DOI:10.11817/j.ysxb.1004.0609.2020-39300

高强可焊7A62铝合金的成分设计与跨尺度相强化作用

郎玉婧,周古昕,王 生,杜秀征,乔 丽,陈 敏,刘 敏

(中国兵器科学研究院 宁波分院,宁波 315103)

摘 要:基于7A62铝合金的成分设计,研究Zn含量和Zn/Mg质量比对Al-Zn-Mg合金强度的影响。采用透射电镜(TEM和HREM)详细地研究7A62铝合金峰值时效的析出相,从多个晶体学方向观察了强化析出相的形貌及其与基体的关系。结果表明:Zn/Mg质量比为2~3、Zn含量增加至6.84%(质量分数)时,7A62合金的强度明显增加。峰值时效后,7A62合金基体形成了体积分数约60%、尺寸小于10 nm的沉淀强化相和体积分数约10%、尺寸为100~200 nm的弥散强化相。基体主要强化析出相是高密度均匀分布的η′相,与基体呈现半共格和晶体取向关系,形成较高晶格错配度;跨尺度位错缠结的弥散强化相是由Al、Zn、Mg、Mn元素组成的平衡相。7A62合金的化学成分和微结构特征使其成为高强可焊的铝合金。

关键词:7A62铝合金;跨尺度;η′强化相;晶格错配;力学性能

文章编号:1004-0609(2020)-01-0009-09 中图分类号:TG146.21 文献标志码:A

可焊铝合金结构材料是现代工业发展必不可少的关键材料,采用新一代高性能可焊铝合金结构材料是满足航空航天、交通运输等领域关键构件轻量化的重要手段和有效途径。AA7039和AA7020铝合金是美国研发的Al-Zn-Mg中强铝合金,作为板材和锻件应用于美国“全焊接结构”的车辆制造[1-2]。7N01铝合金是日本研发的Al-Zn-Mg中强铝合金,作为型材应用于日本第二代“全焊接结构”高速铁路车辆和日本新干线[3]。在Al-Zn-Mg合金的基础上,俄罗斯通过添加合金元素Sc和Zr,开发了中强可焊的01975铝合金[4]。我国在20世纪研发出了中强可焊的7A52铝合金,并作为板材和锻件应用于我国“全焊接结构”的车辆制造[5]。随着车辆轻量化要求的进一步提高,周古昕研发出高强可焊Al-Zn-Mg铝合金,2013年申请合金牌号为7A62,该合金与7A52铝合金相比,抗拉强度提高25%以上,抗应力腐蚀的极限强度提高90 MPa左右;焊接工艺与7A52基本相同,焊接性能相当,可与7A52进行焊接连接,焊接兼容性好。目前,7A62铝合金板材和锻件已被应用于多种新型特种车辆中。

Al-Zn-Mg系合金是一种时效强化型合金,它的组织常为铝基体中包含细小的η(MgZn2)和η′、粗大的T(Al2Mg3Zn3)、杂质相AlMnFe和Mg2Si等[6-7];其强度主要得益于大量均匀弥散分布半共格η′,少量共格GP区和Al3Zr相起到补充强化作用,与基体非共格η相强化效果较弱,而粗大硬脆相会促进变形时裂纹的萌生[8]。纵观国内外Al-Zn-Mg合金的发展,预设计一种强度明显提升的新型可焊Al-Zn-Mg合金,必须通过合金成分设计调控组织结构以增强合金的力学性能。本文阐述了一种基于高密度跨尺度纳米析出相强化理念设计的7A62铝合金,其强化机制是通过适当增加Zn元素含量和采用适中Zn/Mg质量比,实现时效沉淀相最大化析出分散和高密度位错缠绕平衡相的高剪切应力区。这种合金成分设计理念与“材料素化”新概念[9]异曲同工,不添加贵重或稀有元素,通过跨尺度构筑与组织结构调控,制造少合金化的“素”材料,大幅度提高材料的综合性能。故本文作者通过7A62铝合金的研发,研究调控Zn/Mg比例范围和协同增加Zn含量对Al-Zn-Mg合金强度的影响规律,主要通过析出相结构、数量与尺度,以及其与基体界面关系的表征研究,分析了7A62铝合金化学成分设计对组织调控的影响,探索讨论7A62铝合金跨尺度相的强化作用。

