DOI: 10.11817/j.issn.1672-7207.2019.11.008

5052铝合金热拉伸流变应力及实心凸起板锻造成形研究

林启权1,王晓伟1,董文正1, 2, 3,李彦涛1,王志刚3

(1. 湘潭大学 焊接机器人与应用技术湖南省重点实验室,湖南 湘潭,411105;

2. 华中科技大学 材料成形与模具技术国家重点实验室,湖北 武汉,430074;

3. 日本岐阜大学 机械与系统工程系,日本 岐阜,501-1193)

摘要:采用Instron3369电子万能试验机对5052铝合金板进行热拉伸实验,研究该合金在变形温度为523~723 K,应变速率为0.001~0.100 s-1条件下的流变应力行为。将实心凸起板锻造成形数值仿真结果与板锻造成形实验结果进行对比。研究结果表明:5052铝合金的流变应力随温度升高而降低,随应变速率增大而增大;可用Zener-Hollomon参数的Arrhenius双曲正弦关系来描述该合金的热流变应力行为,其变形激活能为162.72 kJ/mol;该热拉伸本构方程可以准确描述板锻造成形凸起过程的特征,且在673 K时实心凸起板锻造成形性能最好。

关键词:5052铝合金;高温拉伸;本构关系;板锻造;数值仿真

中图分类号:TG314.4 文献标志码:A 文章编号:1672-7207(2019)11-2695-08

Research on heat-tensile flow stress and solid boss plate forging for 5052 aluminum alloy

LIN Qiquan1, WANG Xiaowei1, DONG Wenzheng1, 2, 3, LI Yantao1, WANG Zhigang3

(1. Hunan Key Laboratory of Welding Robots and Applied Technologies, Xiangtan University,Xiangtan 411105, China;

2. State Key Laboratory of Material Forming and Mould Technology,Huazhong University of Science and Technology, Wuhan 430074, China;

3. Department of Mechanical and Systems Engineering, Gifu University, Gifu 501-1193, Japan)

Abstract: The flow stress behavior of 5052 aluminum alloy during hot tensile deformation was studied by thermal simulation test at the deformation temperature of 523-723 K and the strain rate of 0.001-0.100 s-1 on the Instron3369 universal testing machine. The numerical simulation results of the solid boss caused by plate forging was compared with those of the experiment of sheet forging. The results show that the flow stress of 5052 aluminum alloy decreases with the increase of temperature and increases with the increase of strain rate. The flow stress can be represented by a Zener-Hollomon parameter in the hyperbolic sine equation, with the hot deformation activation energy being 162.72 kJ/mol. The constitutive equation can accurately describe the characteristics of the solid boss caused by plate forging, and the forming property of the solid boss plate forging is the best at 673 K.

Key words: 5052 aluminum alloy; high temperature tensile; constitutive model; plate forging; numerical simulation

