添加Mg和T6热处理对Al-12Si-3Cu基合金显微组织、力学性能和摩擦学性能的影响

来源期刊:中国有色金属学报(英文版)2021年第8期

论文作者:M. BEDER Y. ALEMDAG

文章页码:2208 - 2219

关键词:Al-Si-Cu合金;Mg含量;T6处理;显微组织;力学性能;磨损性能;断裂面

Key words:Al-Si-Cu alloys; Mg content; T6 treatment; microstructure; mechanical properties; wear properties; fracture surface

摘 要:通过永久型铸造制备一系列Al-12Si-3Cu-(0.5-2.5)Mg(质量分数,%)合金,然后进行T6热处理,研究添加Mg和T6热处理对Al-Si-Cu-Mg合金显微组织、力学性能和摩擦学性能的影响。采用OM、XRD、SEM、EDS等测试手段研究其显微组织,并进行硬度、拉伸、压缩和Charpy冲击试验,测试其力学性能。用球对盘式摩擦试验机研究合金的干滑动摩擦磨损性能。结果表明,铸态Al-12Si-3Cu-Mg合金显微组织中含有α(Al)、Si、θ-CuAl2、β-Mg2Si、Q-Al5Mg8Cu2Si6和π-Al8Mg3FeSi6相。T6热处理使共晶Si颗粒近球化,形成较细的θ-CuAl2和β-Mg2Si 沉淀相,消除β-Mg2Si相的汉字形貌。添加2.5% Mg降低铸态和T6处理后合金的硬度、抗拉和抗压强度、拉伸伸长率和冲击韧性,增加摩擦因数和体积磨损量。另一方面,T6处理显著提高铸态合金的力学性能和耐磨性能。

Abstract: The aim of the present study was to investigate the influence of Mg addition and T6 heat treatment on microstructure, mechanical and tribological properties of the Al-Si-Cu-Mg alloys. In this context, a series of Al-12Si-3Cu-(0.5-2.5)Mg (wt.%) alloys were produced by permanent mould casting, and then subjected to T6 treatment. Their microstructure and mechanical properties were investigated using OM, XRD, SEM, EDS along with hardness, tension, compression and Charpy impact tests. Dry sliding friction and wear properties of the alloys were studied using a ball-on-disk type tester. It was observed that the microstructure of as-cast Al-12Si-3Cu-Mg alloys consisted of α(Al), Si, θ-CuAl2, β-Mg2Si, Q-Al5Mg8Cu2Si6 and π-Al8Mg3FeSi6 phases. T6 heat treatment gave rise to nearly spherodization of eutectic Si particles, formation of finer θ-CuAl2 and β-Mg2Si precipitates and elimination of Chinese script morphology of β-Mg2Si phase. The addition of Mg up to 2.5 wt.% decreased the hardness, tensile and compressive strengths, tensile elongation and impact toughness of the as-cast and T6-treated alloys and increased their friction coefficient and volume loss. T6 treatment, on the other hand, led to a significant increase in mechanical properties and wear resistance of as-cast alloys.

Trans. Nonferrous Met. Soc. China 31(2021) 2208-2219

M. BEDER1, Y. ALEMDAG2

1. Department of Mechanical Engineering, Gumushane University, Gumushane, Turkey;

2. Department of Mechanical Engineering, Karadeniz Technical University, Trabzon, Turkey

Received 7 August 2020; accepted 22 May 2021

Abstract: The aim of the present study was to investigate the influence of Mg addition and T6 heat treatment on microstructure, mechanical and tribological properties of the Al-Si-Cu-Mg alloys. In this context, a series of Al-12Si-3Cu-(0.5-2.5)Mg (wt.%) alloys were produced by permanent mould casting, and then subjected to T6 treatment. Their microstructure and mechanical properties were investigated using OM, XRD, SEM, EDS along with hardness, tension, compression and Charpy impact tests. Dry sliding friction and wear properties of the alloys were studied using a ball-on-disk type tester. It was observed that the microstructure of as-cast Al-12Si-3Cu-Mg alloys consisted of α(Al), Si, θ-CuAl2, β-Mg2Si, Q-Al5Mg8Cu2Si6 and π-Al8Mg3FeSi6 phases. T6 heat treatment gave rise to nearly spherodization of eutectic Si particles, formation of finer θ-CuAl2 and β-Mg2Si precipitates and elimination of Chinese script morphology of β-Mg2Si phase. The addition of Mg up to 2.5 wt.% decreased the hardness, tensile and compressive strengths, tensile elongation and impact toughness of the as-cast and T6-treated alloys and increased their friction coefficient and volume loss. T6 treatment, on the other hand, led to a significant increase in mechanical properties and wear resistance of as-cast alloys.

Key words: Al-Si-Cu alloys; Mg content; T6 treatment; microstructure; mechanical properties; wear properties; fracture surface

1 Introduction

Al-Si alloys are increasingly employed in automotive industry owing to their attractive properties such as high specific strength, good wear resistance, low thermal expansion coefficient and excellent castability [1,2]. These alloys are especially exploited to produce internal combustion engine parts including engine blocks, cylinder heads, pistons and liners [1-3]. In order to obtain improved performance, Al-Si alloys are generally alloyed with Cu and/or Mg elements [4-7]. Cu addition usually varies from 1 to 4 wt.%, while Mg content is generally lower than 1 wt.% [4,8,9]. As the Cu addition increases, strength and wear resistance of the Al-Si alloys increase due to the formation of θ-CuAl2 phase [4,10,11]. Nevertheless, Cu additions more than 3-4 wt.% lower the eutectic temperature and enlarge solidification range of Al-Si-Cu alloys [11-14]. This gives rise to the formation of porosity, hot tearing and intergranular corrosion in the alloys. On the other hand, Mg addition up to 1 wt.% increases the strength of Al-Si-Cu alloys by forming β-Mg2Si and Q-Al5Cu2Mg8Si6 phases, modifying the eutectic Si particles and converting plate-like AlFeSi phase to more regular π-Al8Mg3FeSi6 phase [7,9,15-17]. However, the volume fractions of β-Mg2Si, π and Q phases increase when the Mg additions exceed 1.5 wt.% [4,9,16,17]. These phases exhibit Chinese script, string-like and bar type morphologies, respectively and adversely affect the tensile properties by forming internal cracks under tensile loading.

