文章编号:1004-0609(2016)02-0280-08

Al-Mg-Sc-Zr合金冷轧板材的超塑性变形行为

孙 雪1,潘清林1, 2,李梦佳2,史运嘉2,严 杰2

(1. 中南大学 轻合金研究院,长沙 410083;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:在温度450~520 ℃和1.67×10-3~1.00×10-1 s-1初始应变速率条件下对Al-Mg-Sc-Zr合金冷轧板材进行拉伸实验,研究该合金的超塑性流变行为,探讨其超塑性变形机理。结果表明:随着变形温度的升高,伸长率先增加后减小,在500 ℃和初始应变速率6.67×10-3 s-1条件下获得的最大伸长率为740%。合金的应变速率敏感因子为0.40,激活能为101 kJ/mol;在超塑性变形过程中,合金组织发生明显的动态再结晶,使原始纤维状晶粒等轴化;Al3(Sc,Zr)粒子可有效钉扎晶界,抑制晶粒长大;超塑性变形过程的主要变形机制为晶界滑移,协调机制为晶界扩散控制的位错蠕变。

关键词:Al-Mg-Sc-Zr合金;冷轧;超塑性;变形

中图分类号:TG146.2 文献标志码:A

向Al-Mg-Mn合金中添加微量元素Sc,可在基体中形成与基体共格的L12型Al3Sc粒子,大量弥散分布的Al3Sc粒子不仅可细化晶粒,提高合金的强度,使合金具有良好的成形性、耐热性、耐蚀性,还可使合金具有良好的超塑性[1-4]。近年来,国内外科研人员对含钪合金的超塑性开展了大量研究工作,多数学者利用等径角挤压[5-7]、搅拌摩擦焊[8-9]等加工技术,细化材料晶粒,从而满足超塑性的等轴、细晶条件。有学者研究指出轧制工艺制备出的带有明显纤维组织的材料也具有良好的超塑性[10-11],CHEN等[12]对Al-Mg-Sc冷轧薄板进行220 ℃退火处理,在450 ℃和2.00×10-4 s-1条件下,试样的最大伸长率可达421%。PENG等[13]对Al-Mg-Mn-Sc-Zr冷轧薄板进行稳定化退火处理,在520 ℃和1.67×10-3 s-1条件下伸长率达到690%。KUMAR等[14]对Al-Zn-Mg-Cu-Sc-Zr合金进行固溶、过时效处理热机械处理,最终制成2.3 mm厚的薄板,在475 ℃和2.00×10-4 s-1条件下,最大伸长率为650%。以上研究均对板材进行了预处理,耗费能源且超塑性拉伸时应变速率较低。因此,开展未经预处理合金板材的超塑性研究具有重要的意义。

本文作者以未经预处理的Al-Mg-Sc-Zr合金冷轧板材为研究对象,研究其在不同温度和应变速率条件下的力学性能和显微组织演变行为,探讨其超塑性变形机制,以期为实际生产提供实验依据。

1 实验

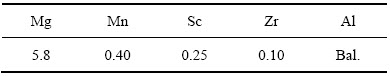

本研究采用活性熔剂保护熔炼,铜模水冷铸造的方法,利用纯铝、纯镁、Al-Mn、Al-Sc、Al-Zr等中间合金,制备合金铸锭。铸锭经460 ℃、24 h均匀化退火后,铣面至25 mm,再经热轧、中间退火和冷轧,制成厚度为2 mm的薄板[15],合金板材的化学成分如表1所列。

拉伸试样根据GB/24172-2009标准,采用线切割加工技术沿板材轧制方向制取,试样标距尺寸为18 mm×6 mm×2 mm。超塑性拉伸试验在GWT2504型高温拉伸机试验机上进行,采用对开式三段电阻丝加热,温度波动范围为±1 ℃。试验温度为450、475、500、525 ℃,初始应变速率为1.67×10-3、6.67×10-3、1.67×10-2、6.67×10-2、1.00×10-1 s-1。实验设备升温至指定温度后,放入试样并保温15 min。试验过程保持夹头速度恒定,至拉伸试样断裂后立即水淬冷却,以保留高温变形组织。

