Synthesis and characterization of Fe3O4 magnetic nanoparticles andtheir heating effects under radiofrequency capacitive field

来源期刊:中南大学学报(英文版)2010年第6期

论文作者:李旭红 冯志明 欧阳伟炜 谢小雪 廖遇平 唐劲天

文章页码:1185 - 1189

Key words:Fe3O4; magnetic nanoparticles; radiofrequency capacitive field; synthesis; characterization; heating effects

Abstract: Fe3O4 magnetic nanoparticles with diameters varying from 10 to 426 nm were synthesized and characterized. Heating effects of Fe3O4 magnetic nanoparticles under radiofrequency capacitive field (RCF) with frequency of 27.12 MHz and power of 60-150 W were investigated. When the power of RCF is lower than 90 W, temperatures of Fe3O4 magnetic nanoparticles (75-150 mg/mL) can be raised and maximal temperatures are all lower than 50 ℃. When the power of RCF is 90-150 W, temperatures of Fe3O4 magnetic nanoparticles can be quickly raised and are all obviously higher than those of normal saline and distilled water under the same conditions. Temperature of Fe3O4 magnetic nanoparticles can even reach 70.2 ℃ under 150 W RCF. Heating effects of Fe3O4 magnetic nanoparticles are related to RCF power, particle size and particle concentration.

J. Cent. South Univ. Technol. (2010) 17: 1185-1189

DOI: 10.1007/s11771-010-0616-z![]()

LI Xu-hong(李旭红)1, 2, FENG Zhi-ming(冯志明)3, OUYANG Wei-wei(欧阳伟炜)2,

XIE Xiao-xue(谢小雪)2, LIAO Yu-ping(廖遇平)2, TANG Jin-tian(唐劲天)4

1. Department of Rehabilitation, Third Xiangya Hospital, Central South University, Changsha 410013, China;

2. Department of Oncology, Xiangya Hospital, Central South University, Changsha 410008, China;

3. College of Chemistry and Chemical Engineering, Hunan Normal University, Changsha 410081, China;

4. Institute of Engineering and Physics, Tsinghua University, Bejing 100084, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2010

Abstract: Fe3O4 magnetic nanoparticles with diameters varying from 10 to 426 nm were synthesized and characterized. Heating effects of Fe3O4 magnetic nanoparticles under radiofrequency capacitive field (RCF) with frequency of 27.12 MHz and power of 60-150 W were investigated. When the power of RCF is lower than 90 W, temperatures of Fe3O4 magnetic nanoparticles (75-150 mg/mL) can be raised and maximal temperatures are all lower than 50 ℃. When the power of RCF is 90-150 W, temperatures of Fe3O4 magnetic nanoparticles can be quickly raised and are all obviously higher than those of normal saline and distilled water under the same conditions. Temperature of Fe3O4 magnetic nanoparticles can even reach 70.2 ℃ under 150 W RCF. Heating effects of Fe3O4 magnetic nanoparticles are related to RCF power, particle size and particle concentration.

Key words: Fe3O4; magnetic nanoparticles; radiofrequency capacitive field; synthesis; characterization; heating effects

1 Introduction

Fe3O4 magnetic nanoparticles are of scientific and technological interest because they can be used in sealing, oscillation damping, position sensing and biomedical applications [1]. They were applied to cancer detection and cancer therapy because of their unique magnetic properties and low toxicity: drug delivery and hyperthermia. Hyperthermia was recognized as a promising form of cancer therapy with little side effect [2].

Compared with available hyperthermia modalities, magnetic nanoparticle hyperthermia under alternating magnetic field yields better results in uniform heating of the deeply situated tumors [3]. In this approach, fluid consisting of magnetic particles (magnetic fluid) is selectively delivered to the tumor, and an alternating magnetic field is then used to heat the particles and the corresponding tumor, so the tumor cells can be killed directly without damages of ambient healthy cells when their temperatures are increased up to 41-46 ℃ [4-6]. In this way, focused heating of the particles was obtained in the regions where the static field was dominated by the alternating magnetic field. It is found that the heating effect of Fe3O4 magnetic nanoparticles is not only related to the amplitude and frequency of the alternating current (AC) field, but also strongly depends on the physical properties of the materials. For example, the particle size and its distribution are important factors for dominating the heating efficiency [7-8].

