DOI:10.19476/j.ysxb.1004.0609.2019.05.18

氯化铵选择性浸出红土镍矿有价金属

李金辉1,徐志峰1,高 岩2,李德顺1,刘 叶1,赵春蝶1

(1. 江西理工大学 冶金与化学工程学院,赣州 341000;

2. 河南省冶金研究所有限责任公司,郑州 450053)

摘 要:采用湿法氯化的方法可以有效降低酸耗和抑制杂质离子的浸出,采用氯化铵-盐酸体系选择性浸出红土镍矿中有价金属。结果表明:在浸出温度90 ℃、盐酸浓度2 mol/L、固液比1:6、浸出时间90 min条件下镍的浸出率为89.45%,钴的浸出率为88.56%,锰的浸出率为90.23%,而铁的浸出率只有19.30%,实现了在低酸情况下的选择性浸出。对红土镍矿中不同矿相在氯盐溶液中的浸出机理进行了研究。结果表明:氯盐的加入有利于针铁矿相的溶解,但对其他铁矿相影响不显著。因此,氯盐的加入有利于针铁矿相中有价金属的浸出,抑制其他铁矿相中铁的浸出。

关键词:氯化铵;红土镍矿;选择性浸出;浸出机理;活度

文章编号:1004-0609(2019)-05-1049-09 中图分类号:TF815 文献标志码:A

镍在日常生活中是一种非常重要的有色金属,由于其具有良好的导磁性、可塑性、耐腐蚀性,被广泛用于不锈钢、催化剂、磁性材料以及电镀等行业,是国家经济和社会发展的重要战略资源[1]。世界原生镍资源主要分为硫化镍矿、红土镍矿和海底锰结核,陆地镍资源中65%为红土镍矿[2]、35%为硫化镍矿。随着硫化镍矿的不断开采,其开采难度不断加大,资源日益枯竭,所以开发利用红土镍矿资源日益迫切[3]。

近年来,针对红土镍矿的冶金方法研究逐渐成为研究的热点,处理工艺多种多样,主要分为火法工艺和湿法工艺[4-5]。火法冶炼适合处理高镁低铁型的腐殖土层红土矿,主要是采用还原焙烧的方法制备镍铁合金和还原硫化熔炼生产镍锍,但是能耗高且会产生大量的尾渣[6-8]。湿法冶金方法包括还原焙烧-氨浸法、高压酸浸法和常压酸浸法,由于其能耗低、收率高近年来也一直备受关注[9-12]。还原焙烧-氨浸法最早用于工业化处理红土矿,具有工艺成熟、镍回收率高等优点,缺点是流程复杂、钴回收率低[13]。高压酸浸工艺由于其有价金属浸出率高而铁浸出率低受到广泛关注,但是苛刻的操作条件限制了其应用[14-15]。常压酸浸工艺尽管操作简单、有价金属浸出率高,但是过高的酸耗和较低的选择性抑制了它的发展[16-17]。

氯化冶金是一种别具优势的方法,它可以实现有价金属镍钴与杂质金属铁镁等的高效分离和镍钴的选择性提取[18-22]。FAN等[23]采用六水氯化铝作为氯化剂对用活性碳还原后的红土镍矿在300~500 ℃进行选择性氯化,镍和钴的氯化率可以达到90%以上,而铁的氯化小于4%。FAN等[24]采用水合氯化亚铁作为氯化剂对预还原后的红土镍矿选择性氯化生成氯化镍和氯化钴,镍和钴的氯化可以达到90%左右,而其他杂质的氯化得到显著的抑制。王成彦等[17]采用氯化离析-氨浸的方法处理红土镍矿取得了卓有成效的研究成果,具有很高的学术价值。而氯化湿法冶金在理论上有其独特的优势,如氯化物水溶液体系除了在溶解度、氢离子活度、形成配合物和还原电位等方面的特殊性之外,氯离子具有很强的去极化和消除钝化的作用对湿法冶金过程也很有利[19, 25-26]。正是由于这些优势,氯化湿法冶金由于其独特的优势将成为未来发展的重点。

本文作者把氯化铵加入到稀盐酸溶液中,通过氯盐的加入可以提高氢离子活度从而降低盐酸的用量,达到高酸浸出效果的同时抑制杂质金属的浸出,实现对红土镍矿中有价金属选择性提取浸出。同时,考察不同因素对有价金属选择性提取的影响,以及实现选择性提取的机理。本文的研究成果将会为氯化湿法冶金的发展提供一种新的发展方向,同时也为红土镍矿的湿法浸出工艺提供一种新的思路。

