Grain refining and property improvement of AZ31 Mg alloy by hot rolling

MIAO Qing(苗 青), HU Lian-xi(胡连喜), SUN Hong-fei(孙宏飞), WANG Er-de(王尔德)

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 10 June 2009; accepted 15 August 2009

Abstract: Hot rolling of AZ31 Mg alloy was performed by using as-cast alloy ingot as the starting material. The microstructures and mechanical properties of the as-rolled alloy subjected to various rolling passes were investigated. The results show that the grain size of the alloy can be refined steadily with increasing rolling passes by dynamic recrystallization. With the steady refining of the grain size, both the mechanical strength and the plasticity of the alloy are improved correspondingly. In particular, when the grain size is reduced to about 5 μm after 5 rolling passes, the yield strength, ultimate tensile strength and tensile fracture strain of the alloy are 211 MPa, 280 MPa and 0.28 in the transverse direction, they are 200 MPa, 268 MPa and 0.32 in the rolling direction, respectively.

Key words: AZ31 Mg alloy; hot rolling; grain refining; mechanical properties

1 Introduction

Because of their low density and high specific strength, Mg alloys are becoming more and more important in structural applications[1-2]. Indeed, Mg alloys are nowadays widely used in aerospace, automobile, 3C areas and medicine[3-5]. Due to their hexagonal close-packed crystal structure, however, Mg alloys present limited workability at room temperature. In addition, the mechanical strength of most Mg alloys is not good enough for high performance structural applications. Therefore, improvement of their mechanical strength and ductility is urgently demanded.

It is well accepted that grain refining is an effective way to improve the mechanical strength of metallic materials[6-9]. In most cases, the yield stress, σy, can be related to the grain size, d, by the Hall-Petch expression σy=σ0+kd -1/2, where σ0 and k are positive constants for a specific material. For Mg alloys, the strengthening by grain refining can be very tempting because of their high k values[10-11]. Indeed, recent reports[12-15] on equal channel angular pressing (ECAP), differential speed rolling (DSR) and large-strain hot rolling (LSHR) have shown that when the grains of Mg alloys are refined, both the mechanical strength and the plasticity at room-temperature can be improved significantly. By using the grain refining effect of dynamic recrystallization, a hot rolling process was established to produce fine grained Mg alloy sheets recently. In this work, the grain refining and property improvement of AZ31 Mg alloy by this rolling process were studied.

2 Experimental

As-cast AZ31 Mg alloy plate ingot with 16 mm in thickness was used as the starting material for hot rolling. Before rolling, the ingot was homogenized by an annealing treatment at 400 ℃ for 10 h. The rolling was performed on a roll mill equipped with an induction heating system to heat the rolls during rolling. For each pass of rolling, the thickness reduction was 30%-35%, the rolling speed was 5 m/min, and the roll and billet temperatures were controlled to be in the range of 350-400 ℃ and 250-300 ℃, respectively.

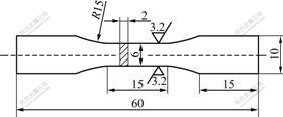

The microstructures and mechanical properties of the alloy subjected to various rolling passes were investigated. The microstructure was observed by optical microscope. The grain size was measured by the straight line intercept method. In order to evaluate the mechanical properties of tensile specimen, the geometry and dimensions of this tensile specimen are shown in Fig.1.

Fig.1 Geometry and dimensions of tensile specimen (Unit: mm)

The tensile specimen were prepared from the as-rolled alloy along both the transverse and the rolling directions. The tensile tests were performed at room temperature using an INSTRON-5569 standard testing machine. For all tensile tests, the gauge span was 15 mm, and the strain rate was 1.0×10-3s-1.

3 Results and discussion

3.1 Microstructure

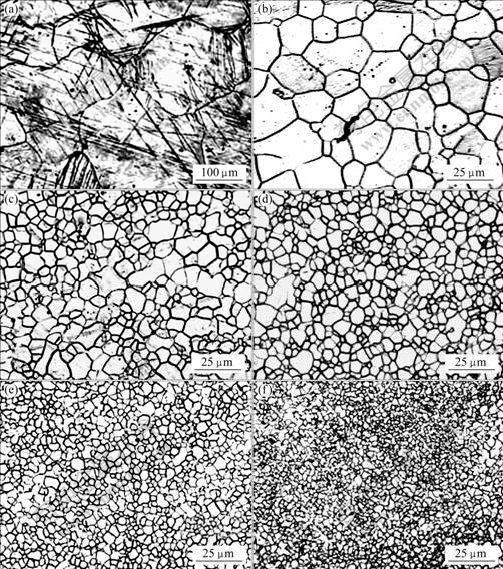

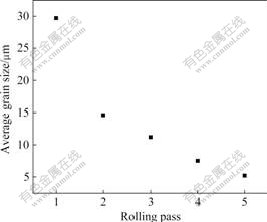

Fig.2 shows the microstructures of the as-rolled alloy subjected to various rolling passes. From Fig.2, it can be seen that the as-rolled AZ31 Mg alloy is featured by a dynamic recrystallization microstructure, and the grain refining is steady with the increase of the number of the rolling passes. In particular, the average grain size of the alloy reduces rolling passes in the starting as-homogenized state, as shown in Fig.3.