RF hyperthermia with high frequency and high power (1-2 kW) is widely used in different countries as an adjuvant therapy for advanced tumors [9-10]. RF ablation is limited in toliver, kidney, breast, lung and bone cancers. Under such conditions, selective heating of tumor is only possible when heat dissipation by blood flow in normal tissue is much greater than that in tumor tissues. Although these techniques are effective, currently RF ablation is the preferred technique and the most widely practiced. Yet, RF techniques applied energy in an unfocused manner, and energy was delivered to both tumor and normal tissues [11]. So, damage to normal tissues could be inevitable.

Researchers conducted experiment with non invasive radiowave thermal ablation of cancer cells using nanoparticles as a novel approach to treat cancer. The idea is that RF treatment of malignant tumors at any site in the body should be possible if it is possible to get agents that release heat under the influence of the RF field to the specific tumor site. Most RF ablation research so far has worked with gold nanoparticles because they are easily prepared, and binding of cancer- targeting agents to the nanoparticles is easily achieved [12].

Radiofrequency capacitive field (RCF) with high frequency and low power as a routine physical therapy has been used in clinically for a long time. In this work, a series of magnetite particles with different sizes were synthesized by two chemical methods and their heating effects under RCF with high frequency and low power were investigated.

2 Experimental

2.1 Regents and instruments

All chemical reagents purchased were analytically pure and used directly without purification.

Erbtherm1100 P hyperthermia system was applied (27.12 MHz, 0-200 W, 11.0 m wavelength, Italy). RCF power could be regulated by changing output power of the system. IT-24P-Tiny thermocouple thermometer, 24 gauge polyurethane coated wire with polyester insulated thermocouple bead (Physitemp, US), and temperature- recording instrument with four channels (Beijing Kunlun Tianchen Instrument Science and Technology Co., China) were used.

2.2 Synthesis and characterization of Fe3O4 magnetic nanoparticles

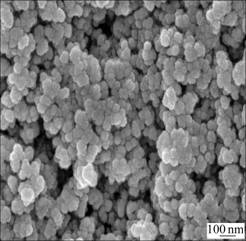

Magnetite particles with different diameters were prepared by two chemical methods. Samples were prepared according to the method of MOLDAY [13]. This method yielded particles with sizes about 10 nm, as shown in Fig.1. The others with diameters of about 92, 256 and 426 nm were prepared by a procedure that involved the aging of Fe(OH)2 gels at 90 ℃ for 4-6 h with KNO3 as the oxidizing agent [14]. The sizes were controlled by adjusting the concentration of the reactant of FeSO4. By using a powerful permanent magnet, all of the obtained samples were cleaned to remove excessive soluble reagents and washed with double-distilled water. Finally, the magnetite particles were dried into powder at room temperature under vacuum.

Fig.1 TEM image of Fe3O4 magnetic nanoparticles

Morphology and average diameter of Fe3O4 magnetic nanoparticles were detected by transmission electron microscope (TEM, Hitachi H-600, Japan) and image analysis system (CMIAS98A, Beijing University of Aeronautics and Astronautics, China) [15]. Samples for TEM measurement were prepared by dispersing Fe3O4 magnetic nanoparticles in acetone at an appropriate concentration and then depositing on formvar-coated copper grids and drying. Their magnetic properties were measured by a vibration sample magnetometer (VSM, Lakeshore, model 7300).

2.3 Heating effect of Fe3O4 magnetic nanoparticles under RCF

All samples used in the measurements were freshly prepared and dispersed in normal saline (NS) to form homogenous suspensions and treated with ultrasound for 30 min before measurements. Homogenous Fe3O4 magnetic nanoparticle suspensions in centrifuge tube packed with polystyrene foam plastics to act thermal insulation, were treated with 27.12 MHz RCF produced by Erbtherm1100 P hyperthermia system, NS and distilled water (DW) in centrifuge tube packed with polystyrene foam plastics under the same condition were used for control.

