铜闪速炉沉淀池渣中锍液滴沉降机理及其影响因素

周 萍, 余建平, 陈红荣, 梅 炽

(中南大学 能源科学与工程学院, 长沙 410083)

摘 要: 通过分析沉淀池内锍液滴的沉降机理, 导出了渣中最大锍液滴直径的计算公式。 根据闪速炉的实际生产条件, 计算出渣中最大锍液滴直径的理论值为0.063mm, 并用矿相显微镜对沉淀池出口处的渣样进行了观察, 渣中最大锍颗粒粒径为0.06mm, 两者结果一致。 由此证明了沉降机理分析的正确性。 在此基础上, 进一步分析渣中锍夹带损失影响因素。 结果表明: 增大熔体中离散态分布的锍液滴直径是降低渣中铜夹带损失的重要措施; 其次是升高渣温度有助于渣中锍的沉降; 减小渣层厚度等措施对降低渣中铜夹带损失作用不大。

关键词: 闪速炉; 沉淀池; 锍液滴; 沉降 中图分类号: TF801

文献标识码: A

Settling mechanism and influencing factors on matte droplets in settler slag of copper flash smelting furnace

ZHOU Ping, YU Jian-ping, CHEN Hong-rong, MEI Chi

(School of Energy Science and Engineering,Central South University, Changsha 410083, China )

Abstract: By analyzing the settling mechanism of the matte droplets in settler, the formulas for maximum diameter of matte particle were derived. Based on the real operating data in the copper flash smelting furnace, the theoretical value of maximum diameter of matte particle was calculated to be 0.063mm. Moreover, the slag at the outlet of settler was observed using ore microscope and the maximum diameter of matte droplets was 0.06mm. The theoretical value of maximum diameter is in good agreement with the observed value. Thus, the validity of analysis of settling mechanism was verified. Based on the above results, factors of copper loss in slag were analyzed. The results indicate that firstly, increasing the diameters of discrete matte droplets in slag is an important means to reduce copper loss in slag; secondly, it is also helpful to reduce copper loss by raising the temperature of slag, but it has little effect by reducing the thickness of the slag layer.

Key words: flash smelting furnace; settler; matte droplets; settling

自20世纪80年代以来, 以高投料量、 高铜锍品位、 高富氧浓度、 高容积热强度为代表的“四高”技术措施, 使闪速炉在本体结构保持基本不变的前提下, 实际生产能力比最初设计值提高一倍以上, 生产率大幅度提高而生产成本进一步下降, 使闪速炉成为火法炼铜的主流设备。 目前, 闪速熔炼铜产量已占世界铜产量的45%以上[1-3]。 然而, 闪速熔炼的“四高”发展趋势, 给闪速炉沉淀池生产管理带来了许多新问题[4-5]。 其中一个重要问题是: 高投料量导致熔体在沉淀池内流速加快, 渣锍分离时间缩短, 闪速炉渣含铜升高, 从而增加下游设备贫化电炉的负担, 间接引起弃渣含铜升高[6-8]。

为了降低闪速炉渣含铜, 各工厂从生产实践的角度提出了众多相应技术措施[9-10], 如采取薄渣层操作、 提高沉淀池熔体温度等措施, 收到一定效果, 但渣含铜还是相对较高。 生产实践及相关资料表明, 沉淀池出口渣中铜机械夹杂损失占到总铜损失的50%以上[11-12], 对闪速炉渣实测结果也表明渣中铜以硫化物态铜损失的占到64%, 而且硫化态铜多以众多的、 细小的铜锍颗粒的形态存在。 这充分说明, 降低机械夹杂损失是降低沉淀池渣含铜的关键。 由于造成铜机械夹杂损失的主要原因是沉淀池渣中部分未能完全沉降的锍颗粒引起的。 因而, 对沉淀池内锍颗粒沉降规律进行深入研究, 将有助于提高沉淀池渣锍分离效率、 降低闪速炉渣含铜。

