文章编号:1004-0609(2009)07-1257-07

B、Si改性炭/炭复合材料及其摩擦磨损特性

涂欣达,易茂中,葛毅成,彭 可,冉丽萍,雷宝灵,杨 琳

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:以低密度的C/C复合坯体为预制体,分别采用反应熔渗(RMI)、化学气相沉积(CVD)、浸渍?原位反应技术对其进行陶瓷改性。结果表明:改性陶瓷分别以SiC和c-BN的形式渗入C/C复合坯体内。摩擦试验结果表明:采用RMI技术制备的C/C-SiC复合材料摩擦因数较高,高达0.3到0.9;采用CVD技术制备的C/C-SiC复合材料的摩擦因数在0.20~0.36之间;而采用浸渍?原位反应技术制备的c-BN改性C/C复合材料的摩擦因数较低,为0.10~0.20。SEM观察表明:采用RMI技术制备的C/C复合材料的摩擦表面粗糙、未形成完整的摩擦膜,而采用另两种技术制备的C/C复合材料均形成了较完整、致密的摩擦膜。

关键词:C/C复合坯体;碳化硅;氮化硼;摩擦磨损

中图分类号:TB 332 文献标识码:A

C/C composites modified by B, Si and their friction and

wear properties

TU Xin-da, YI Mao-zhong, GE Yi-cheng, PENG Ke, RAN Li-ping, LEI Bao-ling, YANG Ling

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The low density C/C composites were modified by B and Si using reaction melt infiltration (RMI), chemical vapour deposition (CVD) and impregnation and in-situ reaction. The results show that the modified ceramics are successfully added in the matrix carbon as SiC or c-BN. The C/C-SiC modified by RMI has high friction coefficient which reaches 0.30?0.90. The friction coefficient of C/C-SiC modified by CVD changes in 0.20?0.36, while the composites modified by c-BN using impregnation and in-situ reaction hold the lowest friction coefficient, which is 0.10?0.20. The wear surfaces of the RMI-modified composites are very rough without any integrated friction film, while the wear surfaces of the other two composites are compacted and integrated.

Key words: C/C composites; SiC; boron nitride; friction and wear

C/C复合材料的质量轻、比强度和比模量高、热导率高、热容大、热膨胀系数低以及摩擦磨损特性优异,已被广泛应用于航空航天领域[1?3]。但C/C材料的摩擦磨损行为受湿度、温度等环境因素影响较大而容易氧化。这些缺陷在一定程度上限制了C/C复合材料的应用。因此,提高C/C复合材料抗湿度、温度等环境的影响,改善摩擦磨损行为已成为扩展其应用领域的关键技术之一[4?7]。

目前,研究人员采用了SiC、BN以及金属如Cu和Al等作为C/C复合材料的基体改性材料[8?9]。其中,KRENKEL和BERNDT[10]认为采用SiC改性可以提高C/C复合材料在高温下的摩擦磨损行为及抗氧化能力。中南大学冉丽萍等[11]和肖鹏等[12]则认为添加SiC制备的C/C复合材料能保持较高且稳定的摩擦因 数,同时该材料对使用的工况条件要求较低。SEGHI等[13?14]采用h-BN改性C/C复合材料,性能测试结果表明:材料密度为1.55 g/cm3的C/C-BN复合材料在同等条件下的磨损量较密度为1.78~1.8 g/cm3的C/C复合材料降低50%,表现出优异的摩擦磨损特性。此外,针对金属改性,杨琳等[15]和冉丽萍等[16]制备的C/C-Cu复合材料具有良好的导电性能和自润滑性能。

因此,采用陶瓷、金属改性C/C复合材料能有效改善该类材料的摩擦磨损行为和抗氧化能力,具有显著的技术和经济优势。该类材料已逐渐应用到F1方程式赛车、直升机旋翼用刹车片、坦克用刹车盘和闸片、高速列车刹车闸片和高级轿车刹车上[10, 12]。