Cu and Mg additions, on the other hand, improve the heat treatability of quaternary Al-Si-Cu-Mg alloys compared with ternary Al-Si-Cu and Al-Si-Mg ones [4,10,18]. Amongst the adopted heat treatments, T6 treatment consisting of the solution treatment, quenching and natural or artificial peak aging is commonly applied to Al-Si-Cu-Mg casting alloys [4,10]. This treatment promotes the formation of fine θ and β-Mg2Si precipitates and transforms needle-like Si particles into more regular morphologies [4,7,10,19]. Unlike Al-Si-Cu and Al-Si-Mg alloys, the formation of both θ and β-Mg2Si precipitates in Al-Si-Cu-Mg alloys depends on the Cu/Mg ratio in solid solution [4,6,10,20,21]. It is reported that Mg2Si precipitates form when this ratio is about 2 at.% while the θ phase takes place at a ratio of about 8 at.% [4,10]. It is also reported that high amount of Cu and Mg additions enhance the formation of θ, π and Q strengthening precipitates [4,6,7,10,18]. The above literature surrey shows that the influence of high amount of Mg addition on mechanical and tribological properties of Al-Si-Cu alloys is still hot topics and it needs to be systematically investigated. Therefore, the aim of present study was set to assess the influence of high amount of Mg addition and T6 treatment on hardness, tensile and comprehensive properties, and friction and wear behaviors of Al-12Si-3Cu based alloys.

2 Experimental

2.1 Preparation of alloys and T6 treatment

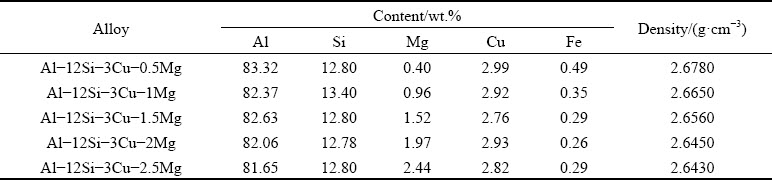

Al-12Si-3Cu-(0.5-2.5)Mg (wt.%) alloys were produced by using commercially pure Al (99.7%), Mg (99.9%), Al-20Si and Al-50Cu intermetallics. These alloys were placed into an induction furnace and melted at 780 °C and then poured from 750 °C into mild steel mould after stirring for 5 min. The mould was manufactured as a conical shape with a length of 180 mm, a bottom diameter of 57 mm and a top diameter of 70 mm. After the solidification was completed, ingots were extracted from the mould and their chemical compositions were determined by spectral analysis. To determine the density of alloys, cylindrical samples having a size of d10 mm × 10 mm were machined and their mass and volume were measured. Density of alloys was calculated by dividing their mass to their volume. The chemical compositions and densities of the alloys were shown in Table 1.

Ingots were divided into two parts along their longitudinal sections. In order to determine the properties of alloys, the first part was used to characterize the as-cast state, while the second part was subjected to T6 treatment. For this treatment, half ingots were solutionized at 510 °C for 24 h, quenched in water at room temperature and aged at 175 °C for 10 h. The T6 treatment parameters were chosen based on the previous works [4,6,10].

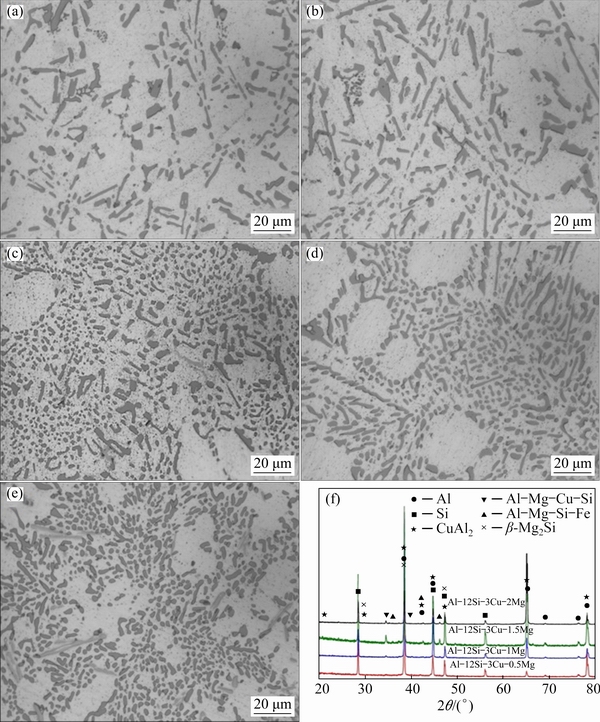

2.2 Microstructural examinations

The microstructures of the alloys were analyzed by using optical microscopy (OM), scanning electron microscopy (SEM) equipped with energy dispersive spectroscopy (EDS) and X-ray diffractometry (XRD). For microscopic examinations, samples were prepared according to standard metallography techniques including mounting, grinding and polishing, and then etched with fluoroboric acid solution (6 vol.% HBF4 + 94 vol.% distilled water). For XRD analysis, the samples were scanned at Bragg angles from 20° to 80° with a scanning speed of 3 (°)/min using Cu Kα radiation.

