文章编号:1004-0609(2013)08-2267-07

TiAlCrN涂层的高温氧化行为

王赛玉1,蔺绍江1,陈 肖2

(1. 湖北理工学院 机电工程学院,黄石 435003;

2. 华中科技大学 材料成形与模具技术国家重点实验,武汉 430074)

摘 要:对Ti(C,N)基金属陶瓷基体上沉积的TiAlCrN涂层在800~1 000 ℃静态空气中的氧化行为进行研究,并与在相同实验条件下的TiAlN涂层以及Ti(C,N)基金属陶瓷基体的氧化行为进行比较。采用分析天平、XRD和SEM (EDS)等分析测试手段对涂层和金属陶瓷基体的高温氧化质量增加特性、氧化产物的物相以及氧化膜的表面和截面形貌进行了研究。结果表明:TiAlCrN涂层在800、900和1 000 ℃的静态空气中氧化质量增加速率最小,氧化膜的表面颗粒也最细小;TiAlCrN涂层在1 000 ℃的氧化产物为TiO2、Al2O3以及少量非计量化合物Cr2O2.4;TiAlCrN涂层在1 000 ℃氧化4 h形成的氧化膜内部有一富含Al2O3和Cr氧化物的氧化层,富Al、Cr内层对氧离子向涂层内部扩散具有强烈的阻碍作用;Cr元素提高涂层中贫Al区的抗氧化性能以及与Al2O3形成(Al, Cr)2O3阻止氧向内扩散,使得TiAlN涂层添加Cr后高温抗氧化能力得到提高。

关键词:TiAlCrN涂层;氧化行为;氧化膜;扩散

中图分类号:TG174.45 文献标志码:A

High temperature oxidation behavior of TiAlCrN coating

WANG Sai-yu1, LIN Shao-jiang1, CHEN Xiao2

1. School of Mechanic and Electric Engineering, Hubei Polytechnic University, Huangshi 435003, China;

2. State Key Laboratory of Material Processing and Die and Mould Technology, Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: The oxidation behaviour of TiAlCrN coating deposited on Ti(C,N)-based cermet was investigated in static air at 800-1 000 ℃. The oxidation behaviours of TiAlN coating and Ti(C,N)-based cermet substrate also were compared under the same condition. The analytical balance, XRD and SEM(EDS) were employed to observe high temperature oxidation mass gains, oxide phase identification and oxide film morphology of coatings and substrate. The results show that the mass gains rate of TiAlCrN coating is the lowest in 800, 900 and 1 000 ℃ static air among these samples. The oxidation products at 1 000 ℃ are TiO2, Al2O3 and a little of non-stoichiometric compound Cr2O2.4. There is a Al2O3-rich and Cr-rich oxide layer in the TiAlCrN coating oxide film, and this oxide layer hinders the diffusion of oxygen ions to the inner. Cr improves the oxidation resistance of Al-poor areas in TiAlCrN coating and reacts with Al2O3 to form (Al, Cr)2O3, thereby, the oxidation resistance of TiAlN coating is improved after Cr is added.

Key words: TiAlCrN coating; oxidation behaviour; oxide film; diffusion

TiN基硬质涂层具有较高硬度、较高耐磨性、优异的化学稳定性以及与金属间低的摩擦因数,因此,其常作为保护性涂层广泛应用于切削刀具、模具的表面,以提高工模具的使用效率和寿命[1-2]。在金属材料的切削加工中,硬质涂层不仅可以增加刀具的表面硬度和耐磨性,还起到热屏障作用,避免大量的切削产生的热量传导至基体,使得在较高温度下仍能保持刀具基体材料的高强韧性。当涂层被氧化后再进行切削加工时,涂层不再对刀具基体产生保护作用,同时刀具的力学性能急剧下降,从而降低刀具的使用效率和耐用度。因此,研究涂层的高温抗氧化能力,对提高涂层的适用性和耐用度具有十分重要的意义。

