文章编号:1004-0609(2010)05-0840-06

铝合金2A12-O的动态充液拉深

王会廷,高 霖,沈晓辉,陈明和

(南京航空航天大学 机电学院,南京 210016)

摘 要:针对铝合金板材成形性差的特点,提出液体内向流动动态充液拉深新技术。采用铝合金2A12-O板材对成形过程进行了初步实验验证后,运用有限元方法探讨不同的径向压力和不同的预胀路线对成形零件壁厚分布的影响。结果表明,采用该方法可以显著提高铝合金2A12-O的成形极限,成功拉深出拉深比达2.85的杯形件;径向压力显著影响杯形件壁厚的分布,通常较大的径向压力下的壁厚也较大。

关键词:铝合金2A12-O;动态充液拉深;径向压力;反向液体流动

中图分类号:TG349 文献标志码:A

Hydrodynamic deep drawing process of 2A12-O aluminum alloy

WANG Hui-ting, GAO Lin, SHEN Xiao-hui, CHEN Min-he

(College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China)

Abstract: A new method, named hydrodynamic deep drawing with radially inward flowing liquid, was proposed, aiming at the poor formability of aluminium alloy sheet. After a preliminary experimental validation of the proposed method by using 2A12-O aluminum alloy, the effects of different radial pressures and different pre-bulging loading paths on the wall thickness distribution of the formed cups were investigated with the assistance of FEM. The results show that the foming limit of 2A12-O aluminum alloy is obviously improved by the method, and a cup with a drawing ratio of 2.85 is formed successfully. The radial pressure during the deep drawing process has a great influence on the wall thickness distribution of the formed cups. In general, the higher the radial pressure, the thicker the wall thickness.

Key words: 2A12-O aluminum alloy; hydrodynamic deep drawing; radial pressure; radially inward flowing liquid

随着汽车、航空航天等领域零部件轻量化的需要,铝、镁等轻质合金获得了越来越多的关注和应用[1-4]。但在常温下,铝镁等轻质合金成形性能差,是制约其获得更广泛应用的瓶颈之一[5]。充液拉深技术采用液压技术和板料成形相结合,是一种先进的板料成形新技术,与传统拉深方法相比,具有拉深比大、零件成形表面质量好、尺寸精度高和能够成形复杂零件等优点,现已广泛应用于汽车、航空、航天等领域零部件的成形[6-8]。

根据液体在板料成形时的特征不同,充液拉深可以分为液体静态充液拉深和液体动态充液拉深。对于液体静态充液拉深,部分液体除了从调节液池压力的溢流阀溢出外,没有其它泄漏,板料和凹模之间采用密封装置进行密封。而对于液体动态充液拉深成形,部分液体将从板料和模具之间的缝隙流出,在板料和模具之间形成动态润滑效应[9]。一些研究表明[10-13],作用于毛坯法兰周边的径向压力可以显著提高板料的极限拉深比。在静态充液拉深中,为了获得加载于板料法兰周边的径向压力,除了辅以独立的液压加载系统并将高压液体引至法兰边缘外,还必须在板料和凹模及压料板之间设计一定的密封装置。此密封装置由于和板料之间的摩擦易于损坏而需经常更换。在液体动态充液拉深中,径向压力可以通过改变压料板和凹模边缘挡块之间的间隙来进行调整[14-15],但通过此方法获得的径向压力始终低于液池压力。

本文作者提出液体内向流动动态充液拉深技术,采用不同于以往充液拉深的压力加载路线,在板料和模具之间不使用专用密封装置的条件下,依靠板料法兰底面的压力使板料和压料板之间形成密封,通过径向主动加载使液体通过板料法兰和凹模之间的间隙从法兰周边流向液池,从而获得高于液池压力的径向压力辅助下的板料充液拉深。