Table 1 Chemical compositions and densities of Al-12Si-3Cu-(0.5-2.5)Mg alloys (wt.%)

2.3 Mechanical tests

The hardness of the samples was measured with Brinell hardness by using a d2.5 mm ball indenter at a load of 625 N. The tensile and compressive tests were carried out on dog-bone shaped and cylindrical samples, respectively. Dog-bone shaped samples were prepared by using a wire electro discharge machine (W-EDM) with a gauge section of 2.5 mm × 5.6 mm and length of 20 mm while cylindrical ones having a diameter of 10 mm and a height of 10 mm were machined with lathe. These tests were conducted at a strain rate of 5×10-4 s-1 and room temperature. In compression tests, strength value that caused to 50% reduction in height of cylindrical samples was taken as a compressive strength for alloys. Due to brittle nature of the alloys, un-notched samples having dimensions of 10 mm × 10 mm × 55 mm were used to determine their impact toughness. The tests were performed using a Charpy impact tester with an accuracy of ±0.083 J. To confirm the accuracy of results, each tests were repeated at least five times for all conditions. The fracture surfaces of tensile samples were also examined with OM and SEM.

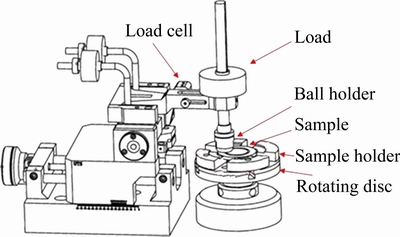

2.4 Dry sliding wear tests

Dry sliding wear tests were carried out by using a ball-on-disc type tribometer designed according to ASTM: G99 standard. The schematic diagram of tribometer is given in Fig. 1. Its working principle is available in previous works [22-24]. The disc type samples having dimensions of d24 mm × 7 mm were cut from the ingots with W-EDM, and then were ground and polished in automatic grinding and polishing machine and were cleaned ultrasonically in acetone. After measuring their mass with a balance having a sensitivity of ±0.01 mg, they were placed into sample holder and run against 6 mm diameter 100Cr6 steel ball. These tests were performed under a normal load of 5 N at a sliding speed of 0.16 m/s for a sliding distance of 1500 m. After tests, samples were removed, cleaned and weighed to obtain the mass loss. The measured mass loss due to wear was divided by density of the alloys and converted into volume loss. During tests, the friction force was recorded and friction coefficient was calculated. Each wear test was repeated at least three times and average values of results were taken as the volume loss of the alloys. To determine the wear mechanism of the alloys, contact surfaces and wear particles were also examined with SEM.

Fig. 1 Schematic illustration of ball-on-disc tribometer

3 Results and discussion

3.1 Microstructure

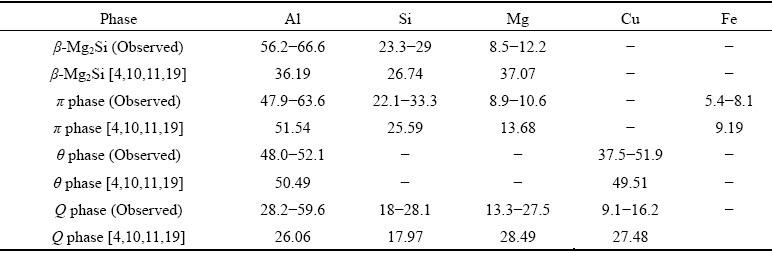

Microstructures and XRD patterns for as-cast alloys are given in Fig. 2. Their microstructures consist of α(Al) matrix, mainly eutectic and little amount of primary Si, Cu- and Mg-containing phases. Additions of Mg above 0.5 wt.% refine the Si particles and result in their accumulation of between α(Al) grains, as shown in Figs. 2(b-e). The EDS analysis results of Cu- and Mg-containing phases are given in Table 2. XRD and EDS analysis results suggest that these phases consist of θ-CuAl2, β-Mg2Si, π-Al8Mg3FeSi6 and Q-Al5Mg8Cu2Si6 compounds. The β, π and Q compounds become more visible in the microstructure of the alloys containing more than 1 wt.% Mg. It is observed that β-Mg2Si phase exhibits Chinese script morphology while π and Q ones form as bar and blocky types (see Fig. 2(c)). These observations can be attributed to the solidification behavior of as-cast Al-Si- Cu-Mg alloys [4,11,19]. When the molten alloy begins to cool, α(Al) nucleus forms first. The nucleus grows in dendritic shape with decreasing temperature. When the chemical composition and temperature of remaining liquid attain to eutectic conditions, the Mg reacts with Si and β-Mg2Si forms. Meantime, eutectic Si and π phases also take place under these conditions. As the temperature decreases, the Q and θ phases occur with subsequent eutectic reactions, and then solidification is completed [11]. On the other hand, the formation of the β, π, and Q phases during solidification consumes a portion of Si amount in molten alloy. This restricts the growth of Si and leads to the formation of finer eutectic Si distributed around α(Al) dendrites. However, the finer eutectic Si particles exhibit a small growth when Mg addition exceeds 1 wt.% (Figs. 2(c-e)). This can be related to the increase in volume fraction of secondary phases with increasing Mg addition [11,20]. As it can be seen from Table 2, the secondary phases include more amount of Al than the Si. This means that the amount of Al decreases while that of Si increases in liquid during solidification. The excessive Si in liquid leads to a small growth in eutectic Si particles. Therefore, eutectic microstructure of the alloys exhibits a different appearance with increasing Mg addition.