1 实验

1.1 实验原料及表征

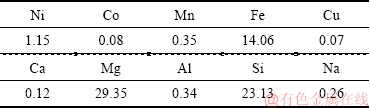

实验所用低品位红土镍矿,其来源于云南元江不同地表深度的红土镍矿,经干燥、破碎干磨混合均匀后过孔径150 μm的筛之后进行实验研究。通过对实验样品进行成分分析结果见表1。

表1 红土镍矿样品化学成分分析

Table 1 Chemical composition analysis of sample (mass fraction, %)

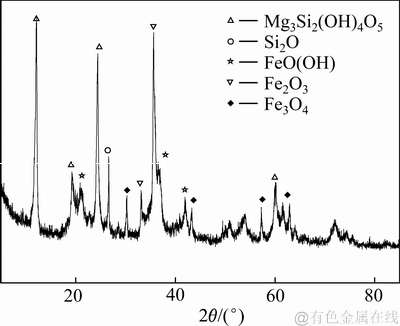

对原矿进行物相分析,图1所示为原矿的XRD谱。由图1可以看出,矿相的主要成分为蛇纹石(Mg3[Si2O5(OH)4])、针铁矿(FeO(OH))、二氧化硅(SiO2)和铁的氧化物(Fe3O4、Fe2O3),结合矿石的化学成分,可认为其属于硅镁质型红土镍矿。

图1 原矿的XRD谱

Fig. 1 XRD pattern of raw ore

1.2 试验方法

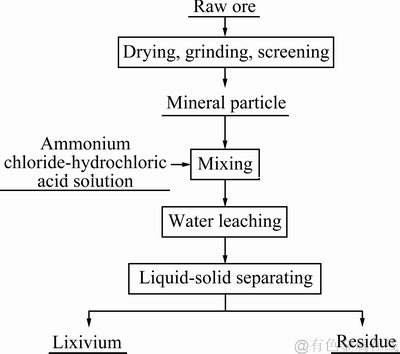

常压条件下,在酸性介质溶液中加入一定数量的氯化铵,在一定温度下直接浸出红土镍矿中的有价金属。具体步骤为:将配置一定浓度的盐酸溶液,计量加入氯化铵后与矿料投入至三口烧瓶内混合,控制搅拌速度和反应温度,反应一段时间后,固液分离,工艺流程见图2所示。滤渣在鼓风干烘箱中105 ℃下烘干后备用检测,分析滤液中镍、钴、锰、铁等元素的含量计算浸出率。浸出率是浸出液中金属离子的含量与原矿中金属含量的比值(η)[27],可表示为

式中:V为浸出液的体积,V;ρ为浸出液的浓度,g/mL;m为原矿的质量,g;x为原矿中的金属的含量,%。

图2 氯化浸出工艺流程图

Fig. 2 Process flow of hydro-chloride leaching

1.3 分析方法

采用化学滴定分析的方法测定溶液中铁离子浓度,采用WFX-1380型原子吸收分光光度计分析浸出液中镍、钴、锰等金属离子含量,采用D8 Advance X-射线衍射仪对原矿和浸出渣进行物相分析,采用日本日立公司SU8000型描电子显微镜-能谱仪对浸出渣进行SEM-EDS分析。

2 结果与讨论

2.1 不同氯盐对有价金属浸出率的影响

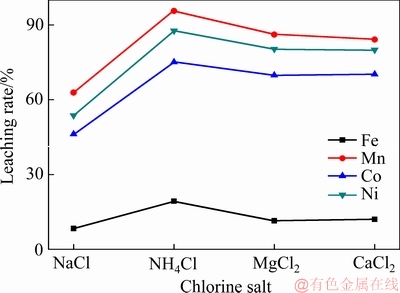

称取矿样10 g,盐酸浓度为2 mol/L,固液比1:6,反应温度90 ℃,浸出时间1.5 h,控制一定的搅拌速度,考察氯离子浓度3 mol/L的不同氯盐对有价金属镍、钴、锰和铁浸出的影响,所得到的镍、钴、锰、铁的浸出率如图3所示。

图3 不同氯盐对金属浸出率的影响

Fig. 3 Influence of different chlorine salt on leaching rate of metals

由图3可以看出,用氯离子浓度均为3 mol/L的不同氯盐进行实验时,氯化钠对各种离子的浸出率最低,而氯化铵对各种离子的浸出率最高,氯化镁和氯化钙对各离子的浸出率次之,且两者相近。综合考虑,本实验采用的氯盐以氯化铵较宜。