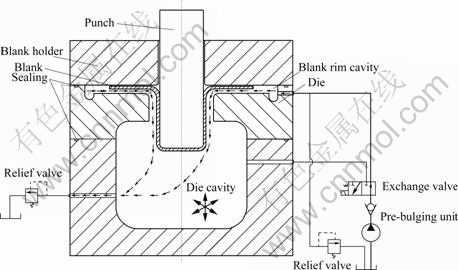

1 液体内向流动动态充液拉深技术原理

图1所示为液体内向流动动态充液拉深的原理图,凹模和压边圈之间采用固定间隙。模具闭合后,压边圈被固定,以保证间隙和压边力。辅以独立的液压加载系统,通过换向阀分别和液池及法兰外缘型腔相连,以实现预胀和径向压力地加载。液池压力和径向压力分别通过两个与各自型腔相连的溢流阀进行控制。高压泵首先向凹模液池内供油,液池内液体压力升高托起板料并使板料紧紧贴在压料板上,板料和压料板之间形成一定的密封,从而使液体不会从板料和压料板之间流出。同时使板料和凹模之间形成了一定的间隙。当压力达到预设的压力时,换向阀换向使高压泵向板料法兰周边型腔内供油,板料法兰周边的压力升高,液压油将通过板料和凹模之间的间隙,从法兰边缘流向液池内,这时液池内的压力也将慢慢上升,但由于板料和凹模之间的间隙非常小,沿程阻力大,液池内的压力将低于毛坯法兰周边的压力。当液池内的压力达到设定的预胀压力时,完成预胀过程,此时冲模开始下行,液池内的压力受到压缩,压力急剧升高,液池内的最高压力由溢流阀进行控制,直至完成整个拉深过程。在拉深过程中,适当的液池压力可使板料和凹模脱离接触并始终紧紧贴在压料板上,液体从板料法兰周边通过板料和凹模之间的间隙流向液池内,使板料和凹模之间获得动态润滑,同时实现了高于液池压力的径向压力。

2 初步实验验证与分析

为了对提出的新方法的可行性进行验证,根据其原理设计模具并进行初步实验研究。实验材料选用1.0 mm厚的铝合金2A12-O板材, 其力学性能见表1。实验在100 t单动液压机上进行,冲模速度为25 mm/s,模具尺寸见表2。试验中使用的成形介质是32号耐磨机械液压油。

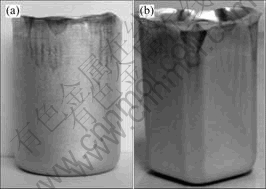

实验中凹模和压边圈之间采用固定间隙,其间隙为料厚的1.1倍。确定间隙后,压边圈被固定,以保证间隙和压边力。图2所示为实验中采用1 mm厚的2A12-O铝合金板料成功拉深出的杯形件和多边形零件。从图2可以看出,成形零件的表面光滑、质量好,除了零件上部由于材料增厚及起皱趋势有和模具接触摩擦的痕迹外,其余部分没有和凹模接触的痕迹。因此,如果合理地控制液池内压力,使其与模具行程之间形成一定的函数关系,在拉深过程中板料可以始终贴紧在压料板上,并且在拉深过程中使板料

图1 液体内向流动动态充液拉深原理图

Fig.1 Schematic diagram of hydrodynamic deep drawing with radially inward flowing liquid

表1 铝合金2A12-O的力学性能

Table 1 Mechanical property for 2A12-O aluminum alloy

表2 模具尺寸

Table 2 Dimensions of tool

图2 成形零件照片

Fig.2 Photos of formed parts: (a)Cup; (b)Polygonal part

不和凹模接触,从而在板料和凹模之间形成一定的间隙,液体可以通过这个间隙从毛坯法兰边缘流向液池内从而使拉深过程中获得动态润滑。初步实验研究表明,所提出的新工艺切实可行,工作过程平稳可靠,操作方便,易于控制;当液池压力和径向压力选择合理时,液体不会从板料和压料板之间溢出,在板料和压料板之间可以形成自然密封。

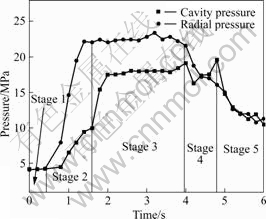

在液体内向流动动态充液拉深过程中,液池压力和法兰边缘的径向压力是两个重要的参数,它们与其它充液拉深过程中的变化趋势明显不同。图3所示为采用此方法拉深过程中的液池和径向压力变化图,其压力数据分别由两个连在液池和法兰边缘型腔的压力传感器采集得到。实验中采用的毛坯直径为115 mm。从图3可以看出,液体内向流动动态充液拉深过程可以分为5个阶段:阶段1是预压阶段,在此阶段中高压泵向液池内供油,板料被托起并贴紧在压料板上,使板料和压料板之间形成密封,同时在板料和凹模之

图3 拉深过程中液池压力和径向压力的变化

Fig.3 Variation of liquid pressures in die cavity and blank rim cavity

间形成一定的间隙;阶段2是预胀阶段,高压泵向板料法兰边缘供油,液体从法兰边缘流向液池,液池内压力升高至预胀压力;阶段3是压力控制阶段,此阶段冲模开始下行,液池压力和径向压力分别由两个溢流阀控制;阶段4是板料和压料板之间失去接触,密封失效,径向压力急速下降阶段;阶段5是板料被拉深进入凹模,液池压力下降阶段。