In general, for hot working with dynamic recrystallization, the grain size of the deformed metal is dependent on the deforming temperature, the deformation amount and the strain rate. In earlier studies [16-18], it has been shown that the microstructures of

Fig.2 Microstructures of as-rolled AZ31 Mg alloy after different rolling passes: (a) As-homogenized; (b) 1 pass; (c) 2 passes; (d) 3 passes; (e) 4 passes; (f) 5 passes

Fig.3 Average grain size of as-rolled AZ31 Mg alloy after different rolling passes

hot-deformed Mg alloys are closely related to the deforming temperature and deformation amount. In order to achieve a steady grain refining effect by recrystallization, the real temperature of the alloy during each rolling pass should not be too higher than the dynamic recrystallization temperature, so that the grain growth rate is kept at a lower level. In the present study, under the processing parameters chosen, the grain size of the as-rolled alloy reduces steadily with the increase of the number of the rolling passes.

3.2 Mechanical properties

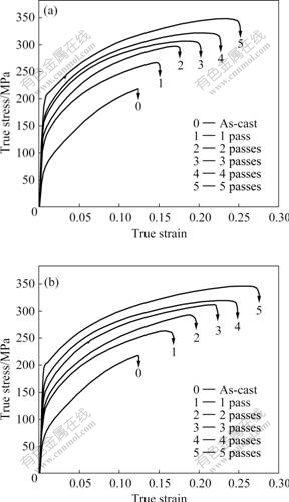

Fig.4 shows the tensile mechanical properties of the as-rolled AZ31 Mg alloy at room temperature after different rolling passes. It is seen from Fig.4 that the yield strength, ultimate tensile strength and tensile fracture strain of the alloy increase significantly with the increase of the number of the rolling passes. Indeed, both the mechanical strength and the plasticity of the as-cast alloy are very low, and the yield strength, ultimate tensile strength and tensile fracture strain are only about 50 MPa, 190 MPa and 0.13, respectively. In comparison, after 5 rolling passes, the yield strength, ultimate tensile strength and tensile fracture strain of the alloy are enhanced to 211 MPa, 280 MPa and 0.28, respectively, in the transverse direction; they are 200 MPa, 268 MPa and 0.32 in the rolling direction, respectively. It is obvious that the steady grain refining results from the dynamic recrystallization during hot rolling. In addition, the difference in the mechanical properties between the transverse and the rolling direction is quite small. This suggests that, due to the dynamic recrystallization during hot rolling, the development of microstructure anisotropy or texture is not serious in the sheet plane of as-rolled alloy.

Fig.4 Tensile stress—strain curves of as-rolled AZ31 alloy after various rolling passes: (a) Transverse direction; (b) Rolling direction

3.3 Fracture morphologies

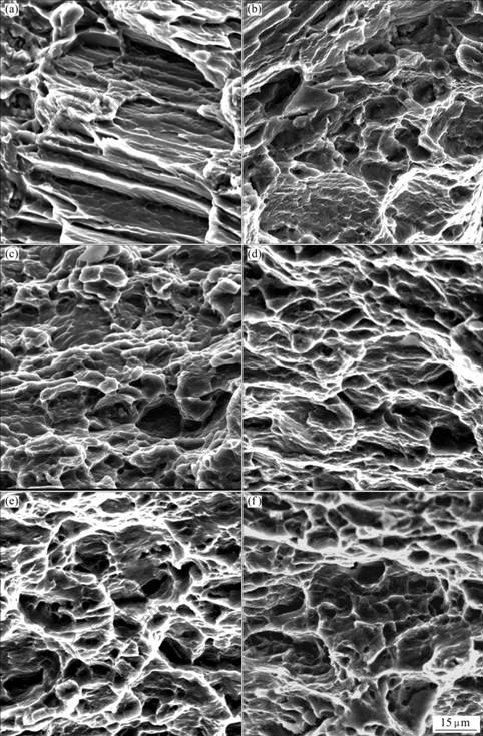

Fig.5 shows the morphologies of the fracture surface of the tensile specimens. From Fig.5(a), it is seen that the fracture of the as-cast alloy is featured by a typical river-like cleavage pattern, which is consistent with its poor plasticity. In comparison, though some small local cleavages exist in those specimens with fewer rolling passes, no river-like cleavage, which is over the whole fracture surface, can be observed in all the as-rolled alloy specimens (Figs.5(b)-(f)). This is attributed to the steady grain refining and also the elimination of casting defects with the increase of the rolling passes. Indeed, for the alloy which has been subjected to 3 or more rolling passes, the local cleavage can be hardly seen and the fracture is featured by the ductile dimple-pattern (Figs.5(d)-(f)). Therefore, both the mechanical strength and fracture strain increase with increasing rolling passes.