本文作者分别采用反应熔渗、化学气相沉积、浸渍?原位反应等技术,以SiC、c-BN为改性物质,对C/C复合坯体进行改性并探讨其对材料摩擦行为的影响。

1 实验

1.1试样的制备

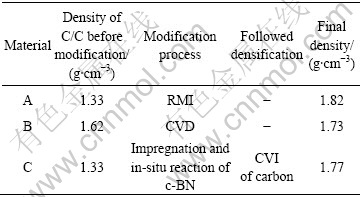

以两种密度的C/C坯体作为改性基体,分别采用熔渗(RMI)和浸渍?原位反应以及化学气相沉积技术(CVD)向坯体内分别添加B、Si类陶瓷相,改性处理方法如表1所列。

表1 C/C复合材料的改性制备技术及其性能参数

Table 1 Modification processes and properties of C/C composites

1.2 分析测试

采用MeF3A偏光金相显微镜观察材料A的金相形貌。用XRD检测3种材料的物相。

将上述材料加工成20 mm×12 mm×6 mm的块状摩擦试样, 摩擦面为20 mm×12 mm。对偶件为40Cr钢环,尺寸为d 40 mm×d 16 mm×10 mm。试样与对偶的表面粗糙度均为0.8 μm。在MM?2000型摩擦磨损实验机上分别测试3种材料长时间的滑动摩擦行为。配副间线速度为0.42 m/s。载荷分别为60、80、100、120和150 N,实验时间为5 h。通过摩擦实验计算出材料的摩擦因数,并用SEM观察试样的摩擦表面形貌。

2 结果与讨论

2.1 试样A的金相组织分析

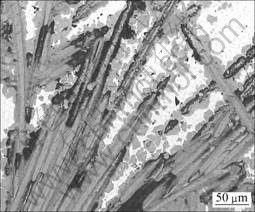

图1所示为RMI制备的改性C/C复合材料样品的显微组织。从图1中看到,纤维周围都分布着灰色的SiC,而白色的Si分布在更外面。图中还可以清晰地看到炭纤维、SiC和Si的分布。