高硬度的TiN涂层(显微硬度约2 000 HV [3])是当前使用最广泛的硬质涂层材料之一,但是TiN在使用温度超过550 ℃时会迅速氧化生成TiO2,从而使涂层失效[4-5]。在TiN二元涂层体系加入Al元素形成的TiAlN涂层的研究具有里程碑意义[6],由于TiAlN具有更高的硬度(显微硬度约3 000 HV [3])和优异的高温抗氧化性能(开始氧化温度在800 ℃以上[7-8]),因此,其迅速被广泛应用于高速切削刀具领域。已有研究表明:向TiAlN系涂层中添加少量的Cr能进一步提高涂层的抗氧化温度。文献[9]研究指出,在Ti0.46Al0.54N涂层中添加0.03 Cr可将涂层的开始氧化温度从870 ℃提高到920 ℃[9]。YAMAMOTO等[10]研究指出,向Ti0.1A10.73N涂层中添17%(质量分数)的Cr可使涂层的抗氧化温度接近1 000 ℃。虽然向TiAlN系涂层中引入Cr能提高涂层的抗氧化温度已经获得证实,但目前Cr元素在TiAlN系涂层中的抗氧化机理的研究和分析并不深入。因此,本文作者对Ti(C,N)基金属陶瓷基体上沉积的TiAlCrN涂层在高温静态空气中的氧化行为进行研究,并与在相同实验条件下获得的TiAlN涂层和Ti(C,N)基金属陶瓷基体的氧化行为进行比较,对Cr元素提高抗氧化能力的相关机理进行分析和探讨。

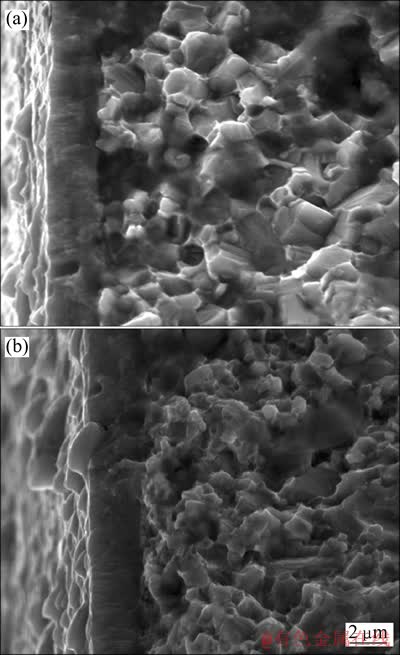

1 实验

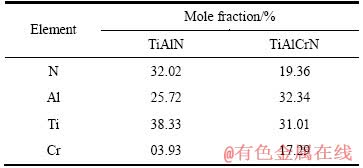

Ti(C,N)基金属陶瓷基体材料是采用传统的粉末冶金工艺制备的,其主要化学成分为(质量分数)TiC-10%TiN-6.5%WC-16%Mo-20%Ni。涂层是采用长沙神弧离子镀膜有限公司的DHD-08型多功能等离子体镀膜仪完成的,分别使用合金Cr靶、Ti靶和Al靶制备TiAlCrN和TiAlN涂层,厚度分别为3 μm和2.5 μm(如图1所示)。工作气体采用工业纯氩(99.9%)和工业高纯氮气(99.999%)。具体过程为:将经过处理的基体试样装入炉中,抽至极限真空(2 mPa)后,通入氩气至5~10 Pa,基体加上900 V的负偏压,持续10 min。加热基体至500 ℃,启动Cr靶,基体偏压为-300 V,沉积Cr底层,时间为5 min;启动Ti靶,基体偏压为-300 V,沉积Ti过渡层,时间为5 min;之后通入适量的工作气体,适当调整Ti靶和Cr靶电流(沉积TiAlN时,Cr靶关闭),启动Al靶(靶电流控制在100~150 A)并降低基体偏压至-100 V,沉积TiAlCrN(或TiAlN)涂层,沉积时间为60 min。沉积结束后,待试样冷却至50 ℃以下后出炉。TiAlCrN和TiAlN涂层的化学成分如表1所列。TiAlN涂层成分中的Cr来自于涂层与基体间的Cr过渡层,该过渡层的存在有利于提高涂层与基体间的结合力。图2所示为沉积态涂层的XRD谱。

