J. Cent. South Univ. Technol. (2008) 15: 305-308

DOI: 10.1007/s11771-008-0057-0

Structural characteristics and properties of polyurethane modified TDE-85/MeTHPA epoxy resin with interpenetrating polymer networks

LI Zhi-hua(李芝华), HUANG Yao-peng(黄耀鹏), REN Dong-yan(任冬燕), ZHENG Zi-qiao(郑子樵)

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Diglycidyl-4, 5-epoxycyclohexane-1, 2-dicarboxylate(TDE-85)/methyl tetrahydrophthalic anhydride (MeTHPA) epoxy resin was modified with polyurethane(PU) and the interpenetrating polymer networks(IPNs) of PU-modified TDE-85/MeTHPA resin were prepared. The structural characteristics and properties of PU-modified TDE-85/MeTHPA resin were investigated by Fourier transform infrared(FTIR) spectrum, emission scanning electron microscopy(SEM) and thermogravimetry(TG). The results indicate that epoxy polymer network (Ⅰ) and polyurethane polymer network (Ⅱ) of the modified resin can be obtained and the networks (Ⅰ) and (Ⅱ) interpenetrate and tangle highly each other at the phase interface. The micro morphology presents heterogeneous structure. The integrative properties of PU-modified TDE-85/MeTHPA epoxy resin are improved obviously. The PU-modified TDE-85/ MeTHPA resin’s tensile strength reaches 69.39 MPa, the impact strength reaches 23.56 kJ/m, the temperature for the system to lose 1% mass (t1%) is 300 ℃, and that for the system to lose 50% mass (t50%) is 378 ℃. Compared with those of TDE-85/MeTHPA resin, the tensile strength, impact strength, t1% and t50% of the PU-modified resin increases by 48%, 115%, 30 ℃, 11 ℃, respectively. The PU-modified TDE-85/MeTHPA resin has the structure characteristics and properties of interpenetrating polymer networks.

Key words: polyurethane; epoxy resin; interpenetrating polymer networks; tensile strength; impact strength; thermal stability

1 Introduction

Epoxy resins such as diglycidyl-4,5-epoxycyclo- nexan-1,2-dicarboxylate (TDE-85) epoxy can offer many good properties. New composite materials, coatings and adhesives based on TDE-85 have been designed, developed, and widely applied in many high-tech fields[1]. But the disadvantages, such as brittleness, easy stress cracking under impact stress after curing, limit their further application in high-tech fields[2]. Therefore, a lot of attention is paid to the improvements of toughness, strength and thermal stability of TDE-85. Conventional methods to improve the toughness of epoxy resins always weaken the properties of rigidity and thermal stability. However, interpenetrating polymer networks (IPNs) with synergistic complexation can improve the impact strength, modulus, rupture elongation, rigidity and thermal stability, which has widely attracted people’s attention since the technique has been developed[3-6]. When epoxy resins(EP) are modified by polyurethane (PU), PU/EP IPN with two independent and interpenetrated cross-link networks can be formed under certain conditions. The strength and toughness of materials obtained can be improved at the same time[7-10]. Therefore, the study on the IPNs of PU-modified TDE-85/methyl tetrahydrophthalic anhydride(MeTHPA) resin is the development direction and significant means of TDE-85 modification. Nowadays, there are many researches on the formulations, properties, structural characteristics and applications of TDE-85 epoxy-based resins[11-13], while no reports about PU-modified TDE-85/MeTHPA resin have been reported.

Therefore, in this work, polyurethane prepolymer (PUP) was synthesized by using toluene diisocyanate (TDI) and polypropylene glycol(PPG) with number average molecular mass of 1 000. A series of PU- modified TDE-85/MeTHPA epoxy resins were prepared with PUP, TDE-85 and MeTHPA. The structures and properties of PU-modified TDE-85/MeTHPA epoxy resin were investigated.

2 Experimental

2.1 Materials

TDE-85 was provided by Tianjin Jingdong Chemical Plant. PPG with number average molecular mass of 1 000 was supplied by Tianjing No.3 Petroleum Chemical Plant. MeTHPA was supplied by Wenzhou Qingming Chemical Plant. TDI was supplied by Shanghai No.1 Reagent Plant. And trimethylol propane (TMP) and 1, 4-butanedio (1,4-BDO) were provided by Shanghai Reagent Plant.