Fig.5 Morphologies of fractured specimens of as-rolled AZ31 Mg alloy after different rolling passes: (a) As-cast; (b) 1 pass; (c) 2 passes; (d) 3 passes; (e) 4 passes; (f) 5 passes

4 Conclusions

1) Under the rolling conditions chosen, the grain size of AZ31 Mg alloy can be refined steadily with increasing rolling passes by dynamic recrystallization. In particular, the grain size of the alloy is reduced to about 5 μm by 5 rolling passes.

2) Due to the grain refining effect, the mechanical properties of the AZ31 Mg alloy can be significantly improved by hot rolling. With the steady refining of the grain size by increasing rolling passes, both the mechanical strength and plasticity of the alloy correspondingly increase. When the grain size is reduced to about 5 μm after 5 rolling passes, the yield strength, ultimate tensile strength and tensile fracture strain of the alloy achieve 211 MPa, 280 MPa and 0.28 respectively, in the transverse direction; they are 200 MPa, 268 MPa and 0.32, respectively, in the rolling direction.

References

[1] MORDIKE B L, EBERT T. Magnesium properties-application- potential [J]. Mater Sci Eng A, 2001, 302(1): 37-45.

[2] KAMADO S, KOJIMA Y. Development of magnesium alloys with high performance [J]. Materials Science Forum, 2007, 546/549(1): 55-64.

[3] EIGENFELD K, TILCH W, ERCHOV S, PODOBED O. Integrated magnesium technology [J]. Advanced Engineering Materials, 2004, 6(7): 520-525.

[4] DOEGE E, DR?DER K. Sheet metal forming of magnesium wrought alloys—formability and process technology [J]. Journal of Materials Processing Technology, 2001, 115(1): 14-19.

[5] STAIGER M P, PIETAK A M, HUADMAI J, DIAS G. Magnesium and its alloys as orthopedic biomaterials: A review [J]. Biomaterials, 2006, 27(9): 1728-1734.

[6] CHINO Y, MABUCHI M. Influences of grain size on mechanical properties of extruded AZ91 Mg alloy after different extrusion processes [J]. Advanced Engineering Materials, 2001, 3(12): 981-983.

[7] BARNETT M R, KESHAVARZ Z, BEER A G, ATWELL D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn [J]. Acta Materialia, 2004, 52(17): 5093-5103.

[8] KIM W J, AN C W, KIM Y S, HONG S I. Mechanical properties and microstructures of an AZ61 Mg alloy produced by equal channel angular pressing [J]. Scripta Materialia, 2002, 47(1): 39-44.

[9] GARCES G, DOMINGUEZ F, PEREZ P, GARUANA G, ADEVA P. Effect of extrusion temperature on the microstructure and plastic deformation of PM-AZ92 [J]. Journal of Alloys and Compounds, 2006, 422(1/2): 293-298.

[10] CHEN Zhen-hua, YAN Hong-ge, CHEN Ji-hua, QUAN Ya-jie, WANG Hui-min, CHEN Ding. Magnesium alloy [M]. Beijing: Chemical Industry Press, 2004: 10-22. (in Chinese)

[11] CHANG T C,WANG J Y, O C M, LEE S. Grain refining of magnesium alloy AZ31 by rolling [J]. Journal of Materials Processing Technology, 2003, 140(1/3): 588-591.

[12] KIM W J, HONG S I, KIM Y S, MIN S H, JEONG H T, LEE J D. Texture development and its effect on mechanical properties of an AZ61 Mg alloy fabricated by equal channel angular pressing [J]. Acta Materialia, 2003, 51(11): 3293-3307.

[13] KANG F, WANG J T, PENG Y. Deformation and fracture during equal channel angular pressing of AZ31 magnesium alloy [J]. Mater Sci Eng A, 2008, 487(1/2): 68-73.

[14] PEREZ-PRADO M T, VALLE J A, RUANO O A. Achieving high strength in commercial Mg cast alloys through large strain rolling [J]. Materials Letters, 2005, 59(26): 3299-3303.

[15] WATANABE H, MUKAI T, ISHIKAWA K. Effect of temperature of differential speed rolling on room temperature mechanical properties and texture in an AZ31 magnesium alloy [J]. Journal of Materials Processing Technology, 2007, 182(1/3): 644-647.

[16] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49 (7): 1199-1207.

[17] RAVI KUMAR N V, BLANDIN J J, DESRAYAUD C. Grain refinement in AZ91 magnesium alloy during thermomechanical processing [J]. Mater Sci Eng A, 2003, 359(1/2): 150-157.

[18] FATEMI VARZANEH S M, ZAREI-HANZAKI A, BELADI H. Dynamic recrystallization in AZ31 magnesium alloy [J]. Mater Sci Eng A, 2007, 456(1/2): 52-57.

(Edited by LI Yan-hong)

Corresponding author: HU Lian-xi; Tel: +86-451-86418613; E-mail: hulx@hit.edu.cn