图1 材料A的显微组织

Fig.1 Microstructure of material A

2.2 材料的XRD分析

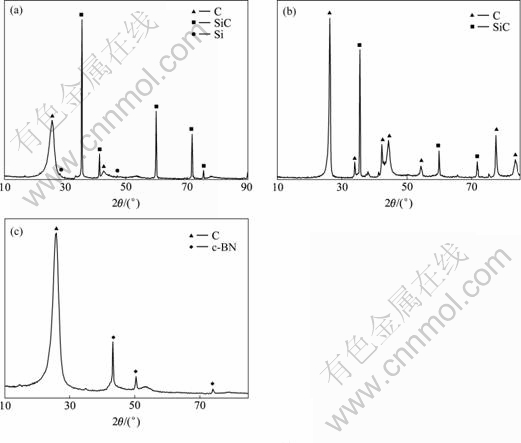

图2所示为材料A、B、C的XRD谱。由图2可知,材料A的物相成分为C、SiC和游离的Si;材料B中含有C和SiC;材料C的物相主要为C和c-BN。

图2 材料的XRD谱

Fig.2 XRD patterns of materials: (a) Material A; (b) Material B; (c) Material C

2.3 B和Si对材料的摩擦因数的影响

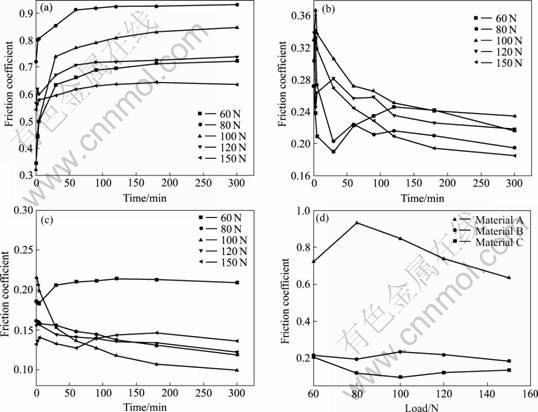

图3(a)、(b)、(c)所示分别为材料A、B和C在不同载荷下摩擦因数随时间延长的变化。图3(d)所示为材料A、B、C在摩擦5 h时摩擦因数随载荷的变化。由图3(a)可见,80 N载荷下材料A的摩擦因数值最高,100 N载荷下的次之,120 N和60 N载荷下的摩擦因数值接近,而150 N载荷下的摩擦因数值最低。从图3(b)可以看到,材料B的摩擦因数在实验中后期的实验值都在0.20到0.26范围内波动。随着时间延长,变化趋势也都比较接近。从摩擦因数值的大小看,处在同一时间100、120和150 N载荷下的3组实验的摩擦因数值随着载荷增大而减小;60 N和80 N载荷下的两组实验也呈现出类似的规律;100 N载荷下的摩擦因数值最大;150 N载荷下的摩擦因数最低。由图3(c) 可知,材料C的摩擦因数值基本变化趋势都是随载荷的增加而降低。当载荷为60 N时,摩擦因数先升高然后缓慢降低,基本维持在0.21左右;150 N下的摩擦因数次之;80 N和120 N下的摩擦因数比较接近;100 N下的摩擦因数降低最快。从图3(d)的曲线可知,材料A的摩擦因数值都比较大,且在载荷为80 N时达到最大值,随后随载荷的增加而下降;材料B和C的摩擦因数较低,且波动不大,摩擦因数大都集中在0.20左右,而材料C的摩擦因数较材料B的更低。

图3 材料A、B和C的摩擦因数在不同载荷下随时间变化及5 h时摩擦因数随载荷的变化

Fig.3 Changes of friction coefficients of materials A(a), B(b) and C(c) with time under different loads and changes of friction coefficient with loads at 5 h(d)

2.4 材料摩擦表面的微观形貌分析

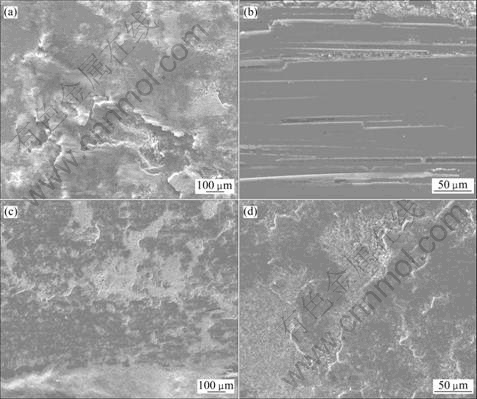

图4所示为材料A在60和150 N载荷下的磨损形貌。由图4(a)可见,在60 N下,摩擦表面摩擦膜较厚且分布不均匀,摩擦膜之间存在较大的堆叠、交叉,未形成大块致密的形貌。由图4(b)可见,在部分纤维束摩擦表面存在大量的纤维磨损形貌,磨痕间存在较多细小、粒状的磨屑。由图4(c)可见,150 N下,摩擦表面比其在60 N的致密,显示出波浪状的磨屑堆积、碾磨的形貌。在黑色、较致密的摩擦膜之间有灰色的、磨屑堆积较松散的摩擦形貌出现。由图4(d)可见,在波浪状的、由磨屑被碾压形成的致密的摩擦膜端头均有大量细小、粒状的磨屑分布,且随着距离致密的摩擦膜越远、磨屑数量越少。这表明磨屑是向着摩擦滑动方向移动、堆积到一定数量后受到碾压逐渐成膜的。且在摩擦膜受到磨损后产生的新的磨屑再次逐渐向前移动成膜,因而形成了此类摩擦形貌。

图4 材料A在不同载荷下的磨损表面形貌

Fig.4 SEM images of worn surface of material A under different loads: (a), (b) 60 N; (c), (d) 150 N

