文章编号:1004-0609(2012)09-2600-08

激光熔覆WC颗粒增强复合涂层的组织及耐磨性

刘建弟,张述泉,王华明

(北京航空航天大学 材料科学工程学院 大型整体金属构件激光直接制造教育部工程研究中心,北京 100191)

摘 要:为了提高TA15钛合金的耐磨性,在TA15钛合金表面利用激光熔覆预置的大粒度WC颗粒与TA15混合粉末层制备WC颗粒增强耐磨复合涂层。采用金相显微镜(OM)、扫描电镜(SEM)分析涂层的显微组织,采用X射线衍射(XRD)结合能谱(EDS)对涂层进行物相鉴定,测试涂层在二体磨料磨损及室温干滑动磨损条件下的耐磨损性能并分析磨损机理。结果表明:增强相WC颗粒在涂层中较均匀分布,初生(TiW)C/TiC相和(TiW)C+(Ti, W)共晶组织组成增强相的基体,涂层在二体磨料磨损及干滑动磨损条件下表现出优异的耐磨性能,较钛合金基材耐磨性能提高几十至上百倍;WC颗粒与基体中韧性的高硬相及优异的抗粘着性能对涂层耐磨性起主导作用。

关键词:激光熔覆;颗粒增强;钛合金;碳化钨;耐磨性

中图分类号:TB333 文献标志码:A

Microstructure and wear resistance of

laser cladding WC particles reinforced composite coatings

LIU Jian-di, ZHANG Shu-quan, WANG Hua-ming

(Engineering Research Center of Ministry of Education on Laser Direct Manufacturing for Large Metallic Components,

School of Materials Science and Engineering, Beijing University of Aeronautics and Astronautics, Beijing 100191, China)

Abstract: The wear resistant composite coatings reinforced by WC particles were fabricated by laser cladding using blends of WC particles with large size and TA15 powders as the raw materials. Microstructure and worn surface morphologies of the coatings were analyzed and characterized by optical microscopy (OM), scan electron microscopy (SEM) equipped with energy dispersive spectrometer (EDS) and X-ray diffraction (XRD). Wear resistance of the coatings was evaluated under two-body abrasive and dry sliding wear test condition at room temperature. The results show that WC particles have a uniform distribution in the coatings, which consists of the primary phase (TiW)C/TiC and (TiW)C+(Ti,W) eutectic phase as the matrix. Under two-body abrasive and block-on-ring dry sliding wear conditions, compared with titanium alloy substrate, the wear-resistance of coatings has improved dozens to one hundred times. High hardness of WC particles and the tough matrix with excellent anti-adhesion properties play a key role in improving wear resistance of the coatings.

Key words: laser cladding; particles reinforcement; titanium; WC; wear resistance

钛合金因其独有的低密度、高强度、优异的耐蚀性和高温力学性能广泛应用于航空、航天、海洋、化工等工业装备中[1-3],但因其摩擦因数大、易粘着、耐磨性低而限制了钛合金在恶劣磨损环境中的应用。由于磨损失效常起源于材料的表面,所以在不影响基材原有优异性能的前提下,利用合适的表面改性手段可以有效改善钛合金的耐磨性能[4]。

传统的表面改性技术有离子注入、等离子氮化、化学/物理气相沉积等方法[5-6],由于加工制得的涂层薄或与基材结合力弱等缺点,这些方法难以满足在高

基金项目:国家重美基础研究发展计划资助项目(2010CB606305)

收稿日期:2011-08-29;修订日期:2011-11-28

通信作者:王华明,教授,博士;电话:010-82317102;E-mail: wanghm@buaa.edu.cn

接触应力条件下的使用要求。激光熔覆技术具有稀释率低、熔覆层与基材完全物理冶金结合、变形量小而且涂层厚度可在几十微米至几毫米之间变化等优点,因而得到了广泛研究和应用。近几年来,激光熔覆硬质增强相复合材料制备耐磨涂层引起了人们的高度关注,陶瓷材料具有一般金属材料难以比拟的耐磨性和耐蚀性,Al2O3、TiC、TiB2、WC等高硬度陶瓷相在涂层中的应用,使涂层的耐磨性在很大程度上得到提高,此方面研究国内外已有报道[7-10]。吴玉萍等[9]利用等离子熔覆Ni60B粉、钛粉和石墨混合粉原位合成的TiC陶瓷颗粒,大部分呈球状及少量方块状,尺寸为1~2 μm;KENNEDY等[10]利用平均粒度为7 μm TiB2及粒度为5 μm TiC陶瓷颗粒制备了颗粒增强复合涂层。无论是“原位”生成的硬质增强相TiC或TiB2还是外加颗粒强化,增强相都非常细小,尺度均在纳米至十几微米之间,难以阻止或抵挡粗磨粒条件下的磨损失效。另外,由于高温钛合金的高活性,一些通常很稳定的硬质相,如Al2O3、SiC等在钛合金溶液中易出现稳定性问题[11]。为此,具有高硬度和高温稳定性的大粒度WC颗粒成为理想的钛合金耐磨涂层增强相,WC不仅和钛合金的热膨胀系数很接近,同时与基体的润湿性可以通过WC与Ti在高温下的反应来改善[12-13]。