1 锍液滴在沉淀池内的运动过程

大小不同的熔滴(渣与锍的混合物)自反应塔落入沉淀池后, 由于锍液滴密度较大向熔池底部沉降, 而渣的密度较小向上浮。 因此, 在沉淀池内熔体分为渣层与锍层上下两层。 锍液滴在熔渣中的运动可看成水平方向和垂直方向运动的合成(见图1)。 在水平方向上, 锍液滴和渣一起向渣出口方向运动。 在垂直方向上, 锍液滴要穿过渣层向熔池底部的锍层沉降。 很显然, 直径较大的锍液滴经过一段时间后穿过渣层进入锍层, 而直径较小的锍液滴没有足够的沉降时间进入锍层, 随渣流出沉淀池, 形成机械夹杂损失。 实验中将渣流出沉淀池时, 恰能进入锍层的锍液滴直径称为最大锍液滴直径记为dmax, 最大锍液滴直径间接反映了渣中铜机械夹杂损失的大小。 当dmax较大时, 表示渣中含有大液滴的锍, 那么渣中铜机械损失较大, 因而在生产中希望渣中所能存在的最大锍液滴直径越小越好。

图1 锍液滴沉降轨迹示意图

Fig.1 Sketch of settling track of matte droplet

为清楚起见, 分别讨论锍液滴在水平与与垂直方向的运动, 并在讨论前对锍液滴沉降过程作如下简化:

1) 不考虑锍液滴之间的碰撞长大、 分裂破碎;

2) 不考虑沉淀池内SO2气泡对锍液滴沉降过程的影响;

3) 假设沉淀池连续、 稳定排放渣, 即认为沉淀池内熔渣呈活塞流、 匀速流动。

1.1 锍液滴水平方向的运动

沉淀池内锍液滴水平运动速度与渣的流速相同, 可由下式求出:

将式(2)代入式(1)得锍液滴在水平方向速度:

当沉淀池的长度为l时, 锍液滴在沉淀池内的停留时间tx

1.2 锍液滴垂直方向的运动

由于锍液滴以一定的初速度落入沉淀池, 在垂直方向锍液滴运动过程是个非匀变速沉降过程。 其速度与位移的表达式可由微分方程精确描述。 对微分方程的求解结果表明: 锍液滴的初速度对液滴的沉降时间的影响可忽略不计; 在所研究的粒径范围内, 锍液滴在垂直方向的瞬时沉降速度v可近似由Stokes沉降速度公式表示为[13]

式中 μs为渣的动力粘度, kg/(m·s)。

则锍液滴从渣表面沉降到锍层所用时间ty为:

2 渣中最大锍液滴直径理论计算及工业测试

联立式(4)与(6)可得渣中最大锍液滴直径dmax的计算公式:

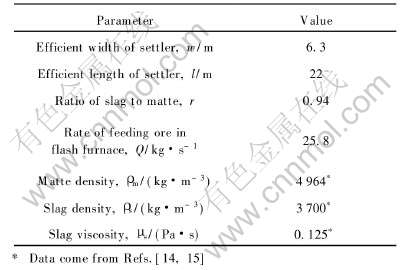

按闪速炉的实际生产条件(见表1), 由式(7)可计算出沉淀池出口处渣中能存在最大锍液滴直径不应超过0.063mm。

表1 计算锍液滴沉降时间的数据

Table 1 Data for calculating settling time of matte droplets

在Nikon透反两用矿相显微镜下, 对沉淀池出口处的渣样进行了矿相显微观察与分析。 结果表明: 渣中有大量的、 微小的、 未能沉降的锍颗粒, 其大多数直径小于0.01mm(见图2); 扩大显微镜观察范围, 观察到渣中有少量的粒径较大的锍颗粒, 其大部分为椭圆形。 这是由于锍颗粒在沉淀池内为液相, 液滴在下落过程中受重力、 摩擦阻力的影响及液滴表面张力的综合作用, 使得液滴近似成椭球形, 取样时采用的高温急冷方式, 保持了高温下椭球形的物理形态。 寻找样品中最大的锍颗粒, 并测量其粒径为0.051mm×0.071mm(见图3)。为了便于比较, 将椭球形锍颗粒换算成同等体积的球形颗粒。 以此作为椭球形锍颗粒的当量直径, 转换后实际锍颗粒的当量直径为0.060mm。

