Zr基非晶合金在过冷液相区静液挤压的变形行为及结构

张曙光1, 胡 捷2, 朱学新1, 王发东1, 3, 徐 骏1, 石力开1

(1. 北京有色金属研究总院 复合材料中心, 北京100088;

2. 北京有色金属研究总院 加工工程中心, 北京 100088;

3. 北京科技大学 材料科学与工程学院, 北京 100083)

摘 要: 研究了Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶合金在过冷液相区内静液挤压的变形行为以及结构变化。 结果表明: 非晶合金在高应变速率下产生了明显的塑性变形, 直径从16mm变为12mm, 断裂为4段, 且样品断口上随机分布着充分发展与未充分发展的脉纹式切变带, 由此可看出非晶合金的变形为非牛顿体变形行为; 挤压后的样品约有3%的非晶相发生晶化, 在非晶基体上析出10~20nm的纳米晶粒, 导致挤压后非晶合金的热稳定性降低; 静液挤压高应变速率变形条件使非晶合金产生非均匀流变, 是造成非晶合金断裂的主要原因。

关键词: ZrTiCuNiBe非晶合金; 块体非晶合金; 过冷液相区; 静液挤压; 塑性变形 中图分类号: TG304; TG139.8

文献标识码: A

Deformation behavior and structure of Zr base bulk amorphous alloy in supercooled liquid region by hydrostatic extrusion

ZHANG Shu-guang1, HU Jie2, ZHU Xue-xin1, WANG Fa-dong1, 3,XU Jun1, SHI Li-kai1

(1. National Engineering Research Center for Nonferrous Metals Composites,General Research Institute for Non-ferrous Metals, Beijing 100088, China;

2. Nonferrous Metals Processing Engineering Research Center, General Research Institute for Non-ferrous Metals, Beijing 100088, China;

3. School of Materials Science and Engineering,University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The deformation behavior and structure of Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk amorphous alloy processed at 663K with strain rate of 0.28s-1 by hydrostatic extrusion were studied. The results show that the alloy undergoes obvious plastic elongation, the specimen fractures into four sections and the diameter changes from 16mm to 12mm. The fracture surfaces distribute randomly well developed and partially developed veinal patterns. The deformation behavior of alloy is non-Newtonian flow behavior. About 3% amorphous matrix of extruded specimen transforms crystal, the crystal particles with size of 10-20mm are precipitated in the amorphous matrix, the thermostability of the extruded specimen was lowered. The failure of the alloy is mainly attributed to non-uniform viscous flow under high strain rate resulting from the hydrostatic extrusion process.

Key words: ZrTiCuNiBe amorphous alloy; bulk amorphous alloy; supercooled liquid phase region; hydrostatic extrusion; plastic deformation

大块非晶合金BMG(Bulk metallic glass 或者Bulk amorphous alloy)由于其重要的研究意义和潜在的应用价值引起了人们广泛的研究兴趣。 但绝大部分大块非晶合金样品通常只能制备成诸如短杆状、 板状等简单形状, 难以满足实际应用的需求。 大量研究表明, 块体非晶合金在室温下由于不均匀的变形方式没有明显的塑性延伸率(〈1%), 而在过冷液相区内则可表现出均匀的(牛顿)粘滞性流动, 通过挤压、 模锻和轧制等工艺手段能够进行超塑性加工成形, 并制备出形状复杂的样品[1-16]。

但是, 非晶合金的超塑性变形具有强烈的温度和应变速率敏感性, 即变形温度处于过冷液相区内, 并且在很窄的一个温度范围内, 应变速率一般为10-4~10-3 s-1。 对于目前发现的绝大多数大块非晶合金体系, 其过冷液相区的温度宽度只有几十度, 再加上缓慢的变形速率, 不仅导致加工效率很低, 而且还非常容易影响非晶合金在变形过程中的晶化, 因此可供加工的温度区间非常窄, 加工过程中的温度控制非常困难。 这也是块体非晶合金到目前为止, 在成形加工和实用化方面发展缓慢的主要原因。 只是由于小尺寸非晶合金的均匀加热和变形相对较易控制, 因此初步开展了块体非晶合金在形成一些微小零部件方面的研究[8-12, 15, 16], 例如, 可像玻璃一样将其吹成表面非常光滑的非晶合金球, 采用模挤压和模锻方法将其加工成微型齿轮, 用于精密光学机械的部件。