1 实验

实验所用的合金为高纯99.99%Al、高纯99.9%Mg、高纯99.9%Zn,以及中间合金Al-10Mn、Al-50Cu、Al-2.5Zr、Al-3Ti等,设计的Al-Zn-Mg合金的名义成分列于表1。合金经740~760 ℃熔炼铸造、(465 ℃,24 h)均匀化处理、420 ℃热轧成形、(465 ℃,1 h)固溶处理、(121 ℃,24 h) T6峰值时效处理,合金制成20 mm厚板材。

化学成分依据GB/T 7999—2015采用直读光谱法检测。拉伸试验在CMT-4105试验机上完成,拉伸试样沿轧制板材L-T方向制取,拉伸速度2 mm/min。布氏硬度测试在320HBS-3000布氏硬度试验机上完成。合金薄膜试样的显微组织在FEI TECNAI G2场发射透射电镜上观察,加速电压200 kV。电镜薄膜样品采用电解双喷减薄技术制备,电解液为30%硝酸和70%甲醇溶液(体积分数),电流50~70 mA,温度控制-20 ℃左右。采用Image-Tool对TEM照片中η′相和T相进行统计。利用材料热力学模拟软件JMatPro7.0计算几种典型中强可焊Al-Zn-Mg铝合金第二相的平衡析出。

表1 设计的Al-Zn-Mg合金的化学成分

Table 1 Chemical compositions of investigated Al-Zn-Mg alloys

2 实验结果

2.1 化学成分设计

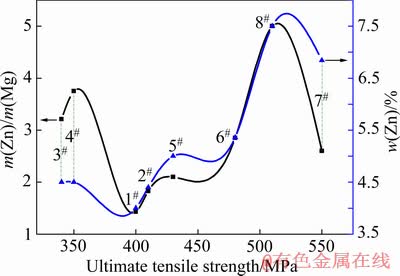

高强可焊铝合金的成分设计研究采用计算与实验相结合的方法,由于形成平衡相MgZn2的Zn/Mg质量比应为5.27,故试验设计考察m(Zn)/m(Mg)≤5的Al-Zn-Mg合金名义成分。通过试验方法测得设计合金强度值与Zn/Mg质量比和Zn含量的变化曲线,见图1,在1.43≤m(Zn)/m(Mg)≤3时,合金1#、2#、5#、6#和7#的强度随Zn含量的增加而增强,合金7#的Zn含量为6.8%时,强度可达550 MPa以上;在3<m(Zn)/ m(Mg)≤5时,合金3#、4#和8#的强度也随Zn含量的增加而增强,合金8#的Zn含量为7.5%时,强度为500 MPa;而当Zn含量一定时,m(Zn)/m(Mg)>3的合金3#和4#的强度低于1.43≤m(Zn)/m(Mg)≤3的合金2#的强度。试验结果表明:合金的强度受Zn/Mg质量比值协同Zn含量的共同影响,m(Zn)/m(Mg)>3时合金强度下降明显。由于高强可焊铝合金设计抗拉强度的目标值≥ 550 MPa,伸长率≥7%,因此,新合金的成分设计Zn含量6.7%~7.4%以及Zn/Mg质量比范围为2~3时,该铝合金牌号为7A62。

图1 高强可焊铝合金成分设计的强度值变化曲线

Fig. 1 Strength change curves of high-strength welded aluminum alloy with composition

实测7A62铝合金的化学成分如表2所列。除Zn、Mg元素外,Cu是Al-Zn-Mg系合金中极为重要的元素,它能提高沉淀相的弥散度,改善晶间结构和沿晶腐蚀性能[10]。7A62合金中添加并控制Cu含量,可使合金具有良好的焊接性、较低应力腐蚀敏感性和淬火敏感性,添加微量的Mn、Cr、Zr、Ti元素能够提高合金的再结晶温度和细化铸态组织晶粒,添加极微量Be元素可避免大铸锭的热裂倾向,少合金化并控制低含量杂质元素Fe和Si,合金将具有较高的强塑性和良好的加工成形性。

2.2 力学性能

图2(a)所示为几种典型的中强可焊Al-Zn-Mg合金规定的抗拉强度和伸长率以及7A62铝合金设计的目标性能,图2(a)所示01975[4]、7A52[11]、7039[12]、7020[13]、7N01[3]合金随着强度的增加伸长率减小;其中01975合金中添加了Sc元素形成细小弥散的Al3(Sc、Zr)粒子,提高强度同时具有较高的塑性[14],但明显增加合金成本。图2(b)所示为7A62-T6合金的拉伸应力-应变曲线,实测的抗拉强度、屈服强度以及伸长率分别是615~645 MPa、575~603 MPa及11%~14%。7A62铝合金表现出更高的时效硬化,布氏硬度HB达165~175,抗拉强度和屈服强度较7A52铝合金均增加了约150 MPa,布氏硬度HB增加了约30,且没有牺牲合金伸长率,这一现象超越了铝合金强-塑性关系特征。拉伸试验和硬度试验结果表明:采用m(Zn)/ m(Mg)≈2.6同时提高Zn含量至6.84%(质量分数),更有利于Al-Zn-Mg系合金的强化作用;适当降低Si、Fe、Cr的含量,能有效地提升合金塑性。