本文作者利用激光熔覆预置粉末法制备大粒度WC颗粒增强耐磨复合涂层,对熔覆层的显微组织及颗粒在涂层中分布进行分析,并测试颗粒及其周围组织的显微硬度变化规律及在二体磨料磨损和室温干滑动磨损条件下的耐磨损性能,根据滑动磨损的表面及亚表面形貌进一步分析涂层的磨损机理。

1 实验

1.1 试验原料与设备

选择尺寸为50 mm×40 mm×10 mm的近αTi- 6.5Al-2Zr-1Mo-1V即TA15锻造钛合金作为基材,激光熔覆前基材表面(50 mm×40 mm)利用砂纸去除表面氧化层并用酒精清洗。将铸造WC颗粒(粒度范围150~250 μm)与TA15合金真空等离子旋转电极雾化球形粉末(粒度范围50~110 μm)按质量比3:1进行混合,TA15合金粉末的成分见表1。混合粉末在预铺基材前,先机械搅拌10 min使粉末混合均匀,然后置于100 ℃烘干炉中烘干约4 h去除潮气。使用有机粘合剂将混合粉末铺于基材表面厚度约为1.2 mm。激光熔覆试验在YLS-10000光纤钛合金零件激光快速成型系统中进行,激光熔覆工艺参数如下:激光功率为6 kW,扫描

表1 TA15钛合金粉末的成分含量

Table 1 Composition content of TA15 titanium alloy powders (mass fraction, %)

Al

Zr

Mo

V

Fe

6.35

1.94

1.58

2.14

0.04

Si

O

H

C

Ti

0.018

0.092

0.001 4

0.008 8

Bal.

速率为600 mm/min、激光光斑直径为6 mm、搭接率为33%。由于钛合金活性高,钛合金零件激光熔覆过程中极易发生氧化,因此,激光熔覆在预抽真空反充氩气的保护腔内进行,腔内气氛氧含量小于60×10-6。

1.2 实验方法

按常规方法制备金相试样,采用Nephot-II金相显微镜(OM)、CS3400扫描电镜(SEM)及配备的能谱仪(EDS)分析熔覆层的显微组织,采用X射线衍射光谱(XRD)结合能谱进行物相鉴定并使用SISCIASV8.0图像分析软件对WC颗粒的体积分数进行测试。在载荷5 N、保载时间10 s的条件下,用HXZ-1000半自动维氏硬度计测定复合涂层中自WC颗粒至基体的显微硬度分布。

二体磨粒磨损在ML-100销盘式磨损机(见图1(a))

图1 二体磨粒磨损试验和环块式干滑动磨损试验的原理示意图

Fig. 1 Schematic illustrations of two-body abrasive wear test (a) and block-on-ring dry sliding wear test (b)

上进行,将360#砂纸粘附于转盘上,将试样加工为d 6 mm×10 mm,装于卡具上使涂层与砂纸接触,滑动速度为0.5 m/s,轴向载荷为4.89 N,磨损时间为2 min。室温干滑动磨损在MM-200环块式干滑动磨损机(磨损原理示意图如图1(b)所示)上进行,未经合金化处理的钛合金试样作为标准试样,选择淬火-低温回火处理的45#钢(洛氏硬度约为53)作为对磨环,试验参数如下:法向载荷分别为49、98和147 N,滑动速度为0.88 m/s,滑动总行程为1.58×103 m。采用称重法,用精度为0.1 mg的Sartorius 110S电子天平称量标样及试样的磨损量。

2 结果与讨论

2.1 激光熔覆耐磨复合涂层相组成及增强相的分布

在TA15钛合金表面利用激光熔覆WC颗粒与TA15混合粉末制备复合涂层过程中,激光照射区域钛合金首先发生熔化形成熔池,大粒度WC颗粒在钛合金熔体中发生部分熔解,碳元素和钨元素进入钛合金溶液中,激光扫过后颗粒被“捕获”同熔池一起快速凝固下来形成颗粒增强的复合涂层。激光熔覆WC颗粒增强耐磨复合材料涂层的XRD谱如图2所示。由图2可见,熔覆层中除β-Ti、α-Ti、WC和W2C的衍射峰之外,还出现TiC、(TiW)C和TiW的衍射峰。