2.2 Experimental process

2.2.1 Synthesis of isocyanate-terminated PUP PPG of proper quantity was filled into a clean and dried four-neck flask, and stirred at 120 ℃ for 1 h to dehydrate. Then it was cooled down to around 50 ℃ and stoichiometric quantity of TDI was added in the flask. The mixture under stirring was gradually heated to about 80 ℃ and maintained until the reaction was completed. Then isocyanate-terminated PUP was obtained.

2.2.2 Cast under vacuum

Moulds coated with antisticking agent were kept in the furnace at 80 ℃ for further use. TDE-85 and MeTHPA were dried at 80 ℃ under vacuum for 2 h, then cooled to 60 ℃. TDE-85 together with isocyanate- erminated PUP obtained, 1,4-BDO as chain-extended agent, TMP as cross-linked agent, MeTHPA as curing agent and 2,4,6-tris(dimethyl-aminomethyl) phenol (DMP30) as curing accelerant according to proper proportion were added into the vacuum casting machine. The mixture was stirred and heated for a certain time, then cast into the moulds. The resins cured after a series of processes as procedure heating solidification (120 ℃/ 2 h+140 ℃/2 h+160 ℃/2 h).

2.3 Measurements

The structures of polymers were characterized by Nicolet AVATAR360 type FT-IR spectrometer. Solid samples were tested with KBr pressed disc method, and liquid samples were tested directly or after diluted with tetrachloromethane.

The morphologies of the samples were analyzed by field SEM (Sirion200 type, FEI Company). Fracture surface of fresh-broken sample was firstly etched by dimethylformamide, and then pretreated by spraying aurum and fixed in metal carriers by conductive adhesive tape.

The tensile strength of materials was measured by electronic tensile tester (CMT5105 type, SANA Company) according to standard GB 1040-79 (China). The impact strength of materials was measured by impact testing machine (JB-5 type, Wuzhong material testing) according to standard GB 1043-79 (non-notched sample).

Also, the thermogravimetry(TG) in curing process was used to detect the mass loss of samples with Q600 type synchronous thermal analyzer, and the determined parameters of TG included air atmosphere, velocity of heating-up (10 ℃/min), and temperature range (30-600 ℃).

3 Results and discussion

3.1 FTIR spectrum

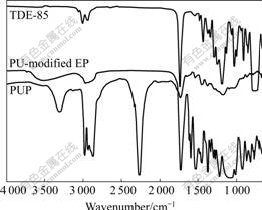

FTIR spectrum analysis is a major method to investigate the curing mechanism and structural characteristics of samples. The FTIR spectra of TDE-85, PUP and PU-modified TDE-85/MeTHPA resin samples (PU-modified EP) are shown in Fig.1. The FTIR spectrum of modified resin shows the disappearance of the characteristic band for isocyanate at 2 270 cm-1 in the PUP and the characteristic band for epoxy group at 908 cm-1 in TDE-85. This illuminates that isocyanate group in PUP and epoxy group in TDE-85 are depleted thoroughly.

Fig.1 FTIR spectra of TDE-85, PUP and PU-modified TDE-85/ MeTHPA resin

The systemic researches in Refs.[14-15] indicate that the epoxy polymer network (Ⅰ) is obtained by the curing reaction between TDE-85 and MeTHPA. Meanwhile, the polyurethane polymer network (Ⅱ) is obtained by the chain-extended and cross-link reaction of 1,4-BDO, TMP, and PUP during the modification.

3.2 Morphology

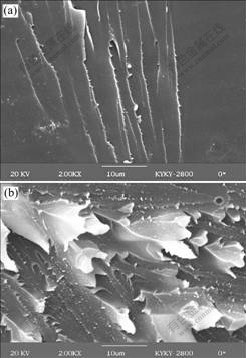

The two-phase distribution and interpenetration degree of EP and PU can be detected by SEM observation. The SEM images of fracture surfaces after tensile stress of TDE-85/MeTHPA resin sample and PU-modified TDE-85/MeTHPA resin sample are shown in Fig.2.