表1 Al-Mg-Sc合金的化学成分

Table 1 Chemical composition of Al-Mg-Sc alloy (mass fraction, %)

冷轧试样和拉伸后的试样,经机械抛光和阳极覆膜后在POLYVER-MET型光学显微镜下进行偏光观察,样品断口和断口侧面用Sirion 200型场发射扫描电镜进行观察分析。透射试样取自实验拉伸试样的变形部分,经机械减薄后双喷穿孔而成,电解液采用25% HNO3+75% CH3OH(体积分数)的混合溶液,温度为-25~-20 ℃,在TECNAIG2型透射电镜上进行观察。

2 结果与分析

2.1 超塑性变形行为

图1所示为Al-Mg-Sc-Zr合金冷轧板材超塑性变形的真应力-真应变曲线。曲线的共同特征为随着应变的增加,流变应力迅速上升,到达峰值应力后流变应力显著下降,直至断裂。超塑性变形过程中同时存在加工硬化和动态软化两种现象。若二者达到动态平衡,则会出现稳态流变阶段。在实验中并未观察到明显的稳态流变阶段,与NIEH等[16]和DUAN等[17]观察到的实验结果相似。

在500 ℃、不同初始应变速率条件下的真应力-真应变曲线如图1(a)所示。随着初始应变速率的减小,流动应力的峰值逐渐减小;在较高初始应变速率下,真应力-真应变曲线出现明显的锯齿状,这是由于在高应变速率下晶粒内部发生剧烈的动态再结晶,出现强烈的软化和硬化交替现象。当初始应变速率大于1.67×10-3 s-1时,流变应力显著上升。这是由于在较高初始应变速率下,位错密度迅速上升,可动位错减少,加工硬化率急剧增加,而变形时间较短,致使动态回复再结晶等软化作用不显著,最终导致应力逐渐增加。

图1(b)所示为Al-Mg-Sc-Zr合金在初始应变速率6.67×10-3 s-1不同温度下进行超塑性变形的真应力-真应变曲线。随着温度的升高,流变应力的峰值逐渐减小。这是由于当温度较高时,合金中的原子激活能和扩散速率增加,位错的滑移、攀移等较为激烈,位错节点易脱锚,动态再结晶的形核率较高,晶界的迁移、扩散速率也逐步增强,软化程度强于应变硬化程度,从而流变应力呈现出随温度升高而逐渐降低的趋势。

图1 温度和初始应变速率对Al-Mg-Sc-Zr合金冷轧板材真应力-真应变曲线的影响

Fig.1 Effects of initial strain rate and temperature on true stress-true strain curves of cold-rolled Al-Mg-Sc-Zr alloy sheet

Al-Mg-Sc-Zr合金在不同温度和不同初始应变速率下拉伸至断裂的伸长率如图2所示。在450~525 ℃范围内,该合金的伸长率均在200%以上。最佳超塑性变形条件为500 ℃和初始应变速率6.67×10-3 s-1,获得的最大伸长率为740%。即使在初始应变速率为1.00×10-1 s-1的高应变速率条件下,伸长率仍可达到284%。

由图2可知,在相同变形温度条件下,伸长率随应变速率的降低呈先升高后降低的趋势。这是由于协调超塑性变形的晶界扩散、动态回复及动态再结晶等软化机制需要时间,随着变形速率的降低,超塑性变形时间延长,软化作用显著,可抵消加工硬化引起的应力集中,有利于超塑性变形;应变速率过低时,试样在高温下保温时间过长,晶粒易长大、粗化,使晶界滑移和晶粒转动难以进行,导致晶界附近区域应力高度集中,从而降低合金的塑性。

在相同初始应变速率条件下,伸长率随着温度的升高先增加后减小,呈抛物线型变化,在500 ℃时达到最大值。在较低温度范围内,随着变形温度的升高,原子的自由能逐渐提高,晶粒之间的扩散协调速率及晶界的协调变形能力也逐渐提高,因此,伸长率逐渐升高;当温度超过500 ℃后,随温度的升高,伸长率下降,可能是由于高温下晶界处出现的低熔点液相过多,致使晶界的变形协调性变差所致[16]。

