文章编号: 1004-0609(2005)07-1045-06

Cu-Cr合金快淬带的凝固数值模拟

王宥宏1, 2, 孙占波1, 宋晓平1

(1. 西安交通大学 理学院, 西安 710049; 2. 太原科技大学 材料分院, 太原 030024)

摘 要: 建立了单辊快淬凝固过程的数值分析模型, 将真空室、 冷却辊和样品带作为一个整体换热系加以考虑, 以厚度为60μm的Cu-25%Cr合金快淬带为模拟对象, 对其凝固过程进行了分析研究。 由冷却曲线和温度场曲线模拟结果可知, 带子的凝固时间为1.0×10-4s; 单辊快淬的平均冷却速度在106K/s数量级, 且凝固潜热的释放不会明显地引起冷却过程的温度回升; 带子的凝固速度在0.010~0.394m/s范围之内随凝固时间的延长逐渐由大变小。 通过比较模拟结果和实验结果, 且参考已有研究结论, 证明了该模型的正确性, 得到了Cu-Cr体系的一些凝固规律和凝固参数。

关键词: CuCr合金; 凝固模拟; 快速凝固; 熔体快淬 中图分类号: TG146.1

文献标识码: A

Numerical simulation of single roller melt-spinning for solidification process of Cu-Cr alloy

WANG You-hong1, 2, SUN Zhan-bo1, SONG Xiao-ping1

(1. Physics Institute, Xian Jiaotong University, Xian 710049, China;

2. Materials Institute, Taiyuan Science and Technology University, Taiyuan 030024, China)

Abstract: The numerical simulation model of single roller melt-spinning for solidification process of Cu-25%Cr alloy was built, and the vacuum chamber, cooling roller and sample were taken into account as a holistic heat system. By the cooling curve and the temperature field, it can be known that, the solidification time of ribbon is 1.0×10-4s, the even solidification rate of ribbon with 60μm thickness is about 106K/s, and the temperature of cooling process does not obviously go back by the release of solidification latent heat. The solidification rate of ribbon is at 0.010-0.394m/s, and it changes from high to low with the prolonged solidification time. The simulative results are compared with the experimental and published ones, the validity of the model has been testified, some solidification rules and parameters of Cu-Cr alloys were firstly gotten.

Key words: CuCr alloy; solidification simulation; rapid solidification; melt-spinning

在各种急冷快速凝固技术中, 单辊熔体快淬方法是目前在实验室广泛使用的一种方法。 制带过程的温度精确测量是至今无法解决的难题。 杨等[1]曾用数值模拟方法研究制带过程的冷却速度, 但没有考虑沿带厚度方向的冷却速度变化, 且其中对傅立叶导热偏微分方程的理解有误。 他们认为傅立叶导热方程的“热传导是一个速度为无限大的扩散过程”, 实际情况并非如此。

还有一些对制带过程冷却速度的研究[2-6], 使用的是一种“热流量”法, 其中主要工作是确定换热系统各部分之间的换热系数, 但要得到一个准确的换热系数是很不容易的。 且使用该方法只能得到带子的一个平均冷却速度。

快速凝固理论研究的主要问题有: 冷却速度、 过冷度、 凝固速度和微观组织等。 对于急冷凝固方法核心问题是冷却速度; 对于大过冷度凝固方法核心问题是过冷度。 人们采用实验实测法和理论凝固模拟法对冷却速度或过冷度进行了一定深度的研究, 但还存在着一些问题与不足[1-12]。 如: 1) 对所有采用急冷方式进行的快速凝固均无法准确测温, 即使进行测温, 也仅限于对样品表面的温度进行粗略测量。 2) 用数值模拟方法进行冷却速度或过冷度分析开展得不够广泛和细致。 如: 冷却体的温度假设为常温不变; 没有考虑冷却体和样品的热物理参数随温度变化; 冷却速度、 过冷度和凝固速度的计算都包含大量的经验因素在内; 有时认为样品内沿厚度方向各部分的温度都一样; 模拟合金种类十分有限, 主要是Al合金、 Fe合金、 Ti合金和一些高温合金等。 3) 仅可见到对表面熔化法[8]和雾化沉积法[12]的温度场模拟结果, 而溶体快淬法等许多方法就没有有关其温度场和凝固速度的研究结果。