静液挤压技术是利用高压液体对变形材料进行挤压加工, 静液挤压时在模具入口处连续供应高压液体(通常还混有润滑液)以保证毛坯和模具接触面间具有良好的连续润滑, 从而可降低摩擦力, 使挤压力大大下降, 同时减少了脆性材料挤压时表面严重受剪引起的破坏, 并使得工件表面与心部变形均匀。 在挤压过程中, 材料在高静水压作用下的变形有可能抑制或减少材料变形中微裂纹的产生, 在一定程度上还能使微裂纹愈合, 改善材料组织, 提高材料的工艺塑性, 进行低温大变形量加工, 特别适合硬脆等难变形材料的加工[17]。 因此, 本文作者拟采用静液挤压技术对块体非晶合金进行塑性加工, 期望扩大非晶合金的加工温度窗口, 并探索提高变形速度的可能性。 Lowhaphandu等[18]的研究表明, 常温下静水压力对Zr-Ti-Ni-Cu-Be非晶合金的断裂应力与应变影响甚微, 但却显著影响宏观断面的位向。 本文作者对Zr41.2Ti13.8Cu12.5Ni10Be22.5块体非晶合金在过冷液相区内进行静液挤压, 初步探讨其变形和断裂行为以及微观结构的变化, 为进一步深入研究静液挤压对非晶合金变形行为的影响奠定了基础。

1 实验

选用Zr41.2Ti13.8Cu12.5Ni10Be22.5 (摩尔分数, %)非晶合金作为实验材料, 所用原材料纯度大于99.8%。 采用非自耗钨极电弧炉熔炼母合金, 在Ti吸收和高纯氩气保护条件下反复熔炼4~6次, 使成分均匀。 用真空感应炉喷铸成直径为16.5mm的圆柱状锭材, 用车床将圆柱车为直径为16mm的圆柱, 去除微孔、 飞边等铸造缺陷, 经 X射线衍射分析, 圆柱无明显的晶态衍射峰, 表明试样在X射线衍射测试极限内为非晶态。 差示扫描量热(DSC)分析测量得到非晶合金的玻璃转变起始温度Tonsetg=631K, 玻璃转变的终了温度Tendg=647K, 晶化温度Tx=708K。

文献[19]的研究结果表明, Zr41.2Ti13.8Cu12.5-Ni10Be22.5合金在673K, 0.2s-1和0.02s-1 应变速率条件下都具有较好的塑性, 尤其在0.02s-1时, 流变应力只有74MPa, 非常适于进行超塑性加工。 然而, 静液挤压的优势在于高速大变形量加工, 由于坯料的周围为黏性介质, 远不如常规挤压时坯料直接与挤压筒内壁接触所受到的约束刚性大。 在挤压速度较慢、 坯料直径与挤压筒直径之差过大(高压介质的量过多)、 或挤压粘结性高的金属时, 非常容易产生滑动-黏着即类似蠕动的变形[17], 因此本文作者选定应变速率为0.1~1s-1时进行静液挤压。

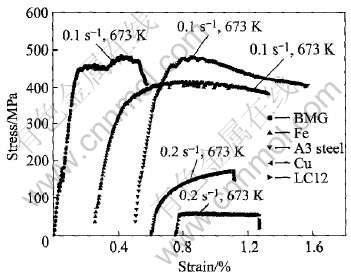

静液挤压工艺在采用包套时, 包套与芯料间的变形特性越相近越好, 这样可以避免在两者之间的界面上产生附加拉应力。 因此, 采用Gleeble1500热模拟实验机进行非晶、 纯铁、 A3钢、 紫铜和LC12硬铝等材料试样的高温压缩实验, 选择与非晶试样具有相近变形行为的材料作为挤压包套材料。 样品的应变速率分别为0.2和0.1s-1, 变形温度为673K, 结果如图1所示。