实验结果表明,未经预处理的Al-Mg-Sc-Zr合金冷轧板材在较宽的温度和初始应变速率范围内,呈现出良好的超塑性能。

图2 Al-Mg-Sc-Zr合金在不同温度和不同初始应变速率下的伸长率

Fig.2 Elongation of cold-rolled Al-Mg-Sc-Zr at various temperatures and initial strain rates

根据唯象学理论,超塑性变形的本构方程可用以下方程表示[18]:

(1)

(1)

式中:A为常数;D0为扩散系数;E为弹性模量;b为伯格斯矢量; 为波尔兹曼常数;T为绝对温度;d晶粒尺寸;p为晶粒尺寸指数,一般为2~3;m为应变速率敏感因子;

为波尔兹曼常数;T为绝对温度;d晶粒尺寸;p为晶粒尺寸指数,一般为2~3;m为应变速率敏感因子; 为应力;Q为应变激活能,取决于不同的扩散控制机制;R为气体常数。

为应力;Q为应变激活能,取决于不同的扩散控制机制;R为气体常数。

式(1)中应变速率敏感因子m是衡量材料超塑性的重要指标,用于表征材料抵抗颈缩的能力。本实验采用斜率法确定应变速率敏感因子。m一般定义为

(2)

(2)

图3所示为不同温度下1.67×10-3~1.00×10-1 s-1应变速率范围内合金超塑性变形流变应力( =0.3)和应变速率的自然对数坐标关系。由式(2)可知,曲线的斜率为m值。对图3数据进行一元线性回归处理,得出450、475、500、525 ℃的应变速率敏感因子分别为0.37、0.39、0.42和0.41。随变形温度的升高,m值逐渐上升,500 ℃时m值达到最大值,随后开始下降。在500 ℃和1.67×10-3~1.00×10-1 s-1范围内,m值0.42接近0.5,表明超塑性变形的主要变形机制为晶界滑移。

=0.3)和应变速率的自然对数坐标关系。由式(2)可知,曲线的斜率为m值。对图3数据进行一元线性回归处理,得出450、475、500、525 ℃的应变速率敏感因子分别为0.37、0.39、0.42和0.41。随变形温度的升高,m值逐渐上升,500 ℃时m值达到最大值,随后开始下降。在500 ℃和1.67×10-3~1.00×10-1 s-1范围内,m值0.42接近0.5,表明超塑性变形的主要变形机制为晶界滑移。

图2中伸长率的最大值也出现在500 ℃,即m的最大值和伸长率的最大值出现在同一温度。由此可知m值越大,伸长率越大。但也有研究表明,m值越大,伸长率不一定最大[6]。

图3 Al-Mg-Sc-Zr合金不同温度下真应力和初始应变速率的关系

Fig.3 Relationship between true stress and initial strain rate of Al-Mg-Sc-Zr alloy

不同扩散控制的超塑性变形过程的激活能不同,在铝基体中晶界扩散激活能为84 kJ/mol,Mg原子在铝基体中的晶格扩散激活能为136 kJ/mol。为进一步探明超塑性变形机理,根据式(2)计算Al-Mg-Sc-Zr冷轧板材的超塑性变形的激活能Q:

(3)

(3)

式中: 为

为 =0.3时的流变应力;m为应变速率敏感因子。

=0.3时的流变应力;m为应变速率敏感因子。

图4所示为不同初始应变速率下流变应力 与温度T的关系曲线,根据曲线斜率即可求出超塑性变形的激活能。经计算求得不同应变速率下超塑性变形激活能的平均值约为101 kJ/mol,介于晶格扩散和晶界扩散的激活能之间,且更接近晶界扩散的激活能84 kJ/mol。这表明在超塑变形过程中,晶格扩散与晶界扩散同时存在,但晶界扩散是主要途径。

与温度T的关系曲线,根据曲线斜率即可求出超塑性变形的激活能。经计算求得不同应变速率下超塑性变形激活能的平均值约为101 kJ/mol,介于晶格扩散和晶界扩散的激活能之间,且更接近晶界扩散的激活能84 kJ/mol。这表明在超塑变形过程中,晶格扩散与晶界扩散同时存在,但晶界扩散是主要途径。