图2 沉淀池渣的显微照片

Fig.2 Ore micrograph of slag in settler(A refers to matte droplets)

图3 渣含最大锍颗粒处的显微照片

Fig.3 Ore micrograph of slag with maximum matte droplet

对比理论计算结果(0.063mm)与显微观察结果(0.060mm), 可知渣中最大锍液滴直径的理论计算值与实际测量值相符合。 这再次说明锍液滴沉降过程视为匀速过程是合理的。

3 渣中铜机械夹杂损失的影响因素

分析计算锍液滴在渣中沉降时间的式(6)及计算渣中最大锍液滴直径式(7)可看出, 渣中铜机械夹杂损失受闪速炉结构参数、 熔体物性参数和闪速炉工艺条件3方面的影响。

3.1 沉淀池结构参数的影响

1) 沉淀池长与宽对锍液滴沉降的影响

由式(7)不难看出, 渣中所能存在的最大锍液滴直径与沉淀池长度、 沉淀池宽度的平方根成反比, 这表明延长沉淀池长度及增大沉淀宽度可以减小渣中铜机械夹杂损失。 但事实上, 沉淀池昂贵的制造成本, 使企业不可能轻易改变其结构尺寸。 另外, 对沉淀池内流场模拟的结果也表明[13], 在沉淀池纵向截面(垂直于熔体流动方向的截面)上熔体流动不均匀, 有些区域流得过快, 而有些区域流动得很慢。 如再增大沉淀池宽度, 这种流动不均匀性更会加剧, 起不到降低熔体流速的作用。 因此, 通过加宽熔池宽度来降低渣中锍的夹带是很难奏效的。

2) 渣层厚度

直观上理解, 渣层薄, 渣中的锍易于沉降, 渣中铜机械夹杂损失低。 但是, 式(7)表明渣中所能存在的最大锍液滴直径与渣层厚度无关。

其原因主要是, 闪速炉正常生产时投料量是固定的, 因而进入熔池的渣量是固定的。 渣层薄时, 渣的流速快。 受渣的影响, 锍液滴水平方向速度也快, 锍液滴在沉淀池内的停留时间相应缩短。 这一因素, 抵消了渣层薄所带来的有益之处。 所以生产中想通过薄渣层操作来加速锍液滴的沉降, 即降低渣中铜机械夹杂损失是不可行的。

但是, 薄渣层操作有利于沉淀池上方重油燃烧热传导至锍层, 易使沉淀池内熔体温度均匀, 从这一方面来看, 薄渣层操作有利于生产。

3.2 熔体物性参数的影响

1) 渣与锍的密度差

沉淀池是依靠渣与锍的密度差来使渣与锍分层, 增大渣与锍的密度差将有助于熔池内渣的上浮, 锍的下沉。 式(7)也表明渣中最大锍液滴直径与渣锍密度差的平方根成反比。 由于渣与锍的密度差受到渣成分、 锍品位、 及渣温度的影响。 因而, 生产中调整闪速炉工艺参数时, 应综合考虑影响渣锍密度的因素, 尽可能控制渣与锍的密度差处于最大状态。