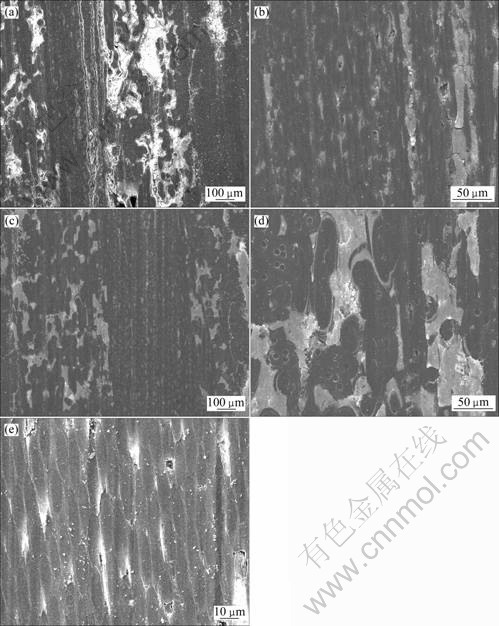

图5所示为材料B在60和150 N载荷下摩擦5 h后的磨损形貌。从图5(a)中可以看出,材料的磨粒磨损现象突出。在纤维取向平行于摩擦滑动方向的区域形成比较完整的磨损膜,而在网胎区域则有大量灰白色磨屑堆积。由图5(b)可见,在纤维轴向与摩擦表面成一定夹角的摩擦区域,除部分纤维端头被磨损形成的孔洞外,其余部分基本保持了较平整、致密的摩擦膜,磨屑数量也比较少;而在磨粒磨损形成的磨痕中,也形成了由细小的磨屑组成的灰色的、有微小裂纹的摩擦膜。由图5(c)可见,经150 N摩擦后,材料形成了完整致密的摩擦膜,未发现显著的纤维束磨损形貌,磨屑堆积区域均被挤压形成灰色的、较致密的摩擦膜。但这些摩擦膜受到了纤维的阻碍,呈非连续的形貌。在图5(d)中就可以清楚地看到,非连续的磨损表面是由于纤维对磨屑的推移有一定的阻碍作用,使磨屑在纤维附近堆积起来形成了一个个圆形的黑色区域。图5(e)所示为纤维取向和磨损方向成一较大角度区域的磨损面形貌。由图5(e)可以看到,纤维被磨损后的椭圆磨损断面,在磨损断面周围有呈白色的磨屑的堆积。

图5 材料B在不同载荷下的磨损表面形貌

Fig.5 Morphologies of worn surface of material B under different loads: (a), (b) 60 N; (c), (d), (e) 150 N

