DOI: 10.11817/j.issn.1672-7207.2021.03.021

深部矿井高温巷道热交换降温技术探讨

吴星辉1, 2,蔡美峰1, 2,任奋华1, 2,郭奇峰1, 2,王培涛1, 2,张杰1, 2

(1. 北京科技大学 土木与资源工程学院,北京,100083;

2. 金属矿山高效开采与安全教育部重点实验室(北京科技大学),北京,100083)

摘要:金属矿山进入深部开采后会面临一系列的关键难题,其中最突出的就是高温环境。然而被动式降温技术成本较高,为了维持深部矿井高温巷道正常生产,必须为采矿深井降温找到一条经济有效的技术途径。基于循环水热交换技术提出将深部采矿降温和岩体地热开采相结合的理论,利用数值模拟方法研究增强型和传统型降温系统的单孔换热过程和换热孔群效应。研究结果表明:增强型降温系统的热通量比传统型降温系统热通量提高26.80%,同时在热交换作用下,高温巷道的温度降低4%,循环水系统的出水口温度相对于初始进水口温度增加35.32%;换热孔群的热通量受周围换热孔的热干扰影响,在换热孔群运行24 h后,换热孔之间热干扰效应随时间推移而增大,圆形换热孔群中心孔受热干扰最小,而正方形换热孔群的中心孔受热干扰最大,边界孔次之,转角孔受热干扰最小。当换热孔群孔间距小于等于2.0 m时,正方形换热孔群热通量相对损失量小于圆形换热孔群热通量相对损失量;孔间距大于2.0 m时,换热孔群热通量相对损失量几乎不受孔群形状的影响。采用热交换技术,开发利用深部矿井高温巷道围岩中的地热资源,可以大幅度抵消被动式的降温成本。换热孔群形状和孔间距的合理布置同样可以提高降温效率,降低热通量的相对损失量。

关键词:深部开采;热交换;循环水;热通量;巷道降温

中图分类号:TD853 文献标志码:A 开放科学(资源服务)标识码(OSID):

文章编号:1672-7207(2021)03-0890-11

Heat exchange cooling technology of high temperature roadway in deep mine

WU Xinghui1, 2, CAI Meifeng1, 2, REN Fenhua1, 2, GUO Qifeng1, 2, WANG Peitao1, 2, ZHANG Jie1, 2

(1. School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Key Laboratory of High-Efficient Mine and Safety of Metal Mines(University of Science and Technology Beijing), Beijing 100083, China)

Abstract: In the process of deep mining of metal mines, a series of key problems were encountered, the most prominent of which was the high temperature environment. However, the cost of passive cooling technology was high. In order to maintain the normal production of high temperature roadway in deep mine, it was necessary to find an economic and effective technical method for the cooling of deep mine. Based on the exchange technology of circulating water and heat, the theory of combining deep mining cooling with rock mass geothermal exploitation was put forward, and the numerical simulation method was used to simulate the single hole heat exchange process and heat exchange hole group effect of enhanced and traditional cooling systems. The results show that the heat flux of the enhanced cooling system is 26.80% higher than that of the traditional cooling system, the temperature of the high temperature tunnel reduces by 4% under the effect of heat exchange, and the outlet temperature of the circulating water system increases by 35.32% compared with the initial inlet temperature. The heat flux of the heat exchange holes is affected by the heat interference of the surrounding heat exchange holes. After 24 h of operation, the heat interference effect between heat exchange holes increases with time, and the center hole of circular heat exchange holes has the least heat interference. The center hole of square heat exchange hole group has the largest thermal interference, the boundary hole takes the second place, and the corner hole has the smallest thermal interference. When the distance between the holes is less than or equal to 2.0 m, the heat flux loss rate of square holes is less than that of circular holes. When the hole spacing is larger than 2.0 m, the heat flux loss rate of the heat exchange holes is almost not affected by the shape of the holes. Using heat exchange technology to develop and utilize the geothermal resources in the surrounding rock of high temperature roadway in deep mine can greatly offset the passive cooling cost. By arranging the shape and spacing of heat exchange holes reasonably, the cooling efficiency can also be improved, and the heat flux loss rate will also decrease at the same time.

Key words: deep mining; heat exchange; circulating water; heat flux; roadway cooling

当今世界,能源开发和环境保护日益成为制约人类发展的重要因素。绿色、清洁和环保的能源已成为许多国家优先研究的课题[1]。但随着地下采矿、隧道建设和核废料处置等深部地下空间工程的实施,高地温作用下的地下工程问题开始涌现出来,例如桑珠岭隧道,最高岩体温度可达89.5 ℃[2-3]。高地温不仅影响作业人员身体机能,同样对采矿岩体的物理力学特征造成一定程度的损伤[2, 4-5]。赵阳升等[6]通过声发射试验发现花岗岩在达到65 ℃时会发生热破裂,随着温度升高热破裂呈阶段性变化;左建平等[7]通过高温岩石疲劳试验发现花岗岩热开裂临界温度为68~88 ℃;姚梦迪[8]对高温处理后的3类岩石开展力学试验,发现随着温度升高,大理岩和花岗岩的峰值强度和弹性模量逐渐下降,而砂岩先升高后降低;YANG等[9]对高温处理后的预制单裂隙花岗岩试样进行物理力学特性试验,发现随着处理温度升高,峰值强度和弹性模量先增大后减小,峰值应变先减小后增大。

