 3D model

In order to realize the spatial relationship between the geologic fault and the ore body, and comprehend the impact led by the fault on the ore body during the period of mining, it is necessary to build the geologic fault 3D model based on 22 sheets of prospecting cross-section plane, shown in Fig.3.

Fig.3 3D model of geologic fault

3.3 Ore body 3D model

Usually, there are two methods for ore body 3D modeling[11-16]. Method 1 is to build the ore body 3D model using the prospecting cross-section plane. Method 2 is to build the ore body 3D model based on the borehole data. We should choose the proper method according to the aim of modeling. Generally, we should use several methods synthetically to build the ore body model in order to show the ore body shape exactly. Here, we chose method 2 synthetically to build the ore body 3D model. Figs.4 and 5 show the 3D model of the ore body and the mixed rock within the ore body.

Fig.4 3D model of ore body

Fig.5 3D model of mixed rock

3.4 Opening 3D model

For the sake of reflecting the spatial relationship between the ore body and openings, and also providing the basis for other new opening design, we built opening 3D models. All drifts 3D models of 6 sublevels are built based on the sublevel ichnography, other opening’s models, such as ramp and raise, are built based on their midline and actual cross-section size. Fig.6 shows the opening 3D model of sublevel 355.

Fig.7 shows the compound model of surface, geologic fault, underground openings and ore body.

Fig.6 Opening model of sublevel 355

Fig.7 Compound model of surface, geologic fault, underground opening and ore body

4 Cavity 3D modeling and its volume

calculation

Cavity 3D modeling is to realize the basic shape, location, volume of the cavities, and the spatial relationship between cavities and underground openings, simultaneously to assist the following mining design according to the three-dimensional configuration and the position of cavity, and also to settle the foundation for cavity stability numerical simulation. In order to build the cavity model well, we accomplished the cavity 3D model based on 22 sheets of actual surveying maps. Fig.8 shows the distribution of cavities in all sublevels, and Fig.9 shows the volume distribution of cavities in different mining districts and classified by the situation whether the cavity has been filled or not.

5 Reserve calculation

In the interest of calculating reserves of the deposit, we built the grade block model. Personal status model unit block size for 20 m×15 m×10 m was definited and the smallest unit block size for 5 m×5 m×2.5 m was decomposed. The spherical variation function model was used, the variation function was analyzed separately along the ore body extend direction, proneness and the thickness in three directions. Then main parameters of theoretical variation function were educed, and the reliability of the variation function curve was checked by using cross-validate. In view of various elements personal status distribution characteristic in the mining area, the Ordinary Kriging was used to estimate each main metal element grade[17-20].

Fig.8 Distribution of cavities in sublevels

Fig.9 Distribution of cavity volume in different mining districts

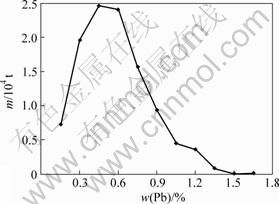

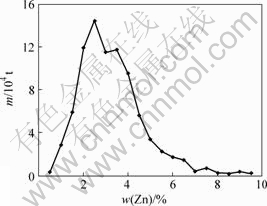

Each metal reserve based on the grade block model was calculated and the grade-tonnage curve for each metal was generated, as shown in Figs.10, 11 and 12.

Fig.10 Grade-tonnage curve of Sn

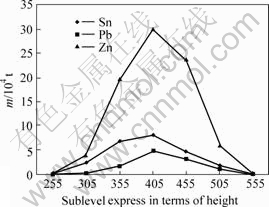

As well, every metal reserve in each sublevel was calculated and sublevel-tonnage curve was created, asshown in Fig.13.

Fig.11 Grade-tonnage curve of Pb

Fig.12 Grade-tonnage curve of Zn

Fig.13 Sublevel-tonnage curve of each metal

The results of comparing each metal’s calculated reserve to its actual prospecting reserve of the mine are shown in Fig.14. It is obvious that the calculated reserve of each metal is almost equal to its actual prospecting reserve. The absolute errors of Sn, Pb, and Zn reserves are only 1.45%, 1.59% and 1.62%, respectively.

Fig.14 Calculated reserves vs actual prospecting reserves

6 Conclusions

1) Surpac Version is a kind of practical large-scale mining engineering software. With the help of it, the geologic database of a mine is established and 3D models of the surface, geologic fault, ore body, cavity and underground openings are built.