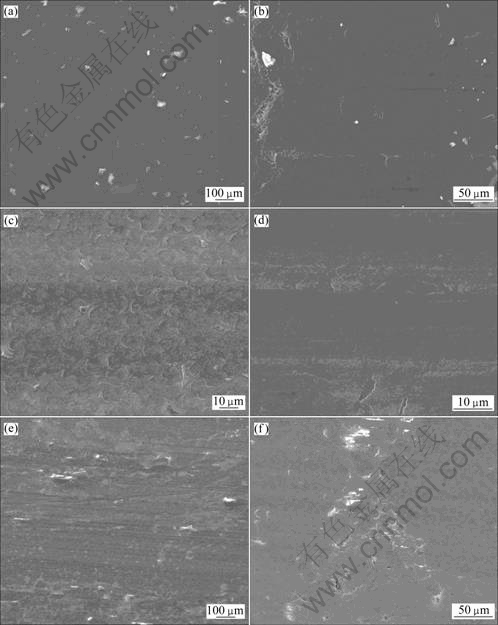

图6所示为c-BN改性C/C材料分别在60和150 N载荷下摩擦5 h后的磨损表面形貌。由图6(a)和(b)可见,材料的磨损形貌完整、致密,只有少量的磨屑存在。而从图6(c)可以看到,摩擦膜上有很多小的圆形的形状区域。这是由于该区域的纤维轴向是垂直于磨损方向的,其高强高韧的特性阻碍了磨屑的推移、堆积、成膜,从而形成了此类形貌。由图6(d)可见,在纤维轴向取向和滑动方向一致的摩擦区域,在摩擦膜孔洞、裂纹边缘存在摩擦膜向滑动方向延展形貌,有填充孔洞、裂纹的迹象。这表明,在外力作用下,该材料的摩擦膜存在自修复倾向,从而能得到完整、致密的摩擦膜,这对提高材料的摩擦磨损性能具有较大帮助。与60 N的磨损形貌相比,从图6(e)中可以看到,在150 N时,摩擦表面磨屑数量较多,磨粒磨损的痕迹明显。而图6(f)显示出磨屑的移动也同样受到纤维的影响。在局部范围内形成了层片状的摩擦膜,摩擦膜内孔洞、裂纹等缺陷含量增加。这是由于载荷增加和磨损增大产生的结果。

图6 材料C在不同载荷下的磨损表面形貌

Fig.6 Morphologies of worn surface of material C under different loads: (a), (b), (c), (d) 60 N; (e), (f) 150 N

由本研究可知,采用RMI制备的材料A中SiC呈大块团聚形貌,在制备过程中熔融的Si与碳反应激烈,产生较大的热应力,对基体材料损伤大,导致材料内部产生较多裂纹缺陷,在摩擦时易产生大量的磨屑。且团聚的SiC在摩擦过程中难以被材料内残余的碳包覆而形成具有自润滑性能的摩擦膜,从而导致材料A的摩擦因数高、不稳定,摩擦表面粗糙。相比之下,采用CVD改性的C/C-SiC以及c-BN改性的材料B和C因改性陶瓷尺寸小、呈粒状分布,且含量较少,对基体的损伤小,具有高自润滑作用的基体炭能包覆在硬质颗粒表面,能有效降低材料的磨损,故而此两种材料的摩擦因数较低、摩擦膜完整。因此,采用细小的、未团聚的陶瓷相改性的C/C复合材料具有较优异的摩擦特性。

3 结论

1) 通过RMI法渗硅的C/C坯体的摩擦因数较高,而采用化学气相沉积和浸渍?原位反应技术向C/C坯体添加SiC和c-BN的试样摩擦因数相对较低。

2) 采用CVD向C/C坯体内添加细小的、未团聚的SiC和c-BN陶瓷相改性C/C复合材料能有效降低材料的磨损,形成较为完整的摩擦膜,具有较为优异的摩擦特性。

REFERENCES

[1] SAVAGE G. Carbon-carbon composites[M]. London: Chapman & Hall Press, 1992: 323?361.

[2] MOHAMED S, ALY-HASSAN H. Comparison of 2D and 3D carbon/carbon composites with respect to damage and fracture resistance[J]. Carbon, 2003, 41(5): 1069?1078.

[3] 葛毅成, 易茂中, 黄伯云, 李丽娅. 润滑状态对C/C复合材料摩擦磨损特性的影响[J]. 中国有色金属学报, 2004, 14(8): 1405?1409.

GE Yi-cheng, YI Mao-zhong, HUANG Bai-yun, LI Li-ya. Influence of lubricationon tribology properties of C/C composites[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1405?1409.

[4] 葛毅成, 易茂中. 溶胶浸渍抗氧化涂层对C/C复合材料摩擦特性的影响[J]. 中国有色金属学报, 2007, 17(4): 586?590.

GE Yi-cheng, YI Mao-zhong. Effect of sol-impregnation anti-oxidation coating on sliding friction characteristics of C/C composite[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(4): 586?590.

[5] CHEN J D, CHEN J H, JU C P. Effect of humidity on the tribological behavior of carbon-carbon composites[J]. Wear, 1996, 193: 38?47.