图1 非晶合金、 纯铁、 A3钢、 紫铜和硬铝的应力—应变曲线

Fig.1 Stress—strain curves of bulk amorphous alloy, iron, A3 carbon steel,copper and LC12 hard aluminum

由此可见, 在673K、 应变速率为0.1s-1的条件下, 纯铁和A3钢与非晶合金的变形特性较为接近, A3钢的变形抗力更为接近非晶合金, 但其变形抗力不如纯铁那样恒定。 由此可看出, 静液挤压容易产生滑动-黏着即类似蠕动的变形, 挤压速率不能太低, 本文作者选定应变速率为0.1~1s-1的条件进行静液挤压, 因此非晶的实际应变速率可能要高于测试条件下的应变速率。 一般来说, 非晶合金的变形抗力随着应变速率的提高而上升, A3钢与实际变形时非晶合金的变形抗力更为接近, 故选定A3钢作为非晶合金的挤压包套材料。

进行静液挤压实验时, 由于非晶合金外有包套, 使得加热速率明显降低, 为了保证非晶合金加热温度的准确性和避免发生晶化, 首先进行模拟加热实验, 采用箱式电阻炉, 选用与非晶合金挤压加工时同样尺寸和结构的包套和加热条件, 只将芯料换为不锈钢, 测定其加热曲线, 然后据此制定非晶合金的加热制度, 最后在非晶合金实际加热时进行测温, 对拟定的加热制度进行修正, 力求加热温度的准确性。 在达到设定的加热温度, 保温30s后迅速取出装入挤压筒, 再装入加热后的挤压介质, 然后进行挤压。 由于本研究所用设备安全方面的限制, 挤压筒加热温度为300℃。 挤压介质的主要成分为石墨粉+MoS2+润滑油等, 加热到300℃。 Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶合金棒的尺寸为d16mm×132mm, 包套材料为A3钢, 包套壁厚为4.5mm, 挤压筒直径为50mm, 模具出口直径为17.5mm, 挤压模具半角为20°, 挤压轴速度11mm/s, 实际挤压温度为663K。

通过X射线衍射仪分析确定所制备试样的相结构, 采用Netzsch DSC204差示扫描量热仪测量试样的热力学参数, 采用扫描电镜和高分辨电镜观察试样的断口形貌和微观结构。

2 结果与讨论

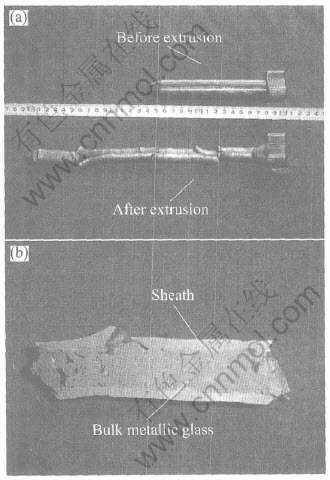

Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶合金棒(外覆包套)静液挤压后断成4截, 挤压前后的形貌及一段非晶合金棒坯纵剖面的形貌如图2所示。 由图2可看出, 除去头尾部分, 绝大部分非晶是完好的, 也略见分布的一些小孔洞, 非晶与包套的接触面微呈波浪形, 这可能与静液挤压过程中的压力波动有关。 非晶合金棒产生了明显的塑性变形, 挤压后的平均直径约为11.8mm。 挤压过程中的应变速率可计算为[16]:

式中 [AKε·]为应变速率; Ve为挤压轴移动速度; D为挤压筒直径; r为挤压比; θ为挤压模具半角。 挤压比r可计算为

式中 d1、 d2分别为坯料变形前后的直径, 本实验中分别为16和11.8mm, 即r=1.8, 亦即非晶合金总长度延伸了1.8倍。 根据式(1)和实际挤压过程参数, 可以计算出非晶合金的[AKε·]约为0.28s-1。 在这样高的应变速率下, 非晶合金没有发生牛顿粘性流动, 但毕竟产生了明显的塑性延伸, 说明较高的静水压力对非晶合金进行高应变速率的塑性加工提供了可能。