2) 渣温度

式(6)及式(7)均表明, 降低渣粘度有利于渣中锍液滴的沉降。 影响渣粘度的主要因素有温度及成分, 其中温度对粘度的影响较大(见图4)。

图5所示为锍液滴沉降时间与渣温度之间的关系。 从图5中可看出: ①随着炉渣温度的升高, 锍液滴穿过0.2m厚渣层所需的沉降时间也随之缩短; ②对于小粒径的液滴, 提高渣温的作用更加明显。 ③渣温度高过1270℃后, 此时炉渣温度对锍液滴的沉降时间影响不大了。 这是由于炉渣温度大于1270℃后, 炉渣温度对炉渣粘度的影响减小所致(见图4)。

图4 沉淀池渣粘度与温度的关系

Fig.4 Relationship between viscosity and temperature of slag in settler

图5 锍液滴沉降时间与渣温度的关系

Fig.5 Relationships between settling time of matte droplets and temperature of slag

根据以上分析, 生产中如能将渣温度控制在1250~1300℃之间, 将非常有利于小粒径的锍液滴沉降。

3.3 锍液滴直径的影响

式(6)表明, 锍液滴在渣中的沉降时间与锍液滴的直径平方成正比, 如增大锍液滴直径, 锍液滴进入渣层的时间可大大缩短。 表2列出了不同直径的锍液滴穿过不同厚度的渣层所需要的时间。

对渣层厚度为0.2m时表中的数据进行分析可知, 当锍液滴直径小于0.07mm时, 锍液滴需在渣中停留2h以上才能沉入锍层。 而实际生产中, 渣在熔池内的停留时间也就是2h左右, 很显然, 直径小于0.07mm的锍液滴不可能沉入锍层。 但是, 当锍液滴直径为0.1mm时, 锍液滴只需约1h便可进入锍层。 因此, 锍液滴直径对锍液滴沉降起决定性作用, 在生产中应采取各种措施, 促使锍液滴碰撞长大, 加速锍液滴沉降。

4 结论

1) 在分析锍液滴水平及垂直运动的基础上,

表2 不同直径的液滴穿过不同厚度的渣层所需要的时间

Table 2 Spending time of matte droplets with different diameter moving through slag layer with different slag thickness

导出了渣中所能存在的最大锍液滴直径的计算公式。 根据闪速炉的实际生产条件, 计算出了渣中最大锍液滴直径的理论值为0.063mm, 并用矿相显微镜对沉淀池出口处的渣样进行了观察, 渣中最大锍颗粒粒径为0.06mm, 两者结果一致。 证明了锍液滴沉降机理分析及其渣中最大锍液滴直径的计算式的有效性, 可用于分析渣中铜机械夹杂损失。

2) 利用沉降时间计算公式及渣中所能存在的最大锍液滴直径计算公式分析了影响渣中铜机械夹杂损失的因素。 分析表明: 渣层厚度对锍液滴沉降过程影响不大。 而加长沉淀池长与宽、 增大渣锍密度差、 降低渣粘度、 降低闪速炉投料量、 增大锍液滴直径均有利于渣中锍液滴的沉降。 由于受生产条件的限制, 沉淀池长宽及闪速炉投料量等参数不可能被改变。 因而, 从企业可操作的角度来看, 在沉淀池或反应塔采取一定措施, 使分散于渣中的细小的锍液滴相互碰撞长大是降低渣中铜机械夹杂损失的重要措施。 其次, 调整渣中铁硅比含量、 保持渣温度在1250~1300℃之间, 以使渣的粘度保持在较小状态是降低渣中铜机械夹杂损失的另一重要措施。

REFERENCES

[1]Hanniala P, Helle L, Kojo I V. A look into the future of the copper smelting business[A]. PENG Jin-hui, MA Ke-yi. Proceedings of ICHNM′2002[C]. Kunming: Yunnan Science and Technology Press, 2002: 19-31.

[2]Akagi S, Fujii T, Maeda M, et al. Method for pyrometallurgical smelting of copper[J]. Applied Thermal Engineering, 1998, 18(6): 1053-1054

[3]Sohn H Y. Advances in sulfide smelting technology R & D, and education[A]. Stephens R L, Asteljoki J. The Mineral Metal &Material Society[C]. San Antonio: Texas, 1998: 3-37.