铝合金作为一种密度低、比强度高的轻合金材料被广泛应用于汽车制造、航天航空等工业领域。然而,铝合金在室温下塑性低,成形性能差,因此,其开发和应用受到了很大制约。针对这一问题,开发适合铝合金热成形工艺引起国内外研究者的广泛研究[1-4]。铝合金种类众多,其热处理后状态也各不相同,要通过温热成形技术提升铝合金板材的成形性能,对铝合金材料的选择尤为重要。近年来,周国伟等[5-8]对7075和7151等高强铝合金的热拉深性能、显微组织、断裂行为等进行了温热成形技术研究,但7×××系铝合金生产成本高,主要用于航天航空领域。选择生产成本相对较低和成形性能良好的5000系铝合金板材进行温成形技术研究具有重要的实践意义。5052铝合金属于Al-Mg系合金,耐蚀性和加工性好,并具有中等强度,主要用于制造飞机油箱、油管、汽车钣金件以及装饰件、托架、铆钉等。对金属板材本构方程的研究一直是金属塑性成形研究的重点,目前,关于5052铝合金的研究和应用仍主要集中在合金的疲劳性能、组织性能及铝合金型材的冷热挤压成形和板材的常温成形上。刘阳阳等[9-10]选用5052铝合金铸锭,开展了温度为573~723 K,应变速率为0.001~10.00 s-1热压缩试验,并基于Zener-Hollmon参数模型得到了本构方程;TIAN等[11-12]研究了应变速率对5A02-O铝合金室温动态力学行为和组织演变的影响。目前,有关5052铝合金板材热拉伸流变应力研究尚未见报道。板锻造成形工艺是以板料或者半成品毛坯在不同温度下将拉深、翻边、弯曲等传统的板材成形工艺与模锻、镦粗、挤压等传统的体积成形工艺相结合的复合成形工艺,目前,板锻造成形技术在日本、德国等工业发达国家得到了大力推广,并开发了大量的板锻造成形零件[13-14],如MERKLEIN等[15]基于板锻造成形技术,以厚度为2 mm的C40钢为坯料,提出了圆筒齿轮板锻造一体化成形方案,解决了传统机加工方法成本高、效率低的问题。KO等[16]采用拉深、镦挤板锻造成形工艺,成形带2个空心凸起的汽车车门锁扣,大大简化了传统成形工艺,并减小了零件的质量。WANG等[17-18]对温板锻成形、大厚差板材成形进行了研究,解决了传统加工中空薄壁零件不能满足使用要求和加工难度大等问题。LIN等[19-20]对厚板翻边和薄板凸起的相关板锻复合成形工艺、筒形件实心凸起板锻造成形工艺及机理进行了研究。本文作者以5052铝合金板材为研究对象,采用美国Instron3369电子万能试验机进行温拉伸实验,获得不同温度和应变速率下的的应力应变曲线,基于Hollomen模型建立适用于热变形条件下的5052铝合金本构方程。将获得的本构方程导入DEFORM软件中,对带有凸起结构的筒形件进行板锻造等温成形有限元数值模拟并对其进行板锻造等温成形实验,探讨不同工艺参数和模具结构参数下实心凸起的成形性,通过测量成形件凸起高度、底部减薄量以及凸起度的实验值和模拟值,验证该本构方程的准确性和有效性。

1 5052铝合金板热拉伸实验

1.1 实验材料

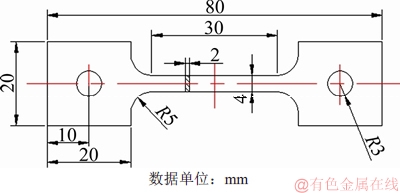

温成形技术是指将成形毛坯通过加热装置加热到一定成形温度,保证材料在该温度下具有较好的延展性,然后,将加热后的毛坯件放入模具中进行成形,从而获得具有深度大、回弹性小、结构复杂的零部件工艺过程。为了得到适用于温热成形有限元数值仿真的流变应力模型,必须对材料进行热拉伸成形试验。实验材料为5052-H32铝合金板材,其化学成分如表1所示。实验所用试样形状根据国标GB/T 228.1—2010设计,如图1所示。在实验过程中,将试样放在Instron3369电子万能试验机的加热装置中加热到设定温度,并保温3 min,使其试样温度均匀,然后,采用位移加载直至断裂。试验温度为523~723 K,应变速率为0.001~0.100 s-1。温度和应变速率由计算机系统自动控制。

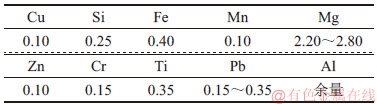

表1 5052-H32铝合金化学成分(质量分数)