Fig. 2 Optical micrographs showing microstructures of as-cast Al-12Si-3Cu-0.5Mg (a), Al-12Si-3Cu-1Mg (b), Al-12Si-3Cu-1.5Mg (c), Al-12Si-3Cu-2Mg (d), Al-12Si-3Cu-2.5Mg (e), and XRD patterns of Al-12Si-3Cu-(0.5-2)Mg alloys (f)

Table 2 Chemical compositions of Cu and Mg-containing phases (wt.%)

Microstructures and XRD patterns of the T6-treated alloys are shown in Fig. 3. T6 treatment has no significant effect on the morphologies of π and Q phases but brings about the formation of finer β-Mg2Si and θ precipitates. T6 treatment also causes to nearly spherodization of eutectic Si particles and their more homogenous distribution in α(Al) matrix. These observations can be explained in terms of solutionizing and aging behavior of Al-Si-Cu-Mg alloys [4,6,10,11]. It is well known that dissolution of the π and Q phases is very slow since they have relatively high solution temperature. Therefore, they remain almost stable during solutionizing and do not transform to any phase with aging followed by quenching. On the contrary, the dissolution of β-Mg2Si compound is relatively easy due to high diffusion rate of Mg in Al, thus, it dissolves in α(Al) matrix within a short time and results in a saturated solid solution after quenching [4,6,21]. In the early stage of aging, Mg and Si atoms start diffusing from saturated solution and coherent or semi-coherent metastable Mg2Si precipitates form [4,6,10]. These precipitates grow by incorporating Mg and Si atoms from saturated solution with aging time and non-coherent fine β-Mg2Si precipitates form. In addition, θ phase is also easy to dissolve in α(Al) matrix with solution treatment but its dissolution takes longer time (about several hours) owing to lower diffusion rate of Cu in Al as compared to Mg and Si [4,21]. Since solutionizing time for θ phase in this study is longer than that reported in Refs. [4,6,11], it can be expected that θ phase can dissolve in α(Al) matrix as β-Mg2Si and results in the formation of finer precipitates with aging. On the other hand, it is well known that Si atoms exhibit faster diffusion rate than Al atoms during solutionizing [21]. As indicated in previous works [4,6,10,11], this led to the fragmentation and spherodization of the needle Si particles and their homogenous distribution in α(Al) matrix.

Fig. 3 Optical micrographs showing microstructures of T6-treated Al-12Si-3Cu-0.5Mg (a), Al-12Si-3Cu-1Mg (b), Al-12Si-3Cu-1.5Mg (c), Al-12Si-3Cu-2Mg (d), Al-12Si-3Cu-2.5Mg (e), and XRD patterns of Al-12Si-3Cu-(0.5-2)Mg alloys (f)

3.2 Mechanical properties

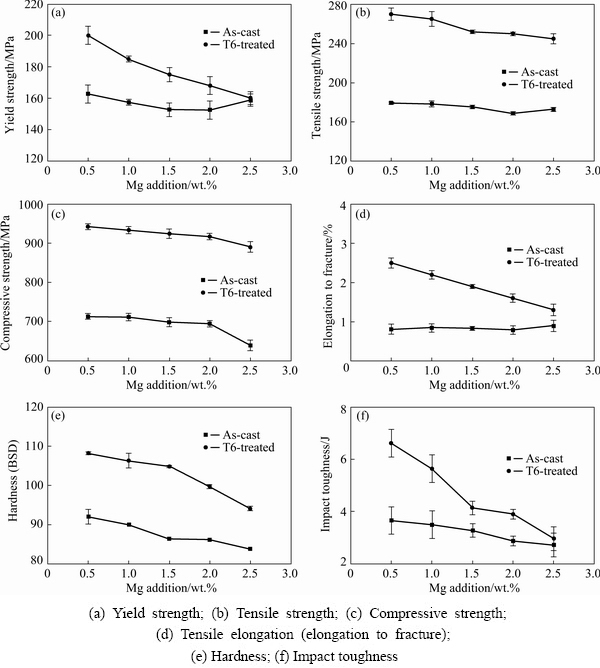

The variations in yield and tensile strengths, compressive strength, tensile elongation (elongation to fracture), hardness and impact toughness of the as-cast and T6-treated alloys are shown in Fig. 4 as a function of Mg addition. The figures show that these values decrease with increasing Mg addition.

Fig. 4 Variations in mechanical properties of as-cast and T6-treated Al-12Si-3Cu based alloy with addition of Mg

Although decreasing trend of these properties is more remarkable for T6-treated alloys, this treatment leads to a significant improvement in mechanical properties of alloys as compared to as-cast ones. These findings can be explained according to microstructural alterations of the alloys in both as-cast and T6-treated states. As the Mg addition increases, the eutectic Si- and Mg- containing phases show a denser distribution between α(Al) grains in microstructure of as-cast alloys, as shown in Figs. 2(b-e). This results in growing of soft α(Al) dendrites but weakening of the interdendritic region due to their brittleness and irregular shapes [22-24]. Growing of soft α(Al) areas leads to a decrease in hardness and compressive strength of the alloys while the weakening effect lowers their tensile properties. After T6 heat treatment, β-Mg2Si and θ phases form precipitates, Chinese morphology of Mg2Si is eliminated, eutectic Si particles nearly spheroidize and disperse homogenously in α(Al) matrix. The formation of precipitates and homogenous distribution of Si particles result in precipitation hardening, while the morphological alteration of eutectic Si particles with β-Mg2Si gives rise to lower cracking tendency [9,13,25-30]. These two effects lead to a significant improvement in mechanical properties of the alloys upon T6 treatment. Nevertheless, the morphologies of π and Q phases remain unchanged with T6 treatment. Since these phases have higher cracking tendency, they cause a remarkable deterioration in mechanical properties and impact toughness of T6-treated alloys.