Temperatures of Fe3O4 magnetic nanoparticles in a tube under 27.12 MHz RCF were detected by IT-24P-Tiny thermocouple thermometer and recorded dynamically by temperature-recording instrument with four channels.

The experimental results obtained were analyzed by software SPSS 13.0. Heating rates were compared using chi-square (χ2) test between two groups. P values less than 0.05 were considered to be significant.

3 Results and discussion

3.1 Synthesis and characterization

According to TEM image analysis, it is found that there are not particles with extremely wide size distribution. Therefore, it is considerable that there are different degrees of aggregates and different packing densities of aggregates; these particles are polydisperse and some of them agglomerate due to magneto-dipole interactions between particles (see Fig.1).

Saturation magnetization (Ms) and coercivity (Hc) are the main technical parameters to characterize the magnetism of a ferromagnetic particle sample. Ms and Hc of Fe3O4 magnetic nanoparticles are listed in Table 1.

Table 1 Magnetic parameters of Fe3O4 magnetic nanoparticles

3.2 Effect of particle size on heating effect

Fe3O4 magnetic nanoparticles are of particular interest because they exhibit effective optical absorption, excellent fluorescent enhancement and superpara- magnetic behavior. So they can be used for both cancer detection and treatment.

RF ablation with high frequency and high power (1-2 kW) is a treatment for cancer by inserting a thin needle guided by computed tomography or ultrasound through the skin into a tumor. Electrical energy is then delivered through a number of electrodes deployed through the needle, causing a zone of thermal destruction that encompasses the tumor [10]. But route medical use frequency of RCF is 13.56 (22 m wavelength), 27.12 (11 m wavelength), and 40.68 MHz (7.5 m wavelength). The frequency of 27.12 MHz applied in the present work is most commonly used for physical therapy clinically [16-17].

According to Table 2, heating effects of Fe3O4 magnetic nanoparticles under RCF are demonstrated. Temperatures of magnetic particles are strongly size- dependent in the applied RCF. For magnetic particles with diameters varying from 10 to 426 nm, temperatures of Fe3O4 magnetic nanoparticles increase as particle diameter decreases. Maximal temperature of Fe3O4 magnetic nanoparticles with diameter of 10 nm is obviously higher than that of Fe3O4 magnetic nanoparticles with other particle diameter. Fe3O4 magnetic nanoparticles with diameter of 10 nm were selected to test the effects of RCF power, particle concentration and particle dosage on their heat generation.

Table 2 Maximal temperatures of Fe3O4 magnetic nanoparticles with different diameters under RCF ℃

3.3 Effect of RCF power on heating effect

The maximal temperatures of 75 and 150 mg/mL Fe3O4 magnetic nanoparticles, NS and DW treated with 60-80 W RCF for 30 min are shown in Table 3. When the power of RCF is less than 90 W, the heating effect of Fe3O4 magnetic nanoparticles is weak. Temperature of Fe3O4 magnetic nanoparticles (75-150 mg/mL) can be raised and the maximal temperatures are lower than 50 ℃. Except no statistical temperature difference between 150 mg/mL and 75 mg/mL Fe3O4 magnetic nanoparticles groups and between NS and DW groups (P>0.05), there is statistical temperature difference between the other groups (P<0.05) (Fig.2), such as 150 mg/mL Fe3O4 magnetic nanoparticles and NS groups. The temperatures of Fe3O4 magnetic nanoparticles under 60, 70 and 80 W RCF cannot reach 50 ℃.