目前,国内外对采矿领域热害的治理研究已经相当成熟[10-12],HE[13]提出HEMS技术,将矿井突水涌入工作面,对工作面进行降温;凡雨杰[14]提出将换热器贴附壁面进行降温;FENG等[15]提出利用全风冷系统解决矿井热害问题。高地温环境主要是由高温岩层热辐射造成。现有降温技术是一种被动式降温技术,把地热当成一种灾害防治;而实际上,地下空间的大幅度降温反而会影响空间岩体的稳定性。

许多学者开始关注采矿建设过程中高温岩石降温引起的岩石力学特性问题,提出了不同温降路径下的岩石力学参数变化规律。唐世斌等[16]通过理论分析和数值模拟方法发现岩石受到降温冲击作用后,换热边界会产生拉应力,导致岩石更易于开裂;朱振南等[17]对遇冷水作用后的高温花岗岩进行物理力学特性试验和SEM电镜观察,发现花岗岩单轴抗压强度和弹性模量随温度升高而减小,岩石在温度超过300 ℃时出现明显的塑性,同时出现宏观微裂纹萌发、扩展和贯通;靳佩桦等[18]对20~600 ℃急冷却作用后的花岗岩进行物理力学特性和岩石渗透性试验,认为随着温度升高,岩石抗压强度、弹性模量和抗拉强度均下降,渗透率先增大后减小;WU等[19]通过数值模拟的方法研究冷却水流速对高温岩石热冲击速度的影响,发现流速越大,热冲击速度越大,二者之间存在线性关系。

岩体内部产生的温度应力容易造成采矿工程岩体变形和破裂,为了防止这种情况发生,研究如何提高采矿降温效率而不会使岩石产生较大温度应力对工程建设有指导意义。本文作者认为地热是一种天然能源,如果在深部采矿建设过程中,采用热交换技术将深部采矿建设和地热开发相结合,就能大幅度增强传统式的降温效率。已有大量学者针对地热资源的开采研究热交换技术。PAHUD等[20]提出在混凝土桩中埋置管式换热器,并在慕尼黑机场大厦进行了500多个桩的应用;LI等[21]将U型埋管应用于换热孔和桩身,发现双U型换热管的传热比单U型管的换热效果好;GAO等[22-23]讨论分析换热孔的几何结构,发现W形管比单U形管、双U形管和三U形管热交换效率更高;ZARRELLA等[24]通过数值模拟和现场试验,分析了三U型和螺旋埋管换热性能,发现螺旋管的换热率比三U型管的换热率高23%;KONG等[25]提出在混凝土中加入具有高传热特性的石墨粉,制备增强型传热混凝土,通过试验和数值模拟发现加入石墨粉的能量桩换热能力更高。

目前,优化通风线路和构筑冰墙等提高采矿降温效率的传统方法比较完善,难以得到很大的改进。传统通风和冰墙降温可能会导致岩石内部产生热应力,因此,对采矿岩体进行热交换是提高采矿降温效率和减少岩体温度应力的主要途径。为保证力学性能稳定,在采矿中钻取换热孔,孔内通过混凝土将具有较高导热系数的螺旋换热管[24]与岩体黏结。本文作者研究通过向螺旋换热管注入常温循环水,在混凝土中加入具有高传热特性的石墨粉,循环水以混凝土为媒介与岩体进行热交换。为了对比换热、通风组合降温和单通风降温效果,利用COMSOL多物理场数值软件建立深部高温巷道降温模型,对比分析二者的热通量、降温速率和出水口温度。

1 循环水热交换降温机理

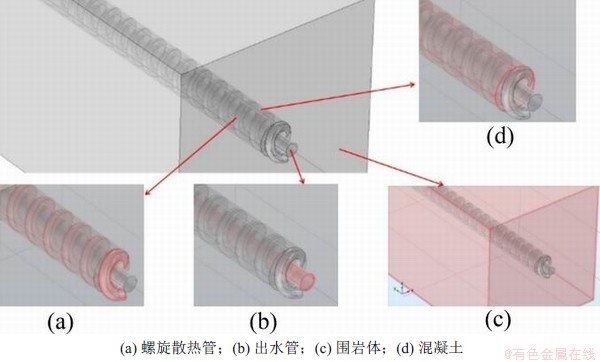

图1所示为热交换技术降温机理示意图。采矿循环水换热系统由常温循环水、螺旋换热管、出水管、混凝土和岩体组成。常温循环水由螺旋换热管(图1(a))注入,由出水管(图1(b))流出,在此过程中常温循环水通过混凝土(图1(d))不断与周围岩体(图1(c))进行换热,吸收周围岩体的热量,导致出水口温度有所提高,周围岩体温度则会相应下降。在循环水系统的换热过程中,首先要考虑如何让周围岩体的热量更大程度与循环水进行热交换,而影响循环水与周围岩体换热的介质是管道和混凝土。

图1 热交换技术降温机理示意图

Fig. 1 Schematic diagram of cooling mechanism of heat exchange technology

为此,有学者认为石墨比一些金属材料如铁和铅等具有更好的传热能力和导热性,石墨在常温下具有良好的化学稳定性,对酸、碱和有机溶剂具有良好的抵抗能力。因此,选择具有高传热特性的石墨粉加入混凝土中,提高混凝土的导热性能。