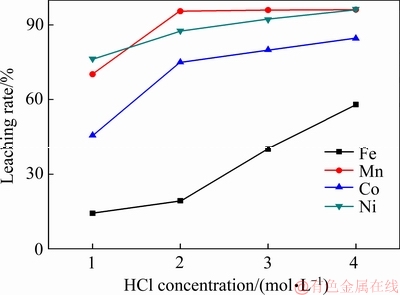

2.2 盐酸浓度对有价金属浸出率的影响

称取矿样10 g,氯化铵浓度为3 mol/L,固液比1:6,反应温度90 ℃,浸出时间1.5 h,控制一定的搅拌速度,考察盐酸浓度对有价金属镍、钴、锰和铁浸出的影响,所得到的镍、钴、锰、铁的浸出率如图4所示。

由图4可以看出,随着盐酸浓度的增加,镍、钴、锰、铁的浸出率都会增加。盐酸浓度由1mol/L增加到2mol/L时,钴的浸出率提高最明显,由45.66%增加到75.09%;其次是锰的浸出率,由70.21%增加到95.60%; 而镍和铁的浸出率提高不显著,镍的浸出率由76.45%增加到87.67%。当盐酸浓度由2 mol/L增加到4 mol/L时,镍、钴、锰3种金属离子的浸出率提高不明显,而铁的浸出率由19.3%增加到60%,其浸出率提高非常显著。显然,增加酸的用量有利于矿物中溶于酸的金属离子的浸出,但是有价金属离子的浸出率没有明显的提高,考虑到生产过程减少酸耗的成本以及高浓度酸对设备的腐蚀,同时,对红土镍矿浸出工艺中要尽量保证铁的较低浸出率,以降低后期净化除铁的处理量。因此,确定盐酸浓度为2mol/L。

图4 盐酸浓度对金属浸出率的影响

Fig.4 Influence of hydrogen chloride concentration on leaching rate of metals

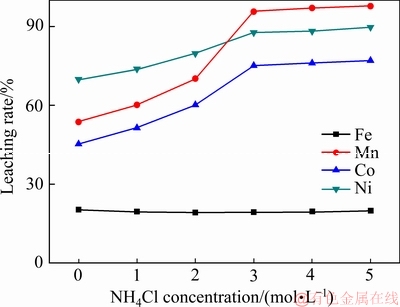

2.3 氯化铵浓度对有价金属浸出率的影响

称取矿样10 g,盐酸浓度为2 mol/L,固液比1:6,反应温度90 ℃,浸出时间1.5h,控制一定的搅拌速度,考察氯化铵浓度对有价金属镍、钴、锰和铁浸出的影响,所得到的镍、钴、锰、铁的浸出率如图5所示。

由图5可以看出,当氯化铵浓度由0增加到3 mol/L时,镍的浸出率由69.85%增加到89.7%,钴的浸出率45.26%增加到75.09%,锰的浸出率由53.64%增加到95.6%,而铁的浸出率基本保持不变。当氯 化铵浓度超过3 mol/L时,所有金属离子的浸出率没有显著的提高。综合考虑,氯化铵的浓度为3 mol/L为宜。

图5 氯化铵浓度对金属浸出率的影响

Fig. 5 Influence of ammonium chloride concentration on leaching rate of metals

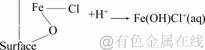

采用盐酸-氯化铵溶液体系浸出红土镍矿,盐酸提供氢离子产生溶液的酸性环境。向盐酸溶液中加入氯化铵,增加氯离子的含量,可以提高酸性溶液中氢离子活度[28-29],相比较传统工艺只有在8 mol/L的高酸条件下才能获得较高的浸出率[30],该工艺显著降低了酸的使用[31]。实验表明,盐酸-氯化物溶液与针铁矿中镍和铁的浸出有着密切的关系。在较低的温度下,主要是溶液中酸对针铁矿浸出,酸的浓度是影响矿物浸出的主导因素,而在温度超过80 ℃时,金属离子的浸出不仅取决于酸的浓度,还取决于氯离子的浓度。首先针铁矿的表面进行水合,随后通过质子和氯离子的吸附到表面部位,进而达到溶解的效果[32]。氯盐溶液溶解针铁矿的机理可表示为,在针铁矿表面与氯离子结合形成铁氯的配合物,其反应如下:

形成的配合物与溶液中的氢离子结合生成铁的可溶性配合物,最终实现在不增加酸浓度的条件下促进了针铁矿相的分解反应,其反应如下:

→

→

总反应: →

→

2.4 浸出温度对有价金属浸出率的影响

称取矿样10 g,氯化铵浓度为3 mol/L,盐酸浓度为2 mol/L,固液比1:6,浸出时间1.5 h,控制一定的搅拌速度,考察浸出温度对有价金属镍、钴、锰和铁浸出的影响,所得到的镍、钴、锰、铁的浸出率如图6所示。