图2 激光熔覆涂层的XRD谱

Fig. 2 XRD pattern of laser cladding coatings

颗粒增强复合涂层的性能通常由增强相的尺寸、

体积分数及增强相与基体界面的键合情况所控制。图3所示为激光熔覆WC颗粒增强耐磨复合涂层的横截面(垂直于激光扫描方向)与纵截面(平行于激光扫描方向)中WC颗粒分布的金相照片。从图3可以看出,不规则的WC钨粒度很大,尺寸范围在100~250 μm之间,颗粒在复合涂层中分布比较均匀,涂层与基材的结合处存有少量气孔但并没有出现裂纹等缺陷。通过图片分析软件测得涂层中WC颗粒的体积分数约为39%。图4所示为涂层与基材结合处的典型形貌。由

图3 激光熔覆涂层WC颗粒分布的金相照片

Fig. 3 OM photographs of transverse section (a) and longitudinal section (b) of laser cladding coatings showing WC particles distribution

图4 激光熔覆涂层与基材结合处的金相照片

Fig. 4 OM photograph of combination zone of laser cladding coatings and substrate

图4可以看出,涂层与基材为无界面物理冶金结合,并没有出现颗粒聚集沉底的现象。

2.2 激光熔覆耐磨复合涂层的组织形貌

在激光熔覆及其快速凝固过程中,基材散热比较快,熔池底部首先凝固,固-液界面逐渐向熔池表面方向推进,距离表面越近,WC颗粒与钛合金熔液相互作用的时间越长,进入钛合金熔液的C原子和W原子数就越多。

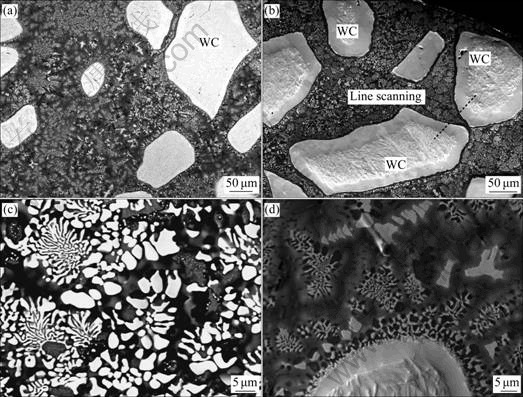

图5所示为激光熔覆WC颗粒增强耐磨复合涂层颗粒在涂层中的典型形貌。在本研究所选用的激光工艺参数和预置粉末成分配比下制得的复合涂层,WC颗粒被涂层的基体所包围,在涂层中均匀分布(见图5(a))。WC颗粒中心到涂层基体的组织形貌逐渐发生变化(见图5(d))。

对图5(b)中两相邻WC颗粒中C、Ti、W元素含量进行线扫描,扫描结果(见图6)表明,从WC颗粒到基体,W含量呈递减趋势,穿过边界层后又增多,而相应的Ti含量呈现相反的变化,C含量与Ti含量的变化趋势一致。WC颗粒在钛合金熔体中熔解,W元素与C元素向熔池中扩散,形成富钨富碳层,由于Ti与C的强亲和力很快结合形成TiC层而阻断了W元素扩散的途径,跨过TiC层基体中的W含量渐渐升高。颗粒到基体的渐变成分说明颗粒与基体间不存在润湿性问题而为一种牢固结合。

根据WC颗粒增强相之间的涂层基体的组织形貌(见图5(c)),结合XRD和EDS的分析结果,涂层基体由先析出相TiC或树枝晶((TiW)C为TiC的固溶体)及枝晶间的花瓣状(TiW)C+TiW共晶相组成。

HOFMEISTER等[14]曾用W和TiC的混合粉末为实验原料激光加工得到了由共晶组织 (W, Ti)+(Ti, W)C包围初生枝晶(Ti, W)C的组织结构,并指出该组织硬度在1 100~1 300 HV之间。在本研究中涂层顶部组织基体组织与此类似,根据该组织所特有的硬度值可以预测其具有良好的抗粘着磨损性能。