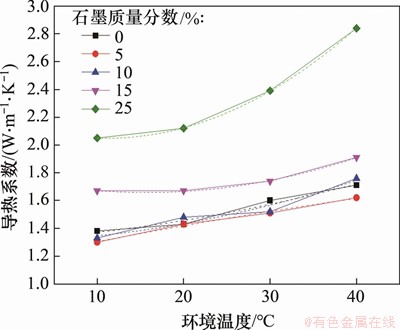

对不同环境温度(10,20,30和40 ℃)下的不同石墨质量分数的混凝土样品进行热导率测量。根据石墨混凝土导热系数的测试结果[25],拟合出不同石墨质量分数下混凝土材料的导热系数(k),如图2所示。由图2可见:随着温度增大,不同石墨质量分数的混凝土导热系数均增大。石墨质量分数为0~15%时,混凝土的导热系数随温度增加不明显;当石墨质量分数达到25%时,混凝土的导热系数随温度升高而迅速提高,增长速度几乎是相同温度下混凝土的2倍,说明在高温环境下加入石墨对混凝土的传热有重要的促进作用,而且温度越高,促进效果越明显。不同石墨质量分数在高温作用下的导热系数拟合公式可以表示为:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

式中:k导热系数,W·m-1·K-1;T为温度,℃。

图2 不同温度作用下的混凝土导热系数

Fig. 2 Thermal conductivity of concrete under different temperatures

在前人研究基础上,采用质量分数为25%的石墨混凝土代替普通混凝土。在模拟高地温环境下利用循环水换热降温时,采用式(5)计算混凝土导热系数,由图2可知,其导热系数比普通混凝土的高。

2 深部矿井高温巷道降温系统

2.1 增强型降温模型

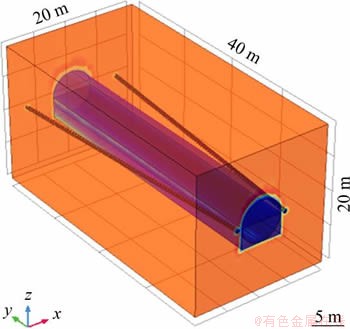

增强型降温模型由岩体、半圆拱形高温巷道和换热孔(螺旋换热管、出水管和混凝土)组成。半圆拱形高温巷道直径为6 m,深为40 m。考虑到模拟循环水换热系统长期运行的需要和消除边界条件的影响,岩体的尺寸应足够大,设长为20 m,高为20 m,深为40 m。在循环水换热系统中换热管道呈螺旋形,外半径为0.2 m,管道半径为0.1 m,轴向节距为0.5 m。常温循环水从螺旋换热管入口进入后,首先沿螺旋管到达底部,然后通过直管流回出水口。在传统通风降温系统中,在半圆拱形高温巷道入口模拟通风机进行通风,为了达到最大的降温效果,本文取风速为3 m/s,整体降温模型如图3所示。在模型中采用质量分数为25%石墨增强混凝土导热系数,巷道岩体为花岗岩,其余模型参数如表1所示。

图3 增强型降温系统模型示意图

Fig. 3 Schematic diagram of enhanced cooling system model

表1 增强型降温模型的热物理参数

Table 1 Thermal physical parameters of enhanced cooling system model

为了对比分析增强型降温系统与传统通风降温系统在高地温环境短时间内的运行情况,将系统的运行时间设为5.0 h。循环水为20 ℃的常温水,循环流速为1 m/s,围岩初始温度为60 ℃,在考虑稳定边界的情况下,整个模拟过程中保持围岩外边界温度为60 ℃。

2.2 不同降温系统的热通量对比

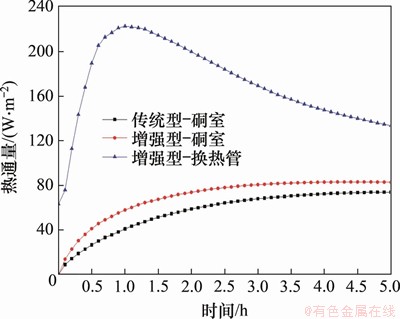

传统型降温系统的热通量曲线如图4所示。由图4可见:高温巷道表面的热通量从0 h的0 W/m2迅速上升,1.5 h后升到51.42 W/m2,此后的热通量增速明显减小,到第5.0 h后热通量基本稳定在73.91 W/m2,说明高温巷道初始温度和围岩温度相同时不发生热交换,所以0 h时热通量为零。通风工作开始后,低温空气进入高温巷道,巷道围岩与空气在温差作用下进行快速热交换,导致这一阶段的热通量迅速上升;随着围岩温度升高,二者温差减小,热通量增长变缓;当整个系统形成一个相对稳定的温度梯度时,巷道表面的热通量也随之趋于稳定,而此时巷道内温度达到最低。

图4 传统型和增强型降温系统的热通量变化图

Fig. 4 Heat flux change diagram of traditional and enhanced cooling system

由图4可知:增强型与传统型降温系统的高温巷道表面热通量变化曲线相似,但前者的热通量整体都有明显提高,最大差值为17.17 W/m2。随着时间延长,增强型降温系统高温巷道表面热通量稳定在82.76 W/m2,比传统型降温系统高8.85 W/m2。因此,在岩体内增加循环水换热系统不会影响高温巷道表面的热交换,反而会促进热交换,提高其热通量。

增强型降温系统的螺旋换热管热通量要远大于高温巷道表面热通量。首先螺旋管内循环水通过螺旋管与围岩进行热交换,螺旋管增大了环水与岩体的接触面积,同时质量分数为25%石墨的混凝土导热系数比巷道围岩的导热系数大得多。在初始阶段,循环水通过螺旋管以混凝土为介质迅速与岩体进行热交换,此时岩体的温度会逐渐降低,而混凝土温度会越来越大,导致混凝土的导热系数变大,所以在这一阶段的热通量增长较快;当混凝土与岩体之间的温差变小,混凝土的温度不再升高,反而会出现小幅度下降,该阶段的热通量因温差以及混凝土导热系数的下降而减小;随着整个循环水换热系统温度梯度的稳定,螺旋管的热通量也趋于稳定,在5.0 h后热通量为133.57 W/m2。