Table 3 Maximal temperatures of samples under RCF with different powers ℃

Fig.2 Time-dependent temperature curves of different samples under 90 W RCF: 1—150 mg/mL Fe3O4 magnetic nanoparticles; 2—75 mg/mL Fe3O4 magnetic nanoparticles; 3—NS; 4—DW

Maximal temperatures of 75 and 150 mg/mL Fe3O4 magnetic nanoparticles, NS and DW treated with 90- 150 W RCF for 30 min are shown in Table 3. When the power of RCF is above 90 W, temperatures of Fe3O4 magnetic nanoparticles can be quickly raised by RCF and are obviously higher than those of NS and DW under the same conditions. Temperature of 75 mg/mL Fe3O4 magnetic nanoparticles treated with 150 W RCF for 8 min reaches about 64.6 ℃. Temperature of 150 mg/mL Fe3O4 magnetic nanoparticles treated with 150 W RCF for 30 min quickly raised to about 70.2 ℃ and retains this level.

In contrast to temperature of Fe3O4 magnetic nanoparticles under RCF, temperatures of NS and DW are almost unchanged when the power of RCF is lower than 90 W and can also be raised when the powers of RCF are 90-150 W and all lower than those of Fe3O4 magnetic nanoparticles under the same conditions. Except no statistical temperature difference between 150 mg/mL and 75 mg/mL Fe3O4 magnetic nano- particles groups and between NS and DW groups (P>0.05), there is a statistical temperature difference between the other groups (P<0.05) (Fig.2), such as 150 mg/mL Fe3O4 magnetic nanoparticles and NS groups.

Temperature-rising of Fe3O4 magnetic nanoparticles under 90, 110, 130 and 150 W RCF is directly related to RCF power according to linear regression and correlation analysis of temperature at 10 min (r=0.956 7 and r= 0.964 9, n=4, P<0.05).

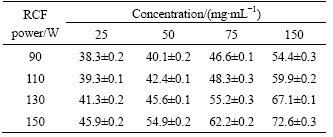

3.4 Effect of particle concentration on heating effect

Maximal temperatures of 25, 50, 75 and 150 mg/mL Fe3O4 magnetic nanoparticles treated with 90-150 W RCF for 30 min are shown in Table 4. The temperature- rising of Fe3O4 magnetic nanoparticles under 90 W RCF is directly related to particle concentration according to linear regression and correlation analysis of temperature at 10 min (r=0.989 4 and r=0.974 9, n=4, P<0.05).

Table 4 Maximal temperatures of samples with different particle concentrations under RCF ℃

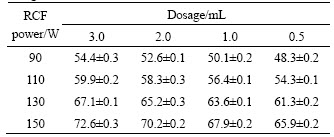

3.5 Effect of Fe3O4 dosage on heating effect

Maximal temperatures of Fe3O4 magnetic nanoparticles with different dosages of 3.0, 2.0, 1.0 and 0.5 mL treated with 90-150 W RCF for 30 min are listed in Table 5. There are statistical temperature-raising rate difference and maximal temperature between different groups (Ftime=373 898.9, P<0.05).

Maximal temperature of Fe3O4 magnetic nanoparticles treated with 150 W RCF can reach 70.2 ℃, temperature-raising rate is more quickly than that of other groups. According to statistical analysis (Fig.2 and Table 5), maximal temperatures and heating rates of Fe3O4 magnetic nanoparticles under RCF are related to the power of RCF, concentration of particles and acting time, and the temperatures of Fe3O4 magnetic nano- particles can be regulated by changing paricle concentration, dosage and the RCF power.

Table 5 Maximal temperatures of samples with different dosages under RCF ℃

3.6 Possible mechanism of thermal effects

RCF with 27.12 MHz and 0-200 W is RF electromagnetic wave as a source of heat produces deep heating via conversion of electromagnetic energy to thermal energy [17]. Oscillation of high-frequency electrical and magnetic fields produces movement of ions, rotation of polar molecules, and distortion of non-polar molecules, resulting in heat generation. But the heating effects of Fe3O4 magnetic nanoparticles under RCF with 27.12 MHz and 0-200 W were not reported [16-17].

The mechanism of the heating effect is not clearly and different from that of Fe3O4 magnetic nanoparticles under AC field [17]. According to the results obtained above, the heating effects of Fe3O4 magnetic nanoparticles under RCF are strongly dependent on the size, particle concentration and RCF power, and the heating effects may be related to RCF energy absorption and the Brownian motion of the magnetic particles.