图2 Zr基非晶合金静液挤压棒坯的照片及其纵剖面(外覆包套)

Fig.2 Photo of hydrostatically extruded Zr41.2Ti13.8Cu12.5Ni10Be22.5 amorphous alloy with A3 carbon steel sheath(a) and longitudinal cross-section of extruded sample (b)

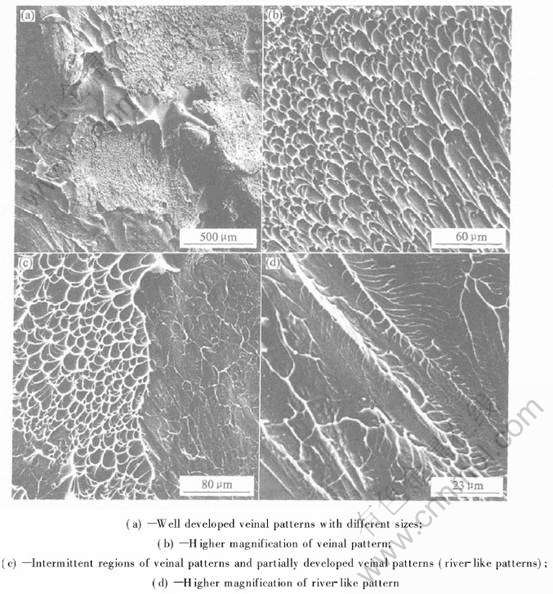

从图2(b)中可看出, 非晶合金棒坯基本沿着与载荷轴大约成45°的平面上断裂, 显示出断裂过程仍由剪应力控制。 非晶合金棒坯的断口形貌如图3所示。 整个断裂面上有充分发展的脉纹状剪切带(图3(a)), 也有类似河流状的、 未充分发展的脉纹状剪切带(图3(d))。 从图3(a)中可看到极其充分发展的大尺寸脉纹状剪切带, 类似接近熔化后发生的粘性流动, 将非晶合金撕扯成很薄的片层, 在这些片层上又分布着较小尺寸充分发展的脉纹状剪切带, 其放大观察如图3(b)所示。 有一些区域随机分布着的河流状剪切带(图3(c)左部)与充分发展的脉纹状剪切带(图3(c)右部)相邻存在, 河流状剪切带的放大观察如图3(d)所示, 且由图中可以见到一些类似熔滴的小球状物。

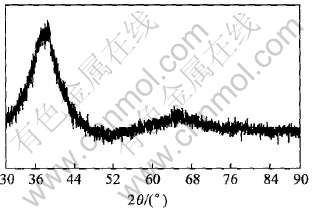

根据沈军等[13]测量的Zr41.2Ti13.8Cu12.5Ni10-Be22.5非晶合金的时间-温度转变曲线结果, 非晶合金在663K时的晶化孕育时间约为450s。 由于非晶合金加热到设定时间后只保温30s, 从放入挤压筒内到开始挤压, 整个过程不超过2min。 因此, 非晶合金在挤压开始前应该还是非晶态, 挤压后的非晶棒坯经X射线衍射分析只有一个大弥散峰, 无明显的晶态衍射峰(图4), 这表明挤压过程并没有导致非晶合金明显产生晶化。