[4]CHEN Hong-rong, MEI Chi, XIE Kai, et al. Operation optimization of concentrate burner in copper flash smelting furnace[J]. Trans Nonferrous Met Soc China, 2004, 14(3): 631-636.

[5]梅炽, 谢锴, 陈红荣, 等. 闪速炼铜“高效反应区”的形成条件与应用效果[J]. 有色金属, 2003, 55(14): 85-88.

MEI Chi, XIE Kai, CHEN Hong-rong, et al. Generating condition and applying results of high efficient reaction core in copper flash smelting[J]. Nonferrous Metals, 2003, 55(14): 85-88.

[6]朱祖泽, 贺家齐. 现代铜冶金学[M]. 北京: 科学出版社, 2003.

ZHU Zu-ze, HE Jia-qi. Current Copper Metallurgy[M]. Beijing: Science Press, 2003.

[7]李贻煌. 贵溪冶炼厂降低电炉渣含铜的研究和实践[J]. 有色金属(冶炼部分), 2000(2): 15-16.

LI Yi-huang. Research about decreasing copper losses in electricity furnace Guixi Smelting Factory[J]. Nonferrous Metals(Metallurgy Volume), 2000(2): 15-16.

[8]周俊. 铜闪速熔炼贫化电炉渣含铜的线性回归分析[J]. 矿冶, 2003, 12(2): 32-35.

ZHOU Jun. Linearity regress analysis of electricity furnace in copper flash smelting process[J]. Mine and Metallurgy, 2003, 12(2): 32-35.

[9]昂正同. 降低闪速熔炼渣含铜实践[J]. 有色金属(冶炼部分), 2002(5): 41-44.

ANG Zheng-tong. Decreasing copper losses in flash smelting furnace[J]. Nonferrous Metals(Metallurgy Volume), 2002(5): 41-44.

[10]左立雄. 浅谈贵冶闪速炉沉淀池的管理[J]. 铜业工程, 2002(1): 98-101.

ZUO Li-xiong. Discussing the manage of flash furnace the settler at Guixi[J]. Copper Engineering, 2002(1): 98-101.

[11]刘纯鹏. 铜冶金物理化学[M]. 上海: 上海科技出版社, 1990.

LIU Chun-peng. Copper Metallurgy Physical Chemistry[M]. Shanghai: Shanghai Science and Technology Press, 1990.

[12]Sridhar R. Copper losses and thermodynamic considerations in copper smelting [J]. Metallurgical and Materials, 1997, B28(4): 191-200.

[13]余建平. 铜闪速炉沉淀池锍沉降机理分析与流场温度场数值模拟研究[D]. 长沙: 中南大学, 2006.

YU Jian-ping. Analysis of Matte Settling Mechanism and Numerical Simulation Research on Fluid Field and Temperature Field in Settler of Copper Flash Furnace[D]. Changsha: Central South University, 2006.

[14]《有色冶金炉设计手册》编委会编. 有色冶金炉设计手册[M]. 北京: 冶金工业出版社, 2000.

Editor Committee of Nonferrous Metallurgy Furnace Design Handbook. Nonferrous Metallurgy Furnace Design Handbook[M]. Beijing: Metallurgical Industry Press, 2000.

[15]《有色金属提取冶金手册》编辑委员会. 有色金属提取冶金手册(铜镍卷)[M]. 北京: 冶金工业出版社, 2000.

Editor Committee of Nonferrous Metal Extracting Handbook. Nonferrous Metal Extracting Handbook (Copper and Nickel Volume)[M]. Beijing: Metallurgical Industry Press, 2000.

(编辑何学锋)

基金项目: 国家高技术研究发展计划资助项目(2002AA001040)

收稿日期: 2006-06-04; 修订日期: 2006-10-08

通讯作者: 周 萍; 电话: 0731-8830897; E-mail: zhoup@mail.csu.edu.cn