RCF is an alternating current with special properties. RCF current can be delivered using resistive or capacitive technology. Such a feature is capacitive transfer, or the ability of RCF current to appear to flow through paths that contain insulating material, like the insulator of a capacitor.

Because of capacitive technology, a magnetic field is created between the insulated hand piece and ground electrode. So, the heating effects of Fe3O4 magnetic nanoparticles under RCF are attributed to RCF energy absorption, two kinds of power loss mechanisms, hysteresis loss and Brownian motion of the magnetic particles [17-19]. The grade of power loss depends on the particle sizes. Relaxation loss is caused by the relaxation processes of ultrafine monodomain magnetic particles in RCF, which is the gradual alignment of the magnetic moments during the magnetization process. The relaxation processes of a ferrofluid may take place through two distinct mechanisms [20-22].

4 Conclusions

(1) A series of Fe3O4 magnetic nanoparticles with different diameters are prepared. Saturation magnetization (Ms) and coercivity (Hc) of Fe3O4 magnetic nanoparticles are measured.

(2) The heating effects of Fe3O4 magnetic nanoparticles under RCF with frequency of 27.12 MHz and power of 60-150 W are investigated. When the power of RCF is less than 90 W, temperatures of 75- 150 mg/mL Fe3O4 magnetic nanoparticles can be raised and maximal temperatures are less than 50 ℃. When the powers of RCF are 90-150 W, temperatures of Fe3O4 magnetic nanoparticles can be quickly raised, and can even reach 70.2 ℃ under 150 W RCF.

(3) Heating effects of Fe3O4 magnetic nanoparticles are related to particle size, the power of RCF and concentration of particles.

References

[1] LAURENCE D E, HERVEE M, KATEL H, EMILIE M, MARTIN S, CLAUDE L, PIERRE D, IGOR C. Nanovectors for anticancer agents based on superparamagnetic iron oxide nanoparticles [J]. Int J Nanomedicine, 2007, 2(4): 541-550.

[2] JOHANNSEN M, JORDAN A, SCHOLZ R, KOCH M, LEIN M, DEGER S, ROIGAS J, JUNG K, LOENING S. Evaluation of magnetic fluid hyperthermia in a standard rat model of prostate cancer [J]. J Endourol, 2004, 18(5): 495-500.

[3] LATORRE M, RINALDI C. Applications of magnetic nanoparticles in medicine: Magnetic fluid hyperthermia [J]. P R Health Sci J, 2009, 28(3): 227-238.

[4] SHIDO Y, NISHIDA Y, SUZUKI Y, KOBAYASHI T, ISHIGURO N. Targeted hyperthermia using magnetite cationic liposomes and an alternating magnetic field in a mouse osteosarcoma model [J]. J Bone Joint Surg Br, 2010, 92(4): 580-585.

[5] GUO Zhong-hua, TANG Lu-Xin, TANG Jin-tian, XIE Bin, DENG Xiao-hui. Development of measurement and control technologies for hyperthermia treatments of tumors with AC magnetic field [J]. Chinese Journal of Medical Instrumentation, 2006, 30(1): 39-42. (in Chinese)

[6] LIU Xuan, XU Bo, XIA Qi-sheng, ZHAO Tian-de, TANG Jin-tian. A method of showing thermal effect of iron oxide nanoparticles in alternating magnetic field [J]. Chinese Journal of Cancer, 2005, 24(9): 1148-1150. (in Chinese)

[7] HERGT R, DUTZ S. Magnetic particle hyperthermia: Biophysical limitations of a visionary tumour therapy [J]. J Magn Magn Mater, 2005, 293: 80-86.

[8] MA Ming, WU Ya, ZHOU Jie, SUN Yong-kang, ZHANG Yu, GU Ning. Size dependence of specific power absorption of Fe3O4 particles in AC magnetic field [J]. J Magn Magn Mater, 2004, 268: 33-39.

[9] HABASH R W, BANSAL R, KREWSKI D, ALHAFID H T. Thermal therapy. Part I: An introduction to thermal therapy [J]. Crit Rev Biomed Eng, 2006, 34: 459-489.