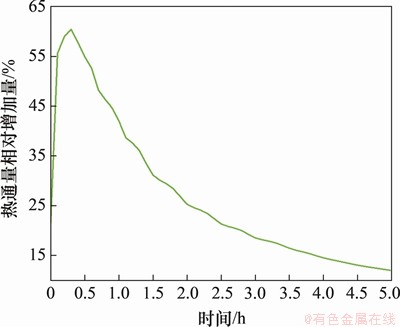

图5所示为增强型降温系统相对于传统型高温巷道表面的热通量增长量。由图5可见:相对增加量的总体趋势随时间延长而减小,从60.37%降到11.97%。增强型降温系统相对于传统型降温系统高温巷道(连续运行5.0 h)的平均热通量相对增加量约为26.80%,说明增强型降温系统对高温巷道的热交换特性有较大的积极影响。

图5 增强型降温系统相对于传统型高温巷道表面热通量增加量

Fig. 5 Increase of heat flux on roadway surface of enhanced cooling system compared with traditional cooling system

2.3 岩体温度分析

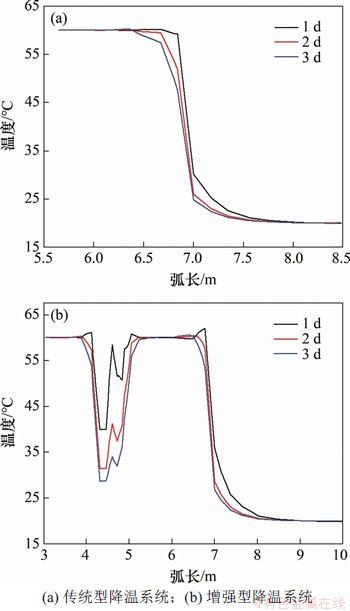

图6所示为高温巷道不同位置温度随时间的演化曲线。由图6(a)可见:由于模型为轴对称模型,且边界温度始终保持60 ℃,则由第5.0 h左半部弧长为5.5~8.5 m的温度曲线可知,高温巷道中心温度最低(19.99 ℃)。岩体温度首先随弧长增大而迅速下降,当弧长为7.2 m时,温度为22.41 ℃,下降速度开始明显减慢。当弧长为8.0 m左右时,温度变化很小,仅下降了2.50 ℃左右。随着时间延长,降温对岩体的影响范围增大,传统型降温系统运行1,3和5 d对围岩的影响深度分别为0.3,0.4和0.7 m。

图6 高温巷道不同位置温度随时间的演化曲线

Fig. 6 Temperature evolution curve with time at different distances of high temperature roadway

由图6(b)可见:在弧长为5.5~8.5 m,温度变化曲线与传统降温系统基本相同,但在弧长3.5~5.5 m时岩体温度出现凹点,主要是循环水换热系统与其周边岩体进行换热所致,同时这种现象导致模型整体温度有所降低。弧长4.2 m位置和巷道中心位置出现的低温峰值分别为28.69 ℃和20.00 ℃,比传统降温系统的岩体温度分别低32.31 ℃和0.91 ℃。这表明,循环水换热系统允许更多热量通过混凝土进入循环水,导致巷道围岩区域的整体温度下降。随着温度下降,岩体与巷道表面的温度差也会减小,从而降低高温巷道壁产生温度应力的可能性。

2.4 高温巷道与循环水系统温度变化规律

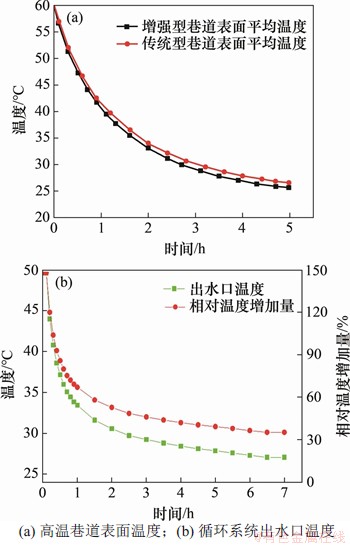

传统型降温系统的高温巷道表面温度如图7(a)所示,表面温度在0~1.5 h迅速下降,主要是因为在此阶段内的热通量迅速增加,巷道与岩体的热量交换增多。1.5 h后温度由37.22 ℃缓慢下降,到第5.0 h后温度基本稳定在26.60 ℃。这说明在1.5 h后,由于热通量的缓慢变化导致巷道表面降温速度减小,最终在5.0 h后温度基本不再发生变化,这与热通量变化趋势相对应。故热通量可以表征高温巷道热量交换程度,热通量越大,温度变化越大。同样,由图4可知,增强型降温系统与传统型降温系统的高温巷道表面温度曲线变化趋势相似,而前者表面温度要大于后者表面温度。随着时间延长,增强型降温系统巷道表面温度稳定在25.61 ℃,比传统型降温系统低1.00 ℃,这说明了利用循环水热交换技术对高温巷道降温是有效的,而且通过热交换技术可以在出水口得到如图7(b)所示温度变化的温水。