It is observed that TDE-85/MeTHPA resin presents unilateral continuity structure in Fig.2(a). The image of PU-modified TDE-85/MeTHPA resin sample is shown in Fig.2(b), which shows two-phases: PU phase and epoxy phase. But the interface of two-phase and phase separation is not obvious. At phase interface, networks (Ⅰ) and (Ⅱ) interpenetrate and tangle highly with each other, which results in the formation of the representative IPN structure.

3.3 Mechanical properties

The mechanical properties of both TDE-85/ MeTHPA resin and PU-modified TDE-85/ MeTHPA resin are shown in Table 1. Compared with TDE-85/ MeTHPA resin, the tensile strength and impact strength

Fig.2 SEM images of TDE-85/MeTHPA resin sample (a) and PU-modified TDE-85/MeTHPA resin sample (b)

Table 1 Mechanical properties of TDE-85/MeTHPA resin and PU-modified TDE-85/MeTHPA resin

of PU-modified TDE-85/MeTHPA resin are increased by 48% and 115%, respectively, which illuminates that both the tensile strength and impact strength are significantly improved.

The mechanical properties of materials depend on their structures. In the tensile and impact tests, only single epoxy network suffers the force without stress transfer between networks in epoxy resin system, while the interpenetrating networks of EP and PU suffer the force with stress dispersion in the modified system. This means that higher stress and energy will be needed to break the IPNs structure. Therefore, tensile strength and impact strength in the PU-modified TDE-85/MeTHPA resin are increased.

3.4 Fractography analyses

The SEM images of fracture surfaces of TDE-85/ MeTHPA resin and PU-modified TDE-85/MeTHPA resin sample after impact tests are shown in Fig.3. It can be seen that the impact fracture surface of TDE-85/ MeTHPA resin is a smooth plane, which results in low impact strength. In contrast, the fracture surface of PU-modified TDE-85/MeTHPA in Fig.3(b) becomes rougher and the cracks arrange irregularly. When the resin system is impacted, this kind of structure guarantees that more energy can be effectively absorbed and more stress can be found. So its impact strength is improved after modification.

Fig.3 SEM images of fracture surface of TDE-85/MeTHPA resin (a) and PU-modified TDE-85/MeTHPA resin (b)

The TDE-85/MeTHPA resin with single epoxy network structure shows the deformation and brittle fracture under force, while the PU-modified TDE-85/ MeTHPA resin has the interpenetrated and tangled networks between PU and EP. This means that higher stress and energy will be needed to break the networks. Therefore, the toughness of PU-modified TDE-85/ MeTHPA resin is improved, which corresponds to the results of mechanical tests.

3.5 Thermal stability

The mass fractions of PUP in samples A and B are 0, 15%, respectively. TG data of samples A and B are shown in Table 2. As can be seen in Table 2 that the temperature of losing 1% mass (t1%) for sample B is 300 ℃, which is 30 ℃ higher than that of sample A. The temperature of losing 50% mass (t50%) for sample B is 378 ℃, which is 11 ℃ higher than that of sample A. These indicate that the thermal stability of PU- modified TDE-85/MeTHPA resin is improved after modification. The reason for this is that PU and epoxy molecules can inter-penetrate or tangle with each other in PU-modified TDE-85/MeTHPA resin. More energy is needed to break the interpenetration polymer network than the simple epoxy resin network, and the thermal stability of PU- modified TDE-85/MeTHPA resin is improved.

Table 2 Thermal properties of TDE-85/MeTHPA resin and PU-modified TDE-85/MeTHPA resin

4 Conclusions

1) The EP polymer network (Ⅰ) is obtained by the curing reaction between TDE-85 and MeTHPA, while the PU polymer network (Ⅱ) is obtained by the chain- extended and crosslinking reactions of 1,4-BDO, TMP and PUP. The PU-modified TDE-85/MeTHPA epoxy resin designed presents two-phase (PU, EP) structure. At phase interface, networks (Ⅰ) and (Ⅱ) interpenetrate and tangle highly with each other, which form the representative IPN structure.

2) The PU-modified TDE-85/MeTHPA epoxy resin is prepared with PPG (number average molecular mass of 1 000) and PUP (15% in mass ratio to total content). Its tensile strength is 69.39 MPa, its impact strength is 23.56 kJ/m2, its t1% is 300 ℃, and its t50% is 378 ℃. Compared with the properties of TDE-85/MeTHPA resin, the tensile-strength, impact strength, t1% and the t50% of the modified resin are increased by 48%, 115%, 30 ℃ and 11 ℃, respectively. The comprehensive pro- perties of PU-modified TDE-85/MeTHPA epoxy resin are improved due to the formation of PU/EP IPN structure.