表2 7A62铝合金的实测化学成分

Table 2 Actual chemical composition of 7A62 alloy (mass fraction, %)

图2 典型中强可焊Al-Zn-Mg合金的标准最小抗拉强度和伸长率变化特点和7A62-T6合金的拉伸性能曲线

Fig. 2 Change in minimum ultimate tensile strength and ductility specified for representative medium-strength welded Al-Zn-Mg alloy(a) and tensile curves of 7A62-T6 alloy(b)

2.3 时效强化相

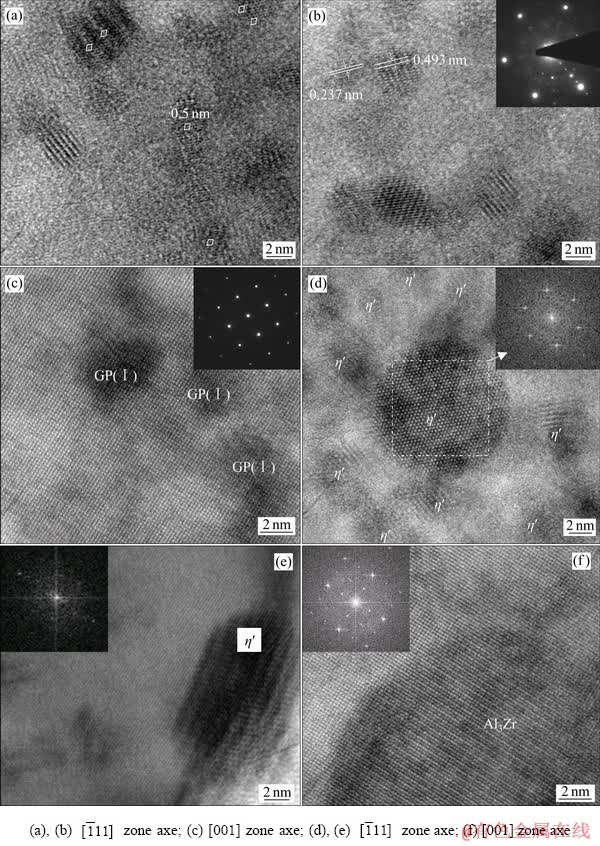

图3(a)所示为7A62合金T6时效后纳米析出强化相的形貌,在基体的晶内中观察到极微小纳米球形沉淀析出相,析出相粒子尺寸小于10 nm,体积分数约60%(见表3),分布细密均匀。变形过程中位错运动必须挣脱这些粒子的阻碍,即绕过粒子生成位错环或切割粒子形成高剪切应力,增加合金基体强化效果,这些高密度分散的小于10 nm球形析出相则贡献着Al-Zn-Mg系合金的主要强度和硬度性能[15-16]。图3(b) 所示为 晶带轴的选区电子衍射花样,可以看出,除基体Al的强斑点以外,还有明显的附加斑点存在,这些附加斑点主要来自η′相。在

晶带轴的选区电子衍射花样,可以看出,除基体Al的强斑点以外,还有明显的附加斑点存在,这些附加斑点主要来自η′相。在 位置和

位置和 位置附近团聚斑点即为η′相[6],在

位置附近团聚斑点即为η′相[6],在 位置附近弱斑点即为GP区[6],在(220)/2位置附近亮斑点则为超点阵结构的Al3Zr相[17]。这就说明7A62铝合金T6峰时效时主要析出强化相是弥散η′相、GP区和Al3Zr相强化,η′相对强度贡献最大。这些相的详细结构特征通过Al基体的

位置附近弱斑点即为GP区[6],在(220)/2位置附近亮斑点则为超点阵结构的Al3Zr相[17]。这就说明7A62铝合金T6峰时效时主要析出强化相是弥散η′相、GP区和Al3Zr相强化,η′相对强度贡献最大。这些相的详细结构特征通过Al基体的 、[100]入射方向的高分辨透射电镜(HREM)像进行鉴别。