图1 涂层的截面显微照片

Fig. 1 Cross-sectional micrographs of TiAlCrN(a) and TiAlN(b) coatings

表1 涂层的化学成分

Table 1 Chemical composition of coatings

图2 TiAlCrN与TiAlN涂层的XRD谱

Fig. 2 XRD patterns of TiAlCrN and TiAlN coatings

氧化试验是在高温氧化炉中进行的。试样在800、900及1 000 ℃的静态空气中氧化4 h,每隔1 h取出一组试样(每组试样中包含3类样品),冷却至室温后称取试样的净质量,获得试样净质量的变化,并换算成单位面积的质量变化,绘制其氧化动力学曲线。试样的质量称取是在TG-328A型分析天平上进行的,其测量精度是±0.1 mg。采用Philips X’Pert Pro型X射线衍射仪鉴定氧化产物的物相,采用QUANTA 200型环境扫描电子显微镜(SEM)观察氧化物表面和截面形貌。并使用其配备的能谱分析仪(EDS)进行微区成分分析。

2 结果与分析

2.1 涂层的氧化动力学

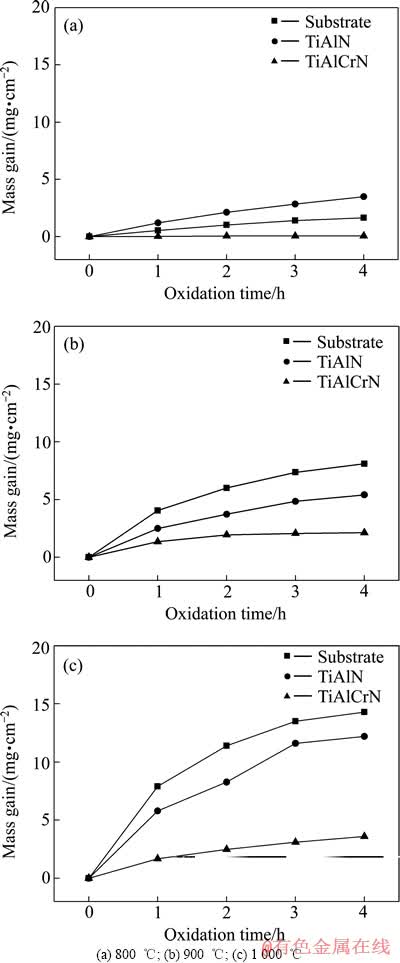

金属陶瓷基体材料和TiAlCrN、TiAlN涂层在不同温度下的氧化增重曲线如图3所示。不同温度下金属陶瓷基体、TiAlN涂层和TiCrAlN涂层的氧化质量增加曲线都满足抛物线规律,说明3类材料都具有一定的抗氧化能力。并且3类试样的氧化质量增加速率由大到小依次为金属陶瓷基体、TiAlN、TiAlCrN,这表明在这3类材料中TiAlCrN涂层具有最优异的抗氧化能力。TiAlCrN涂层在800 ℃下氧化4 h后质量几乎未发生变化,这也进一步说明了TiAlCrN涂层具有极强的抗氧化能力。氧化质量增加呈抛物线规律是因为在氧化初始阶段,氧化过程的控制步骤为空气中的氧与试样表面的化学反应,此时主要是氧原子与试样表面原子的吸附,并且氧原子与试样表面的金属原子间的结合力由范德华力转变为化学键,其中的转变过程较为复杂而速率较快;随着氧化过程的进行,氧化反应由化学吸附向形成氧化膜转变,试样进入稳态氧化阶段,氧化控制步骤为氧离子和金属离子在氧化层中的扩散,此时氧化速率较低,其原因是表面形成的氧化膜能够有效地阻碍氧离子向内扩散,并且随着氧化过程的进行氧化膜厚度增加,离子的扩散距离越来越大[11]。