由图6可以看出,温度对镍、钴、锰和铁的浸出率有较大的影响,在一定的温度范围内,随着浸出温度的升高,镍、钴、锰和铁的浸出率都有一定的增加, 而且温度对镍、钴、锰浸出率的影响程度大致一直。当浸出温度超过80 ℃时,镍、钴、锰的浸出率增加趋势较显著,而铁的浸出率增加趋势较小。这是由于随着温度的增加,溶液中氯离子对矿物的影响作用增加,有利于有价金属镍、钴、锰的浸出。当温度达到90 ℃后,随着矿物中有价金属含量的不断减少,浸出难度增加,在继续增加温度铁的浸出率将会明显增加。所以本实验采用浸出温度为90 ℃。

图6 浸出温度对金属浸出率的影响

Fig. 6 Influence of leaching temperature on leaching rate of metals

2.5 液固比对有价金属浸出率的影响

称取矿样10 g,盐酸浓度为2 mol/L,固液比1:6,氯化铵的浓度为3 mol/L,浸出时间1.5 h,控制一定的搅拌速度,考察浸出温度对有价金属镍、钴、锰和铁浸出的影响,所得到的镍、钴、锰、铁的浸出率如图7所示。

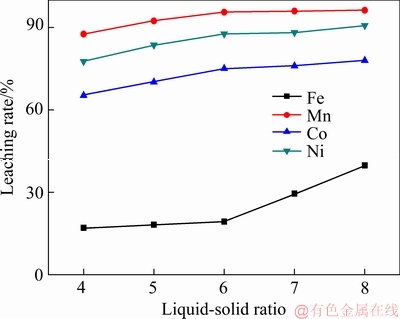

由图7可知,随着液固比的增加,镍、钴、锰的浸出率都有所提高,而铁的浸出率几乎没有增加,但当液固比由6增加到8时,有价金属的浸出率几乎不变,而铁的浸出率增加较为显著,这主要是由于开始增加液固比时主要浸出红土镍矿中的有价金属,达到一定程度后,矿浆中的有价金属离子较少,较难浸出,再增加液固比会使矿物中铁离子浸出增加。根据单因素实验条件确定盐酸浓度为2 mol/L、氯化铵浓度为3 mol/L,所以在考察液固比时,溶液的浓度都是确定的,随着液固比的增加,反应的盐酸和氯化铵的总量也会增加,导致溶液中铁的浸出率相应的增加。所以采用液固比为6为宜。

图7 液固比对金属浸出率的影响

Fig. 7 Influence of liquid-solid ratio on leaching rate of metals

2.6 浸出时间对有价金属浸出率的影响

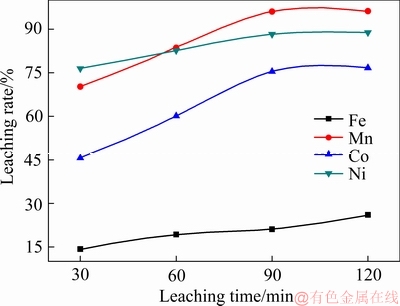

称取矿样10 g,盐酸浓度为2 mol/L,固液比1:6,氯化铵的浓度为3 mol/L,浸出温度90 ℃,控制一定的搅拌速度,考察浸出时间对有价金属镍、钴、锰和铁浸出率的影响,结果如图8所示。

由图8可知,从反应初始阶段,有价金属的浸出率随着时间的延长就开始增加,时间由30 min到90 min时,有价金属镍、钴、锰的浸出率都增加更显著,而铁的浸出率虽然也有增加,但是较其他金属的小。主要原因是由于在氯化铵-盐酸体系的浸出反应中有价金属离子镍、钴、锰要优先于铁而先浸出,随着反应的进行,有价金属的达到一定的浸出率后,铁将会继续浸出,所以在90 min以后有价金属的浸出率几乎不变,而铁的浸出率增加较为显著。因此,较好的浸出时间为90 min。

图8 浸出时间对金属浸出率的影响

Fig. 8 Influence of leaching time on leaching rate of metals

3 浸出机理分析

根据原矿的物相分析结果可知,红土镍矿中的有价金属主要以氧化物的形式存在于不同矿相中,研究红土镍矿中不同矿相的溶解机理对了解有价金属镍、钴和锰以及杂质金属铁的浸出行为有重要意义。根据矿物学分析可知,本实验主要的含镍红土矿的矿物种类是针铁矿和不同镍含量的层状硅酸盐的蒙脱石的和蛇纹石。基于前期研究成果与方法[33],本文作者针对盐酸-氯化铵体系对红土镍矿中的有价金属浸出机理进行研究。

红土镍矿浸出反应过程中,主要是酸的溶解作用,将矿物中的有价金属溶解到溶液中。而有价金属镍、钴、锰主要存在于铁酸盐的矿相中,同时,也有以氧化物的形式存在于硅酸盐矿相中。根据原矿的相关研究结果分析可知,红土镍矿在酸溶液中浸出可能发生的主要化学反应:

NiFe2O4(s)+2H+=Ni2++Fe2O3(s)+H2O(l)

CoFe2O4(s)+2H+=Co2++Fe2O3(s)+H2O(l)

MnFe2O4(s)+2H+=Mn2++Fe2O3(s)+H2O(l)

2NiO·SiO2(s)+4H+=2Ni2++2SiO2(s)+2H2O(l)

2MnO·SiO2(s)+4H+=2Mn2++2SiO2(s)+2H2O(l)

NiO(s)+2H+=Ni2++H2O(l)

CoO(s)+2H+=Co2++H2O(l)

FeO(OH)(s)+3H+=Fe3++2H2O(l)

Fe2O3(s)+6H+=2Fe3++3H2O(l)

结合矿物浸出过程中可能发生的反应方程式可以看出,酸性环境对矿物的溶解有决定性的作用,而矿物的溶解过程直接决定金属离子的浸出行为。因此,研究矿物中不同矿相在酸溶液中溶解变化过程十分重要。由原矿的XRD谱可知,红土镍矿存在的主要矿相为:蛇纹石矿相(Mg3[Si2O5(OH)4])、针铁矿矿相(FeO(OH))、赤铁矿矿相(Fe2O3)和磁铁矿矿相(Fe3O4)。通过对不同条件下矿物的浸出渣中的XRD分析可以得出各主要矿相在浸出时发生的变化,进而分析红土镍矿在酸性溶液中的浸出机理。

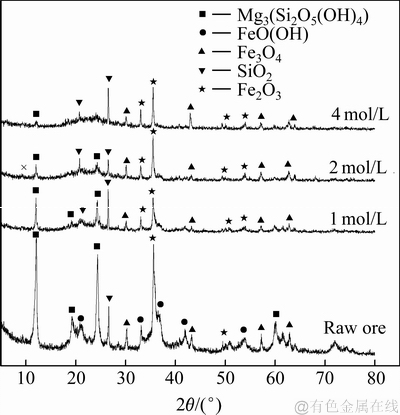

图9所示为其他工艺条件不变、不同酸浓度下红土镍矿浸出渣的XRD谱。由图9可知,随着酸浓度的增加,针铁矿矿相在不同位置的特征吸收峰有较大的变化,其特征衍射峰逐渐减弱直至消失。在酸浓度为2 mol/L时,浸出渣中的矿相中已经看不到针铁矿矿相,而蛇纹石矿相会随着酸浓度的增加也逐渐消失, 形成SiO2。根据图中蛇纹石矿相和针铁矿矿相的吸收特征峰进行比较可知,针铁矿矿相在浸出过程中优先于蛇纹石矿相而先发生溶解。而赤铁矿矿相和磁铁矿矿相在酸浓度较低时很难发生反应,这也与实验结果中铁的浸出率较低相吻合。

图9 不同酸浓度红土矿浸出渣的XRD谱

Fig. 9 XRD patterns of leaching residue with different acid concentrations

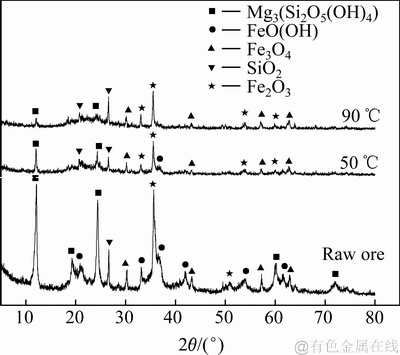

图10所示为固定其他为最佳工艺条件不同浸出温度下红土镍矿浸出渣的XRD谱。由图10可知,当浸出温度增加到50 ℃和90 ℃时,针铁矿矿相和蛇纹石矿相在特定位置的特征吸收峰都减弱,有些位置的特征峰甚至消失。而当浸出温度达到90 ℃时,浸出渣中基本没有针铁矿矿相,而仍有蛇纹石矿相,所以升高温度更有利于针铁矿的溶解。结合浸出率实验结果可知,随着温度的升高有价金属的浸出率不断增加,而铁的浸出率增加不明显,也验证温度对红土镍矿中矿相的影响机理。而赤铁矿矿相和磁铁矿矿相随着温度的变化不显著,在温度达到90 ℃时,浸出渣中的赤铁矿和磁铁矿基本没有改变,说明其晶体结构较稳定。所以升高温度有利于有价金属的浸出率,与实验结果相符合。