从图3可以看出,采用本研究提出的方法,在充液拉深过程中可以得到高于液池压力的径向压力,并且该径向压力在预胀阶段就可以获得,因而改变毛坯拉深初期凸模圆角处的应力应变分布。由于板料和凹模之间存在间隙,因此径向压力和液池压力之间的压力差将使液体从法兰边缘流向液池内。内向流动动态充液拉深与其它充液拉深方法相比,最显著的区别就是前者的液体流动方向与后者的液体流动方向相反。预胀阶段的径向压力可以改变拉深初期冲模圆角处板料的应力和应变分布,从而减少预胀阶段冲模圆角板料的变薄。

3 有限元分析

有限元是分析板料成形机理和各工艺参数影响的有效工具,可以减少实验工作量和降低实验成本。在初步实验验证该方法可行的基础上,采用有限元法对液体内向流动动态充液拉深技术进行研究,探讨各参数对成形过程的影响,确定合适的工作参数,优化成形过程。本文作者运用大型商业有限元软件MSC.marc对充液拉深过程进行模拟研究。

3.1 模型的建立

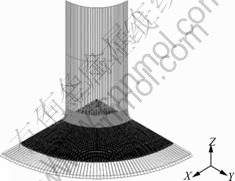

模拟板料选用的材料为铝合金2A12-O,其基本力学性能参数由单拉实验获得,见表1。为了减少计算的时间,根据成形过程的对称性,选取模型的1/4进行模拟。模具尺寸见表2,模拟中模具设为刚性体,板料毛坯采用实体壳单元(solid shell element)进行划分。实体壳单元可以正确有效地模拟双面接触,并且拉深过程中的径向压力可以直接加载到法兰边缘,而不需要先做等效处理后再加载到板料边缘节点上,因而更真实地模拟现场的边界条件而不需再简化。压边采用定间隙法,为初始料厚的1.1倍。凸模速度设定为25 mm/s。由于有限元软件MSC. Marc还不能根据变形情况实现液池压力的自动加载,因此液池压力通过子程序Forcem加载,在模型中通过定义区域来限定压力施加对象,进入区域的节点将被施加一定的压力;径向压力可以通过Marc提供的Table功能加载。所建立的有限元模型如图4所示。

3.2 模拟参数的确定

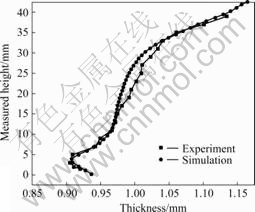

在模拟中采用与实验相同的模具尺寸、液池压力和径向压力,通过调整不同的模拟参数,将得到的模拟结果和实验结果相比较,选取合理的模拟参数。选用d115 mm的板料毛坯,并将实验得到的液池压力和径向压力(见图3)通过子程序加载到有限元模型中。在与实验条件相同的条件下,通过反复调整模拟参数,并且与实验结果相比较,对有限元中采用的参数进行优化,得到了合理可信的模拟结果。图5所示为有限元模拟零件壁厚和零件壁厚的比较。从图5可以看出,模拟结果和实验结果基本吻合,说明采用Marc实体壳单元建立的模型,并且选用一定的参数可以正确模拟板料的成形过程。对比模拟结果和实验结果可

图4 有限元模型示意图

Fig.4 Schematic diagram of mold of FEM

知,Marc设置采用如下的模拟参数可以得到合理可信的模拟结果:摩擦采用剪切摩擦模型,板料的摩擦因数为0.01,冲模摩擦因数为0.2,凹模摩擦因数为0.01,压料板的摩擦因数为0.01;板料液压成形是一个高度非线性问题,为了精确模拟成形过程,实体壳单元设置为11层,模拟中材料划分的单元总数为4 000。

图5 有限元模拟零件壁厚和实验零件壁厚的比较

Fig.5 Comparison of thickness distributions of FEM simulated and experimental samples