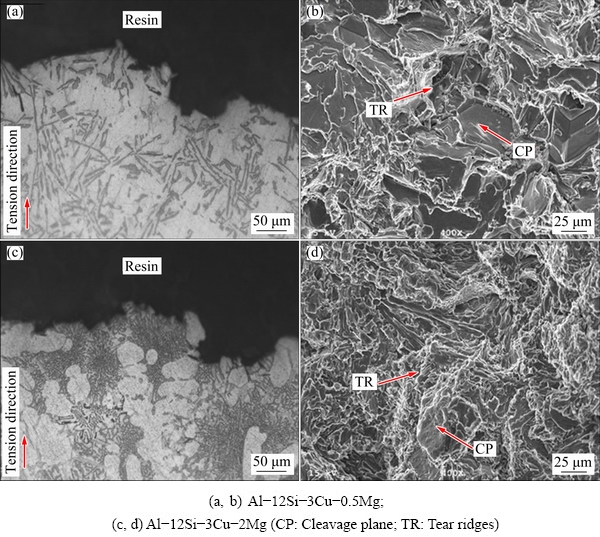

Fig. 5 OM (a, c) and SEM (b, d) images of tensile fracture surfaces of as-cast alloys

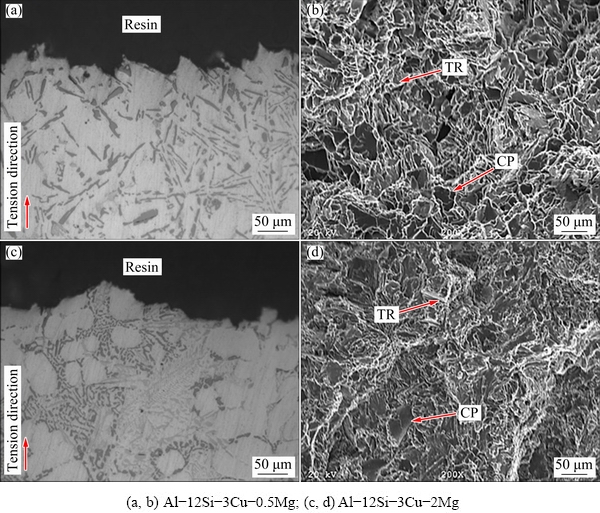

Fig. 6 OM (a, b) and SEM (c, d) images of tensile fracture surfaces of T6-treated alloys

Tensile fracture surfaces of the selected as-cast and T6-treated alloys are given in Figs. 5 and 6, respectively. As it can be seen in Figs. 5(a, c) and 6(a, c), the cracks initiate as a result of breaking and/or debonding of hard particles (Si, Mg- and Cu-containing phases) and propagate along a path around α(Al) phase and then cause tensile fracture. Figures 5(b, d) and 6(b, d) show that fracture surfaces of the alloys are composed of cleavage planes (CP) and tear ridges (TR). It is observed that the cleavage planes are the surfaces of Si and Cu- and Mg-containing particles or their detached areas (α(Al)), while the tear ridges are the rupture surfaces of α(Al) phase elongated tensile directions. Cleavage planes appear as larger areas on fracture surface of as-cast alloy containing 1 wt.% Mg, above which they become narrower and tear ridges start to be more visible (Figs. 5(b, d)). T6 treatment gives rise to more tear ridges and narrower facets on fracture surfaces of Al-Si-Cu-Mg alloys (Figs. 6(b, d)). This observation can be attributed to the morphologies of Si, and Cu- and Mg-containing particles in microstructure of as-cast and T6-treated Al-Si-Cu-Mg alloys. These particles act as stress riser points, thus they can easily break up and/or detach from α(Al), and then lead to the formation of cracks [9,13,22-28]. These cracks propagate by following hard particle rich areas around α(Al) phase and result in the formation of cleavage planes and tear ridges [9,13,22-28]. As the Mg addition increases, Si particles are refined, thus their size and interface between α(Al) phases decrease and size of α(Al) phase increases. This leads to a decrease in the areas of the cleavage planes but an increase in the amount of tear ridges. In addition, spherodization and homogenous distribution of Si particles with refining in β-Mg2Si and θ phases after T6 treatment contribute to the formation of narrow cleavage planes and visible tear ridges. This observation indicates that T6-treated alloys exhibit more ductile fracture compared to as-cast ones.

3.3 Dry sliding test results

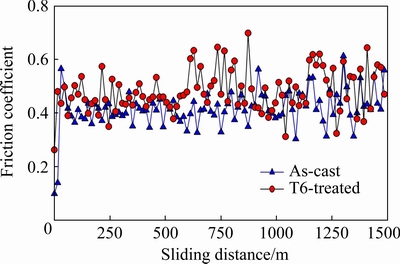

The representative friction coefficient curves for as-cast and T6-treated Al-Si-Cu-Mg alloys with respect to sliding distance are given in Fig. 7. Friction coefficient of the alloys increases sharply at the beginning of test run and starts gradually decreasing within a short sliding distance and then attains a period characterized by fluctuations. This observation can be explained in terms of material tribology [29-32]. During the initial stage of wear tests, the contact area is small due to the geometry of contact surfaces [31]. This gives rise to high pressure on sample surface and leads to the formation of adhesion bonding between contact surfaces [29-32]. These bonds resist to sliding and cause a sudden increase in friction coefficient of the alloys. With subsequent sliding, contact area the increases and attains to stable state, thus the pressure decreases and remains an almost constant value. This brings about a decrease in the friction coefficients of the alloys and attains them to almost stable values. However, material transfer between contact surfaces gives rise to a fluctuation in friction coefficient of the alloys at the stable state [22-24].