、[100]入射方向的高分辨透射电镜(HREM)像进行鉴别。

关于η′相结构的公认观点:η′相具有六方结构,a=0.496 nm,c=1.40 nm,形貌为圆片状。沿 观察,η′相是直径为3~4 nm的圆片状,沿

观察,η′相是直径为3~4 nm的圆片状,沿 观察,η′相是长5~6 nm,厚1~2 nm的长条状。高分辨电镜观察和电子衍射研究表明[15],Al晶面间距d{111}Al=0.234 nm,η′相[001]晶带轴的晶面间距dη′=0.496 nm。图4(a)所示为在

观察,η′相是长5~6 nm,厚1~2 nm的长条状。高分辨电镜观察和电子衍射研究表明[15],Al晶面间距d{111}Al=0.234 nm,η′相[001]晶带轴的晶面间距dη′=0.496 nm。图4(a)所示为在 晶带轴η′相的HREM像,大部分呈环形高分辨晶格,相邻环形晶格中心的距离0.5 nm,这与η′相的空间晶格点阵常数a=0.496 nm是一致的。图4(b)所示为圆片状析出相在{111}Al面析出,测得基体铝d{111}Al= 0.237 nm,球形析出相dp=0.493 nm,再次说明该析出相仍为η′相。图4(a)和(b)中η′相与基体局部具有半共格关系,由于溶质原子与基体原子的半径差较大,存在错配度使得基体晶格畸变形成应变场,增加基体强度。

晶带轴η′相的HREM像,大部分呈环形高分辨晶格,相邻环形晶格中心的距离0.5 nm,这与η′相的空间晶格点阵常数a=0.496 nm是一致的。图4(b)所示为圆片状析出相在{111}Al面析出,测得基体铝d{111}Al= 0.237 nm,球形析出相dp=0.493 nm,再次说明该析出相仍为η′相。图4(a)和(b)中η′相与基体局部具有半共格关系,由于溶质原子与基体原子的半径差较大,存在错配度使得基体晶格畸变形成应变场,增加基体强度。

图3 7A62铝合金T6态基体纳米析出相的明场像和 晶带轴的衍射图

晶带轴的衍射图

Fig. 3 TEM image of nano precipitated phases of matrix in 7A62 alloy after T6 temper (a) and selected area electron diffraction patterns along  zone axe (b)

zone axe (b)

图4 7A62铝合金T6态基体强化相的HREM像

Fig.4 HREM images of strengthen phases of matrix in 7A62 alloy after T6 temper

Al-Zn-Mg系合金中GP(Ⅰ)区[16]是从过饱和固溶体溶质原子中均匀形核,是Al、Mg、Zn原子的团簇,呈圆片状,主要存在于{100}Al面。图4(c)所示在7A62合金中观察到[001]Al晶带轴的HREM像,析出相应力场衬度明显,直径约3~4.2 nm,与基体完全共格,形成最小晶格错配,基体没有发生明显畸变,保持基体韧性的同时强化合金。过渡相η′与基体存在一定的晶体学取向,并有很匹配的晶格结构,呈半共格关系,鉴于结构上η′过渡相与基体的差别,较GP区与基体的差别更大些,故η′过渡相是由GP区直接演变过来的,图4(d)所示为沿 方向观察到的圆片状η′过渡相,与基体呈半共格关系,分布弥散,数量众多,强化作用显著。在晶界处观察到不连续的析出相,如图4(e)所示,该相仍为η′过渡相,存在于{111}Al面,由于晶界是高扩散率通道,因此该相尺寸为晶内图4(b)中η′相形貌的5~6倍,但其仍与基体呈半共格关系,具有强化晶界的作用。

方向观察到的圆片状η′过渡相,与基体呈半共格关系,分布弥散,数量众多,强化作用显著。在晶界处观察到不连续的析出相,如图4(e)所示,该相仍为η′过渡相,存在于{111}Al面,由于晶界是高扩散率通道,因此该相尺寸为晶内图4(b)中η′相形貌的5~6倍,但其仍与基体呈半共格关系,具有强化晶界的作用。

在7A62铝合金中添加Zr元素用以细化铸态组织晶粒,同时在基体中析出纳米级高温强化相,进一步提高合金的基体强度和高温稳定性。图4(f)所示为具有超点阵结构的Al3Zr相HREM像。Al3Zr相沿{100}Al面析出,为直径约20 nm圆球状,与基体完全共格,强化相的衬度明显。尽管数量较少(如图3(a)中12~20 nm球状析出相),但纳米尺度与基体完全共格的Al3Zr粒子起到强化基体的作用,因此,Zr是7A62铝合金中极为重要的元素之一。