Table 1 Chemical compositions of 5052-H32 aluminum alloy%

图1 高温拉伸试验试样几何尺寸

Fig. 1 Geometrical dimensions of specimen for high temperature tensile test

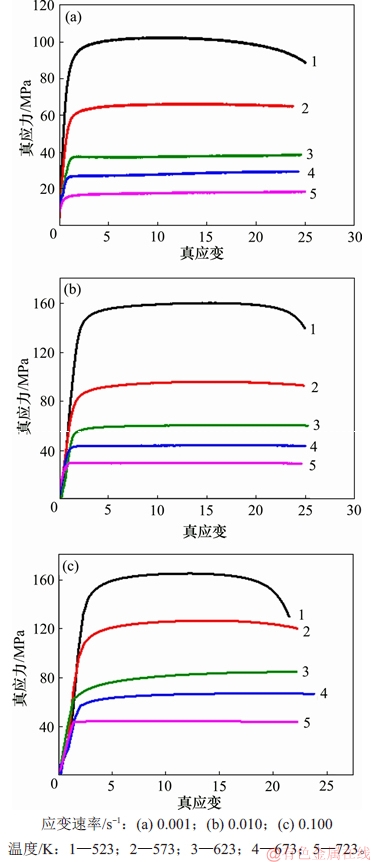

1.2 真应力-应变曲线

通过在不同应变速率和温度下的进行热拉伸实验,获得5052铝合金的真应力-应变曲线如图2所示。由图2可看出:随着应变不断增大,真应力先迅速增大,当升高到屈服强度后,应力增大的趋势变缓;当应变超过一定值后,应力维持不变或者缓慢下降直至断裂发生;在弹性阶段时,材料的弹性模量几乎保持不变,而当塑性变形发生时,合金材料的组织受到影响,且温度越高,屈服强度越低,抗拉强度也越低。

图2 5052铝合金在不同温度和应变速率下的真应力-真应变曲线

Fig. 2 True stress-true strain curves of 5052 aluminum alloy at different temperatures and strain rates

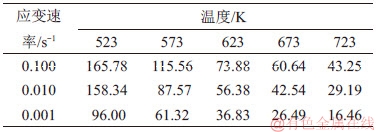

图2中不同变形条件下的峰值应力见表2。从表2可见:在一定应变速率下,随着温度升高,峰值应力与其呈负的相关性,在应变速率为0.01 s-1,温度从523 K升高到723 K时,对应的峰值应力从158.34 MPa减少到29.19 MPa;而在一定变形温度下,随着应变速率增大,峰值应力呈现出正相关性,如当温度为673 K,应变速率从0.001 s-1增大到0.100 s-1时,峰值应力从26.49 MPa增大到60.64 MPa。

表2 不同变形条件下的峰值应力

Table 2 Peak stress of alloy under different deformation conditions MPa

1.3 5052铝合金本构方程的建立

材料在热变形过程中,材料的流变应力行为与变形温度、应变率和应变之间存在耦合关系,对材料在温热成形工艺的数值模拟分析有重要意义。任何应变或稳态下的高温流变应力 取决于变形温度T和应变速率

取决于变形温度T和应变速率 ,普遍采用SELLARS等[21-22]提出的双曲正弦形式加以描述,在不同条件下分别表示为以下形式:

,普遍采用SELLARS等[21-22]提出的双曲正弦形式加以描述,在不同条件下分别表示为以下形式:

(1)

(1)

(2)

(2)

在任意条件下,

(3)

(3)

式中:A1,A2,A,n1,n,β和α均为常数;A,A1和A2为结构因子;Q为变形激活能;T为热力学温度;R为气体常数; 为应变速率;

为应变速率; 为流变应力;n和n1为应力指数;α=β/ n1。该流变应力模型可以较好地描述材料热变形特性。

为流变应力;n和n1为应力指数;α=β/ n1。该流变应力模型可以较好地描述材料热变形特性。

此外,SELLARS等[21]通过实验验证了热变形调件可以通过温度补偿应变速率因子Zener-Hollomon参数Z来描述:

(4)

(4)

对式(1)和式(2)取对数得:

(5)

(5)

(6)

(6)

对式(3)两边取对数后偏微分得到热变形激活能Q:

(7)

(7)

对式(4)两边取对数得

(8)

(8)