Fig. 7 Changes in friction coefficients of as-cast and T6-treated Al-12Si-3Cu-1.5Mg alloys with sliding distance at load of 5 N and sliding speed of 0.16 m/s

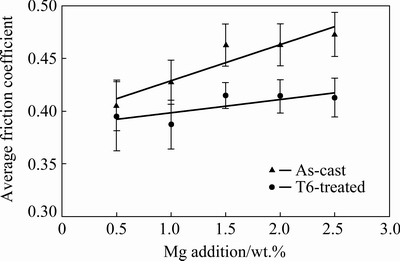

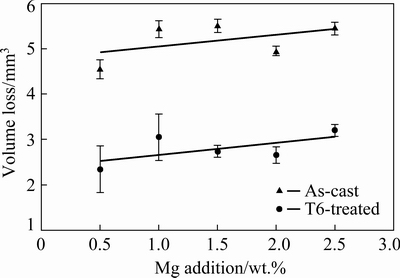

The average values for friction coefficient at steady state and volume loss of the alloys are shown in Figs. 8 and 9 as a function of Mg addition, respectively. It can be noted from these figures that the average friction coefficient and volume loss of as-cast and T6-treated alloys increase with increasing Mg addition. Despite this, it is seen that T6 treatment causes a remarkable decrease in volume loss and friction coefficient of the as-cast alloys. The observations can be explained in terms of microstructure, strength and hardness of as-cast and T6-treated alloys. As mentioned above, Si particles are refined and gather in interdendritic areas with increasing Mg additions, thus soft α(Al) phase becomes coarse and volume fraction of hard particles (β, π and Q phases) increases. This microstructural alteration gives rise to two detrimental effects on friction and wear behavior of the alloys. Firstly, inhomogeneous distribution of Si particles and coarsening of α(Al) give rise to a decrease in strength and hardness of alloys. This leads to a decrease in their load bearing capacity and an increase in adhesion between contact surfaces. Secondly, hard particles (β, π and Q) besides the Si form cracks in adhesion layer due to their low plastic deformation capability [4,6,10,11]. It is well known that the formation of cracks facilitates the delamination of the adhesion layer and increases the size of wear particles removed from sample surface [24]. As a result, friction coefficient and volume loss of Al-Si-Cu-Mg alloys increase with increasing Mg addition. However, T6 treatment increases the strength and hardness of the alloys due to the formation of more regular shape Si, elimination of Chinese script morphology of β-Mg2Si particles and precipitation hardening. The increase in their strength and hardness improves the load bearing capacity of the matrix and leads to a remarkable decrease in the friction coefficient and volume loss of T6-treated alloys.

Fig. 8 Changes in average values of friction coefficient for as-cast and T6-treated alloys as function of Mg addition

Fig. 9 Changes in volume loss for as-cast and T6-treated alloys as function of Mg addition at load of 5 N and sliding distance of 1500 m

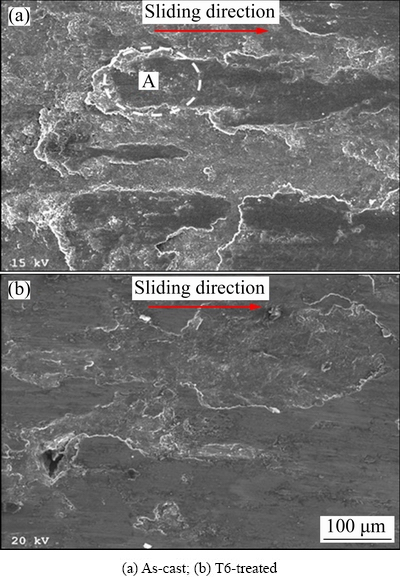

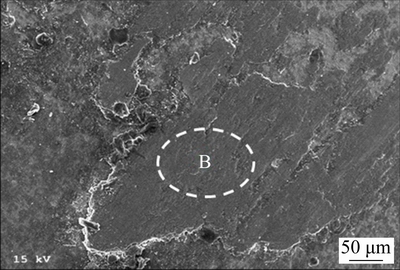

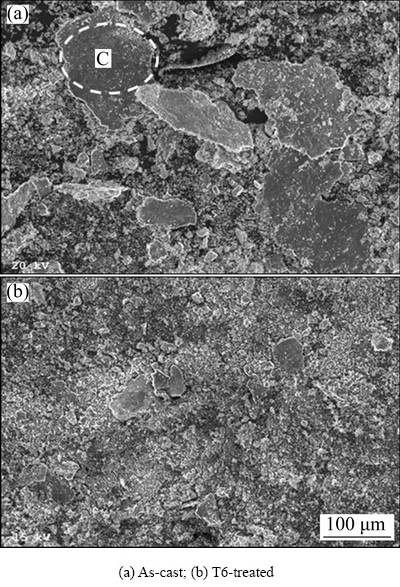

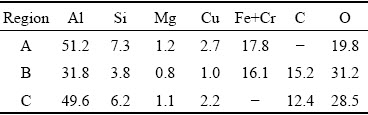

SEM examinations reveal that worn surfaces of as-cast and T6-treated alloys are characterized by adhesion and delamination layers with slight scratches. Representative surface appearances for as-cast and T6-treated Al-12Si-3Cu-2Mg alloys and ball used in wear test of as-cast one are given in Figs. 10 and 11, respectively. SEM examinations also show that wear particles consist of the mixture of large and small size particles with dust ones while ball surfaces are partially coated by wear materials, as shown in Fig. 12. Chemical compositions of adhered materials to surfaces of both samples and ball as well as wear particles, named as A, B, C, respectively, are tabulated in Table 3. This table indicates that the chemical compositions are similar to other and are mainly composed of Al, Si, Cu, Mg, Fe, Cr and O elements. These observations can be related to multi-phase structures of the Al-Si-Cu-Mg alloys. As mentioned above, the microstructure of produced alloys consists of hard particles distributed in soft α(Al) matrix. It is well known that the hard particles have higher load bearing capacity, thus their presence in matrix increases the adhesion resistance [22-24,29-32]. Contrarily, α(Al) phase is soft and exhibits higher adhering tendency to ball surface when the load is applied. After run starts, the tangential force raptures the adhesion bonding between contact surfaces and causes the formation of wear particles. These particles firstly transfer to ball surface, and then back transfer to the sample surface. During this transfer, the wear particles adhere to sample and ball surfaces and result in the formation of adhesion layer on their surfaces. At subsequent sliding step, the adhesion layer becomes brittle due to oxidation [22-24]. Interfacial cracks caused by hard particles exhibit fast propagation in brittle layer and connect each other. After the connection is completed, the adhesion layer starts to partial delamination. This produces large sized wear particles from adhesion layer [22-24]. Some of these particles move away between contact surfaces due to centrifugal forces, the remaining ones break up during rotating and transform small and dust type wear particles. These particles also lead to the formation of fine scratches by acting ploughing effect.