2.3 激光熔覆耐磨复合涂层的硬度分布及耐磨损性能

激光熔覆耐磨复合涂层中WC颗粒及其周围显微硬度分布曲线如图7所示。从图7可以看出,从WC 颗粒到由硬质相TiC和(TiW)C及(W, Ti)+(Ti, W)C共晶组织组成的基体,硬度由3 500 HV到900 HV呈现梯度递减,这与涂层中颗粒周围组织形态的变化相对

图5 激光熔覆涂层典型组织的SEM像

Fig. 5 SEM images showing typical microstructures of middle zone (a) and top zone (b) in laser cladding coatings and regions between (c) and around (d) particulates

图6 激光熔覆涂层中碳、钛、钨的线扫描结果

Fig. 6 Line scanning results of carbon (a), titanium (b) and tungsten (c) in laser cladding coatings

图7 激光熔覆涂层中WC颗粒及周围显微硬度分布

Fig. 7 Microhardness distribution of WC particle(a) and regions around WC particle(b) in laser cladding coatings

应,基体组织的显微硬度达900 HV与钛合金(约350 HV)相比,涂层基体的硬度得到了明显提高。

从图8可以看出,激光熔覆耐磨复合涂层在二体磨粒磨损和室温干滑动磨损条件下均表现出优异的耐磨性能。与未经处理的基材相比,载荷加大对涂层磨损影响不大。通过扫描电镜(SEM)结合能谱(EDS)对标样和涂层的室温干滑动磨损表面及磨损亚表面形貌及成分进行分析[15],进一步研究钛合金和涂层的磨损机理。

未处理的TA15基材与涂层的磨损表面形貌及放大图如图9所示。从图9(a)可以看出,钛合金由于硬度低,摩擦因数大,表面出现明显的犁沟现象为典型的显微切削的磨损特征;而复合涂层中高硬度WC颗粒和基体起到抵抗显微切削的作用,磨损表面(见图

图8 TA15基材及激光熔覆涂层二体磨粒磨损(a)及室温干滑动磨损(b)随加载载荷的变化

Fig. 8 Wear resistance of TA15 substrate and laser cladding coatings for two-body abrasive wear (a) and room temperature dry sliding wear (b) as function of applied test load

图9 TA15基材与激光熔覆涂层及放大的干滑动磨损表面形貌

Fig. 9 Worn surface morphologies of Tal5 substrate (a), laser cladding coatings (b) and its enlarged view (c) for dry sliding wear

9(b)和(c))相对比较平整,没有明显的沟痕,但在涂层表面上有一层粘附层。通过EDS分析,粘附层的主要成分为Fe和O,由此可以推断,粘附层是在磨损过程中由对磨环上的材料转移到涂层表面上的,转移层的存在有利于提高涂层的耐磨性能。放大的磨损照片(见图9(c))中涂层的组织清晰可见,与在组织分析中所观察到的形貌相同,没有发生变形或出现磨削痕迹。 图10所示为TA15钛合金基材与耐磨涂层的磨损亚表面形貌。由图10(a)可见,未经处理的钛合金基材在磨损过程中晶粒沿着磨损方向出现了严重的塑性变形;而耐磨涂层由于WC颗粒与涂层基体牢固地结合为一体,高接触应力下基体将载荷转移到耐磨硬质WC颗粒上而避免了磨损,图10(b)所示的塑性变形说明高硬度基体有一定的韧性,有效避免了脆性剥落。通过以上分析可知,高硬度WC颗粒及韧性基体相间牢固结合为提高抗切削抗粘着磨损起到了关键性作用。

图10 TA15基材(a)与激光熔覆涂层(b)的干滑动磨损亚表面形貌

Fig. 10 Worn subsurface morphologies of TA15 substrate (a) and laser cladding coatings (b) for dry sliding wear

3 结论

1) 以WC颗粒与TA15钛合金预置混合粉末为原料,通过激光熔覆技术在TA15钛合金基材表面上制备了WC颗粒增强耐磨复合涂层,涂层中WC颗粒分布较均匀,未发生明显的沉底现象。

2) 由于WC颗粒向钛合金熔体熔解呈现组织过渡区,因此颗粒至周围硬度亦呈现梯度递减特征。WC颗粒之间的基体为由初生(TiW)C/TiC相和(TiW)C+(Ti,W)的共晶组织组成。

3)在二体磨料磨损及干滑动磨损条件下,由于涂层基体及高硬质大粒度增强相的牢固结合及其优异的抗金属粘着能力,使涂层表现出优异的耐磨损性能。

REFERENCES

[1] LUTJERING G, WILLIAMS J C. Titanium [M]. 2nd ed. Berlin: Splinger-Verlag Berlin Heidelberg, 2007: 1-38.