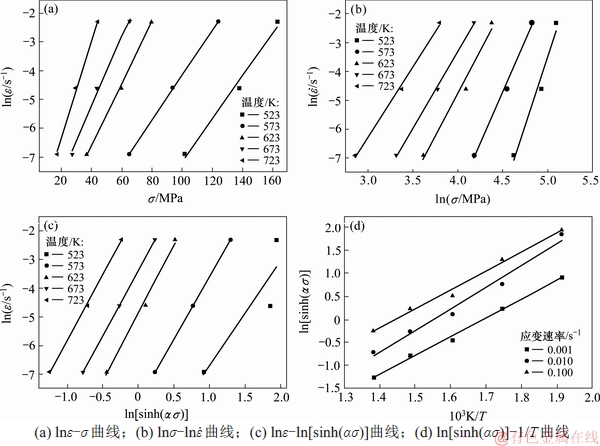

根据上述公式和各影响因素进行线性回归处理得到5052铝合金峰值应力与各影响因素线性回归处理关系曲线,如图3所示。据图3可求得A=3.14×1014,n=5.055,α=0.0211,Q =162.72 kJ/mol。所以,5052铝合金热变形的材料本构方程为

(9)

(9)

图3 5052铝合金峰值应力与各影响因素线性回归处理关系曲线

Fig. 3 Linear fitting curves of peak stress and influence factors of 5052 aluminum alloy

1.4 模型计算结果与实验比较

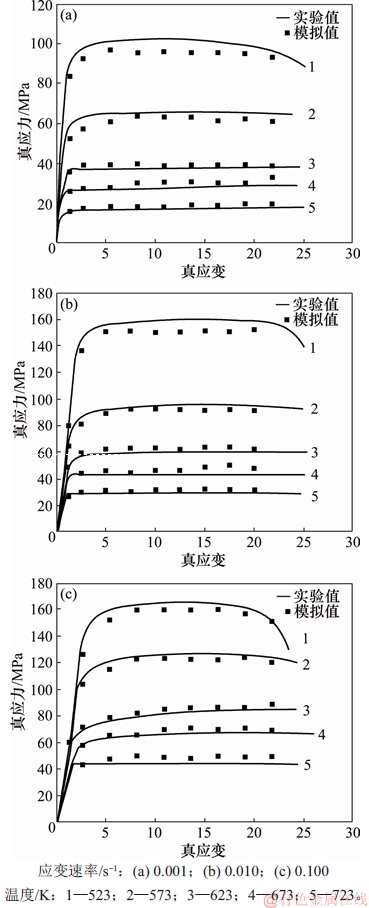

将所求得的各系数代回到流变应力方程中,计算理论应力。图4所示为不同应变、应变速率、温度下应力的实验值与拟合值对比。从图4可见:应力计算曲线和实验曲线的变化趋势和数值均较接近,最大偏差为5.64%,因此,该模型可以很好地描述5052铝合金热变形流动应力行为,可以用于5052铝合金的热变形流变应力的预测和数值模拟。

图4 流变应力实验值与拟合值对比

Fig. 4 Comparisons between experiment and fitted flow stress

2 实心凸起板锻造有限元仿真应用及实验验证

2.1 板锻造成形实心凸起有限元仿真模拟

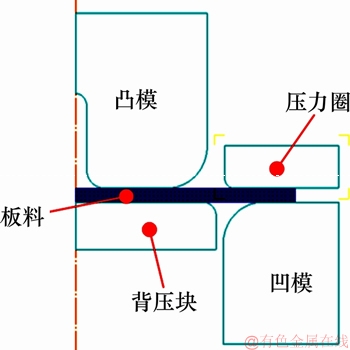

采用板锻造成形工艺对中心带实心凸起的圆筒形件进行等温成形,如图5所示。在成形过程中既有板料成形,又有体积成形,金属塑性流动较复杂,为此,将所获得的5052铝合金热拉伸流变应力模型导入DEFORM软件中,对其成形过程进行有限元数值模拟,并在YP32-315比例控制挤压拉深复合成形试验机上进行板锻成形实验,探讨不同工艺参数和模具结构参数下实心凸起的成形性,并进一步验证流变应力模型的准确性。由于零件具有轴对称性,故采用DEFORM-2D对其进行成形模拟。在有限元模型中,设板料为塑性体外,其他均设为刚性体,背压块、凹模和压边圈与板料之间的摩擦因数设为0.06,凸模与板料之间的摩擦因数为0.03~0.15,成形速度为2 mm/s。其他相关工艺参数如表3所示。