2.4 平衡相

图5 7A62铝合金T6态基体平衡相的TEM像

Fig. 5 TEM images of equilibrium phases of matrix in 7A62 alloy after T6 temper

图5所示为7A62-T6合金基体晶内平衡相TEM像。由图5(a)可以看到,晶内存在着大量位错结构,且伴随着近球状的平衡相,沿轧制方向均匀地分布着,尺寸在100~200 nm左右,体积分数约10%(见表3)。这些平衡相的粒子主要以椭球形和长棒状形貌为主(见图5(b)~(d)),长度方向沿变形方向生长且分布较均匀一致,图5(b)中椭球状平衡相A的TEM-EDS分析如表4所示,该相主要由Al、Zn、Mg、Mn元素组成,是Al-Zn-Mg系合金中强化相T-Al2Mg3Zn3中一部分Zn被Mn置换转变而来的,形成较高熔点平衡相,衬度呈黑色。图5(c)中显示长棒状粒子的衬度几近相同,长棒状平衡相B的TEM-EDS分析如表4所示,该相主要由Al、Zn、Mg、Mn元素组成,但溶质元素含量较平衡相A偏少,衬度呈灰色。图5(d)中异质形核互生的黑色程度椭球状平衡相C也是由Al、Zn、Mg、Mn元素组成(见表4),溶质元素含量较高。由图5和表4中TEM-EDS分析可知7A62-T6铝合金基体中100~200 nm平衡相均为富Mn-Al(Mg、Zn、Mn)T相,可强化基体;由于Mn原子的置换,平衡相电位(-0.813 V)更加接近铝基体(-0.802 V),提升合金强度的同时有助于抗应力腐蚀性能[18]。因此,除Zn、Mg元素外,Mn是7A62铝合金中极为重要的元素之一。

表3 7A62-T6合金基体中η′相和T相的体积分数及尺寸

Table 3 Volume fraction and diameter of η′ and T precipitates in 7A62-T6 alloy

表4 7A62铝合金T6态基体弥散析出相的化学成分

Table 4 Chemical composition of stable phases in 7A62-T6 alloy analyzed by TEM-EDS

3 分析与讨论

3.1 成分设计分析

利用热力学计算几种典型中强可焊Al-Zn-Mg系合金的相平衡析出,分析7A62合金成分设计对组织和性能的影响。图6(a)所示随着主元素Zn含量的增加,η′相含量随之增加,T相含量随之减少;图6(b)所示随着m(Zn)/m(Mg)的增加,η′相含量随之先增加后减小,T相含量随之减少,当m(Zn)/m(Mg)接近3时,无T相生成。这是因为Al-Zn-Mg系合金中GP区是Zn和Mg原子的偏聚区,Zn/Mg质量比由1~1.4之间变化;圆片状亚稳相η′的化学成分配比m(Zn)/m(Mg)为1.4~5.2,均被认为是富Zn相,GP(Ⅰ)区是η′相的异质形核位置;当Zn含量增高,原子浓度较高更有利于Zn原子热扩散形核,形成相对稳定的η′相;m(Zn)/m(Mg)较高时,无过剩Mg元素生成T相。研究表明,m(Zn)/m(Mg)在2~3范围内,随着Zn含量的增加,01975合金和7A62合金的强度优势显著(见图2(a)),7A62铝合金通过Zn含量和m(Zn)/m(Mg)设计,调控基体显微结构获得η′相和T相的析出量及尺度的匹配,使得7A62铝合金的强度明显升高,塑性较好。

图6 典型中强可焊Al-Zn-Mg系合金中T相含量和MgZn2相含量随添加元素Zn含量和m(Zn)/m(Mg)的变化特征

Fig. 6 Changes in mass of T phase and MgZn2 phase with Zn content(a) and m(Zn)/m(Mg)(b) in representative medium- strength welded Al-Zn-Mg alloys

7A62铝合金较7A52合金强度显著增加150 MPa而塑性相当的原因分析如下:如图6所示,7A52采用m(Zn)/m(Mg)≈1.8协同Zn含量4.4%(质量分数),而通过化学成分设计的7A62采用m(Zn)/m(Mg)≈2.6协同增加Zn含量至6.84%(质量分数);这样以来,一方面使得7A62合金中η′相的含量从2%增加到7.5%左右,这种基体高密度η′相是其强度显著提升的主因;另一方面使得7A62合金中T相含量从4.4%减少到1.8%左右,这种弥散T相形成高剪切应变区复合强化合金,由于T相仍为纳米粒子,因此,不会削弱7A62合金的塑性。故7A62合金化学成分设计获得亚稳态η′相沉淀强化和T相弥散强化的复合强化作用,使得合金力学性能具有显著优势。