由图7(b)可知:增强型降温系统连续运行7 h后,出水口温度仍保持在27.06 ℃,相对于循环水入口温度增加了35.32%。在高温巷道表面温度与时间变化关系中,系统运行1 h内出水口温度和温度相对增加率急剧减小,主要原因是换热管的热通量在此阶段先急剧增加后缓慢减小,最后稳定不变。在系统运行1 h以后,出水口温度由33.0 ℃降至27.06 ℃,同时温度相对增加率由66.52%降至35.32%,7 h后基本不再发生变化。模拟结果表明,增强型降温系统可以通过循环水与岩体进行热交换,抽采出的温水可以二次利用,验证了增强型降温系统循环水热交换技术在岩体地热开采中的应用。

图7 高温巷道表面温度和循环水出水口温度随时间增加的变化曲线

Fig. 7 Variation curve of surface temperature of high temperature roadway and routlet temperature of circulating water with time

3 换热孔倾斜角度分析

在换热孔与周围岩体进行热交换过程中,换热孔与高温巷道走向的夹角(α)可能影响换热孔的热交换能力。为此,在模型中改变夹角α,对比换热孔热通量和高温巷道温度变化情况,分析夹角α对热交换的影响。

假定岩体边界足够大,为消除边界效应将岩体边长设为50 m。夹角α分别设置为5°,10°,15°,20°和25°,换热孔与水平面的夹角0°保持不变,其他物理参数设置与上述研究一致。

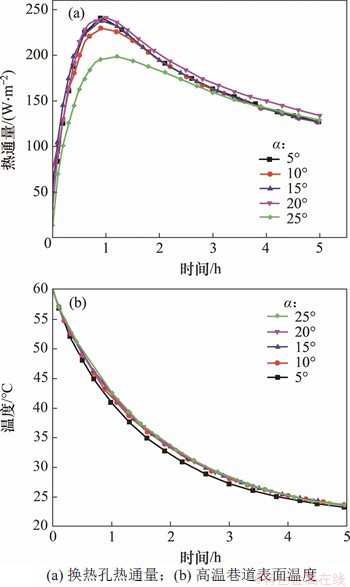

图8所示为不同夹角α作用下的换热孔热通量和高温巷道温度随时间变化的曲线,不同夹角α在相同时间产生的热通量不同。在0.9 h前,夹角为15°时热通量最大;在0.9~5.0 h之间,夹角为20°时热通量最大。这说明热通量与夹角不是简单的单调关系,而是在2个时间阶段内均存在最优夹角。在5.0 h时间内,15°换热孔的热通量比25°换热孔的热通量大14.25%;20°换热孔热通量比25°换热孔的热通量大14.69%,在5.0 h之后热通量基本保持不变。若仅考虑换热孔热通量,换热孔与高温巷道走向夹角α应选20°。

由图8(b)可见:即使在不同夹角α条件下,巷道表面温度的降温速度也没有明显提高,温度随时间的变化曲线基本相同。通过计算5.0 h后的高温巷道表面平均温度,发现在夹角α为5°时,温度要比其他角度时的巷道温度低,而且同一时间内角度越大,表面温度越高。夹角α为5°时的巷道温度比夹角为25°的温度低3.02%,这说明夹角α对高温巷道表面温度的影响不大。因此,换热孔群模拟的讨论中不考虑夹角α。

图8 夹角 对换热孔热通量和高温巷道表面温度的影响

对换热孔热通量和高温巷道表面温度的影响

Fig. 8 Effect of angle α on heat flux of heat exchange holes and surface temperature of high temperature roadway

4 换热孔群效应

4.1 换热孔群模型建立

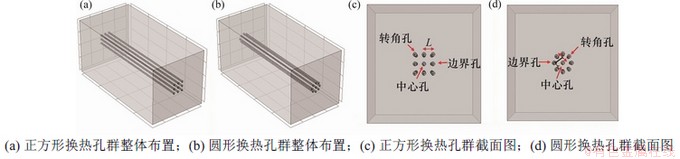

在换热孔群效应分析中,主要考虑孔群布置形状和孔间距对换热孔热交换的影响。为了简化计算,该模型仅由换热孔群和岩体组成。为准确模拟换热孔群的换热效率,模型采用圆形和正方形换热孔群布置进行对比分析。同时将孔间距(L)分别设为1.6,2.0和2.4 m,分析孔间距对换热孔群降温的影响。为了不受边界效应影响,围岩设为长为20 m,深为40 m,高为20 m。在换热孔群中,换热孔之间的热干扰影响具有时间效应,所以模型计算时间设为24 h,换热孔直径、材料参数、初始条件和边界条件的设置与单孔模型相同。通过模拟结果,分析正方形和圆形换热孔群的热通量变化规律,模型如图9所示。

图9 不同换热孔群的换热孔布置模型

Fig. 9 Layout model of heat exchange holes with different heat exchange holes groups

4.2 换热孔群热干扰分析

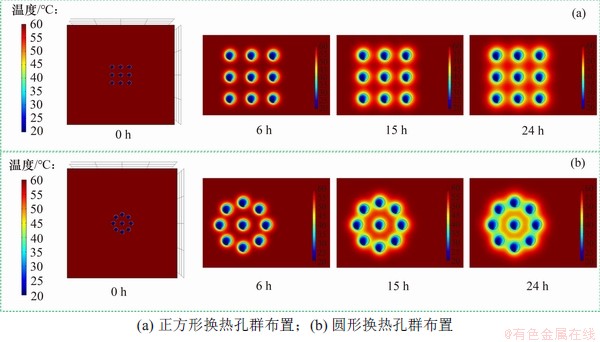

图10所示为不同时间作用下2种换热孔群温度场分布。由图10可见:无论是正方形孔群布置还是圆形孔群布置,对岩体的影响都有一个共同规律,即分析整个换热模型的等温域,换热孔的影响范围随时间而变大。岩体在初始阶段低温区域面积较小,且换热孔之间没有明显扰动。但随着时间推移,受到温度影响的岩体范围越来越大,且低温区域开始相交或重叠,到24 h换热孔之间的区域已完全变为低温区域,这说明换热孔的相互热干扰随时间延长而逐渐增大。