结合科研工作的需要, 本文作者对单辊熔体快淬Cu-25%Cr合金的凝固过程进行了数值凝固模拟。 将冷却辊、 带子和真空室作为一个整体热交换系统考虑, 采用一维傅立叶导热偏微分的差分形式进行模拟计算。

1 模拟模型

通过对单辊熔体快淬过程的传热系统做适当简化, 并作如下假设。

1) 冷却铜辊是该快速凝固方法的主冷却系统, 主传热方向在铜辊径向上, 将其他方向的传热忽略。

2) 样带传热的主方向是沿厚度方向进行的, 将其他方向的传热忽略。

3) 样带在形成过程中与冷却辊接触良好, 忽略它们界面之间的热阻。

4) 样带外表面(自由表面)的传热受冷却辊的导热传热、 与环境之间的辐射传热和强对流传热三方面共同作用。 模型中, 将通过控制代表样带外表面的p节点的温度变化来反映此部分对凝固传热影响。

由此可建立如如图1所示的一维传热模型。 节点1~m代表冷却辊径向厚度。 m值的大小应保证节点1在模拟计算过程中始终保持初始温度293K。 节点m+1~p代表样带厚度。 空间步长均为Δx, Δx=1.0μm, 保持不变; 单元的截面积为单位面积。 铜冷却辊的导热系数(λ1)、 密度(ρ1)和比热容(c1)取常温值, 不考虑随温度变化; 样带的导热系数(λ2)、 密度(ρ2)和比热容(c2)为温度的函数, 不同温度取不同的值。

图1 单辊熔体快淬传热模型

Fig.1 Heat transfer model of single roller melt-spinning

模拟差分方程为

式中对节点m、 m+1和p进行了所示特殊处理。 Tm为样带模拟计算开始温度或浇注温度; Tni为节点i在n时刻的温度。

模拟时间步长Δτ为

热物理参数的处理如下[13-15]:

式中x=λ(Cu)/λ(Cr);

φ(Cu)和φ(Cr)分别为富Cu相和Cr相所占的体积分数。

φ(Cu)和φ(Cr)分别为富Cu相和Cr相所占的体积分数。

c2=w(Cu)·c(Cu)+w(Cr)·c(Cr)

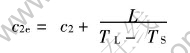

凝固期间c2为c2e:

其中L=w(Cu)·L(Cu)+w(Cr)·L(Cr)

式中w为质量分数; c2e为样带在凝固期间的当量比热容; L为合金的结晶潜热; TL为合金的液相线温度; TS为合金的固相线温度。

2 模拟结果与实验验证

2.1 冷却曲线和温度场分布

模拟带厚为60μm。 其冷却曲线和温度场曲线的模拟结果如图2、 3所示。 图2所示为不同厚度处的冷却曲线。 初始温度为熔化温度2000K, 模拟时间为1.76×10-4s, 冷却曲线分别为样带和冷却辊距冷却面10、 20、 30、 40、 50、 60μm处的温度随冷却时间的变化情况。 T1为液相线温度1790K; Ts固相线温度1348K。 图3所示为与图2相对应的温度场曲线。

由图2所示的冷却曲线可知, 与冷却辊接触的、 厚度约为10μm的样带, 在凝固开始阶段, 温度下降很快; 随着厚度的增加或模拟时间的延长, 温度下降越来越缓慢。 此外, 对于厚度小于40μm处的冷却曲线, 没有出现由于释放结晶潜热而导致冷却曲线的斜率产生明显变化的情况; 而对于模拟带厚度为50和60μm的冷却曲线, 可以明显看到结晶潜热的影响。

图2 冷却速度与厚度的关系

Fig.2 Relation between cooling

图3 温度场曲线

Fig.3 Temperature field curves

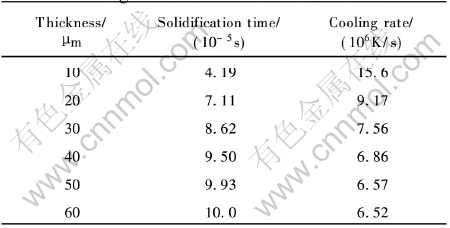

以各节点温度到达1348K计算其凝固时间, 以整个模拟时间段计算其平均冷却速度, 不同厚度[CM(22]处的凝固时间和冷却速度列于表1。 厚度为10μm[CM)] 处的冷却速度达1.56×107K/s; 厚度大于10μm的各节点的冷却速度均在106K/s数量级。