[6] YEN B K. Influence of water vapor and oxygen on the tribology of carbon materials with sp2 valence configuration[J]. Wear, 1996, 192: 208?215.

[7] YEN B K, ISHIHARA T. An investigation of friction and wear mechanisms of carbon-carbon composites in nitrogen and air at elevated temperature[J]. Carbon, 1996, 34(3): 489?498.

[8] 辛 伟, 张红波, 尹 健, 左劲旅. 预制体中添加碳化硼对C/C复合材料氧化特性的影响[J]. 材料导报, 2007, 21(7): 150?155.

XIN Wei, ZHANG Hong-bo, YIN Jian, ZUO Jin-lü. Effect of adding B4C into the preforms on oxidation behavior of carbon/carbon composites[J]. Materials Review, 2007, 21(7): 150?155.

[9] 冉丽萍, 易茂中, 王朝胜, 彭 可, 黄伯云. 添加Al对MSI制备C/C-SiC复合材料组织和力学性能的影响[J]. 复合材料学报, 2006, 23(5): 34?38.

RAN Li-ping, YI Mao-zhong, WANG Chao-sheng, PEN Ke, HUANG Bai-yun. Influence of adding Al on the microstructure and mechanical properties of C/C-SiC composites fabricated by MSI[J]. Acta Materiae Compositae Sinica, 2006, 23(5): 34?38.

[10] KRENKEL W, BERNDT F. C/C-SiC composites for space applications and advanced friction systems[J]. Mater Sci Eng A, 2005, 412(1/2): 177?181.

[11] 冉丽萍, 易茂中, 陈 斌. C/C坯体对RMI-C/C-SiC复合材料组织的影响[J]. 中国有色金属学报, 2005, 15(8): 1208?1213.

RAN Li-ping, YI Mao-zhong, CHEN Bin. Influence of different C/C performs on microstructure of C/C-SiC composites fabricated by RMI[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1208?1213.

[12] 肖 鹏, 熊 翔, 张红波, 黄伯云. C/C-SiC陶瓷制动材料的研究现状与应用[J]. 中国有色金属学报, 2005, 15(5): 667?674.

XIAO Peng, XIONG Xiang, ZHANG Hong-bo, HUANG Bai-yun. Progress and application of C/C-SiC ceramic braking materials[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 667?674.

[13] SEGHI S, FABIO B, ECONOMY J. Carbon/carbon–boron nitride composites with improved wear resistance compared to carbon/carbon[J]. Carbon, 2004, 24(5): 3043?3048.

[14] SEGHI S, LEE J, ECONOMY J. High density carbon fiber/boron nitride matrix composites: Fabrication of composites with exceptional wear resistance[J]. Carbon, 2005, 33(2): 2035?2043.

[15] 杨 琳, 易茂中, 冉丽萍. C/C坯体对C/C-Cu复合材料摩擦磨损行为的影响[J]. 复合材料学报, 2008, 20(2): 10?15.

YANG Lin, YI Mao-zhong, RAN Li-ping. Effect of C/C perform on tribsological behavior of C/C-Cu composites[J]. Acta Materiae Compositae Sinica, 2008, 20(2): 10?15.

[16] 冉丽萍, 易茂中, 王朝胜, 易振华, 杨 琳. 不同载荷和对偶下C/C-Cu 复合材料的摩擦磨损性能[J]. 中南大学学报: 自然科学版, 2007, 38(4): 595?601.

RAN Li-ping, YI Mao-zhong, WANG Chao-sheng, YI Zhen-hua, YANG Lin. Wear behavior of C/C-Cu composites under different loads and couple parts[J]. Journal of Central South University: Science and Technology, 2007, 38(4): 595?601.

基金项目:国家重大基础研究发展计划资助项目(2006CB600906)

收稿日期:2008-08-03;修订日期:2008-11-26

通讯作者:易茂中,教授,博士;电话:0731-88877700;E-mail: yimaozhong@126.com

(编辑 李艳红)