3.2 复合强化作用分析

通过对7A62铝合金力学性能测试和显微结构观察分析,构成了对该合金的初步认识。高强可焊7A62铝合金化学成分设计突破了常规Al-Zn-Mg系合金单一沉淀强化机制,将高密度分散的5 nm左右球形半共格析出相沉淀强化和大量位错缠结均匀分布的200 nm左右近球形析出第二相强化结合,基于高密度纳米析出和较高晶格错配的理念,提高主元素Zn含量6.7%~7.4%和采用m(Zn)/m(Mg)为2~3,通过化学成分设计增加合金基体中主强化相η′的数量,控制微米级粗大硬脆初晶相的形成,取而代之析出近球形100~200 nm平衡相。7A62合金的强度主要依赖于纳米级沉淀析出η′相,其次是跨尺度T相纳米粒子。

7A62铝合金中η′析出相对强度贡献最大,η′相和T相能获得最佳的强韧性匹配,使其具有高的强度和较好的塑性。研究表明(见图3和4),7A62-T6铝合金的强化沉淀析出相主要为η′相,起主要强化作用。7A62铝合金T6状态基体中强化相η′与基体有匹配的晶格结构,晶内η′相沿 晶带轴的HREM像,η′相的衍射花样是[001]η′指数方向的衍射斑。从HRTEM的分析结果看,η′与基体存在一定的晶体学取向关系:

晶带轴的HREM像,η′相的衍射花样是[001]η′指数方向的衍射斑。从HRTEM的分析结果看,η′与基体存在一定的晶体学取向关系: //

// ,

, ∥

∥ 。根据HRTEM获得基体铝晶面间距d{111}Al=0.237 nm和球形η′析出相晶面间距dp=0.493 nm,可计算出两者间半共格相界面的晶格错配度δ为53%,η′相与基体的晶格错配度较大,粒子周围引起高界面能,对屈服强度的贡献

。根据HRTEM获得基体铝晶面间距d{111}Al=0.237 nm和球形η′析出相晶面间距dp=0.493 nm,可计算出两者间半共格相界面的晶格错配度δ为53%,η′相与基体的晶格错配度较大,粒子周围引起高界面能,对屈服强度的贡献

(C1、m1、m2是常数,f为沉淀相的体积分数,r为沉淀相的半径),体积分数约60%的η′相在7A62合金中起到主强化作用。体积分数约10%的100~200 nm左右近球形T相,由于其与基体结合界面良好,并能阻碍位错迁移(见图5(a)),变形和高速冲击时无法形成切割机制和绕过机制而形成位错堆积,形成高能弹性应变区,对切应力的贡献

(C1、m1、m2是常数,f为沉淀相的体积分数,r为沉淀相的半径),体积分数约60%的η′相在7A62合金中起到主强化作用。体积分数约10%的100~200 nm左右近球形T相,由于其与基体结合界面良好,并能阻碍位错迁移(见图5(a)),变形和高速冲击时无法形成切割机制和绕过机制而形成位错堆积,形成高能弹性应变区,对切应力的贡献 (

( 是常数,

是常数, 剪切模量,b布氏矢量,l粒子间距),进一步起到强化基体的作用,更加有益于7A62铝合金的动态冲击性能。

剪切模量,b布氏矢量,l粒子间距),进一步起到强化基体的作用,更加有益于7A62铝合金的动态冲击性能。

4 结论

1) 在Al-Zn-Mg系合金中,在1.43≤m(Zn)/m(Mg)≤ 3时,合金的强度随Zn含量的增加而增强;当Zn含量一定时,m(Zn)/m(Mg)>3的合金强度低于1.43≤ m(Zn)/m(Mg)≤3的合金强度。高强可焊7A62铝合金的成分设计,基于高密度较高晶格错配的跨尺度纳米析出相强化理念,采用了主元素Zn含量为6.7%~7.4%和m(Zn)/m(Mg)为2~3。

2) 7A62-T6合金基体中,高密度分散的5 nm左右球形半共格析出相和高度位错缠结均匀分布的200 nm左右近球形平衡相表现出高界面能和高应变区。基体主要沉淀强化相为η′相,且与基体形成取向关系满足 //