表1 不同厚度处的凝固时间和冷却速度

Table 1 Solidification time and cooling rate at different thicknesses

由图2还可知, 在开始凝固阶段, 冷却辊表面的温度升高非常快, 最高温度可达1276K, 接近纯Cu的熔点(1356K), 故在冷却辊表面经常可以发现微小烧蚀斑点。 另外, 模拟时, 不能假设冷却辊的温度保持不变, 否则, 经计算, 模拟结果和现模拟结果至少存在一个数量级的差别。

从图3所示的温度场曲线可以更加直观了解不同厚度处温度的变化情况和不同时刻的固相区、 固-液两相区和液相区的分布情况。 随着凝固模拟时间的延长, 固-液两相区越来越宽, 凝固后的组织应越来越粗大, 且形貌应越来越复杂。 这对理解和分析快淬带的微观组织形成具有重要意义。

2.2 凝固速度

图4所示为与图2相对应的凝固速度(v)曲线。 v=Δx/τs(其中, Δx为空间步长; τs为相应节点达到1348K的时间)。 由图4可知, 随着凝固层的增厚, 凝固速度越来越小。 在与冷却辊接触的大约5μm范围内, 合金带的凝固速度较大, 其最大值为0.394m/s; 合金带其余部分的凝固速度在0.010~0.045m/s范围之内变化。

图4 凝固速度与带厚的关系

Fig.4 Relation between solidification rate and thickness in solid field

2.3 实验验证

为了验证上述计算模型和热物理参数的正确性, 除了与已有研究结果进行比较之外, 采用了Cu-25%Cr(质量分数)合金制备了60μm厚的样带, 其微观组织如图5所示。 图中深色组织为基体(富Cu相), 亮色组织为富Cr相。 图5(a)所示为低倍横断面微观组织, 由冷却面往内, 富Cr相的晶粒尺寸变的越来越粗大, 晶粒形貌也由球状逐渐演变为不规则形态; 富Cr相尺寸最大的区域是与自由表面较接近的区域。 图2所示的冷却曲线、 图3所示的温度场曲线和图4所示的凝固速度曲线与图5所示的微观组织之间具有良好的对应关系, 定性地说明上述计算模型和热物理参数的处理是符合凝固规律的。

图5(b)所示为高倍局部微观组织, 其晶粒直径为0.2~0.4μm。 根据文献[6],  (其中, d为晶粒直径, μm; a≈50μm ·K·s-1;

(其中, d为晶粒直径, μm; a≈50μm ·K·s-1;  为平均冷却速度, K/s; b≈1/3), 则可知此处的冷却速度为1.8×106~1.3×107K/s。 与模拟结果基本符合。

为平均冷却速度, K/s; b≈1/3), 则可知此处的冷却速度为1.8×106~1.3×107K/s。 与模拟结果基本符合。

图5 带厚60μm的Cu-25%Cr合金的微观组织

Fig.5 Microstructures of Cu-25%Cr alloy in ribbon with 60μm in thickness

3 分析与讨论

从图2和图3中可知, 对于单辊熔体快淬过程, 沿样带厚度方向的冷却速度和温度梯度变化非常大, 若将冷却速度和温度梯度处理为与样带厚度无关的参数, 则必然丢失许多凝固过程的重要细节。

在模拟时间段内, 合金带的冷却速度基本上在106K/s数量级。 表2列出了几种不同快速凝固方法的冷却速度, 这些数据可定量说明本模拟结果的可信程度。 将表2中3组关于熔体快淬冷却速度的研究结果与本研究结果相比较, 文献[2-5]与本模拟结果之间不存在矛盾; 而文献[6]提供的数据可能有一点问题。 Wang等[16]对快淬带的冷却速度研究结果为5.85×106℃/s, 与本模拟结果也相近。 单辊快淬带的厚度通常在20~60μm, 一般认为其冷却速度在106K/s数量级。 对于较薄的快淬带, 其冷却速度要比106K/s大一些。