图10 不同浸出温度下红土矿浸出渣的XRD谱

Fig. 10 XRD patterns of leaching residue at different leaching temperatures

图11所示为固定除时间以外其他为最佳工艺条件下红土镍矿浸出渣XRD谱。由图11可知,随着浸出时间的增加,针铁矿矿相在不同位置的特征吸收峰有较大的变化,当浸出时间达到60 min时,针铁矿矿相在特定位置的特征衍射峰逐渐消失。蛇纹石矿相的特征衍射峰随着浸出时间的增加也有明显的变化,而且在不同位置会出现新的SiO2特征衍射峰,这是由于蛇纹石矿相也不断的分解,其矿相会遭到破坏,而其包裹的其中的SiO2就被释放出来。而随着时间的不断增加,赤铁矿矿相和磁铁矿矿相各自的衍射峰强度都是不断减弱的趋势,结合实验结果可知,随着浸出实验时间的增加,铁的浸出率增加显著,而有价金属的浸出率基本无明显变化。

图11 不同浸出时间红土矿浸出渣XRD谱

Fig. 11 XRD patterns of leaching residue at different leaching time

4 结论

1) 实验确定了盐酸-氯化铵体系浸出红土镍矿的最佳工艺条件为:浸出温度为90 ℃,盐酸浓度为2 mol/L,固液比1:6,浸出时间为90 min的条件下镍的浸出率为89.45%,钴的浸出率为88.56%,锰的浸出率为90.23%,而铁的浸出率只有19.30%,实现了选择性浸出。

2) 通过对盐酸-氯化铵溶液体系浸出红土镍矿机理进行研究,结果表明现有工艺条件下针铁矿最容易分解反应,蛇纹石矿相有部分溶解,释放出有价金属离子同时也会产生SiO2,而赤铁矿矿相和磁铁矿矿相较为稳定。

REFERENCES

[1] 张 亮, 杨卉芃, 冯安生, 曹 飞. 全球镍矿资源开发利用现状及供需分析[J]. 矿产保护与利用, 2016(1): 64-69.

ZHANG Liang,YANG Hui-peng, FENG An-sheng, CAO Fei. Study on current situation and analysis of supply and demand of global nickel resource[J]. Conservation and Utilization of Mineral Resources, 2016(1): 64-69.

[2] 李小明, 白涛涛, 赵俊学, 李文锋, 李志国, 崔雅茹. 红土镍矿冶炼工艺研究现状及进展[J]. 材料导报, 2014, 28(5): 112-116.

LI Xiao-ming, BAI Tao-tao, ZHAO Jun-xue, LI Wen-feng, LI Zhi-guo, CUI Ya-ru. Status and progress of metallurgical technology on laterite nickel ore[J]. Materials Review, 2014, 28(5): 112-116.

[3] 石剑锋, 王志兴, 胡启阳, 郭华军, 李新海, 彭文杰. 硫酸氢铵硫酸化焙烧法红土镍矿提取镍钴[J]. 中国有色金属学报, 2013, 23(2): 510-515.

SHI Jian-feng, WANG Zhi-xing, HU Qi-yang, GUO Hua-jun, LI Xin-hai, PENG Wen-jie. Recovery of nickel and cobalt from nickel laterite ore by sulfation roasting method using ammonium bisulfate[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 510-515.

[4] 吴 展. 红土镍矿硫酸熟化焙烧-水浸浸出液中回收镍钴等价金属的研究[D]. 长沙: 中南大学, 2011.

WU Zhan. Recovery of valuable metals such as nickel and cobalt from sulfuric acid roasting and water leaching of laterite nickel ore [D]. Changsha: Central South University, 2011.

[5] MCDONALD R G, WHITTINGTON B I. Atmospheric acid leaching of nickel laterites review. Part 2. Chloride and bio-technologies[J]. Hydrometallurgy, 2008, 91(1/4): 35-55.

[6] 郭学益, 李 栋, 田庆华, 石文堂. 硫酸熟化-焙烧法从镍红土矿中回收镍和钴动力学研究[J]. 中南大学学报(自然科学版), 2012, 43(4): 23-27.

GUO Xue-yi, LI Dong, TIAN Qing-hua, SHI Wen-tang. Kinetics of sulfation-roasting of nickel laterite for recovery of nickel and cobalt[J]. Journal of Central South University (Science and Technology), 2012, 43(4): 23-27.

[7] MARAGKOS I, GIANNOPOULOU I P, PANIAS D. Synthesis of ferronickel slag-based geopolymers[J]. Miner Engineering, 2009, 22(2): 196-203.

[8] MU Wen-ning, ZHAI Yu-chun. Desiliconization kinetics of nickeliferous laterite ores in molten sodium hydroxide system[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 330-335.

[9] 邱 沙, 车小奎, 郑 其, 段 锦. 红土镍矿硫酸化焙烧-水浸实验研究[J]. 稀有金属, 2010, 34(3): 406-412.