图3 涂层和金属陶瓷基体在不同温度下的氧化质量增加曲线

Fig. 3 Oxidation mass gain curves of coatings and substrate at different temperatures

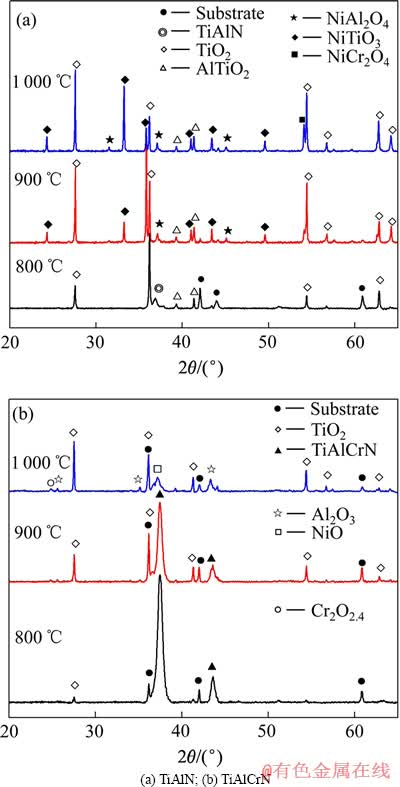

2.2 涂层氧化产物的物相分析

TiAlN涂层高温氧化产物的物相分析如图4(a)所示。经800 ℃氧化4 h后,TiAlN的衍射峰强度与未氧化时相比明显降低,表明TiAlN涂层已开始发生氧化,其氧化产物主要是TiO2。在TiAlN涂层800 ℃氧化4 h后,仍检测到了TiAlN和基体的衍射峰,这说明此时涂层的氧化程度不大而氧化层厚度较小;随着氧化温度增加至900 ℃,TiO2衍射峰增强,且基体的衍射峰消失,这表明涂层发生了进一步氧化,氧化层的厚度增加。此外,氧化层中还检测到了AlTiO2、NiAl2O4和NiTiO3这3种氧化物,它们是在TiAlN涂层被氧化后形成TiO2、Al2O3和NiO的基础上在高温下继续相互发生反应而产生的,其中Ni元素来自于基体的粘结相。TiAlN涂层经1 000 ℃氧化后的XRD谱与900 ℃时的XRD谱非常相似,只是在54°衍射角附近NiCr2O4衍射峰强度增大,这可能是由于氧离子扩散至涂层与基体界面结合处,与涂层中的Cr底层和基体中的Ni发生反应而生成的。从TiAlN涂层的XRD谱可以看出,随着氧化温度升高,TiAlN涂层的氧化变得更加剧烈。

图4(b)所示为TiAlCrN涂层在不同温度下氧化4 h后的XRD谱。TiAlCrN在800 ℃氧化4 h后的XRD谱与沉积态几乎相同,只是在27.5°衍射角附近出现了微弱的TiO2衍射峰,说明TiAlCrN涂层仅发生了极微弱的氧化。且随着氧化温度上升,TiO2衍射峰强度有所增加,但依然可以检测到较强的TiAlCrN衍射峰和基体的衍射峰,这表明涂层的氧化程度很小;当氧化温度升高至1 000 ℃时,TiAlCrN涂层的衍射峰消失,氧化程度增大,但仍能检测到基体的衍射峰,这说明氧化层的厚度较小。氧化产物除TiO2外,还有Al2O3以及少量的NiO和Cr2O2.4。这种非计量化合物Cr2O2.4的生成表明涂层中氧原子的量不足,这说明TiAlCrN涂层形成的氧化膜有效地阻止了氧离子向涂层内部的扩散。对比图2和3可以看出,TiAlCrN涂层的抗氧化能力明显强于TiAlN涂层的,这与2.1中的氧化质量增加实验得到的结论是一致的。