3.3 液池压力加载曲线的优化选择

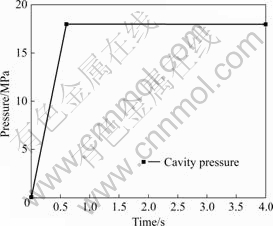

在实验中,设定不同的工艺参数可以满足不同的拉深比对压力的要求。液池压力不足将使板料在拉深过程中不能和凹模圆角完全脱离,导致在拉深初期凸模圆角板料因拉深力过大而破裂,并且板料也不能紧紧地贴在压料板上,板料和压料板之间不能形成有效地密封;液池压力过高,虽然使板料在拉深过程中脱离凹模圆角,但也使板料弯曲和反弯半径急剧减小,反而使拉深应力急剧增大,亦可能使板料拉深时破裂。只有当板料适当脱离与凹模接触并建立起流体润滑时液池压力才是合适的工艺参数。根据平底筒形件成形的特点,经过反复模拟结合少量实验,得到合适的液池压力的加载曲线,如图6所示。由图6可见,采用1 mm厚的铝合金2A12-O板料时,在18 MPa的液池压力下,可以使拉深过程中板料和凹模圆角完全脱离,并且在凹模圆角处形成的弯曲和反弯半径较大,在此液池压力下可以获得较高的拉深比和壁厚较均匀、成形质量较高的零件。

图6 液池压力加载路径

Fig.6 Loading path of cavity pressure

3.4 径向压力对成形的影响

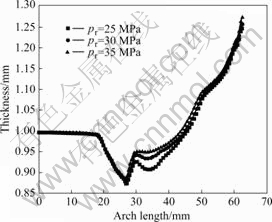

在液体内向流动动态充液拉深中,径向压力是影响产品成形性能和质量的一个重要参数。为研究径向压力的变化对成形过程的影响,在图6所示的液池压力加载路径下,设定3条径向力加载路径进行模拟分析,其最大压力分别为25、30和35 MPa。毛坯直径为130 mm。图7所示为模拟得到的零件壁厚分布图。从图7可以看出,成形零件壁厚最薄点在零件侧壁靠近凸模圆角处;径向压力的变化影响成形零件壁厚的分布,径向压力较大时得到的零件壁厚也较大。

3.5 预胀阶段径向压力对零件壁厚的影响

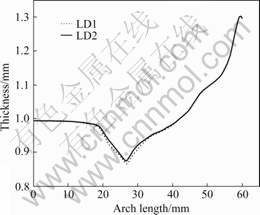

在预胀阶段就可获得高于液池压力的径向压力是本研究所提方法的显著特点之一。在有限元分析中,通过选用不同的径向压力加载路径,研究预胀阶段高于液池压力的径向压力对零件壁厚的影响。图8所示为采用不同的径向压力加载路径(LD1,LD2)时,模拟得到的零件壁厚分布,其他参数如下:径向压力为28 MPa,液池压力为18 MPa,毛坯直径为120 mm,材料厚度为1 mm。径向压力加载路径LD1和LD2的区别是:采用加载路径LD1时,预胀阶段毛坯法兰边缘没有径向力,直到拉深过程开始冲模下行时径向力才加载;LD2是在预胀阶段板料就获得了高于液池压力

图7 径向压力对壁厚分布的影响

Fig.7 Effects of different radial pressures on thickness distributions

图8 径向压力加载路径不同时的壁厚分布

Fig.8 Thickness distributions for radial pressures with different loading paths

的径向压力。由图8可以看出,预胀阶段高于液池压力的径向压力有助于减缓冲模圆角处材料的变薄,使形成的圆角有较大的厚度,降低凹模圆角处的拉应力;预胀阶段高于液池压力的径向压力对成形的杯形件直壁部分的壁厚分布没有影响。

4 结果分析

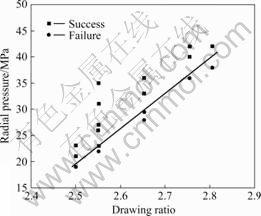

根据模拟中得到的合适的液池压力加载路径,采用不同的径向压力,通过实验确定了一定拉深比时所需最小径向压力,结果如图9所示。从图9可以看出,要成功得到一定拉深比的零件,径向压力必须大于一定的数值;成形零件的拉深比越大,所需要的最小径向压力越大。采用42 MPa的径向压力时,可得到拉深比达2.85的杯形零件。

图9 适用于2A12-O铝合金的径向压力成形区域图

Fig.9 Defined radial pressure zone for 2A12-O aluminum alloy

5 结论

1) 实验及模拟研究结果表明,液体反向流动动态充液拉深技术可行。采用不同于以往充液拉深方法的压力加载路线,在不需要专用的密封装置的情况下,可以获得高于液池压力的径向压力。采用这种方法可以显著提高拉深比,并且使用2A12-O铝合金得到了拉深比2.85的杯形件。

2) 预胀阶段高于液池压力的径向压力可以改变板料拉深初期凸模圆角处的应力应变分布,减少凸模圆角处板料的变薄。

3) 径向压力影响零件壁厚的分布,一般情况下,采用较大的径向压力可得到较大的壁厚。

REFERENCES

[1] 于忠奇, 赵亦希, 林忠钦. 汽车用铝合金板拉深性能评估参数[J]. 中国有色金属学报, 2004, 14(10): 1689-1693.