// ,

, ∥

∥ 。此外基体存在少量过渡相GP(Ⅰ)区和稳定相Al3Zr,与基体呈完全共格关系,跨尺度T相阻碍位错运动,均起到辅助强化作用。

。此外基体存在少量过渡相GP(Ⅰ)区和稳定相Al3Zr,与基体呈完全共格关系,跨尺度T相阻碍位错运动,均起到辅助强化作用。

3) 7A62-T6合金的抗拉强度为615~645 MPa,屈服强度为575~603 MPa,伸长率为11%~14%,布氏硬度HB为165~175,成为可焊接Al-Zn-Mg系的高强铝合金。

致谢:

感谢刘稳对于7A62铝合金材料力学性能测试工作,感谢刘敏对于本项目科研经费的管理。

REFERENCES

[1] 蔡一鸣, 李慧中, 梁霄鹏, 汤国建. 7039铝合金靶板侵彻过程中的组织特征及数值模拟[J]. 中国有色金属学报, 2011, 21(5): 975-980.

CAI Yi-ming, LI Hui-zhong, LIANG Xiao-peng, TANG Guo-jian. Microstructure character and numerical modeling of 7039 aluminum alloy target during impact penetration[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 975-980.

[2] 彭小燕, 曹晓武, 段雨露, 陈举飞, 徐国富, 尹志民. 7020铝合金MIG焊焊接接头的组织与性能[J]. 中国有色金属学报, 2014, 24(4): 912-918.

PENG Xiao-yan, CAO Xiao-wu, DUAN Yu-lu, CHEN Ju-fei, XU Guo-fu, YIN Zhi-min. Microstructures and properties of MIG welded joint of 7020 aluminum alloy [J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 912-918.

[3] 周文标, 覃 珊, 谢尚异, 赵 巍. 7N01铝合金时效析出行为及其对性能的影响[J]. 轻合金加工技术, 2014, 42(4): 60-64.

ZHOU Wen-biao, QIN Shan, XIE Shang-yi, ZHAO Wei. Aging precipitation behavior and its effect on properties of 7N01 aluminum alloy[J]. Light Alloy Fabrication Technology, 2014, 42(4): 60-64.

[4] 赵 凯, 尹志民, 段佳琦, 邓 英, 何振波. 固溶-时效对01975A1-Zn-Mg-Sc合金板材组织性能的影响[J]. 轻合金加工技术, 2011, 39(11): 34-39.

ZHAO Kai, YIN Zhi-min, DUAN Jia-qi, DENG Ying, HE Zhen-bo. Effects of solution and aging treatment on microstructure and properties of 01975 Al-Zn-Mg-Sc aluminum alloy sheet[J]. Light Alloy Fabrication Technology, 2011, 39(11): 34-39.

[5] 刘玲霞, 成建国, 吕 绯. 7A52铝合金焊接结构件疲劳性能研究[J]. 兵器材料科学与工程, 2005, 28(5): 37-40.

LIU Ling-xia, CHENG Jian-guo, Lü Fei. Research on fatigue behavior of welded 7A52 Al components[J]. Ordnance Material Science and Engineering, 2005, 28(5): 37-40.

[6] STILLER K, WARREN P J, HANSEN V, ANGENETE J,  J. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100 and 150 ℃[J]. Materials Science and Engineering A, 1999, 270: 55-63.

J. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100 and 150 ℃[J]. Materials Science and Engineering A, 1999, 270: 55-63.

[7] 万彩云, 陈江华, 杨修波, 刘吉梓, 伍翠兰, 赵新奇. 7xxx系A1ZnMgCu铝合金早中期时效强化析出相的研究[J]. 电子显微学报, 2010, 29(5): 455-460.

WAN Cai-yun, CHEN Jiang-hua, YANG Xiu-bo, LIU Ji-zi, WU Cui-lan, ZHAO Xin-qi. Study of the early& mid-stage hardening precipitates in a 7xxx AlZnMgCu aluminium alloy[J]. Journal of Chinese Electron Microscopy Society, 2010, 29(5): 455-460.

[8] 张 平, 李 奇, 赵军军, 曾庆强. 7A52铝合金中第二相分析及微区电位测试[J]. 中国有色金属学报, 2011, 21(6): 1252-1257.

ZHANG Ping, LI Qi, ZHAO Jun-jun, ZENG Qing-qiang. Analysis of secondary phases and measurement of volta potential of 7A52 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1252-1257.

[9] LI X Y, LU K. Playing with defects in metals[J]. Nature Materials, 2017, 16: 700-701.

[10] LI S, CHEN K H, LIU H W. Effect of high-temperature pre-precipitation on mechanical properties and stress corrosion cracking of Al-Zn-Mg alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 585-589.

