文章编号: 1004-0609(2005)02-0259-05

铜合金直升机旋翼配重构件的金属型铸造及工艺

刘兆晶, 任善之, 吴士平, 李凤珍, 左 锋

(哈尔滨理工大学 材料科学与工程学院, 哈尔滨 150040)

摘 要: 采用金属型铸造并对铜合金材料进行基础试验和计算, 确定了直升机旋翼配重构件的铸造工艺边界参数; 利用CAD对铸造工艺参数及铸造工艺方案进行数值模拟。 结果表明: 经金属型铸造的铜合金密度达到理论密度的99.91%。 经金属模铸造成型的铜合金直升机旋翼配重构件满足设计要求: 即铸造成型后直升机配重构件的质量偏差为±5g, 曲面变形小于0.2mm, 最大截面厚度偏差为±0.1mm。 经铸造后直升机旋翼配重构件的力学性能为: σb=315MPa, σ0.2=143MPa, δ=25%, HB=950。

关键词: 铜合金; 直升机旋翼配重构件; 金属型铸造 中图分类号: V214; TG249.3

文献标识码: A

Permanent-mold casting and foundry technique for helicopter rotor counterbalance component of copper alloy

LIU Zhao-jing, REN Shan-zhi, WU Shi-ping, LI Feng-zhen, ZUO Feng

(College of Materials Science and Engineering,

Harbin University of Science and Technology, Harbin 150040, China)

Abstract: According to the basic test and calculation for copper alloy by permanent-mold casting, foundry technique parameters of the rotor counterbalance component of helicopter were stated. The foundry technique parameters and programs were numerically simulated through CAD. The results show that the copper alloy density by permanent-mold casting attains 99.91% of theory density. The permanent-mold casting for the rotor counterbalance component of copper alloy can satisfy the requirements of design, i.e. the deviation is ±5g, the camber distortion is less than 0.20mm and the maximal section thickness distortion is ±0.10mm. The mechanical properties of the rotor counterbalance component are: σb=315MPa, σ0.2=143MPa, δ=25% and HB=950.

Key words: copper alloy; helicopter rotor counterbalance component; permanent-mold casting

航空工业对国民经济的发展起着重大的促进和推动作用, 飞行器的生产制造是航空工业技术水平的重要标志。 它是高新技术的综合和结晶[1], 其发展在各行业中应处于领先的地位[2, 3]。 直升机技术的发展与计算机辅助制造、 先进制造技术的实用化和应用水平的不断提高密不可分[4-6]。 旋翼是直升机的重要组成部分, 旋翼技术的发展始终处于直升机技术进步的前缘, 旋翼技术的每次进步都给直升机带来了跨越式的发展[7, 8], 因此人们对旋翼及其配重构件的制造要求越来越高。 旋翼配重构件与普通的铸件相比, 人们对其成分、 力学性能、 尺寸精度、 质量偏差等技术要求极为严格, 这就给铸造成型制造增加了很多难度。

本文作者通过对直升机旋翼及旋翼配重构件的理论分析和实验比较, 选用黄铜合金为原料并采用金属型铸造技术制备[9-11]直升机旋翼配重构件。 在对材料进行实验和计算的基础上, 确定直升机旋翼配重构件铸造成型的边界条件; 采用铸造CAD对直升机旋翼配重构件的铸造工艺参数及铸造工艺方案进行数值模拟, 再经过实际浇注验证并确定铸造工艺方案; 最后对铸件的性能进行测试。

1 铸造模型的确定及配制铜合金用原材料

1.1 铸造模型的确定

由于直升机旋翼配重构件的表面质量、 尺寸精度要求严格, 故采用砂型铸造难以保证质量要求; 采用熔模精密铸造虽然表面质量、 尺寸精度能满足要求, 但质量及性能要求难以达到技术指标。 经试验和分析比较, 采用金属型铸造[9]较为合适。

金属型铸造的特点是: 表面质量较好, 在保证铸件的高尺寸精度要求的前提下, 能减少铸件缩松的产生; 由于冷却速度快, 提高了铸件的力学性能, 可满足直升机旋翼配重构件的技术要求; 而且金属型铸造可降低生产成本, 缩短生产周期, 减少污染和能耗。

1.2 铜合金用原材料及密度

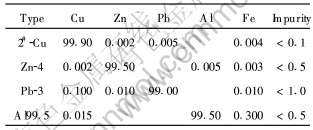

选工业用电解铜、 工业用纯锌锭、 工业用纯铅锭及工业用纯铝等原材料熔炼配置铜合金。 其选用原材料的化学成分见表1。

表1 原材料的化学成分

Table 1 Chemical composition of material (mass fraction, %)