2.3 涂层氧化膜的表面形貌

图5所示为金属陶瓷基体试样以及TiAlN、TiAlCrN涂层在800 ℃氧化4 h后的表面形貌。由图5可看出,表面都有颗粒状的氧化物生成,三者中金属陶瓷基体的表面颗粒较大,TiAlCrN涂层的表面颗粒最小。3类试样在900 ℃和1 000 ℃氧化后表面颗粒尺寸也有相同的规律。以上实验现象表明,TiAlCrN涂层具有最优异的高温抗氧化性能。试样处于高温时,表面发生氧化反应,产生的氧化物形核并逐渐长大,从而形成了表面的颗粒状氧化物。根据XRD的分析可知,涂层中的Al、Cr元素氧化后形成了含Al或Cr的氧化物,例如Al2O3、NiCr2O4、NiAl2O4等,这些氧化物结构致密且稳定性好,它们在涂层表面生成后,能够有效地阻碍氧离子向涂层内部扩散和金属阳离子向外扩散,从而使得氧化物颗粒不易长大,故氧化物颗粒细小。而Ti(C,N)基金属陶瓷的高温氧化层主要由TiO2、NiO以及它们的复合氧化物组成[12-13],与含Al或Cr的氧化膜相比,这种氧化膜在氧化过程中阻碍氧 原子向内部扩散的能力较弱,因此,氧原子能够向里扩散并与内部的原子反应,从而使得金属陶瓷表面的氧化物颗粒继续长大。

图4 涂层在不同温度下氧化4 h后的XRD谱

Fig. 4 XRD patterns of coatings after oxidation at different temperatures for 4 h

在图5中可以看到涂层的表面存在一些团簇状的大颗粒。在多弧离子镀工艺中,采用靶材溅射制备涂层时通常会在涂层的表面形成大的液滴[14],因此,可以确定这些大颗粒为液滴氧化后形成的。KAWATE等[7]指出液滴具有芯-壳结构,其表面为反应生成的氮化物和沉积的氮化物,内部为靶材金属。与金属材料相比,液滴表面的氮化物陶瓷涂层在高温氧化时具有较好的抗氧化性能,这使得液滴表面的氧化物颗粒不会有较大程度的长大,如图5(c)所示。但随着氧化温度的增加或氧化时间的延长,氮化层被消耗掉,氧化过程转变为氧与金属靶材的反应,而金属的抗氧化能力远低于陶瓷涂层的,因而氧化速度较快,氧化物晶粒的生长速度也较快,如图5(d)所示,为TiAlCrN涂层在900 ℃氧化4 h后的表面形貌。与800 ℃时相比,由于氧化温度上升导致氮化层很快被消耗掉,靶材金属迅速被氧化,此时的液滴上形成的氧化物晶粒明显长大,并以柱状晶的形式向周围生长。

图5 金属陶瓷基体和涂层在不同温度下氧化4 h后的表面形貌

Fig. 5 Surface morphologies of substrate and coatings after oxidation at different temperatures for 4 h

在图5(a)中,Ti(C,N)基金属陶瓷表面的氧化层出现了开裂和剥落的现象。YANG等[13]指出,Ti(C,N)基金属陶瓷外氧化层主要是NiO。这是在因为金属陶瓷与陶瓷相Ti(C,N)相比,金属相Ni在高温下容易被氧化生成NiO。但是随着氧化过程的进行,Ti(C,N)陶瓷也会发生缓慢氧化生成TiO2。由于在较宽的温度范围内,与Ni相比,Ti对氧的亲和力更大,生成的氧化物也更稳定,所以Ti容易作为选择性氧化的合金元素优先发生氧化。因此,Ti会夺取NiO中的氧形成稳定性更高的TiO2。然而由于NiO的体积大于金属Ni的体积(NiO的生成氧化物分子的体积和其金属离子的体积比(简称体积膨胀比,PBR值)为1.65[11]),且Ti(C,N)和TiO2的摩尔体积差异较大(分别约为11.4 cm3/mol和18.9 cm3/mol[8]),这导致了氧化膜中存在较大的压应力,超过了氧化膜的结合强度,从而产生了开裂和剥落,这也造成了氧进一步与材料内部反应,加快了材料的腐蚀。