2) Cavity volume based on the cavity 3D model is calculated. A grade block model of the deposit is constructed and the reserve of each metal and every sublevel is worked out respectively.

3) Each calculated metal reserve to its actual prospecting reserves of the mine is compared. The absolute errors of Sn, Pb, and Zn reserves are only 1.45%, 1.59% and 1.62%, respectively. The results show that the models are reliable and the calculated reserves are correct. They can be used to assist the geologic and mining engineers of the mine to do research work of reserves estimation, mine design and plan making.

References

[1] CHEN Ai-bing, QIN De-xin, ZHANG Xue-shu. The application of deposit 3D model based on micromine[J]. Geology & Prospecting, 2004, 40(5): 77-80. (in Chinese)

[2] GUO Xu-dong. Research of the vein lead-zinc deposit modeling method[J]. Nonferrous Mines, 2002, 31(1): 6-9. (in Chinese)

[3] GONG J Y, CHENG P G, WANG Y D. Three dimensional modeling and application in geological exploration engineering[J]. Computers & Geosciences, 2004, 30(4): 391-404.

[4] WU Qiang, XU Hua. An approach to computer modeling and visualization of geological faults in 3D[J]. Computers & Geosciences, 2003, 29(4): 507-513.

[5] Surpac Minex Group. Surpac Vision Software User Manual[M]. Beijing: Surpac Software International, 2002.

[6] LI Hai-hua, ZHANG Rui-xin. Apply Surpac software to visualize mining engineering in open pit[J]. Chinese Mining, 2004, 13(1): 63-65. (in Chinese)

[7] HOULDING S W. Practical Geostatistics, Modeling and Spatial Analysis[M]. New York and Heidelburg: Springer-Verlag, 2000.

[8] SUN Hong-quan. Geostatistics and its Application[M]. Xuzhou: China University of Mining and Technology Press, 1990. (in Chinese)

[9] HOULDING S W. 3D Geoscience Modeling-computer Techniques for Geological Characterization[M]. New York: Springer-Verlag, 1994.

[10] JIA Ming-tao, PAN Chang-liang, XIAO Zhi-zheng. Study on the ore deposit modeling practice based on three-dimension geological statistics[J]. Metal Mine, 2002, 12(8): 42-44. (in Chinese)

[11] ZHU Liang-feng, WU Xin-cai, LIU Xiu-guo. 3D stratum modeling based on borehole data[J]. Geology and Geo-information Science, 2004, 20(3): 26-30. (in Chinese)

[12] LEMON A M. JONES N L. Building solid models from boreholes and user-defined cross-sections[J]. Computers & Geosciences, 2003, 29(3): 547-555.

[13] CHEN Pei-pei, YE Yong, ZHANG Shou-ren. Application of Surpac vision in coal mines[J]. Coal Science and Technology, 2002, 30(3): 29-31. (in Chinese)

[14] NAN Ge-li. Orebody string model and its modeling methods[J]. Nonferrous Mine, 2001, 30(5): 1-4. (in Chinese)

[15] JIA Ming-tao, WANG Li-guan. Study on boundary control technology in deposit modeling[J]. Metal Mine, 1999, 9(9): 19-21. (in Chinese)

[16] XU Yun-he, ZHAO Ji-xin, CHEN Peng-gen. 3D GIS modeling and visualization in geology and mining[J]. Chinese Mining, 2003, 12(4): 60-62. (in Chinese)

[17] DEUTSCH C V, JOURNEL A G GSLIB. Geostatistical Software Library and Users Guide [M]. (2nd ed.) New York: Oxford University Press, 1998.

[18] MARINONI O. Improving geological models using a combined ordinary–indicator Kriging approach [J]. Engineering Geology, 2003, 69(1/2): 37-45.

[19] PAN Guo-cheng. Practical issues of geostatistical reserves estimation in the mining industry[J]. CIM Bulletin, 1995, 88(993): 31-37.

[20] WAN Chang-lin, ZHU Li-ping, GAO Xiang. Applying geological statistics to evaluate a certain copper ore resource in Fujian[J]. Metal Mine, 2002(6): 49-52. (in Chinese)

Foundation item: Project(50490274) supported by the National Natural Science Foundation of China

Received date: 2006-04-24; Accepted date: 2006-06-27

Corresponding author: LUO Zhou-quan,Professor,PhD;Tel: +86-731-2239239;E-mail: lzq505@hotmail.com

(Edited by LI Xiang-qun)