原材料经熔炼在金属型中浇注后, 对铸件不同位置取样进行材料的密度测定。 测试结果: 边缘部分为8.495g/cm3; 中心部分为8.489g/cm3; 过度区为8.492g/cm3; 而铅黄铜的理论密度[12]为: 8.500g/cm3。

测试结果表明, 采用金属型铸造的铜合金铸件其密度达到理论密度的99.91%, 内部的气孔、 疏松等铸造缺陷均控制在较小的范围内, 能满足旋翼配重构件的技术要求。

2 铸造浇注方案的选择

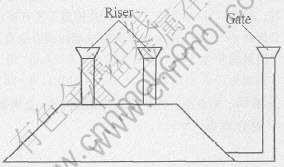

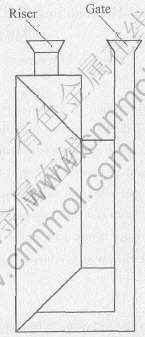

直升机旋翼配重构件的铸造方案可以有两种: 一种是卧式浇注, 浇冒口设在顶部或侧面(如图1所示); 第二种是立式浇注, 浇口采用缝隙浇口或缝隙加底注(如图2所示)。

图1 卧浇工艺方案示意图

Fig.1 Scheme of horizontal pouring program

图2 立浇工艺方案示意图

Fig.2 Scheme of vertical pouring program

经实验及分析表明:

1) 卧浇易于浇注成型, 但不利于排气、 去渣及补缩, 易于产生铸造缺陷; 立浇对浇注成型不利, 但有利排气、 去渣和补缩, 不易产生铸造缺陷。

2) 卧浇对铸造成型条件(如浇注温度、 浇注速度、 模具温度及涂料等)要求较低, 立浇对铸造工艺参数要求较高。

由于直升机旋翼配重构件的技术要求严格, 为保证其铸造质量, 在综合考虑和改进工艺的基础上, 采用立浇的铸造方案: 即缝隙浇口加底注式浇注系统, 顶部设置冒口。

3 浇注系统设计

3.1 浇注温度

由Cu-Zn合金相图[13]可知, 铜合金的液相温度在903℃以上。 考虑到合金流动性、 补缩、 铸型排气等因素, 将浇注温度设定在1050℃~1150℃范围内。

3.2 浇注时间

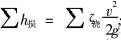

浇注时间是金属型铸造的重要工艺参数, 由下面的公式[14]确定:

式中 t为浇注时间, s; k为浇注系数, 取2.5~4.0; B为铸件最大壁厚, 取9.2cm; m为铸件质量, 取9.0kg。 计算得:

tmin=10.90s, tmax=17.43s

可将浇注时间控制在11~18s之间。

3.3 内浇道截面积

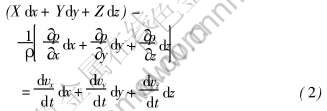

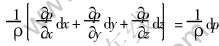

由伯努利方程[15]可知, 质点在理想流体中运动有微分方程:

式中 p为质点在流体中的压强; v为质点及流体的速度; ρ为液体的密度。

由于作用在流体中质点上只有重力, 即

X=Y=0, Z=-g,

故 Xdx+Ydy+Zdz=-gdz

又液体被视为不可压缩物体, 且在恒定流动时ρ为常数, p=p(x, y, z),

故

当dx=vxdt, dy=vydt, dz=vzdt时, 则有

将上述公式代入式(2)有:

积分后整理得:

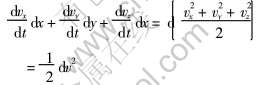

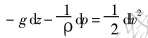

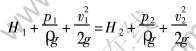

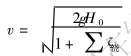

铜合金液体具有一定的粘性, 运动时要产生流动阻力[16], 因此有:

式中 H1、 H2分别为浇注系统上下点的位置, 两者之差为液态金属的静压头; p1、 p2为浇道的入口和出口处液体金属的压力; ρ为液体金属的密度; g为重力加速度; v1、 v2为浇道的入口和出口处液体金属的流速; ∑h损为金属液体在浇注系统中克服各种阻力的流速损失总和, ; ∑ξ浇为浇注系统的沿程和局部阻力系数总和。