2.4 Cr元素的作用

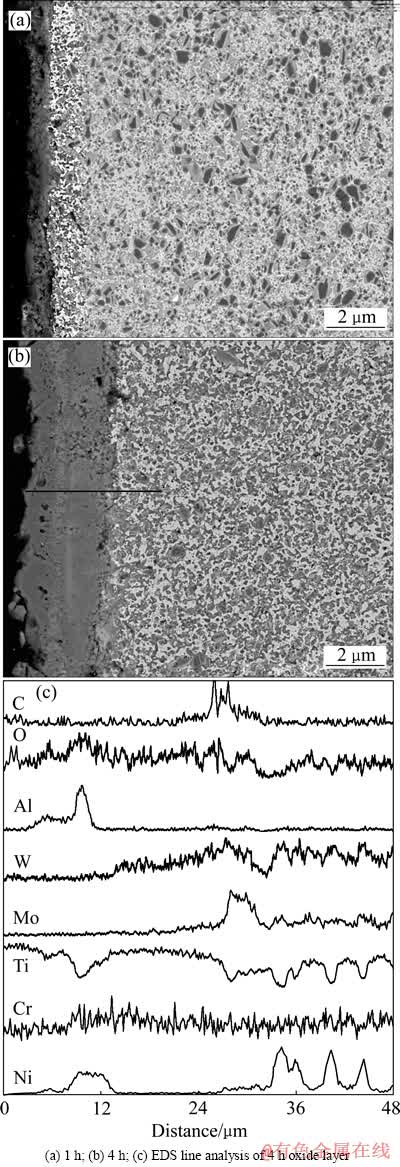

图6 TiAlCrN涂层在1 000 ℃氧化不同时间后的截面形貌和EDS线分析

Fig. 6 Cross-section morphologies and EDS line analysis of TiAlCrN coating after oxidation at 1 000 ℃ for different times

图6所示为TiAlCrN涂层在1 000 ℃氧化1和4 h后的截面形貌和EDS分析。由图6可看出,经1 000 ℃氧化1 h和4 h后,氧化层厚度分别约为11 μm和30 μm,这表明此时涂层已经被氧化,氧离子已经穿过涂层的氧化层与基体发生了反应。从图6(a)中可以看到,在氧化层和未氧化的基体之间存在一个与基体组织相似但相对细小的过渡转变区,这与YANG等[12-13]发现的Ti(C,N)基金属陶瓷的氧化后的截面结构是一致的,这一过渡转变区为金属陶瓷基体未完全氧化所形成的,且由于氧化时间的增加,在图6(b)中的过渡层厚度已有非常明显的增加。图6(a)和(b)中的氧化层都有不同程度的剥落,且都存在一些细小的孔洞,这可能与挥发性氧化物的形成(例如CrO3、WOx)以及C和N元素被氧化形成CO和N2气体有关[8, 13]。图6(c)所示为图6(b)中划线部分氧化层的能谱线分析。从线分析以及图4(b)中的XRD分析结果可以得出:TiAlCrN涂层的氧化层最外层为TiO2。在距离氧化膜-空气界面约10 μm 处,Ti浓度达到一个低谷,而Al浓度上升到峰值,并且Cr浓度也有所增加。结合XRD分析结果可以判断,在氧化膜这个位置形成了一层富含Al2O3和Cr氧化物的氧化层;随着距氧化层-过渡层界面越来越近,W、Mo的浓度逐渐升高。此外,从氧化层能谱线分析可以发现,基体中元素Ni的扩散距离远大于W和Mo的,这种现象可能与它们的离子半径以及扩散激活能的差异有关。