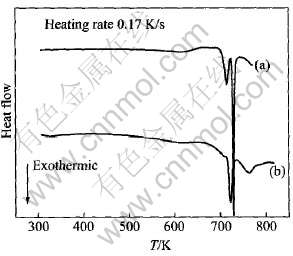

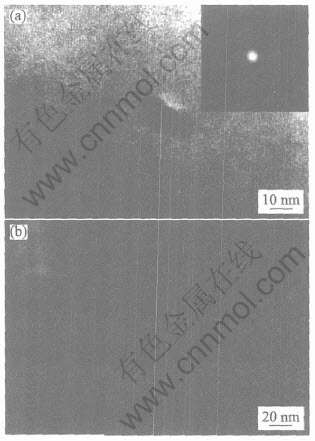

对挤压态样品做了热分析(DSC)和高分辨电镜观察。 图5所示为铸态与挤压态Zr41.2Ti13.8Cu12.5-Ni10Be22.5非晶合金在升温速率为10K/min时的DSC曲线。 由图5可看出, 挤压态样品的第一放热峰基本消失, 第二放热峰位置移向低温, 且峰值高度下降很多, 但有所展宽。 通过比较铸态与挤压态样品放热峰的晶化焓, 即利用Origin软件对放热峰所包围的面积进行积分计算, 可知约有3%的玻璃相发生了晶化。 由于曲线上仍出现了明显的玻璃转变点, 第二放热峰可以看做是残余玻璃相的晶化峰。 且第二放热峰位置移向低温, 说明残余玻璃相的热稳定性变差。 铸态和挤压态样品的高分辨电镜照片如图6所示。 由图6可看出, 铸态样品基本上为非晶结构, 只是偶尔存在纳米尺寸的小晶粒(图6(a))。 挤压态样品中分布较多粒径为10~20nm的晶粒(图6(b)), 这可以解释挤压态样品DSC测试结果中晶化峰的变化。

图3 挤压态非晶合金断口形貌

Fig.3 Fractural morphologies of hydrostatically extruded Zr41.2Ti13.8Cu12.5Ni10Be22.5 amorphous alloy

图4 挤压态Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶合金的X射线衍射谱

Fig.4 XRD pattern of hydrostatically extruded Zr41.2Ti13.8Cu12.5Ni10Be22.5 amorphous alloy

图5 铸态与挤压态Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶的DSC曲线

Fig.5 DSC curves of as-cast(a) and hydrostatically extruded(b) Zr41.2Ti13.8Cu12.5-Ni10Be22.5 amorphous alloy

图6 铸态与挤压态Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶微观结构的高分辨电镜像和选区电子衍射花样

Fig.6 HRTEM images and selected area electron diffraction pattern for as-cast (a) and extruded(b) Zr41.2Ti13.8Cu12.5Ni10Be22.5 amorphous alloy

Xing等[20]对Zr-Cu-Al-Ni-Ti的研究结果表明, 当晶化分数低于45%时, 合金的断裂应力和屈服应力都随晶化分数的增加而提高, 但塑性稍有下降, 此时断裂模式仍为具有脉纹型的塑性断裂形式。 在本研究中, 静液挤压后仅有约3%的非晶合金发生晶化, 基本上仍是由非晶相控制的具有脉纹型的塑性断裂形式。 一般将非晶合金的变形看作是在剪应力作用下两个固体平面在薄粘性流层上的相对滑动, 切变带内的强烈软化(即粘度的下降)使变形集中于切变带内并由于产生脉纹花样的不稳定性而削弱切变带耐断裂的能力[21]。 Conner等[22]在Zr-Nb-Al-Cu-Ni非晶合金中观察到相间存在的光滑区和脉纹区, 与本研究的结果类似, 并解释了光滑区是快速断裂区, 脉纹区是由于绝热加热造成的急剧温升从而导致显著粘性流动的区域。 Subhash等[23]研究了Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶合金在准静态(10-3 s-1)和高应变速率(103 s-1)条件下的单轴压缩行为, 非晶合金在高应变速率条件下的断裂模式也与本研究结果类似, 断面相间存在的脉纹状和河流状剪切带。 在准静态缓慢加载条件下, 似乎更有利于促进整个剪切面上空洞的均匀形核, 使剪切带充分发展成为较均匀分布的脉纹状。 但在快速加载条件下, 可能由于内在的空洞和杂质等缺陷, 或者由于微观成分分布不均, 从而引起应力场和温度场的波动, 造成塑性变形不能很均匀地发展。