Fig. 10 Worn surfaces of Al-12Si-3Cu-2Mg alloys

Fig. 11 Surface of ball used against Al-12Si-3Cu-2Mg alloy in as-cast state

Fig. 12 Wear particles produced during testing of Al-12Si-3Cu-2Mg alloy

Table 3 Chemical compositions of adhered material on surfaces of samples and ball as well as wear particles (wt.%)

4 Conclusions

(1) The microstructure of as-cast Al-12Si- 3Cu-Mg alloys consisted of α(Al), Si, θ-CuAl2, β-Mg2Si, Q-Al5Mg8Cu2Si6 and π-Al8Mg3FeSi6 phases. T6 treatment gave rise to the spherodization of eutectic Si particles. This treatment also caused the formation of finer θ-CuAl2 and β-Mg2Si precipitates and the elimination of Chinese script morphology of β-Mg2Si.

(2) The addition of Mg up to 2.5 wt.% decreased the strength, hardness, ductility and impact toughness of as-cast and T6-treated alloys but increased their friction coefficient and volume loss. T6-treated alloys exhibited higher strength and wear resistance than as-cast ones.

(3) Tensile fracture surfaces of the as-cast and T6-treated alloys were composed of cleavage planes and tear ridges. T6 treatment increased the number of tear ridges on fracture surface of the alloys. This suggested that T6-treated Al-12Si-3Cu-Mg alloys showed more ductile fracture than as-cast ones.

(4) The worn surfaces of as-cast and T6-treated alloys were characterized by adhesion, delamination and fine scratches, yet adhesion and delamination were noted to be main wear mechanisms of the experimented alloys. It was concluded that T6 treatment limited the adhesion and delamination mechanisms of as-cast alloys and increased their wear resistance.

Acknowledgments

This work was carried out at the Material Science Laboratory of Mechanical Engineering Department at Karadeniz Technical University. Authors would like to thank all staffs in the Material Science Laboratory.

References

[1] DWIVEDI D K. Adhesive wear behaviour of cast aluminium–silicon alloys: Overview [J]. Materials & Design, 2010, 31(5): 2517-2531.

[2] YE H. An overview of the development of Al-Si-alloy based material for engine applications [J]. Journal of Materials Engineering and Performance, 2003, 12(3): 288-297.

[3] CAMICIA G, TIMELLI G. Grain refinement of gravity die cast secondary AlSi7Cu3Mg alloys for automotive cylinder heads [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(5): 1211-1221.

[4] SJOLANDER E, SEIFEDDINE S. The heat treatment of Al-Si-Cu-Mg casting alloys [J]. Journal of Materials Processing Technology, 2010, 210(10): 1249-1259.

[5] HAN Y, SAMUEL A M, DOTY H W, VALTIERRA S, SAMUEL F H. Optimizing the tensile properties of Al-Si-Cu-Mg 319-type alloys: Role of solution heat treatment [J]. Materials & Design, 2014, 58: 426-438.

[6] FARKOOSH A R, PEKGULERYUZ M. Enhanced mechanical properties of an Al–Si–Cu–Mg alloy at 300 °C: Effects of Mg and the Q-precipitate phase [J]. Materials Science and Engineering A, 2015, 621: 277-286.

[7] ZUO L, YE B, FENG J, KONG X, JIANG H, DING W. Effect of Q-Al5Cu2Mg8Si6 phase on mechanical properties of Al-Si-Cu-Mg alloy at elevated temperature [J]. Materials Science and Engineering A, 2017, 693: 26-32.

[8] CHANKITMUNKONG S, ESKIN D G, LIMMANEE- VICHITR C. Effect of Cu addition on the microstructure, mechanical and thermal properties of a piston Al-Si alloy [M]. Light Metals, Springer, 2019: 463-469.

[9] YANG H L, JI S X, YANG W H, WANG Y, FAN Z Y. Effect of Mg level on the microstructure and mechanical properties of die-cast Al–Si–Cu alloys [J]. Materials Science and Engineering A, 2015, 642: 340-350.

[10] SJOLANDER E, SEIFEDDINE S. Artificial ageing of Al–Si–Cu–Mg casting alloys [J]. Materials Science and Engineering A, 2011, 528: 7402-7409.

[11] TEBIB M, AJERSCH F, SAMUEL A, CHEN X G. Solidification and microstructural evolution of hypereutectic Al-15Si-4Cu-Mg alloys with high magnesium contents [J]. Metallurgical and Materials Transactions A, 2013, 44: 4282-4295.

[12] CACERES C, DJURDJEVIC M, STOCKWELL T, SOKOLOWSKI J. The effect of Cu content on the level of microporosity in Al-Si-Cu-Mg casting alloys [J]. Scripta Materialia, 1999, 40: 631-637.

[13] SHABESTARI S G, MOEMENI H. Effect of copper and solidification conditions on the microstructure and mechanical properties of Al–Si–Mg alloys [J]. Journal of Materials Processing Technology, 2004, 153-154: 193-198.

[14] TAGHIABADI R, FAYEGH A, PAKBIN A, NAZARI M, GHONCHEH M H. Quality index and hot tearing susceptibility of Al–7Si–0.35Mg–xCu alloys [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(7): 1275-1286.