在TiAlCrN的氧化层中存在一层富含Al2O3和Cr氧化物的氧化层,而正好在这一位置氧的浓度也达到峰值(图6(c)),这说明该富Al、Cr的氧化层对氧离子向涂层内部具有强烈的阻碍作用,这也是TiAlCrN 涂层具有优异抗氧化性的原因。已有许多学者研究表明TiAlN涂层的氧化层分为两层[8, 15-16]:外层主要为Al的氧化物,而内层主要为Ti的氧化物;表面形成的致密的富含Al的氧化层有效地阻止氧离子向涂层内部扩散。富含Ti的内氧化层对涂层的抗氧化性能也有着重要作用,内氧化层含Al量越高,生长越缓慢,涂层的抗氧化性也越好。这种双层氧化层是O2-向里扩散和Al3+向外扩散形成的。由于Al对氧具有非常高的亲和力,且Al2O3的吉布斯生成自由能较低,因此,Al3+向氧化膜和空气界面扩散的驱动力非常大,尺寸较小的Al3+的迁移主要是通过晶界扩散来完成[16],TiAlN涂层中的Cr元素可以降低Al元素发生选择性氧化的所需临界浓度,使其能够形成连续致密Al2O3膜的临界浓度降低[11],这种效应对于贫Al区的抗氧化能力的提高具有很大的促进作用。此外,本研究中发现的富含Al2O3和Cr氧化层的作用与FOX-RABINOVICH等[17]提出的“Cr效应”是一致的,Cr2O3能够溶解于Al2O3形成(Al,Cr)2O3,这种氧化物不仅能促进Al基氧化物通过扩散生长,而且与氧的亲和力低,能够有效地阻止氧离子向内扩散。因此,与TiAlN涂层相比,TiCrAlN涂层显示出更优越的抗氧化能力。

3 结论

1) TiAlCrN涂层、TiAlN涂层和金属陶瓷基体在800、900和1 000 ℃的静态空气氧化实验中,金属陶瓷基体的质量增加速率最大,TiAlCrN涂层的质量增加速率最小;氧化后,金属陶瓷基体试样表面氧化物颗粒较大并且氧化膜出现开裂,而涂层试样表面氧化物颗粒细小,无开裂现象。涂层表面出现的一些大的团簇状氧化物为涂层表面液滴的氧化产物,且随着氧化过程加剧,它们以柱状晶形式向周围快速生长。

2) TiAlCrN涂层在1 000 ℃的氧化产物主要为TiO2、Al2O3以及少量的Cr2O2.4,非计量化合物Cr2O2.4的生成说明TiAlCrN涂层的氧化膜对氧向涂层内部扩散具有有效的阻碍作用,使得TiAlCrN涂层的氧化层中氧含量不足,体现了TiAlCrN涂层优异的高温抗氧化能力;TiAlCrN涂层在1 000 ℃氧化后,氧化层的最外层为TiO2,氧化层内部有一富含Al2O3和Cr氧化物的氧化层,富Al、Cr内层对氧离子向涂层内部扩散具有强烈的阻碍作用。

3) Cr元素提高了涂层中贫Al区的抗氧化性能以及与Al2O3形成(Al, Cr)2O3阻止氧向内扩散,使得TiAlN涂层添加Cr后的抗氧化能力得到提高。

REFERENCES

[1] LOGOTHETIDIS S, KALFAGIANNIS N, SARAKINOS K, PATSALAS P. Investigation of bilayer period and individual layer thickness of CrN/TiN superlattices by ellipsometry and X-ray techniques[J]. Surface and Coatings Technology, 2006, 200: 6176-6180.

[2] QU J, XIONG W H, YE D M, YAO Z H, LIU W J, LIN S J. Effect of WC content on the microstructure and mechanical properties of Ti(C0.5N0.5)-WC-Mo-Ni cermets[J]. International Journal Refractory and Hard Materials, 2010, 28: 243-249.

[3] MAJOR L, MORGIEL J, MAJOR B, LACKNER J M, WALDHAUSER W, et al. Crystallographic aspects related to advanced tribological multilayers of Cr/CrN and Ti/TiN types produced by pulsed laser deposition (PLD)[J]. Surface and Coatings Technology, 2006, 200: 6190-6195.