表2 几种不同快速凝固方法的冷却速度

Table 2 Cooling rates of different rapid solidifications

要研究熔体快淬时合金微观组织的变化, 凝固过程中温度场的分布是一个重要影响因素。 分析图3与图5可知: 冷却辊是单辊熔体快淬系统的主冷却系统, 自由表面的冷却作用是较小的, 图5(a)中富Cr相的尺寸和富集程度说明了这一点, 定性地表明温度场变化规律的模拟结果与微观组织的变化规律基本一致。 通过图5(b)由晶粒度计算所得的冷却速度值与模拟结果也基本符合。

对于60μm厚的Cu-25%Cr(质量分数)合金带, 在1.0×10-4s时间内, 已凝固完毕。 合金带的凝固速度在0.010~0.394m/s范围之内变化。 虽然还未见到关于单辊熔体快淬凝固速度的其它研究结果, 但Kittl等[17]的研究表明: 激光表面熔化快速凝固方法的凝固速度为0.2~2m/s; 魏等[10]的研究表明: 落管快速凝固方法的凝固速度≤0.291m/s。 熔体快淬法的冷却强度介于这两种快速凝固之间, 他们的研究结果可间接从数量上证明本模拟结果是可信的。

式(1)中关于节点p处温度为

上式反映的是冷却辊对节点p温度的作用; “5×103×Δτ”反映的是辐射和对流传热对节点p温度的作用。 要精确确定熔体快淬过程中的辐射换热系数和对流换热系数非常困难, 且二者针对不同的制带过程, 其值是变化的。 为了简单、 可靠地处理p节点的温度变化, 以表2中的一些公认数据为依据, 采用了该种处理方法。

以表2中所列的自由飞行熔体旋转法和紧耦合气体雾化法制备的样品在凝固过程中, 其传热主要是辐射传热和强对流传热。 节点p与环境之间的传热方式与它们的传热方式相同; 传热强度的差异主要在于对流传热热量的多少。 制带过程中, 铜轮的线速度为26m/s, 可与自由飞行熔体旋转法相比, 故将环境对节点p的冷却速度取为5000K/s。

4 结论

1) 熔体快淬过程中的温度测量非常困难, 到目前为止, 没有一个可用的精确测量方法, 而温度场又是影响快淬带微观组织的首要因素, 建立合理地熔体快淬数值模拟模型是实际研究工作迫切需要。

2) 模拟结果证明单辊熔体快淬较厚的带子的平均冷却速度在106K/s数量级。 给出了冷却速度和温度梯度随样带厚度和凝固时间的变化情况。

3) 凝固潜热对冷却曲线的形状有一定影响。 与自由表面较接近的节点, 其冷却曲线的斜率在潜热释放时变化较为明显。

4) 对于60μm厚的Cu-25%Cr(质量分数)合金带, 在1.0×10-4s时间内, 已凝固完毕。 合金带的凝固速度在0.010~0.394m/s范围之内变化。

5) 通过数值模拟研究了单辊快淬冷凝过程, 模拟结果与实验结果较为符合, 验证了该模拟模型和模拟方法的正确性。

REFERENCES

[1]杨院生, 童文辉, 陈晓明, 等. 金属快速凝固的非平衡超急速传热模型[J]. 金属学报, 2003, 39(3): 249-253.

YANG Yuan-sheng, TONG Wen-hui, CHEN Xiao-ming, et al. Transient heat transfer model for rapid solidification of metals[J]. Acta Metallurgica Sinica, 2003, 39(3): 249-253.

[2]张伟堂, 白敏丽. 单辊法制备非晶合金中冷却速率的数值计算[J]. 金属功能材料, 2002, 19(1): 12-18.

ZHANG Wei-tang, BAI Min-li. Numerical simulation of heat transfer during preparing amorphous alloy by single roller spinning[J]. Metallic Functional Materials, 2002, 19(1): 12-18.

[3]Jones H. A perspective on the development of rapid solidification and nonequilibrium processing and its future[J]. Mater Sci Eng A, 2001, A304-306 : 11-19.