[15] JIANG B, XU S, XU H Y, HU M L, HE Y J, JI Z S. Effect of Mg addition on microstructure and mechanical properties of Al-Si-Cu-Fe alloy with squeeze casting [J]. Materials Research Express, 2019, 7(1): 016511.

[16] LIU H, ZHAO G, LIU C M, ZUO L. Effects of magnesium content on phase constituents of Al-Mg-Si-Cu alloys [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(2): 376-381.

[17] HUANG Z L, WANG K, ZHANG Z M, LI B, XUE H S, YANG D Z. Effects of Mg content on primary Mg2Si phase in hypereutectic Al-Si alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3197-3203.

[18] WANG G Q, BIAN X F, WANG W M, ZHANG J Y. Influence of Cu and minor elements on solution treatment of Al–Si–Cu–Mg cast alloys [J]. Materials Letters, 2003, 57(24): 4083-4087.

[19] HEKIMOGLU A P, CALIS M, AYATA G. Effect of strontium and magnesium additions on the microstructure and mechanical properties of Al–12Si alloys [J]. Metals and Materials International, 2019, 25(6): 1488-1499.

[20] ALHAWARI K S, OMAR M Z, GHAZALI M J, SALLEH M S, MOHAMMED M N. Microstructural evolution during semisolid processing of Al–Si–Cu alloy with different Mg contents [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(7): 1483-1497.

[21] FUJIKAWA S I, HIRANO K I, FUKUSHIMA Y. Diffusion of silicon in aluminum [J]. Metallurgical Transactions A, 1978, 9(12): 1811-1815.

[22] ALEMDAG Y, BEDER M. Microstructural, mechanical and tribological properties of Al–7Si–(0–5)Zn alloys [J]. Materials & Design, 2014, 63: 159-167.

[23] ALEMDAG Y, BEDER M. Effects of zinc content on strength and wear performance of Al-12Si-3Cu based alloy [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(12): 2463-2471.

[24] ALEMDAG Y, BEDER M. Effects of Mn content on microstructure, mechanical and dry sliding wear properties of eutectic Al–Si–Cu alloy [J]. Metals and Materials International, 2020, 26: 1811-1819.

[25] MA Z, SAMUEL A M, SAMUEL F H, DOTY H W, VALTIERRA S. A study of tensile properties in Al–Si–Cu and Al–Si–Mg alloys: Effect of β-iron intermetallics and porosity [J]. Materials Science and Engineering A, 2008, 490(1): 36-51.

[26] MOUSTAFA M, SAMUEL F, DOTY H, VALTIERRA S. Effect of Mg and Cu additions on the microstructural characteristics and tensile properties of Sr-modified Al-Si eutectic alloys [J]. International Journal of Cast Metals Research, 2002, 14(4): 235-253.

[27] ZHU M, JIAN Z, YANG G, ZHOU Y. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys [J]. Materials & Design, 2012, 36: 243-249.

[28] HU Z, WAN L, WU S, WU H, LIU X. Microstructure and mechanical properties of high strength die-casting Al–Mg–Si–Mn alloy [J]. Materials & Design, 2013, 46: 451-456.

[29] LASA L, RODRIGUEZ-IBABE J M. Wear behaviour of eutectic and hypereutectic Al–Si–Cu–Mg casting alloys tested against a composite brake pad [J]. Materials Science and Engineering A, 2003, 363(1): 193-202.

[30] ANASYIDA A S, DAUD A R, GHAZALI M J. Dry sliding wear behaviour of Al–12Si–4Mg alloy with cerium addition [J]. Materials & Design, 2010, 31(1): 365-374.

[31] HUTCHINGS I, SHIPWAY P. Tribology: Friction and wear of engineering materials [M]. New York: Butterworth- Heinemann, 2017.

[32] HEKMAT-ARDAKAN A, LIU X, AJERSCH F, CHEN X G. Wear behaviour of hypereutectic Al–Si–Cu–Mg casting alloys with variable Mg contents [J]. Wear, 2010, 269(9): 684-692.

M. BEDER1, Y. ALEMDAG2

1. Department of Mechanical Engineering, Gumushane University, Gumushane, Turkey;

2. Department of Mechanical Engineering, Karadeniz Technical University, Trabzon, Turkey

摘 要:通过永久型铸造制备一系列Al-12Si-3Cu-(0.5-2.5)Mg(质量分数,%)合金,然后进行T6热处理,研究添加Mg和T6热处理对Al-Si-Cu-Mg合金显微组织、力学性能和摩擦学性能的影响。采用OM、XRD、SEM、EDS等测试手段研究其显微组织,并进行硬度、拉伸、压缩和Charpy冲击试验,测试其力学性能。用球对盘式摩擦试验机研究合金的干滑动摩擦磨损性能。结果表明,铸态Al-12Si-3Cu-Mg合金显微组织中含有α(Al)、Si、θ-CuAl2、β-Mg2Si、Q-Al5Mg8Cu2Si6和π-Al8Mg3FeSi6相。T6热处理使共晶Si颗粒近球化,形成较细的θ-CuAl2和β-Mg2Si 沉淀相,消除β-Mg2Si相的汉字形貌。添加2.5% Mg降低铸态和T6处理后合金的硬度、抗拉和抗压强度、拉伸伸长率和冲击韧性,增加摩擦因数和体积磨损量。另一方面,T6处理显著提高铸态合金的力学性能和耐磨性能。

关键词:Al-Si-Cu合金;Mg含量;T6处理;显微组织;力学性能;磨损性能;断裂面

(Edited by Wei-ping CHEN)

Corresponding author: Y. ALEMDAG, Tel: +90-462-3774134, Fax: +90-462-3255526, E-mail: yalemdag@ktu.edu.tr

DOI: 10.1016/S1003-6326(21)65649-2

1003-6326/ 2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press