References

[1] LI Gui-lin. Epoxy resin and epoxy coatings [M]. Beijing: Chemical Industry Press, 2003: 73-75. (in Chinese)

[2] ZHANG Chun-hua, HAN Bing, HUANG Yu-dong. Study on properties of TDE-85/aromatic diamine matrix and carbon fiber composites [J]. Journal of Harbin University of Science and Technology, 2000, 5(5): 60-63. (in Chinese)

[3] HE Shang-jin, SHI Ke-yu, BAI Jie. Studies on the properties of epoxy resins modified with chain-extended ureas [J]. Polymer, 2001, 42(23): 9641-9647.

[4] CHEN C H, CHEN M H. Synthesis, thermal properties, and morphology of blocked polyurethane/epoxy full-interpenetrating polymer network [J]. Journal of Applied Polymer Science, 2006, 100(1): 323-328.

[5] XIE Hong-quan, GUO Jun-shi. Room temperature synthesis and mechanical properties of two kinds of elastomeric interpenetrating polymer networks based on castor oil [J]. European Polymer Journal, 2002, 38(11): 2271-2277.

[6] KRISHNAN S M. Studies on corrosion resistant properties of sacrificial primed IPN coating systems in comparison with epoxy-PU systems [J]. Progress in Organic Coatings, 2006, 57(4): 383-391.

[7] JIA Qing-ming, ZHENG Mao-sheng, CHEN Hong-xiang, SHEN Ren-jie. Morphologies and properties of polyurethane/epoxy resin interpenetrating network nanocomposites modified with organoclay [J]. Materials Letters, 2006, 60(9/10): 1306-1309.

[8] BHUNIYA S, ADHIKARI B. Toughening of epoxy resins by hydroxy-terminated, silicon-modified polyurethane oligomers [J]. Journal of Applied Polymer Science, 2003, 90(6): 1497-1506.

[9] CHEN Chin-hsing, SUN Yun-yun. Mechanical properties of blocked polyurethane/epoxy interpenetrating polymer networks [J]. Journal of Applied Polymer Science, 2006, 101(3): 1826-1832.

[10] LI Jin-bo. High performance epoxy resin nanocomposites containing both organic montmorillonite and castor oil-polyurethane [J]. Polymer Bulletin, 2006, 56(4/5): 377-384.

[11] MA Xiao-yan, YUAN Li, JIA Qiao-ying. Composites of epoxy resin and BMIPBA reinforced with aluminum borate whiskers [J]. Journal of Materials Science and Engineering, 2003, 21(6): 789-792. (in Chinese)

[12] JIANG Li-xiang, SHENG Lei, CHEN Ping. Study on effect of proton irradiation on epoxy resin 648 and TDE-85 [J]. Spacecraft Environ- ment Engineering, 2006, 23(3): 134-137. (in Chinese)

[13] JI Ke-jian, LIU Yuan-jun, ZHANG Yin-sheng. NMR characteriza- tion of epoxy resin [J]. Thermosetting Resin, 2000, 15(1): 9-12. (in Chinese)

[14] WEN Qing-zhen, ZHU Jin-hua, WANG Yuan-sheng. The influence of chain extenders on the reaction rate of polyether-urethane prepolymers [J]. Journal of Naval University of Engineering, 2003, 15(1): 23-26. (in Chinese)

[15] LI Zhi-hua, KE Yu-peng, REN Dong-yan, ZHENG Zi-qiao. Structural characteristics and properties of PU-modified TDE-85/ MeTHPA epoxy resin [J]. Journal of Central South University of Technology, 2007, 14(6): 753-758.

(Edited by CHEN Wei-ping)

Foundation item: Project(2003AA84ts04) supported by the National High-Tech Research and Development Program of China

Received date: 2007-07-18; Accepted date: 2007-09-22

Corresponding author: LI Zhi-hua, PhD; Tel: +86-731-8830838; E-mail: ligfz@mail.csu.edu.cn