[10] PALUSSIERE J, DESCAT E, FONCK M, BONICHON F, CHOMY F, BECOUARN Y, AVRIL A, KIND M, RAVAUD A. Radiofrequency ablation in the treatment of liver and lung tumors [J]. Bull Cancer, 2009, 96(11): 1099-1109.

[11] HABASH R W, BANSAL R, KREWSKI D, ALHAFID H T. Thermal therapy. Part II: Hyperthermia techniques [J]. Crit Rev Biomed Eng, 2006, 34(6): 491-542.

[12] STAUFFER P R. Evolving technology for thermal therapy of cancer [J]. Int J Hyperthermia, 2005, 21(8): 731-744.

[13] MOLDAY R S. Magnetic iron-dextran microspheres: US, 4452773 [P]. 1984-06-05.

[14] SUGIMOTO T, MATIJEVIC E. Formation of uniform spherical magnetite particles by crystallization from ferrous hydroxide gels [J]. J Colloid Interface Sci, 1980, 74: 227-243.

[15] DU Yi-qun, ZHANG Dong-sheng, NI Hai-yan, GU Ning, YAN Shi-yan, TANG Qiu-sha, JIN Li-qiang, WAN Mei-ling. Preparation and characterization of Fe3O4 nano-magnetic particles for tumor hyperthermia [J]. Journal of Chinese Electron Microscopy Society, 2005, 24(6): 608-612. (in Chinese)

[16] OHGURI T, IMADA H, YAHATA K, MORIOKA T, NAKANO K, TERASHIMA H, KOROGI Y. Radiotherapy with 8-MHz radiofrequency-capacitive regional hyperthermia for stage III non-small-cell lung cancer: The radiofrequency-output power correlates with the intraesophageal temperature and clinical outcomes [J]. Int J Radiat Oncol Biol Phys, 2009, 73(1): 128-135.

[17] SHIELDS N, O'HARE N, GORMLEY J. An evaluation of safety guidelines to restrict exposure to stray radiofrequency radiation from short-wave diathermy units [J]. Phys Med Biol, 2004, 49(13): 2999-3015.

[18] WAN Bai-kun, ZHU Xin, CHENG Xiao-man, ZHANG Li-xin, LIN Shi-yin, WANG Wei. Parameter optimization of temperature field in RF-capacitive hyperthermia [J]. Progress in Natural Science, 2001,11(9): 667-674.

[19] HABASH R W, BANSAL R, KREWSKI D, ALHAFID H T. Thermal therapy. Part IV: Electromagnetic and thermal dosimetry [J]. Crit Rev Biomed Eng, 2007, 35: 123-182.

[20] JORDAN A, SCHOLZ R, MAIER-HAU K, JOHANNSEN M, WUST P, NADOBNY J, SCHIRRA H, SCHMIDT H, DEGER S, LOENING S, LANKSCH W, FELIX R. Presentation of a new magnetic field therapy system for the treatment of human solid tumors with magnetic fluid hyperthermia [J]. J Magn Magn Mater, 2001, 225: 118-126.

[21] HE Han-wei, LIU Hong-jiang, ZHOU Ke-chao, WANG Wei, RONG Peng-fei. Characteristics of magnetic Fe3O4 nanoparticles encapsulated with human serum albumin [J]. J Cent South Univ Technol, 2006, 13(3): 6-11.

[22] MATSUI Y, NAKAGAWA A, KAMIYAMA Y, YAMAMOTO K, KUBO N, NAKASE Y. Selective thermocoagulation of unresectable pancreatic cancers by using radiofrequency capacitive heating [J]. Pancreas, 2000, 20 (1): 14-20.

Foundation item: Projects(30571779, 10775085) supported by the National Natural Science Foundation of China; Project(Z07000200540704) supported by Beijing Municipal Science and Technology Commission, China

Received date: 2010-05-12; Accepted date: 2010-10-12

Corresponding author: TANG Jin-tian, PhD, Professor; Tel: +86-10-62773439; E-mail: tangjt@mail.tsinghua.edu.cn