以上分析表明,未经预处理的Al-Mg-Sc-Zr合金板材超塑性变形过程中主要变形机制为晶界滑移,主要扩散控制机制为晶界扩散。

图4 不同应变速率下Al-Mg-Sc-Zr合金超塑性变形流变应力与温度的关系曲线

Fig. 4 Relationship between flow stress and temperature of Al-Mg-Sc-Zr alloy at different strain rates

2.2 超塑性变形过程的组织特征

图5所示为Al-Mg-Sc-Zr合金原始冷轧态。合金原始冷轧态为细长的纤维状轧制变形组织,在500 ℃、6.67×10-3 s-1初始应变速率条件下,高温变形态合金组织见图6。由图6(a)可见,试样夹持部分晶粒组织整体仍为细长的纤维变形组织,呈流线型沿轧向分布。由于仅受时间和温度的影响,夹持部分只出现少量的再结晶晶粒。由图6(b)可见,试样断口附近的组织为均匀、细小的等轴晶粒,表明合金已发生了完全再结晶。图6(b)中还可观察到一些沿晶界分布的空洞。

经剧烈变形后的晶粒组织呈等轴状,沿拉伸方向无明显变形,表明晶界滑移在超塑性变形过程中起了重要作用。高温条件下,晶界的迁移和扩散能力也有所提高,有利于晶界的滑移。超塑性变形过程以晶界滑移为主要变形机制,晶粒通过晶界的迁移和滑移协调超塑性变形[19]。

WANG等[20]研究的Al-Mg-Sc-Zr合金板材完全再结晶温度为580 ℃,本研究中Al-Mg-Sc-Zr合金在超塑性变形条件下、500 ℃时已发生完全再结晶,这是由于在应力和温度的共同作用下,变形组织发生了动态再结晶。

本实验中合金的初始变形组织为纤维状轧制变形组织,不利于超塑性变形。但动态再结晶使合金原始纤维状组织等轴化,等轴晶可降低变形过程中的剪切应力,为Al-Mg-Sc-Zr合金冷轧板材的超塑性变形创造良好的组织条件。因此,与细晶、等轴材料的变形相比,动态再结晶对变形合金的超塑性变形更加重要。动态再结晶还可细化晶粒,细小晶粒晶界短而多,利于晶界的滑移和转动。动态再结晶后,大角度晶界增加,晶界扩散能力增强。此外,动态再结晶可消耗该处周围的应变能,降低位错密度,有效缓解变形时晶界或第二相粒子处的应力集中,利于合金的超塑性变形。

图5 Al-Mg-Sc-Zr合金的冷轧态光学显微组织

Fig. 5 Optical microstructures of cold-rolled Al-Mg-Sc-Zr alloy

图6 初始应变速率6.67×10-3 s-1、温度为500 ℃时Al-Mg-Sc-Zr合金的光学显微组织

Fig. 6 Optical microstructures of Al-Mg-Sc-Zr alloy tested at initial strain rate of 6.67×10-3 s-1 and 500 ℃

图7所示为合金在500 ℃和初始应变速率6.67×10-3 s-1变形条件下拉伸至断裂断口附近的TEM像。

图7 在500 ℃和6.67×10-3 s-1条件下试样拉伸至断裂的TEM像

Fig. 7 TEM images of samples deformed to failure at 500 ℃ and 6.67×10-3 s-1

图7(a)中晶界平直光滑,出现明显的三叉晶界,证明合金内部已出现再结晶现象。

图7(b)中可见豆瓣状Al3(Sc,Zr)粒子弥散地分布在晶界和晶粒内部。Al3(Sc,Zr)粒子与晶界强烈的交互作用使变形阻力增加,阻碍晶界的迁移。Al3(Sc,Zr)粒子中间的无衬度带表明粒子与基体保持稳定的共格关系[3],这种关系使Al3(Sc,Zr)粒子具有良好的稳定性,从而能更有效地钉扎晶界,进而抑制高温热效应和应变引起的晶粒长大和粗化。如图7(c)所示,由于Al3(Sc,Zr)粒子的钉扎作用,再结晶的晶粒尺寸约为5 μm (<10 μm),满足超塑性变形的细晶、稳定条件。