YU Zhong-qi, ZHAO Yi-xi, LIN Zhong-qin. Evaluation parameter of drawability of automotive aluminum alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(10): 1689-1693.

[2] ZHANG S H, WANG Z R, XU Y, WANG Z T, ZHOU L X. Recent developments in sheet hydroforming technology[J]. Journal of Materials Processing Technology, 2004, 151(1): 237-241.

[3] KANG D C, CHEN Y, XU Y C. Hydromechanical deep drawing of superalloy cups[J]. Journal of Materials Processing Technology, 2005, 166(2): 243-246.

[4] 林忠钦, 于忠奇, 孙成智, 陈关龙. 变压边力条件下铝合金板的成形窗口[J]. 中国有色金属学报, 2005, 15(8): 1162-1166.

LIN Zhong-qin, YU Zhong-qi, SUN Cheng-zhi, CHEN Guan-long. Formability window of aluminium alloy sheet at variable blank-holder force [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1162-1166

[5] CHOI H. A study on warm hydroforming of lightweight sheet materials: process optimization[D]. Michigan: The University of Michigan, 2006.

[6] NAKAMURA K, NAKAGAWA T, AMINO H. Various application of hydraulic counter pressure deep drawing[J]. Journal of Materials Processing Technology, 1997, 71(1): 160-167.

[7] 唐井林, 聂绍珉. 充液成形装置及锥形件充液拉深成形研究[J]. 塑性工程学报, 2001, 8(3): 32-34.

TANG Jing-lin, NIE Shao-min. A equipment for hydroforming and research on hydroforming technology on conical parts[J]. Journal of Plasticity Engineering, 2001, 8(3): 32-34.

[8] LANG L H, DANCKERT J, NIELSEN K B, ZHOU X B. Investigation into the forming of a complex cup locally constrained by a round die based on an innovative hydromechanical deep drawing method[J]. Journal of Material Processing Technology, 2005, 167(2): 191-200.

[9] 朗利辉, DANCKERT J, NIELSEN K B. 板液压成形及无模充液拉深技术[J]. 塑性工程学报, 2002, 9(4): 29-34.

LANG Li-hui, DANCKERT J, NIELSEN K B. About sheet hydroforming and hydromechanical deep drawing without draw die[J]. Journal of Plasticity Engineering, 2002, 9(4): 29-34.

[10] TIROSH J, SHIRIZLY A, BEN-DAVID D, STANGER S. Hydro-rion deep-drawing processes of hardening and rate-sensitive materials[J]. International Journal of Mechanical Sciences, 2000, 42(6): 1049-1067.

[11] 刘晓晶, 闫 巍, 郭立伟. 铝镁合金双路径加载充液拉深成形的数值模拟[J]. 中国有色金属学报, 2008, 18 (4): 698-702.

LIU Xiao-jing, YAN Wei, GUO Li-wei. Numerical simulation of aluminum-magnesium alloy cup’s forming by hydrodynamic deep drawing with double loading paths[J]. The Chinese Journal of Nonferrous Metals, 2008, 18 (4): 698-702.

[12] DANCKERT J, NIELSEN K B. Hydromechanical deep drawing with uniform pressure on the flange[J]. CIRP Annals- Manufacturing Technology, 2000, 49(1): 217-220.

[13] LANG L H, DANCKERT J, NIELSEN K B. Study on hydromechanical deep drawing with uniform pressure onto the blank[J]. International Journal of Machine Tools & Manufacture, 2004, 44(5): 495-502.

[14] LANG L H, DANCKERT J, NIELSEN K B. Investigation into hydrodynamic deep drawing assisted by radial pressure: Part Ⅰ. Experimental observations of the forming process of aluminum alloy[J]. Journal of Materials Processing Technology, 2004, 148(1): 119-131.

[15] LANG L H, DANCKERT J, NIELSEN K B. Investigation into hydrodynamic deep drawing assisted by radial pressure: Part Ⅱ. Numerical analysis of the drawing mechanism and the process parameters[J]. Journal of Materials Processing Technology, 2005, 166(1): 150-161.

(编辑 何学锋)

收稿日期:2009-04-21;修订日期:2010-01-05

通信作者:高 霖,教授,博士;电话:025-24896469;E-mail: meelgao@nuaa.edu.cn