[4]程天一, 章守华. 快速凝固技术与新型合金[M]. 北京: 宇航出版社, 1990. 1-139.

CHENG Tian-yi, ZHANG Shou-hua. Rapid Solidification Technology and Novel Alloys[M]. Beijing: Space Navigation Press, 1990. 1-139.

[5]胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 1991. 175-178.

HU Han-qi. Metals Solidification Principle[M]. Beijing: China Machine Industry Press, 1991. 175-178.

[6]张荣生, 刘海洪. 快速凝固技术[M]. 北京: 冶金工业出版社, 1994. 21-22.

ZHANG Rong-sheng, LIU Hai-hong. Rapid Solidification Technology[M]. Beijing: Metallurgical Industry Press, 1994. 21-22.

[7]李月珠. 快速凝固技术和材料[M]. 北京: 国防工业出版社, 1993. 3-29.

LI Yue-zhu. Rapid Solidification Technology and Materials[M]. Beijing: National Defence Industry Press, 1993. 3-29.

[8]Mehrabian R. Rapid solidification[J]. International Metals Reviews, 1982, 27(4): 185-208.

[9]Grant N J. Rapid solidification of metallic particulates[J]. Journal of Metals, 1983(1): 20-27.

[10]王楠, 曹崇德, 魏炳波, 等. Ag-Cu共晶合金在落管中的快速凝固[J]. 金属学报, 1998, 34(8): 824-830.

WANG Nan, CAO Chong-de, WEI Bing-bo, et al. Rapid solidification of Ag-Cu eutectic alloy by drop tube processing[J]. Acta Metallurgica Sinica. 1998, 34(8): 824-830.

[11]SUN Zhan-bo, ZHANG Cheng-yu, ZHU Yao-ming, et al. Microstructure of melt-spun Cu100-xCx(x=3.4-25) ribbons[J]. Journal of Alloys and Compounds, 2003, 361: 165-168.

[12]沈军, 崔成松, 蒋祖龄, 等. 雾化沉积快速凝固过程的计算机模拟(Ⅱ)─数值分析[J]. 金属学报, 1994, 30(8): B342-349.

SHEN Jun, CUI Cheng-song, JIANG Zu-ling, et al. Computer simulation of spray deposition process (Ⅱ): numerrical analysis[J]. Acta Metallurgica Sinica, 1994, 30(8): B342-349.

[13]中国金属学会, 中国有色金属学会. 金属材料物理性能手册(第一册)[M]. 北京: 冶金工业出版社, 1987. 322-323.

Chinese Metals Academy, Chinese Metals Nonferrous Academy. Metals Materials Physics Performance Handbook (Vol.1)[M]. Beijing: Metallurgical Industry Press, 1987. 322-323.

[14]陈则韶, 葛新石, 顾毓沁, 等. 量热技术和热物性测定[M]. 合肥: 中国科学技术大学出版社, 1990. 105-217.

CHEN Ze-shao, GE Xin-shi, GU Yu-qin, et al. Measure Heat Technology and Heat Properties of Matter Measure[M]. Hefei: University of Science and Technology of China Press, 1990. 105-217.

[15]程乃良, 牛四通, 徐桂, 等. 纯物质热化学数据手册[M]. 北京: 科学出版社, 2003. 555-602.

CHENG Nai-liang, NIU Si-tong, XU Gui, et al. Pure Matter Heat ChemicalData Handbook[M]. Beijing: Science Press, 2003. 555-602.

[16]WANG Xiao-jun, CHEN Xue-ding, XIA Tian-dong, et al. Influencing factors and estimation of the cooling rate within an amorphous ribbon[J]. Intermetallics, 2004, 12(10-11): 1233-1237.

[17]Kittl J A, Sanders P G, Aziz M J, et al. Complete experimental test of kinetic models for rapid alloy solidification[J]. Acta Mater, 2000, 48: 4797-4811.

基金项目: 国家自然科学基金资助项目(50371066)

收稿日期: 2004-12-22; 修订日期: 2005-05-13

作者简介: 王宥宏(1963-), 男, 副教授, 博士研究生.

通讯作者: 王宥宏, 副教授; 电话: 0351-6999329; E-mail: keai-998@163.com

(编辑 陈爱华)