[4] LI Yan, LIU Ning, ZHANG Xiao-bo, RONG Chun-lan. Effect of carbon content on the microstructure and mechanical properties of ultra-fine grade (Ti,W)(C,N)-Co cermets[J]. Journal of Materials Processing Technology, 2008, 206(1/3): 365-373.

[5] ZYWITZKI O, KLOSTERMANN H, FIETZKE F, MODES T. Structure of superhard nanocrystalline (Ti,Al)N layers deposited by reactive pulsed magnetron sputtering[J]. Surface and Coatings Technology, 2006, 200: 6522-6526.

[6] CHIM Y C, DING X Z, ZENG X T, ZHANG S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc[J]. Thin Solid Films, 2009, 517: 4845-4849

[7] KAWATE M, SUZUKI T, KAWATEA M, HASHIMOTOB A K, SUZUKI T. Oxidation resistance of Cr1-xAlxN and Ti1-xAlxN films[J]. Surface and Coatings Technology, 2003, 165: 163-167.

[8] VAZ F, REBOUTA L. Thermal oxidation of Ti1-xAlxN coatings in air[J]. Journal of the European Ceramic Society, 1997(17): 1971-1977.

[9] DONOHUE L A, SMITH I J, MNNZ W D, PETROV I, GREENE J E. Microstructure and oxidation-resistance of Ti1-x-y-zAlxCryYzN layers grown by combined steered-arc/ unbalanced-magnetron-sputter deposition[J]. Surface and Coatings Technology, 1997, 94/95: 226-231.

[10] YAMAMOTO K, SATO T, TAKAHARA K, HANAGURI K. Properties of (Ti,Cr,Al)N coatings with high Al content deposited by new plasma enhanced arc-cathode[J]. Surface and coating Technology, 2003, 174/175: 620-626.

[11] 李美栓. 金属的高温腐蚀[M]. 北京: 冶金工业出版社, 2001: 80.

LI Mei-shuan. High temperature corrosion of metal[M]. Beijing: Metallurgical Industry Press, 2001: 80.

[12] YANG Qing-qing, XIONG Wei-hao, LI Shi-qi, DAI Hong-xia, LI Jun. Characterization of oxide scales to evaluate high temperature oxidation behavior of Ti(C,N)-based cermets in static air[J]. Journal of Alloys and Compounds, 2010, 506: 461-467.

[13] YANG Qing-qing, XIONG Wei-hao, LI Shi-qi, YAO Zhen-hua, CHEN Xiao. Early high temperature oxidation behaviour of Ti(C,N)-based cermets in air[J]. Corrosion Science, 2010, 52: 3205-3211.

[14] CHEN Li, DU Yong, WANG S Q, WANG A J, XU H H. Mechanical properties and microstructural evolution of TiN coatings alloyed with Al and Si[J]. Materials Science and Engineering A, 2009, 509: 139-143.

[15] KIM C W, KIM K H. Anti-oxidation properties of TiA1N film prepared by plasma-assisted chemical vapor deposition and roles of A1[J]. Thin Solid Films, 1997, 307: 113-119.

[16] ICHIMURA H, KAWANA A. High-temperature oxidation of ion-plated TiN and TiAIN films[J]. Materials Research Society, 1993, 8(5): 1093-1100.

[17] FOX-RABINOVICH G S, WEATHERLY G C, WILKINSON D S, KOVALEV A I, WAINSTEIN D L. The role of chromium in protective alumina scale formation during the oxidation of ternary TiAlCr alloys in air[J]. Intermetallics, 2004, 12(2): 165-180.

(编辑 李艳红)

基金项目:湖北省自然科学基金资助项目(2012FFC017)

收稿日期:2012-06-25;修订日期:2012-10-06

通信作者:王赛玉,教授,博士;电话:0714-6351903;E-mail: jiang109147@126.com