图10 2种换热孔群在不同时间的温度场分布

Fig. 10 Temperature field distribution of two kinds of heat exchange holes groups for different time

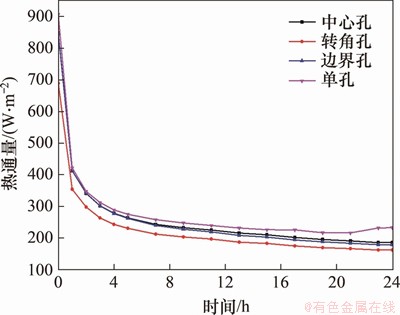

4.3 换热孔群热通量分析

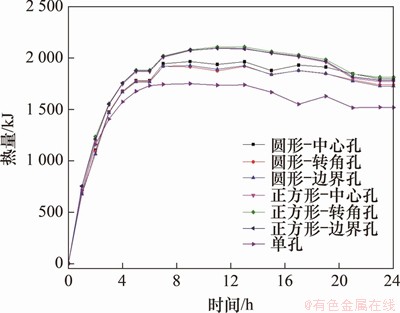

随着热干扰的不断增加,换热孔群中任一个换热孔热通量都要低于单独运行的换热孔,这意味着孔群换热方式导致换热孔换热能力降低。图11所示为圆形换热孔群热通量(1.6 m孔间距)。由图11可见:换热孔群3种位置的换热孔热通量与单孔热通量曲线变化趋势基本一致,在1 h以内热通量迅速降低,1~7 h之间缓慢降低,在7 h之后热通量趋于稳定。换热孔群不同位置的换热孔热通量较单孔明显降低,且随着时间推移,二者之间的差值逐渐增大。

图11 圆形换热孔群热通量(1.6 m孔间距)

Fig. 11 Heat flux of circular heat exchange holes (1.6 m hole spacing)

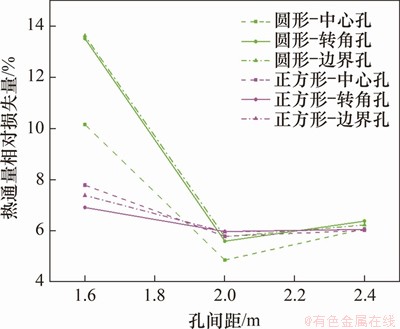

进一步分析数据,计算不同形状、孔间距和位置的换热孔平均热通量,并与单孔平均热通量进行比较,计算热通量相对损失量并绘制如图12的曲线,可得:

1) 圆形换热孔群中,中心孔受热干扰最小,热通量损失也最小;而正方形孔群的中心孔受热干扰最大,边界孔次之,转角孔受热干扰最小。

2) 随着换热孔间距增大,中心孔、边界孔和转角孔的热通量相对损失量先减小后增大,在间距为2.0 m(5倍换热孔直径)时最小。不管是圆形还是正方形布置换热孔群,在1.6,2.0和2.4 m的间距中存在一个最优值可以保证换热孔群的热通量相对损失量最小。当孔间距为2.0 m时,换热孔群的热通量损失量集中在4%~6%。由于受换热孔影响的岩体范围有限,对于孔间距大于2.4 m(6倍换热孔直径)的换热孔,不作为换热孔群热干扰效应讨论。

3) 在相同孔距情况下,圆形换热孔群的热通量损失量比正方形换热孔群的略高。

图12 不同换热孔群的换热孔热通量变化

Fig. 12 Heat flux changes of exchange pore in different heat exchange holes groups

由图12可知:正方形换热孔群与圆形换热孔群相比,转角孔和边界孔的热通量相对增加量要比中心孔的热通量相对增加量有所提高。而正方形换热孔群的热通量相对增加量主要受孔间距的影响,随着孔间距增大,热通量相对增加量先增大后减小,在孔间距为2.0 m时相对增加量为负值,达到-0.85%。在2.4 m孔间距时,各位置换热孔的热通量增量率稳定在0.2%左右。因此,在实际工程中,孔间距为2.0 m以下的换热孔群采用正方形布置可以减小热通量的相对损失量;而孔间距大于2.0 m时,热通量相对损失量几乎不受换热孔群形状的影响。

换热孔群布置虽然较单孔布置增加了换热相对损失量,但其通过循环水吸收的岩体总热量比单孔换热要高得多。根据热力学第二定律,热量由高温物体自发传向低温物体,假设在本文讨论的换热过程中循环水吸收的热量为Q,而Q的表达式为:

(6)

(6)

(7)

(7)

(8)

(8)

式中:c为循环水的比热,取值参照表1;m为循环水的质量,kg; 为和循环水进出换热管的温差,℃;ρ为循环水密度,取值参照表1;v为循环水流速,取1 m/s;S为换热管横截面积,取0.031 4 m2;Tt为某一时刻出水口温度,℃。

为和循环水进出换热管的温差,℃;ρ为循环水密度,取值参照表1;v为循环水流速,取1 m/s;S为换热管横截面积,取0.031 4 m2;Tt为某一时刻出水口温度,℃。