超塑性变形主要是一种晶界行为,高密度且平坦的晶界有利于超塑性[21],而Al3(Sc,Zr)粒子有效抑制应变诱导及热效应引起的晶粒粗化现象,抑制晶粒长大,使合金晶粒在超塑性变形过程中保持细小、等轴的组织结构,提高合金的塑性变形能力。

2.3 断口及表面形貌

图8所示为冷轧板材在500 ℃和6.67×10-3 s-1条件下的断口及断口侧面形貌。由图8(a)可见,断口表面存在大量完整、细小的等轴晶粒,这是晶界滑移的结果;断口表面可见接近等轴且均匀分布的空洞。断口呈沿晶和空洞混合断裂的特征,晶粒表面及空洞周围无明显的撕裂变形痕迹,表明超塑性断裂不是由宏观颈缩造成。

从图8(a)中还可看出,断口表面分布着少量丝状物。一些研究认为,细丝是分布在晶界处的低熔点物质在高温作用下熔化,形成初生液相,初生液相沿晶界扩展,变形过程中在拉应力作用下被拉长、冷却后形成的[22]。超塑性变形过程中,伴随着晶界滑移和晶粒转动的进行,晶粒间产生了粘滞性流动,由此在晶界或粒子连接处产生应力集中,若不能及时通过扩散流动或位错运动等释放应力,晶界滑移就会被迫停止,此时,具有粘性的细丝可使应力得到松弛,晶界滑移等得以继续进行。细丝的存在表明超塑性变形过程中可能存在液相辅助机制[16-17]。从断口侧面形貌图8(d)也可观察到沿晶界分布的丝状物,但丝状物的取向并不完全相同,表明在超塑性变形过程中存在位错蠕变过程[23],辅助协调晶界滑移,促使晶粒发生变位和扭转。

在断口形貌图8(b)中可观察到晶粒逐渐趋于圆角化,由于超塑性变形过程中晶粒发生滑动和转动,晶粒间出现了微小的滑移间隙。图8(c)所示为断口侧面的微观形貌,从图8(c)中可看到断口附近有很多V型和O型的空洞。大量空洞沿拉伸方向连接、长大、聚合。晶粒呈等轴状,晶粒间存在的明显的粘流状塑性变形痕迹进一步表明,晶界滑移是超塑性变形的主要变形机制。图8(c)中还可见少量伸长较少的变形晶粒,在拉应力作用下,空位从垂直于拉伸轴的高势能晶面沿晶界扩散到平行于拉伸轴的低势能晶面,同时,合金中的原子反向扩散,由此导致晶粒发生变形[21]。图8(d)中变形晶粒数量较少,且变形量较小,表明扩散蠕变在超塑性变形过程中的贡献较小。

图8 在500 ℃、初始应变速率为6.67×10-3 s-1时合金板材拉伸至断裂的断口和断口侧面形貌

Fig. 8 Morphologies of cold-rolled alloy sheet deformed to failure at 500 ℃ and initial strain rate of 6.67×10-3 s-1

3 结论

1) 未经预处理的Al-Mg-Sc-Zr合金冷轧板材,在较宽的初始应变速率(1.67×10-3~1.00×10-1 s-1)和较宽温度范围(450~525 ℃)内具有良好的超塑性。在500 ℃和初始应变速率为1.67×10-3 s-1条件下最大伸长率可达740%。即使在初始应变速率为1×10-1 s-1的高应变速率下,伸长率仍可达到284%。

2) 在450~525 ℃范围内,应变速率敏感因子随着温度的升高而升高,在500 ℃时达到最大值0.42,随后降低。超塑性变形过程的平均激活能为101 kJ/mol。

3) 在超塑性变形过程中,合金发生明显的动态再结晶,使原始纤维状晶粒等轴化,为晶界滑移创造了良好的变形条件。Al3(Sc,Zr)粒子钉扎晶界,有效抑制晶粒粗化,使合金保持细小、等轴的晶粒结构,有利于合金的超塑性变形。

4) 冷轧态Al-Mg-Sc-Zr合金的超塑性变形过程是多种机制共同作用的过程,晶界滑移是主要变形机制,晶界扩散控制的位错蠕变为其协调机制。

REFERENCES

[1] JIA Z H, ROYSET J, SOLBERG J K, LIU Qing. Formation of precipitates and recrystallization resistance in Al-Sc-Zr alloys[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1866-1871.