图5 实心凸起板锻造成形有限元模型

Fig. 5 Finite element model of solid boss plate forging

表3 工艺参数

Table 3 Process parameters

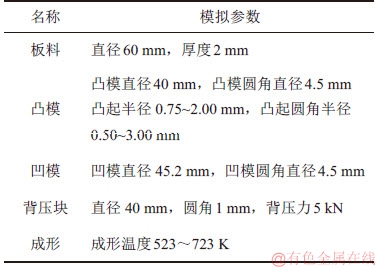

本文通过凸起度[23]来表征板料凸起的成形能力,其定义为

(10)

(10)

其中:σs为材料的屈服强度;P为板锻造凸起成型过程中单位瞬间背压载荷;Vb为凸起结构体积;Vp为参与挤压变形部分的底部板料体积(底部较薄体积),如图6所示。

图6 凸起度几何示意图

Fig. 6 Schematic diagram of boss ability

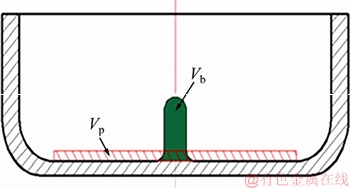

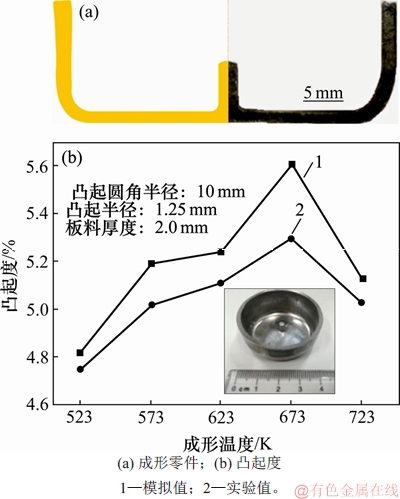

以凸起度作为实心凸起板锻造成形过程中成形性能的衡量标准,对不同的凸起圆角半径、凸起半径及润滑条件下的凸起度进行探讨。研究结果表明:凸起度与变形温度、模具结构参数和摩擦条件密切相关;在不同温度下,凸起度随着凸起圆角半径和凸起半径的变化而变化,如图7所示;随着凸起圆角半径增大,凸起度增大,在凸起圆角半径一定时,随着温度升高,凸起度逐步增大,在673 K时凸起度最大,如图7(a)所示;随着凸起半径增大,凸起度显著增高,随着温度升高,凸起度稳步升高,且在673 K时凸起度最大,如图7(b)所示;随着凸模与板料的库仑摩擦因数增大,凸起度明显升高,凸起度随着温度升高不断增加,在673 K时达到最大值,如图7(c)所示。上述结果表明:在523~723 K范围中,当成形温度为673 K时,板锻造成形实心凸起的性能最好。

图7 工艺参数对板锻造成形实心凸起成形性能的影响

Fig. 7 Effect of process parameters on forming performance of solid boss in plate forging

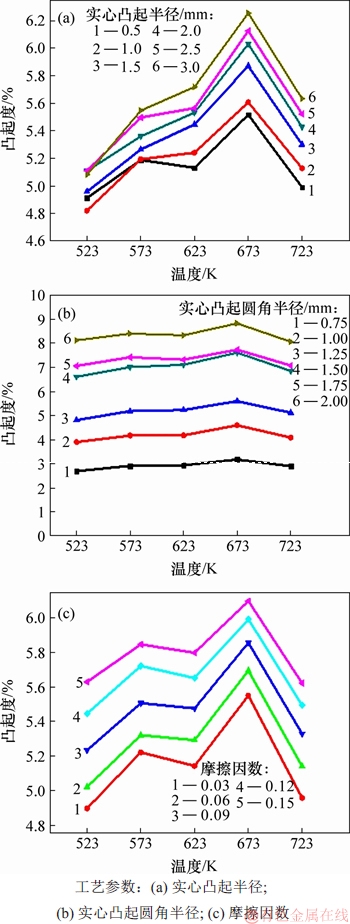

2.2 板锻造成形实心凸起实验验证

在YP32-315比例控挤压拉深复合成形试验机上进行实心凸起板锻造成形试验,对上述有限元模拟结果进行实验验证。进行实心凸起板锻造成形实验时,采用直径为60 mm、厚度为2 mm的5052-H32铝合金板材。凸起结构选用凸起圆角半径为1.00 mm、凸起半径为1.25 mm的凸模,成形温度在523~723 K下进行实心凸起板锻造等温成形试验。