[2] CHEN Yan-bin, LIU De-jian, LI Fu-quan, LI Li-qun. WCp/Ti-6Al-4V graded metal matrix composites layer produced by laser melt injection [J]. Surface and Coatings Technology, 2008, 202(19): 4780-4787.

[3] YANG Sen, LIU Wen-jin, ZHONG Min-lin, WANG Zhan-jie. TiC reinforced composite coating produced by powder feeding laser cladding [J]. Materials Letters, 2004, 58(24): 2958-2962.

[4] 王振廷, 陈华辉. 碳化钨颗粒增强金属基复合材料涂层组织及其摩擦磨损性能[J]. 摩擦学学报, 2005, 25(3): 203-206.

WANG Zhen-ting, CHEN Hua-hui. Microstructure and friction and wear behavior of induction clad Ni-based composite coating reinforced with micro- and nano-WC particulates [J]. Tribology, 2005, 25(03): 203-206.

[5] 于永泗, 赵 群, 张立文, 裴继斌, 王存山. 钛合金激光渗氮层的组织与性能研究[J]. 金属热处理, 2003, 28(12): 21-24.

YU Yong-si, ZHAO Qun, ZHANG Li-wen, PEI Ji-bin, WANG Cun-shan. Structure and property of nitriding layer on titanium alloy by laser [J]. Heat Treatment of Metals,2003, 28(12): 21-24.

[6] 张高会, 张平则, 崔彩娥, 郭丽娜, 潘俊德, 徐 重. 钛合金及其表面处理的现状与展望[J]. 世界科技研究与发展, 2003, 25(4): 62-67.

ZHANG Gao-hui, ZHANG Ping-ze, CUI Cai-e, GUO Li-na, PAN Jun-de, XU Zhong. Status and prospect of surface treatment for titanium alloys [J]. World Sci-tech Research and Development, 2003, 25(4): 62-67.

[7] ZENG Xiao-yan, TAO Zeng-yi, ZHU Bei-di, CUN Kun. Investigation of laser cladding ceramic-metal composite coatings: processing modes and mechanisms [J]. Surface and Coatings Technology, 1996, 79(1/3): 209 -217.

[8] VREELING J A, OCELIK V, DE HOSSON J T M. Ti-6Al-4V strengthened by laser melt injection of WCp particles [J]. Acta Materialia, 2002, 50(19): 4913-4924.

[9] 吴玉萍, 林萍华, 王泽华. 等离子熔覆原位合成TiC陶瓷颗粒增强复合涂层的组织与性能[J]. 中国有色金属学报, 2004, 14(8): 1335-1339.

WU Yu-ping, LIN Ping-hua, WANG Ze-hua. Microstructure and properties of in situ synthesis of TiC particle reinforced composite coating by plasma cladding [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1335-1339.

[10] KENNDY A R., KARANTZALIS A E, WYATT S M. The microstructure and mechanical properties of TiC and TiB2-reinforced cast metal matrix composites [J]. Journal of Materials Science, 1999, 34(5): 933-940.

[11] 曲选辉, 肖平安, 祝宝军, 秦明礼. 高温钛合金和颗粒增强钛基复合材料的研究和发展[J]. 稀有金属材料与工程, 2001, 30(3): 161-164.

QU Xuan-hui, XIAO Ping-an, ZHU Bao-jun, QIN Ming-li. Research and development of high temperature titanium alloy and particles reinforced Ti-mtrix composites [J]. Rare Metal Materials and Engineering, 2001, 30(3): 161-164.

[12] LI Li-qun, LIU De-jian, CHEN Yan-bin, WANG Chun-ming, LI Fu-quan. Electron microscopy study of reaction layers between single-crystal WC particle and Ti-6Al-4V after laser melt injection [J]. Acta Materialia, 2009, 57(12): 3606-3614.

[13] MATEOS J, CUETOS J M, FERNANDEZ E, VIJANDE R. Tribological behaviour of plasma-sprayed WC coatings with and without laser remelting [J]. Wear, 2000, 239(2): 274-281.

[14] HOFMEISTER W, COSTA L, RAIPUT D, LANSFORD K. Cast carbide-metal composite components via laser based solid freeform fabrication [R]. ICALEO, LIA, Orlando, FL, 2007.

[15] CHEN Yao, WANG Hua-ming. Microstructure and wear resistance of laser clad TiC reinforced FeAl intermetallic matrix composite coatings [J]. Surface and Coatings Technology, 2003, 168(1): 30-36.

(编辑 何学锋)