[2] FULLER C B, SEIDMAN D N, DUNAND C D. Mechanical properties of Al(Sc,Zr) alloys at ambient and elevated temperature[J]. Acta Materialia, 2003, 51(16): 4803-4814.

[3] 陈 琴, 潘清林, 王 迎, 彭 虹, 张志野, 尹志民. 微量Sc和Zr 对 Al-Mg-Mn 合金组织与力学性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1555-1563.

CHEN Qin, PAN Qing-lin, WANG Ying, PENG Hong, ZHANG Zhi-ye, YIN Zhi-min. Effects of minor scandium and zirconium on microstructure and mechanical properties of Al-Mg-Mn alloys[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1555-1563.

[4] 王 旭, 陈国钦, 李 冰, 武高辉, 蒋大鸣. 复合添加Sc、Zr、Ti对Al-Mg合金组织与性能的影响[J]. 稀有金属材料与工程, 2010, 39(4): 719-722.

WANG Xu, CHEN Guo-qin, LI Bing, WU Gao-hui, JIANG Da-ming. Effect of minor Sc, Zr and Ti co-addition on microstructure and properties of Al-Mg alloys[J]. Rare Metal Materials and Engineering, 2010, 39(4): 719-722.

[5] AVTOKRATOVA E, SITDIKOV O, MARKUSHEV M, MULYUKOV R. Extraordinary high-strain rate superplasticity of severely deformed Al-Mg-Sc-Zr alloy[J]. Materials Science and Engineering A, 2012, 538: 386–390.

[6] MUSIN F, KAIBYSHEV R, MOTOHASHI Y. High strain rate superplasticity in a commercial Al-Mg-Sc alloy[J]. Scripta Materialia, 2004, 50(4): 511-516.

[7] DAM K, LEJCEK P, MICHALCOVA A. In situ TEM investigation of microstructural behavior of superplastic Al-Mg-Sc alloy[J]. Materials Characterization, 2013, 76: 69-75.

[8] LIU F C, XUE P, MA Z Y. Microstructural evolution in recrystallized and unrecrystallized Al-Mg-Sc alloys during superplastic deformation[J]. Materials Science and Engineering A, 2012, 547: 55-63.

[9] MA Z Y, LIU F C, MISHRA R S. Superplastic deformation mechanism of an ultrafine-grained aluminum alloy produced by friction stir processing[J]. Acta Materialia, 2010, 58(14): 4693-4704.

[10] 林兆荣. 金属超塑性成型原理及应用[M]. 北京: 航空工业出版社, 1990: 24.

LIN Zhao-rong. The principle and application of metal superplastic formation[M]. Beijing: The Aviation Industry Press, 1990: 24.

[11] 赵 莎, 叶凌英, 张新明. 5A90铝锂合金超塑变形的不均匀性及其对空洞演化的影响[J]. 中国有色金属学报, 2013, 23(8): 2125-2132.

ZHAO Sha, YE Ling-ying, ZHANG Xin-ming. Inhomogeneity of 5A90 Al-Li alloy during superplastic deformation and its effect on evolution of cavity[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(8): 2125-2132.

[12] CHEN Ming-he, ZHANG Jie-gang, LI Jin-hua. Superplasticity and superplastic forming ability of Al-Mg-Sc alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S3): s1411-s1414.

[13] PENG Yong-yi, YIN Zhi-min, NIE Bo. Effect of minor Sc and Zr on superplasticity of Al-Mg-Mn alloys[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(4): 744-750.

[14] KUMAR A, MUKHOPADHYAY A K, PRASAD K S. Superplastic behaviour of Al-Zn-Mg-Cu-Zr alloy AA7010 containing Sc[J]. Materials Science and Engineering A, 2010, 527(3): 854-857.

[15] 王 迎, 潘清林, 彭 红, 李 晨, 陈 琴, 尹志民. 退火温度对铝镁钪合金力学和腐蚀性能的影响[J]. 材料科学与工程学报, 2012, 30(6): 913-918.