通过实心凸起板锻造成形试验,将工件沿凸起中心位置割开与仿真结果进行对比,如图 8(a) 所示。从图8(a)可以看出:实验成形的筒形件筒壁高度、凸起高度和板料底部厚度与有限元仿真结果基本吻合;测量实心凸起零件凸起高度和成形后板料底部厚度,计算其板锻造成形实心凸起实验的凸起度,并与板锻造成形实心凸起有限元模拟的凸起度进行对比,实验结果与有限元模拟结果基本吻合,如图 8(b)所示。上述结果表明:该热拉伸本构方程不仅可以准确地描述板锻造成形凸起过程的特征,而且可以有效地满足 5052 铝合金热成形性能的仿真要求。

图8 实验与模拟结果对比

Fig. 8 Comparison of experimental and simulation results of forming part and boss ability

3 结论

1) 5052铝合金在热拉伸变形过程中,流变应力随应变速率增加而升高,流变应力随着变形温度升高而降低。5052铝合金在温度为523~723 K,应变速率为0.001~0.100 s-1变形条件下的材料本构方程为

热激活能Q=162.72kJ/mol。

2) 将所获得5052铝合金流变应力模型用于板锻造成形数值仿真,通过与实验结果进行对比,发现该热拉伸本构模型能够准确地描述板锻造成形凸起过程的成形特征,且5052铝合金在673 K时板锻造成形实心凸起成形性能最好。

参考文献:

[1] WANG Hui, LUO Yingbing, FRIEDMAN P, et al. Warm forming behavior of high strength aluminum alloy AA7075[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 1-7.

[2] ZHAO Kunmin, REN Daxin, WANG Bin, et al. Investigation of the interfacial heat transfer coefficient of sheet aluminum alloy 5083 in warm stamping process[J]. International Journal of Heat and Mass Transfer, 2019, 132: 293-300.

[3] PALUMBO G, PICCININNI A, GUGLIELMI P, et al. Warm forming of an AA5754 component for railway vehicle applications[J]. Procedia Engineering, 2017, 183: 351-356.

[4] ZHENG Kailun, DONG Yangchun, ZHENG Dengqi, et al. An experimental investigation on the deformation and post-formed strength of heat-treatable aluminium alloys using different elevated temperature forming processes[J]. Journal of Materials Processing Technology, 2019, 268: 87-96.

[5] 周国伟, 李大永, 彭颖红. 7075-T6高强度铝合金温热条件下的拉深成形性能[J]. 上海交通大学学报, 2012, 46(9): 1482-1486.

ZHOU Guowei, LI Dayong, PENG Yinghong. Deep drawability of 7075-T6 high strength aluminum alloy at warm condition[J]. Journal of Shanghai Jiao Tong University, 2012, 46(9): 1482-1486.

[6] FU Jinlong, JIANG Hongjun, WANG Kaikun. Influence of processing parameters on microstructural evolution and tensile properties for 7075 Al alloy prepared by an ECAP-based SIMA process[J]. Acta Metallurgica Sinica(English Letters), 2018, 31(4): 337-350.

[7] SRIVATSAN T S, GURUPRASAD G, VASUDEVAN V K. The quasi static deformation and fracture behavior of aluminum alloy 7150[J]. Materials & Design, 2008, 29(4): 742-751.

[8] DENG Ying, YIN Zhimin, HUANG Jiwu. Hot deformation behavior and microstructural evolution of homogenized 7050 aluminum alloy during compression at elevated temperature[J]. Materials Science and Engineering: A, 2011, 528(3): 1780-1786.

[9] 刘阳阳, 文九巴, 贺俊光, 等. 5052铝合金热圧缩本构关系及其数值模拟[J]. 材料热处理学报, 2017, 38(12): 121-128.