由式(6)~(8)可以得到换热孔群和单孔换热时吸收的岩体热量。本文以1.6 m孔间距的换热孔群吸收的岩体热量进行分析,如图13所示。换热孔群吸收岩体的热量都要大于单孔吸收岩体的热量,其中正方形换热孔群吸收的热量要大于圆形换热孔群吸收的热量。不管是换热孔群还是单孔换热,换热孔吸收的热量都是先迅速增长,后缓慢增长,最后趋于稳定。通过换热孔群吸收的岩体热量证明了换热孔群可以增强高温巷道的降温效应,降低了高额的降温成本,并且获得一定热量的可利用水资源。

图13 不同换热孔吸收岩体热量随时间变化曲线

Fig. 13 Heat absorbed by different heat exchange holes in rock mass with time

5 结论

1) 在降温模型连续运行5.0 h的条件下,高温巷道表面的热通量随时间推移而增大,最后趋于稳定,但是增强型降温系统比传统型降温系统的高温巷道表面热通量提高约26.80%;在降温系统的作用下,高温巷道表面温度随时间推移而减小,对岩体的影响范围不断增大。

2) 增强型比传统型降温系统的高温巷道温度降低约1 ℃,循环水系统的出水口温度相对增加35.32%。基于循环水热交换技术的增强型降温系统不仅可以促进深井高温巷道降温,还可以进行地热开采。

3) 换热孔群运行24 h后,换热孔间热干扰随时间推移而增大。受此影响,换热孔群中各孔的热通量均小于单孔单独运行时的热通量。圆形换热孔群中,中心孔受热干扰最小,而正方形孔群的中心孔受热干扰最大,边界孔次之,转角孔受热干扰最小。同时,随着孔间距增大,存在最优孔间距(L=2.0 m)使得热通量相对损失量最低。

4) 在相同孔间距情况下,正方形换热孔群的换热相对损失量比圆形换热孔群的略低,孔间距小于2.0 m的换热孔群采用正方形布置可以减小热通量的相对损失量;而孔间距大于2.0 m时,热通量相对损失量几乎不受换热孔群形状的影响。

5) 考虑布置换热孔群与岩体热量进行热交换的情况下,换热孔群吸收岩体热量与单孔布置相比有显著提高,正方形换热孔群的热交换效果要优于圆形换热孔群的热交换效果。

参考文献:

[1] 王明年, 胡云鹏, 童建军, 等. 高温变温环境下喷射混凝 土-岩石界面剪切特性及温度损伤模型研究[J]. 岩石力学与工程学报, 2019, 38(1): 63-75.

WANG Mingnian, HU Yunpeng, TONG Jianjun, et al. Experimental study on shear mechanical properties and thermal damage model of shotcrete-rock interfaces under variable high temperatures[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(1): 63-75.

[2] 严健, 何川, 汪波, 等. 雅鲁藏布江缝合带深埋长大隧道群岩爆孕育及特征[J]. 岩石力学与工程学报, 2019, 38(4): 769-781.

YAN Jian, HE Chuan, WANG Bo, et al. Inoculation and characters of rockburstsinextra-long and deep-lyingtunnel slocated on YarlungZangbo suture[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(4): 769-781.

[3] 胡建军. 高温作用下石灰岩的热损伤特性研究[D]. 徐州: 中国矿业大学资源与地球科学学院, 2019: 1-2.

HU Jianjun. Study on thermal damage characteristics of limestone under high temperature[D]. Xuzhou: China University of Mining and Technology. School of Resources and Geosciences, 2019: 1-2.

[4] 张嘉文. 大推力-热效应耦合作用热力隧道结构损伤劣化机制多尺度研究[D]. 北京: 北京交通大学土木建筑工程学院, 2019: 1-2.

ZHANG Jiawen. Multi-scale study on the damage deterioration mechanism of the heat-supplying tunnel structuresconsidering the coupling of pipeline thrust and thermal effect[D]. Beijing: Beijing Jiaotong University. School of Civil Engineering, 2019: 1-2.

[5] 王登科, 张平, 浦海, 等. 温度冲击下煤体裂隙结构演化的显微CT实验研究[J]. 岩石力学与工程学报, 2018, 37(10): 2243-2252.

WANG Dengke, ZHANG Ping, PU Hai, et al. Experimental research on cracking process of coal under temperature variation with industrial micro-CT[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(10): 2243-2252.

[6] 赵阳升, 万志军, 张渊, 等. 岩石热破裂与渗透性相关规律的试验研究[J]. 岩石力学与工程学报, 2010, 29(10): 1970-1976.

ZHAO Yangsheng, WAN Zhijun, ZHANG Yuan, et al. Experimental study of related laws of rock thermal cracking and permeability[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(10): 1970-1976.

[7] 左建平, 周宏伟, 方园, 等. 甘肃北山地区深部花岗岩的热开裂试验研究[J]. 岩石力学与工程学报, 2011, 30(6): 1107-1115.

ZUO Jianping, ZHOU Hongwei, FANG Yuan, et al. Experimental research on thermal cracking of deep granite in Beishan region, Gansu Province[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(6): 1107-1115.

[8] 姚孟迪. 热损伤岩石力学特性及裂纹扩展试验研究[D]. 武汉: 武汉大学水利水电学院, 2017: 15-50.

YAO Mengdi. Experimental study on mechanical properties and crack propagation of thermal damaged rock[D]. Wuhan: Wuhan University. School of Water Resources and Hydropower Engineering, 2017: 15-50.