Lu等[21]归纳出非晶合金的3种变形模式: 牛顿体流变、 非牛顿体流变与剪切局域化变形。 为了得到高质量的材料, 工艺参数的选择应使非晶合金在远离剪切局域化变形边界的均匀变形区内进行变形。 从变形模式与变形条件也可看出, 本研究所采用的工艺参数, 非晶合金的变形模式恰好位于剪切局域化变形与非牛顿体流动变形的边界。 挤压过程中的参数波动以及材料本身结构的不均匀, 很容易使得非晶合金的变形跨过边界, 位于剪切局域化变形区内。 另外, 在高应变速率(10-1~103 s-1)及573~683K范围内, Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶合金的粘度急剧下降, 合金的粘性流动从牛顿体过渡到非牛顿体行为。 Wang等[22]的研究也表明, 在676K, 应变速率为0.03~0.09s-1时, 合金应变速率的敏感指数仅为0.1, 显然为非牛顿体流动行为。 这就造成了剪切变形迅速局域化, 并最终导致非晶合金断裂。 因此, 本研究静液挤压高应变速率的变形条件使非晶合金产生非均匀流变是造成非晶合金断裂的主要原因。

3 结论

Zr41.2Ti13.8Cu12.5Ni10Be22.5非晶合金在663K、 应变速率为0.28s-1的条件下, 经静液挤压后产生了明显的塑性延伸, 总长度为原来的1.8倍。 但是, 非晶合金由于没有发生牛顿体均匀粘性流动而致断裂, 在断裂面上随机分布着充分发展的脉纹型与未充分发展的、 类似河流状的脉纹状剪切带。 约有3%的非晶相在挤压后发生晶化, 在非晶基体上析出较多粒径为10~20nm的晶粒, 导致非晶合金挤压后的热稳定性降低。 高应变速率变形条件使非晶合金产生非均匀流变是造成非晶合金断裂的主要原因。

REFERENCES

[1]Inoue A. Bulk Amorphous Alloys[M]. Switzerland, Germany: Trans Tech Publications LTD, 1999. 1-10.

[2]Suh D, Dauskardt R H. Flow and fracture in Zr-based metallic glasses[J]. Ann Chim Sci Mat, 2002, 27(5): 25-40.

[3]Kawamura Y, Shibata T, Inoue A, et al. Superplastic deformation of Zr65Al10Ni10Cu15 metallic glass[J]. Scripta Materialia, 1997, 37: 431-436.

[4]Kawamura Y, Nakamura T, Kato H, et al. Superplasticity in FE-based metallic glass with wide supercooled liquid region[J]. Mater Sci Eng A, 2001, A304-306: 735-739.

[5]Kawamura Y, Nakamura T, Inoue A. Superplasticity in Pd40Ni40P20 metallic glass[J]. Scripta Materialia, 1998, 39: 301-306.

[6]Nieh T G, Wadsworth J, Liu C T, et al. Plasticity and structure instability in a bulk metallic glass deformed in the supercooled liquid region[J]. Acta Mater, 2001, 49: 2887-2896.

[7]Nieh T G, Mukai T, Liu C T. Superplastic behavior of a Zr-10Al-5Ti-17.9Cu-14.6Ni metallic glass in the supercooled liquid region[J]. Scripta Materialia, 1999, 40: 1021-1027.

[8]Saotome Y, Hatori T, Zhang T, et al. Superplastic micro/nano-formability of La60Al20Ni10Co5Cu5 amorphous alloy in supercooled liquid state[J]. Mater Sci Eng A, 2001, A304-306: 716-720.

[9]Saotome Y, Itoh K, Zhang T, et al. Superplastic nanoforming of Pb-based amorphous alloy[J]. Scripta Materialia, 2001, 44: 1541-1545.

[10]XIAO Xue-shan, FANG Shou-shi, WANG Qing, et al. Effect of hot rolling on thermal stability and microstructure of Zr52.5Al10Ni10Cu15Be12.5 bulk metallic glass[J]. Materials Letters, 2004, 58: 2357- 2360.