; ∑ξ浇为浇注系统的沿程和局部阻力系数总和。

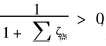

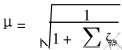

由图2可知, 浇注系统为开放式浇注系统, 所以浇道的入口压力p1=0, 出口的压力p2=0; 设: 金属液体在浇道的入口流速v1=0, 出口处流速v2= v, 浇注系统上点位置H1=H0, 下点的位置H2=0, 将这些条件代入式(3)得:

又

由式(5)可得:

由内浇道的金属液质量m2= ρF内tv, 其中F内为内浇道的截面积, 有:

而 , 令

, 令 代入式(6)得:

代入式(6)得:

故

将所确定的时间t代入式(7), 且m2=6000g, H0=40cm, μ在0.3~0.5之间, 得:

Fmin=2.52cm2, Fmax=8.40cm2

因此, 内浇道直径在8~27mm的范围内。

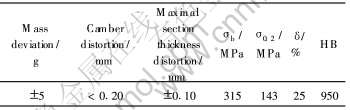

3.4 计算机数值模拟及铸造CAD

将试验和计算的参数值输入计算机, 经计算机对流场和温度场的数值模拟及铸造CAD试浇, 确定铸造工艺方案和工艺参数。 图3所示为一组结果图。 计算机的模拟浇注及计算的最佳参数如下:

F直∶F横∶F内=1∶1.2∶1.5; 内浇道直径为25mm; 冒口高度为铸件平均壁厚的2倍, 即110mm; 浇注温度为1100℃; 浇注时间为14s。

4 熔炼、 成型及铸件的性能

4.1 铜合金的熔炼

采用感应熔炼方式, 选用碳素坩埚炉衬。 其熔炼工艺中关键在于控制炉温。 由于锌极易氧化, 必须控制在合适温度下迅速加锌, 并进行搅拌。 铜水的过热温度必须严格控制, 温度过高将会出现锌的沸腾和氧化, 并吸收大量气体, 易使铸件易产生气孔, 温度过低将影响浇注成型。 铜合金液体的精炼也是控制铜合金质量的重要环节, 为了去气、 脱氧, 使用磷铜作为脱氧剂, 加入量为0.01%。

熔炼铜合金时, 由于含有一定量的Zn, 而Zn又极易氧化烧损, 所以铜液表面的覆盖就显得十分重要。 覆盖剂选用木炭粉或90%玻璃+10%氟石。 当发现有酸性或中性氧化物夹渣时, 应用Na3AlF6 40%和NaCl 60%进行精炼。

铜合金溶液在坩埚中停留时对其损耗有很大影响, 其停留时间与溶液损失呈线性关系, 为了避免不必要的损失, 尽量缩短停留时间, 待溶液过热温度达到后, 立即出炉浇注。

4.2 浇注成型

对金属型成型的铸件来说, 不论厚壁和薄壁铸件, 浇注工艺是重要环节。 浇注温度、 浇注速度及模具温度三者必须有机配合, 才能保证铸件成型并消除表面缺陷, 这也是直升机旋翼配重构件成型的关键技术之一。 根据计算机的模拟浇注所确定的参数, 浇注成型时, 浇注温度控制在1080~1120℃, 浇注时间控制在13~16s, 模具温度在250℃以上, 这样才能保证直升机旋翼配重构件成型后满足其技术要求。

4.3 铸件的性能及质量偏差

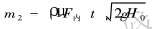

对在金属型中成型的直升机旋翼配重构件进行质量、 几何尺寸偏差的测量, 并取样制成试棒进行加工性能测试, 所得结果如表2所列。

表2 工艺参数的测量结果

Table 2 Measurement results of technique properties

图3 数值模拟及铸造CAD结果图

Fig.3 Numerical simulation and result of casting CAD

从表2可见, 所得结果均达到和超过直升机旋翼配重构件的技术要求和质量标准。

5 结论

1) 采用金属型铸造成型的直升机旋翼配重构件达到铜合金理论密度的99.91%, 能满足质量技术要求。

2) 利用计算机数值模拟和铸造CAD进行工艺试验, 提高了工艺参数的准确性, 并减少了试验次数, 提高了效率。

3) 金属型铸造成型后的直升机旋翼配重构件的质量偏差为±5g, 曲面变形小于0.20mm, 最大截面厚度偏差为±0.10mm。 经金属型铸造成型后的直升机旋翼配重构件的力学性能为: σb=315MPa, σ0.2=143MPa, δ=25%, HB=950。

REFERENCES

[1]崔德刚. 直升机研制与现代集成制造技术[J]. 航空制造技术, 2002(4): 43-58.

CHUI De-gang. Helicopter development and contemporary integrated manufacturing technology[J]. Aeronautical Manufacturing Technology, 2002(4): 43-58.