LIU Yangyang, WEN Jiuba, HE Junguang, et al. Constitutive relation of hot compression of 5052 aluminum alloy and its numerical simulation[J]. Transactions of Materials and Heat Treatment, 2017, 38(12): 121-128.

[10] 郑玉林, 陈文敬, 任文达, 等. 5052铝合金热压缩变形流变应力[J]. 铝加工, 2007(2): 17-20, 24.

ZHENG Yulin, CHEN Wenjing, REN Wenda, et al. Flow stress behavior of 5052 aluminum alloy under hot compression deformation[J]. Aluminium Fabrication, 2007(2): 17-20, 24.

[11] TIAN Yi, HUANG Liang, MA Huijuan, et al. Establishment and comparison of four constitutive models of 5A02 aluminium alloy in high-velocity forming process[J]. Materials & Design, 2014, 54: 587-597.

[12] MA Huijuan, HUANG Liang, TIAN Yi, et al. Effects of strain rate on dynamic mechanical behavior and microstructure evolution of 5A02-O aluminum alloy[J]. Materials Science and Engineering: A, 2014, 606: 233-239.

[13] NAKANO T. Compound technology of sheet metal forming and cold forming[J]. Journal of the Japan Society for Technology of Plasticity, 2001, 42(5): 22-26.

[14] IMURA T. Forming examples of FCF method and points of utilization[J]. Press Working, 2008, 46(1): 28-33.

[15] MERKLEIN M, ALLWOOD J M, BEHRENS B A, et al. Bulk forming of sheet metal[J]. CIRP Annals, 2012, 61(2): 725-745.

[16] KO D C, CHOI H S, JANG W S, et al. Progressive process design of door lock striker with double bosses by the wall-thickening process[J]. The International Journal of Advanced Manufacturing Technology, 2013, 66(5/6/7/8): 1191-1199.

[17] WANG Xinyun, JIN Junsong, DENG Lei. State of the art of stamping forging process with sheet metal blank[J]. Journal of Harbin Institute of Technology(New Series), 2017, 24(3): 1-16.

[18] JIN Junsong, WANG Xinyun, DENG Lei, et al. A single-step hot stamping-forging process for aluminum alloy shell parts with nonuniform thickness[J]. Journal of Materials Processing Technology, 2016, 228: 170-178.

[19] LIN Qiquan, DONG Wenzheng, WANG Zhigang, et al. A new hole-flanging method for thick plate by upsetting process[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2387-2392.

[20] 董文正, 张存园, 林启权, 等. 铝合金实心凸起结构板锻造成形工艺[J]. 中国有色金属学报, 2017, 27(11): 2221-2227.

DONG Wenzheng, ZHANG Cunyuan, LIN Qiquan, et al. Solid boss forming process of plate forging aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(11): 2221-2227.

[21] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[22] MCQUEEN H J, RYAN N D. Constitutive analysis in hot working[J]. Materials Science & Engineering A (Structural Materials, Properties, Microstructure and Processing), 2002, 322(1/2): 43-63.

[23] 董文正. 板料凸起成形的冲锻复合塑性成形工艺及其机理研究[D]. 湘潭: 湘潭大学机械工程学院, 2012: 18-19.

DONG Wenzheng. Mechanisms of boss forming process for sheet metal based on press-forging technology[D]. Xiangtan: Xiangtan University. School of Mechanical Engineering, 2012: 18-19.

(编辑 陈灿华)

收稿日期: 2019 -03 -29; 修回日期: 2019 -05 -22

基金项目(Foundation item):国家自然科学基金资助项目(51575467, 51605408);材料成形与模具技术国家重点实验室开放课题研究基金资助项目(P2018-010);湖南省自然科学基金资助项目(2019JJ50604)(Projects(51575467, 51605408) supported by the National Natural Science Foundation of China;Project(P2018-010) supported by the Open Foundation of the State Key Laboratory of Material Forming and Mould Technology; Project(2019JJ50604) supported by the Natural Science Foundation of Hunan Province)

通信作者:董文正,博士,副教授,从事塑性加工摩擦与润滑等研究;E-mail: wzdong@xtu.edu.cn