QIU Sha, CHE Xiao-kui, ZHENG Qi, DUAN Jin. Experimental study on laterite-nickel ore with sulfating roasting-water immersion methods[J]. Chinese Journal of Rare Metals, 2010, 34(3): 406-412.

[10] BüYüKAKINCI E, TOPKAYA Y A. Extraction of nickel from lateritic ores at atmospheric pressure with agitation leaching[J]. Hydrometallurgy, 2009, 97(1): 33-38.

[11] LI Guang-hui, RAO Ming-jun, LI Qian, PENG Zhi-wei, JIANG Tao. Extraction of cobalt from laterite ores by citric acid in presence of ammonium bifluoride[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(8): 1517- 1520.

[12] 马保中, 杨玮娇, 王 硕, 杨 卜, 王成彦. 硝酸根氧化高压硫酸浸出红土镍矿[J]. 稀有金属, 2016, 40(7): 715-720.

MA Bao-zhong, YANG Wei-jiao, WANG Shuo, YANG Bo, WANG Cheng-yan. High-pressure sulfuric acid leaching of laterite ores using nitrate ion as an oxidant[J]. Chinese Journal of Rare Metals, 2016, 40(7): 715-720.

[13] ZUNIGA M, PARADA F, ASSELIN E. Leaching of a limonitic laterite in ammoniacal solutions with metallic iron[J]. Hydrometallurgy, 2010, 104(2): 260-267.

[14] MA Bao-zhong, WANG Cheng-yan, YANG Wei-jiao, YANG Bo, ZHANG Yong-lu. Selective pressure leaching of Fe (II)-rich limonitic laterite ores from Indonesia using nitric acid[J]. Minerals Engineering, 2013, 45(3): 151-158.

[15] WHITTINGTON B, MUIR D M. Pressure acid leaching of nickel laterites: A review[J]. Mineral Processing and Extractive Metallurgy Review, 2000, 21(6): 527-599.

[16] LUO Jun, LI Guang-hui, RAO Ming-jun, PENG Zhi-wei, ZHANG Yuan-bo, JIANG Tao. Atmospheric leaching characteristics of nickel and iron in limonitic laterite with sulfuric acid in the presence of sodium sulfite[J]. Minerals Engineering, 2015, 78: 38-44.

[17] 王成彦, 尹 飞, 陈永强, 王 忠, 王 军. 国内外红土镍矿处理技术及进展[J]. 中国有色金属学报, 2008, 18(1): 1-8.

WANG Cheng-yan, YIN Fei, CHEN Yong-qiang, WANG Zhong, WANG Jun. Worldwide processing technologies and progress of nickel laterites[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 1-8.

[18] ZHAI Yu-chun, MU Wen-ning, LIU Yan, XU Qian. A green process for recovering nickel from nickeliferous laterite ores[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S1): s65-s70.

[19] LAKSHMANAN V I, SRIDHAR R, CHEN J, HALIM M A. Development of mixed-chloride hydrometallurgical processes for the recovery of value metals from various resources[J]. Transactions of the Indian Institute of Metals, 2016, 69(1): 39-50.

[20] ZHOU Shi-wei, WEI Yong-gang, LI Bo, WANG Hua, MA Bao-zhong, WANG Cheng-yan. Chloridization and reduction roasting of high-magnesium low-nickel oxide ore followed by magnetic separation to enrich ferronickel concentrate[J]. Metallurgical and Materials Transactions B, 2016, 47(1): 145-153.

[21] 赵玉先, 胡启阳, 李新海, 王志兴, 郭华军. 锈蚀法提取预还原红土镍矿中镍和钴[J]. 中国有色金属学报, 2012, 22(11): 3208-3213.

ZHAO Yu-xian, HU Qi-yang, LI Xin-hai, WANG Zhi-xing, GUO Hua-jun. Extraction of nickel and cobalt from reductive laterite by corrosion process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3208-3213.

[22] LI Jin-hui, LI Yang-yang, GAO Yan, ZHANG Yun-fang, CHEN Zhi-feng. Chlorination roasting of laterite using salt chloride[J]. International Journal of Mineral Processing, 2016, 148: 23-31.

[23] FAN Chuan-lin, ZHAI Xiu-jing, FU Yan, CHANG Yong- feng, LI Bin-chuan, ZHANG Ting-an. Extraction of nickel and cobalt from reduced limonitic laterite using a selective chlorination–water leaching process[J]. Hydrometallurgy, 2010, 105: 191-194.

[24] FAN Chuan-lin, ZHAI Xiu-jing, FU Yan, CHANG Yong- feng, LI Bin-chuan, ZHANG Ting-an. Leaching behavior of metals from chlorinated limonitic nickel laterite[J]. International Journal of Mineral Processing, 2012, 110: 117- 120.