[2]陈怡枢. 中国直升机产业发展之路[J]. 航空制造技术, 2001(6): 19-21.

CHEN Yi-shu. Development of Chinese helicopter industry[J]. Aeronautical Manufacturing Technology, 2001(6): 19-21.

[3]倪先平, 蔡汝鸿, 曹喜金, 等. 直升机技术发展现状与展望[J]. 航空学报, 2003, 24(1): 15-19.

NI Xian-ping, CAI Ru-hong, CAO Xi-jin, et al. Present situation and prospects of helicopter technology[J]. Acta Aeronautica et Astronautica Sinica, 2003, 24(1): 15-19.

[4]陈怡枢. 现代直升机与制造技术[J]. 航空制造技术, 2000(6): 28-30.

CHEN Yi-shu. Modern helicopter and the manufacturing technology[J]. Aeronautical Manufacturing Technology, 2000(6): 28-30.

[5]林玉琛, 金孟江. 国外军用直升机的改进与发展[J]. 现代防御技术, 2000, 28(1): 1-8.

LIN Yu-chen, JIN Meng-jiang. Improvement and development of foreign military helicopter[J]. Modern Defence Technology, 2000, 28(1): 1-8.

[6]Aboulafia R. Outlook and specifications of world helicopter industry[J]. International Aviation, 2002(1): 31-34.

[7]杨开天. 加速发展旋翼技术促进我国直升机科技工业的进步[J]. 航空科学技术, 2002(2): 29-31.

YANG Kai-tian. Speeding up rotor technology and bring an advance in Chinese helicopter industry[J]. Aeronautical Science and Technology, 2002(2): 29-31.

[8]向锦武, 郭俊贤, 张晓谷. 直升机减振的旋翼桨叶优化设计研究综述[J]. 北京航空航天大学学报, 2002, 27(1): 32-35.

XUANG Jin-wu, GUO Jun-xian, ZHANG Xiao-gu. An overview of rotor blades optimum design for helicopter vibration reduction[J]. Journal of Beijing University of Aeronautics and Astronautics, 2002, 27(1): 32-34.

[9]朴学东, 李新亚. 铸铁金属型铸造工艺现状及发展趋势[J]. 现代铸铁, 2001, 21(1): 1-7.

PIAO Xue-dong, LI Xin-ya. Presnt situation and development tendency of permanent mould casting process of iron castings[J]. Modern Cast Iron, 2001, 21(1): 1-7.

[10]齐笑冰, 刘子安, 申泽骥, 等. 铸铁件金属型铸造用铜合金金属型研究[J]. 铸造技术, 2001, 23(5): 49-53.

QI Xiao-bing, LIU Zi-an, SHEN Ze-ji, et al. Study of copper alloy metal mold for castings [J]. Foundry Technology, 2001, 23(5): 49-53.

[11]Busch J. Selecting casting technology permanent molds perspective [J]. Modern Casting, 2003, 93(2): 43-45.

[12]中国机械工程学会铸造分会. 铸造手册(铸造非铁合金)[M]. 北京: 机械工业出版社, 2003. 289-293.

Foundry Institution of Chinese Mechanical Engineering Society. Foundry Handbook(Nonferrous Alloy)[M]. Beijing: Machine Industry Press, 2003. 289-293.

[13]铸造工程师手册编写组. 铸造工程师手册[M]. 北京: 机械工业出版社, 2003. 166-174.

Association for Compiling Handbook for Foundry Engineer. Handbook for Foundry Engineer[M]. Beijing: Machine Industry Press, 2003. 166-174.

[14]Foundry Academy of Japanese. Permanent-mold Casting of Iron[M]. Tokyo: Industry News Publishing House, 1976. 154-169.

[15]盛敬超. 工程流体力学[M]. 北京: 机械工业出版社, 1988. 40-70.

SHENG Jing-chao. Engineering Hydrodynamics[M]. Beijing: Machine Industry Press, 1988. 40-70.

[16]曹文龙. 铸造工艺学[M]. 北京: 机械工业出版社, 1989. 35-66.

CAO Wen-long. Casting Technology[M]. Beijing: Machine Industry Press, 1989. 35-66.

基金项目: 国家机械工业局科技项目(2000Q115)

收稿日期: 2004-08-31; 修订日期: 2004-11-24

作者简介: 刘兆晶(1956-), 男, 硕士.

通讯作者: 刘兆晶, 电话: 0451-86398210(H); E-mail: lzj956@21cn.com

(编辑何学锋)