[11] GJB 1540—92. 装甲用铝合金板材规范[S].

GJB 1540—92. Specification for aluminium alloy sheets for armored vehicle[S].

[12] MIL-A-46063E. Military specification armor plate, aluminum alloy, 7039[S].

[13] GB/T 6892—2006. 一般工业用铝及铝合金挤压型材[S].

GB/T 6892—2006. Wrought aluminium and aluminium alloys extruded profiles for general engineering[S].

[14] 徐国富, 彭小燕, 段雨露, 曹晓武, 邓 英, 尹志民. 新型Al-Mg-Sc-Zr 和Al-Zn-Mg-Sc-Zr 合金的研究进展[J]. 中国有色金属学报, 2016, 26(8): 1577-1587.

XU Guo-fu, PENG Xiao-yan, DUAN Yu-lu, CAO Xiao-wu, DENG Ying, YIN Zhi-min. Research advance on new Al-Mg-Sc-Zr and Al-Zn-Mg-Sc-Zr alloys[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1577-1587.

[15] LI X Z, HANSEN V,  J, WALLENBERG L R. HREM study and structure modeling of the η′ phase, the hardening precipitates in commercial Al-Zn-Mg alloys[J]. Acta Materials, 1999, 47(9): 2651-2659.

J, WALLENBERG L R. HREM study and structure modeling of the η′ phase, the hardening precipitates in commercial Al-Zn-Mg alloys[J]. Acta Materials, 1999, 47(9): 2651-2659.

[16] BERG L K,  J, HANSEN V, LI X Z, KNUTSON-WEDEL M, WATERLOO G, SCHRYVERS D, WALLENBERG L R. GP-zones in Al-Zn-Mg alloys and their role in artificial aging[J]. Acta materials, 2001, 49: 3443-3451.

J, HANSEN V, LI X Z, KNUTSON-WEDEL M, WATERLOO G, SCHRYVERS D, WALLENBERG L R. GP-zones in Al-Zn-Mg alloys and their role in artificial aging[J]. Acta materials, 2001, 49: 3443-3451.

[17] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050[J]. Materials Science and Engineering A, 2008, 492: 1-10.

[18] 金龙兵, 赵 刚, 冯正海, 路丽英. 高速列车用中强可焊Al-Zn-Mg合金材料[J]. 轻合金加工技术, 2010, 38(12): 47-51.

JIN Long-bing, ZHAO Gang, FENG Zheng-hai, LU Li-ying. Weld-able moderate strength Al-Zn-Mg alloy for high speed train[J]. Light Alloy Fabrication Technology, 2010, 38(12): 47-51.

Composition design and trans-scale precipitates strengthening of high-strength weldable 7A62 Al-alloy

LANG Yu-jing, ZHOU Gu-xin, WANG Sheng, DU Xiu-zheng, QIAO Li, CHEN Min, LIU Min

(Ningbo Branch, China Academy of Ordnance Science, Ningbo 315103, China)

Abstract: The effects of Zn content and mass ratio of Zn and Mg on the strength of the Al-Zn-Mg alloys were investigated in order to develop a high-strength weldable 7A62 Al-alloy. The hardening precipitates of the 7A62 Al-alloy treated by peak aging were investigated in detail by transmission electron microscopy (TEM and HREM). The results show that the strength of 7A62 alloy with m(Zn)/m(Mg) of 2-3 and Zn content of 6.84% (mass fraction) increases obviously. After peak ageing, this alloy has the precipitates with volume fraction of 60% and the size <10 nm, and has the dispersed particles with volume fraction of 10% and the size of 100-200 nm. The high density uniformity η′ particles are the main strengthening precipitates in the matrix, and are semi-coherent or orientation relationships with the Al matrix, and form the high lattice mismatch. The trans-scale dispersed particles tangled by the dislocation are composed of Al, Zn, Mg, Mn elements. The new 7A62 aluminum alloy can become the high strength of weldable Al-Zn-Mg alloys due to the chemical composition and microstructure characteristics.

Key words: 7A62 aluminum alloy; trans-scale; η′ hardening phase; lattice misfit; mechanical properties

Received date: 2018-05-18; Accepted date: 2018-09-20

Corresponding author: ZHOU Gu-xin; Tel: +86-574-87902219; E-mail: zhouguxin52@163.com

(编辑 李艳红)

收稿日期:2018-05-18;修订日期:2018-09-20

通信作者:周古昕,研究员;电话:0574-87902219;E-mail:zhouguxin52@163.com