[25] ZHANG Pei-yu, GUO Qiang, WEI Guang-ye, MENG Long, HAN Lin-xin, QU Jing-kui, QI Tao. Leaching metals from saprolitic laterite ore using a ferric chloride solution[J]. Journal of Cleaner Production, 2016, 112: 3531-3539.

[26] DEHGHAN R, NOAPARAST M, KOLAHDOOZAN M. Leaching and kinetic modeling of low-grade calcareous sphalerite in acidic ferric chloride solution[J]. Hydrometallurgy, 2009, 96 (4): 275-282.

[27] 李洋洋. 红土镍矿中有价金属提取工艺研究[D]. 赣州: 江西理工大学, 2015.

LI Yang-yang. Research on the extraction processof valuable metals in laterite nickel ore[D]. Ganzhou: Jiangxi University of Science and Technology, 2015.

[28] JU Shao-hua, ZHANG Li-bo, PENG Jin-hui, SHI Zhe, GUO Sheng-hui, LIU Bin-guo, WANG Ya-jian. Thermodynamics of leaching roasted jarosite residue from zinc hydrometallurgy in NH4Cl system[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1179-1183.

[29] ZHAO Pin, GAO Bao-yu, YUE Qin-yan, LIU Si-cheng, SHONB H K. The performance of forward osmosis in treating high-salinity wastewater containing heavy metal Ni2+[J]. Chemical Engineering Journal, 2016, 288: 569-576.

[30] LI Jin-hui, XIONG Dao-ling, CHEN Hao, WANG Rui-xiang, LIANG Yong. Physicochemical factors affecting leaching of laterite ore in hydrochloric acid[J]. Hydrometallurgy, 2012, 129/130: 14-16.

[31] SENANYAKE G. Review of theory and practice of measuring proton activity and pH in concentrated chloride solutions and application to oxide leaching[J]. Minerals Engineering, 2007, 20(7): 634-645.

[32] COMELL R M, POSNER A M, QUIRK JP. Kinetics and mechanisms of the acid dissolution of goethite (α-FeOOH)[J]. Journal of Inorganic and Nuclear Chemistry, 1976, 38(3): 563-567.

[33] 李金辉, 李新海, 胡启阳, 王志兴, 周友元, 郑俊超, 伍 凌. 活化焙烧强化盐酸浸出红土矿的镍[J]. 中南大学学报(自然科学版), 2010, 41(5): 1691-1697.

LI Jin-hui, LI Xin-hai, HU Qi-yang, WANG Zhi-xing, ZHOU You-yuan, ZHENG Jun-chao, WU Ling. Enhancement of nickel extraction from laterite in hydrochloride acid through activated roasting[J]. Journal of Central South University (Science and Technology), 2010, 41(5): 1691-1697.

Selectively leaching valuable metals from laterite nickel ore by ammonium chloride

LI Jin-hui1, XU Zhi-feng1, GAO Yan2, LI De-shun1, LIU Ye1, ZHAO Chun-die1

(1. School of Metallurgy and Chemical Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. Henan Institute of Metallurgy Co., Ltd., Zhengzhou 450053, China)

Abstract: The hydro-chloride leaching can reduce the impurity ion leaching and consumption of acid effectively. The selectively leaching valuable metals from laterite nickel ore with ammonium chloride hydrochloric acid solution were studied. The results show that when the leaching temperature is 90 ℃, hydrochloric acid concentration is 2 mol/L, solid-liquid ratio is 1:6 and leaching time is 1.5 h, the leaching rates of nickel, cobalt, manganese and iron are 89.45%, 88.56%, 90.23% and 19.30%, respectively, which achieve selectively leaching in relatively low acid concentration. Based on the selective leaching mechanism research, the addition of chlorine salt is beneficial to dissolution of goethite than other iron minerals in laterite ore, leading to increasing leaching of valuable metals from goethite mineral and suppression leaching of iron from other iron minerals.

Key words: ammonium chloride; laterite nickel ore; selective leaching; leaching mechanism; ion activity

Foundation item: Project(GJJ160593) supported by the Jiangxi Department of Education, China; Project (20161ACG70010) supported by the Jiangxi Science and Technology Department, China; Project(2017KY17) supported by the Jiangxi Postdoctoral Fund, China

Received date: 2017-10-16; Accepted date: 2018-11-20

Corresponding author: XU zhi-feng; Tel: +86-797-8312047; E-mail:xzf_l@163.com

(编辑 李艳红)

基金项目:江西省教育厅项目(GJJ160593);江西省科技厅项目(20161ACG70010);江西省博士后基金项目(2017KY17)

收稿日期:2017-10-16;修订日期:2018-11-20

通信作者:徐志峰,教授,博士;电话:0797-8312047;E-mail:xzf_l@163.com