WANG Ying, PAN Qing-lin, PENG Hong, LI Chen, CHEN Qin, YIN Zhi-min. Effect of annealing temperature on mechanical and corrosion properties of Al-Mg-Sc alloy[J]. Journal of Materials Science and Engineering, 2012, 30(6): 913-918.

[16] NIEH T G, HSIUNG L M, WADSWORT J, KAIBYSHEV R. High strain rate superplastic in a continuously recrystallized Al-6%Mg-0.3%Sc alloy[J]. Acta Materialia, 1998, 46(8): 2789-2800.

[17] DUAN Y L, XU G F, XIAO D, ZHOU L Q, DENG Y, YIN Z M. Excellent superplasticity and deformation mechanism of Al-Mg-Sc-Zr alloy processed via simple free forging[J]. Materials Science and Engineering A, 2015, 624: 124-131.

[18] LANGDON T G. The physics of superplastic deformation[J]. Materials Science and Engineering A, 1991, 137: 1-11.

[19] 宋玉泉, 刘 颖, 宋家旺. 铝系金属间化合物的超塑性[J]. 金属学报, 2008, 44(1): 1-7.

SONG Yu-quan, LIU Ying, SONG Jia-wang. Superplasticity of aluminium series intermetallic compounds[J]. Acta Metallurgica Sinica, 2008, 44(1): 1-7.

[20] WANG Ying, PAN Qing-lin, SONG Yan-fang, LI Chen, LI Zhi-feng, CHEN Qin, YIN Zhi-min. Recrystallization of Al-5.8Mg-Mn-Sc-Zr alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3235-3241.

[21] 吴诗惇. 金属超塑性变形理论[M]. 北京: 国防工业出版社, 2007: 7-8.

WU Shi-dun. The theory of superplastic deformation of metal[M]. Beijing: National Defense Industrial Press, 2007: 7-8.

[22] LIU F C, MA Z Y. Low-temperature superplasticity of friction stir processed Al-Zn-Mg-Cu alloy[J]. Scripta Materialia, 2008, 58(8): 667-670.

[23] 郑 翊, 严红革, 陈吉华, 余海洋, 苏 斌. 高应变速率轧制ZK60板材的超塑性[J]. 中国有色金属学报, 2014, 24(4): 839-847.

ZHENG Yi, YAN Hong-ge, CHEN Ji-hua, YU Hai-yang, SU Bin. Superplasticity behavior of ZK60 alloy sheet prepared by high strain rate rolling process[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 839-847.

Superplastic deformation behavior of cold-rolled Al-Mg-Sc-Zr alloy sheet

SUN Xue1, PAN Qing-lin1, 2, LI Meng-jia2, SHI Yun-jia2, YAN Jie2

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The tensile tests for cold-rolled Al-Mg-Sc-Zr alloy were conducted at temperature of 450-500 ℃ and initial strain rate of 1.67×10-3-1.00×10-1 s-1. The flow behavior and deformation mechanism were investigated. The results show that the elongation changes as a parabola with the deformation temperature increasing, and the maximum elongation of 740% is achieved at 500 ℃ and 6.67×10-3 s-1. The strain rate sensitivity is 0.40, and the activation energy is 101 kJ/mol. The obvious dynamic recrystallization (DRX) is observed, which can transfer the grain from original fibrous structure to equiaxed microstructure. The Al3(Sc,Zr) particles pin effectively at grain boundaries to resist grain growth. The grain boundary sliding is the dominant deformation mechanism during the superplastic deformation, the dislocation creep controlled by grain boundary diffusion is the main accommodation mechanism.

Key words: Al-Mg-Sc-Zr alloy; cold-rolling; superplasticity; deformation

Foundation item: Project(2012CB619503) supported by the National Basic Research Development Program of China

Received date: 2015-05-19; Accepted date: 2015-10-09

Corresponding author: PAN Qin-lin; Tel: +86-73l-88830933; E-mail: pql@csu.edu.cn

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2012CB619503)

收稿日期:2015-05-19;修订日期:2015-10-09

通信作者:潘清林,教授,博士;电话:073l-88830933:E-mail: pql@csu.edu.cn