[9] YANG Shengqi, HUANG Yanhua, TIAN Wenling, et al. Effect of high temperature on deformation failure behavior of granite specimen containing a single fissure under uniaxial compression[J]. Rock Mechanics and Rock Engineering, 2019, 52(7): 2087-2107.

[10] 黄翰文. 矿井风温预测的统计研究[J]. 煤炭学报, 1981(3): 52-61.

HUANG Hanwen. Statistical research on prediction of mine air temperature [J]. Journal of China Coal Society, 1981(3): 52-61.

[11] 黄翰文. 矿井风温预测的探讨[J]. 煤矿安全, 1980, 11(8): 8-17.

HUANG Hanwen. Discussion on prediction of mine air temperature[J]. Safety in Coal Mines, 1980, 11(8): 8-17.

[12] 杨德源. 矿井风流热交换[J]. 煤矿安全, 2003, 34(Z1): 94-97.

YANG Deyuan. Heat exchange of mine air flow[J]. Coal Mine Safety, 2003, 34(Z1): 94-97.

[13] HE Manchao. Application of HEMS cooling technology in deep mine heat hazard control[J]. Mining Science and Technology (China), 2009, 19(3): 269-275.

[14] 凡雨杰. 壁面贴附水膜板换热器降温实验与数值模拟研究[D]. 徐州: 中国矿业大学安全工程学院, 2017: 1-2

FAN Yujie. Experiment and numerical study on cooling effects of water film plate heat exchange rattacted on the wall[D]. Xuzhou: China University of Mining and Technology. School of Safty Engineering, 2017: 1-2.

[15] FENG Xiaoping, JIA Zhemin, LIANG Hao, et al. A full air cooling and heating system based on mine water source[J]. Applied Thermal Engineering, 2018, 145: 610-617.

[16] 唐世斌, 罗江, 唐春安. 低温诱发岩石破裂的理论与数值模拟研究[J]. 岩石力学与工程学报. 2018, 37(7): 1596-1607.

TANG Shibin, LUO Jiang, TANG Chunan. Theoretical and numerical simulation of rock fracture induced by low temperature[J]. Journal of Rock Mechanics and Engineering. 2018, 37(7): 1596-1607.

[17] 朱振南, 田红, 董楠楠, 等. 高温花岗岩遇水冷却后物理力学特性试验研究[J]. 岩土力学, 2018, 39(S2): 169-176.

ZHU Zhennan, TIAN Hong, DONG Nannan, et al. Experimental study of physico-mechanical properties of heat-treated granite by water cooling[J]. Rock and Soil Mechanics, 2018, 39(S2): 169-176.

[18] 靳佩桦, 胡耀青, 邵继喜, 等. 急剧冷却后花岗岩物理力学及渗透性质试验研究[J]. 岩石力学与工程学报, 2018, 37(11): 2556-2564.

JIN Peihua, HU Yaoqing, SHAO Jixi, et al. Experimental study on physico-mechanical and transport properties of granite subjected to rapid cooling[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(11): 2556-2564.

[19] WU Xinghui, WANG Peitao, GUO Qifeng, et al. Numerical simulation of the influence of flow velocity on granite temperature field under thermal shock[J]. Geotechnical and Geological Engineering, 2021, 39(1): 37-48.

[20] PAHUD D, FROMENTIN A, HUBBUCH M. Heat exchanger pile system for heating and cooling at Zurich Airport[EB/OL]. 1999.

[21] LI Xinguo, CHEN Yan, CHEN Zhihao, et al. Thermal performances of different types of underground heat exchangers[J]. Energy and Buildings, 2006, 38(5): 543-547.

[22] GAO Jun, ZHANG Xu, LIU Jun, et al. Numerical and experimental assessment of thermal performance of vertical energy piles: an application[J]. Applied Energy, 2008, 85(10): 901-910.

[23] GAO Jun, ZHANG Xu, LIU Jun, et al. Thermal performance and ground temperature of vertical pile-foundation heat exchangers: a case study[J]. Applied Thermal Engineering, 2008, 28(17/18): 2295-2304.

[24] ZARRELLA A, DE CARLI M, GALGARO A. Thermal performance of two types of energy foundation pile: helical pipe and triple U-tube[J]. Applied Thermal Engineering, 2013, 61(2): 301-310.

[25] KONG Lipeng, QIAO Lan, XIAO Yunyang, et al. A study on heat transfer characteristics and pile group influence of enhanced heat transfer energy piles[J]. Journal of Building Engineering, 2019, 24: 100768-100776.

(编辑 秦明阳)

收稿日期: 2020 -05 -07; 修回日期: 2020 -07 -20

基金项目(Foundation item):国家重点研发计划项目(2018YFE0101100);中央高校基本科研业务费项目(FRF-TP-18-015A3) (Project(2018YFE0101100) supported by the National Key Research and Development Program of China; Project(FRF-TP-18-015A3) supported by the Fundamental Research Funds for the Central Universities)

通信作者:郭奇峰,副教授,从事深部金属矿山开采研究;E-mail:guoqifeng@ustb.edu.cn

引用格式: 吴星辉, 蔡美峰, 任奋华, 等. 深部矿井高温巷道热交换降温技术探讨[J]. 中南大学学报(自然科学版), 2021, 52(3): 890-900.

Citation: WU Xinghui, CAI Meifeng, REN Fenhua, et al. Heat exchange cooling technology of high temperature roadway in deep mine[J]. Journal of Central South University(Science and Technology), 2021, 52(3): 890-900.