[11]张志豪, 刘新华, 周成, 等. Zr基大块非晶合金的超塑性成形性能[J]. 中国有色金属学报, 2004, 14(7): 1073-1077.

ZHANG Zhi-hao, LIU Xin-hua, ZHOU Cheng, et al. Superplastic forming properties of Zr-based bulk amorphous alloys[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1073-1077.

[12]景勤, 刘日平, 邵光杰, 等. Zr基大块非晶合金的热膨胀与超塑性[J]. 物理学报, 2004, 53(5): 1440-1444.

JING Qin, LIU Ri-ping, SHAO Guang-jie, et al. Thermal expansion and superplasticity of Zr-based bulk amorphous alloy[J]. Acta Physica Sinica, 2004, 53(5): 1440-1444.

[13]沈军, 王刚, 孙剑飞, 等. Zr基块体非晶合金在过冷液相区的超塑性流变行为[J]. 金属学报, 2004, 40(5): 518-522.

SHEN Jun, WANG Gang, SUN Jian-fei, et al. Superplastic flow behavior of Zr base bulk metallic glass in supercooled liquid region[J]. Acta Metallurgica Sinica, 2004, 40(5): 518-522.

[14]Lu J, Ravichandran G, Johnson W L. Deformation behavior of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass over a wide range of strain-rates and temperatures[J]. Acta Materialia, 2003, 51: 3429-3443.

[15]Wang G, Shen J, Sun J F, et al. Superplasticity and superplastic forming ability of a Zr-Ti-Ni- Cu-Be bulk metallic glass in the supercooled liquid region[J]. Journal of Non-Crystalline Solids, 2005, 351: 209-217.

[16]Kawamura Y, Shibata T, Inoue A. Workability of the supercooled liquid in the Zr65Al10Ni10Cu15 bulk metallic glass[J]. Acta Mater, 1998, 46(1): 253-263.

[17]吴诗惇. 冷温挤压技术[M]. 北京: 国防工业出版社, 1995. 183-184.

WU Shi-dun. Cold and Warm Extrusion Technology[M]. Beijing: National Defense Industry Press, 1995. 183-184.

[18]Lowhaphandu P, Montgomery S L, Lewandowski J J. Effects of superimposed hydrostatic pressure on[CM(22*2]flow and fracture of a Zr-Ti-Ni-Cu-Be bulk amor-[CM)]phous alloy[J]. Scripta Materialia, 1999, 41(1): 19-24.

[19]张曙光, 胡捷, 朱学新, 等. Zr基非晶合金在过冷液相区的高应变速率压缩变形行为[]. 中国有色金属学报, 2005, 15(8).

ZHANG Shu-guang, HU Jie, ZHU Xue-xin, et al. High strain rate compressive deformation behavior of Zr-based bulk amorphous alloy in supercooled liquid region[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8).

[20]Xing L Q, Bertrand C, Dallas J P, et al. Nanocrystal evolution in bulk amorphous Zr57Cu20Al10Ni8Ti5 alloy and its mechanical properties[J]. Mater Sci Eng A, 1998, A241: 216-225.

[21]Luborsky F E. Amorphous Metallic Alloys[M]. London: Butterworths Publication, 1989. 309-334.

[22]Conner R D, Choi-Yim H, Johnson W L. Mechanical properties of Zr57Nb5Al10Cu15.4Ni12.6 metallic glass matrix particulate composites[J]. J Mater Res, 1999, 14(8): 3292-3297.

[23]Subhash G, Dowding R J, Kecskes L J. Characterization of uniaxial compressive response of a bulk amorphous Zr-Ti-Cu-Ni-Be alloy[J]. Mater Sci Eng A, 2002, A334: 33-40.

(编辑李艳红)

基金项目: 国家高技术研究发展计划资助项目(2001AA331010); 国家自然科学基金资助项目(50301004)

收稿日期: 2005-08-09; 修订日期: 2005-12-12

通讯作者: 张曙光, 博士; 电话: 021-62932569; 传真: 021-62933074; E-mail: zhangshug@sina.com