Trans. Nonferrous Met. Soc. China 22(2012) s542-s547

Hot formation quality of high strength steel BR1500HS for hot stamping without cooling system

LIU Hong-sheng, XING Zhong-wen, LEI Cheng-xi

School of Mechatronics Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 28 August 2012; accepted 25 October 2012

Abstract: Experiments were designed to manufacture square-box-shaped part, and the effects of hot stamping process parameters including blank holder force (BHF), forming temperature and tool temperature on the hot formation quality were investigated. Since the hot formation quality is highly sensitive to BHF, a BHF controlling system was developed using six hydraulic cylinders to improve the accuracy of applied BHF to ±10 N. The experimental results showed that a mixture microstructure of martensite and bainite with large fraction of martensite at forming temperature of 850 °C was obtained in the hot stamped part, while the microstructure was dominated by the softened phase of pearlite as the forming temperature decreased to 550 °C. The tensile strength was raised from 1550 MPa to 1750 MPa as the tool temperature decreased from 200 °C to ambient temperature. The optimum BHF of 1.62 MPa was determined which can avoid the formation of drawbacks of wrinkle and crack.

Key words: hot stamping; high strength steel; martensite; microstructure; cooling system

1 Introduction

With respect to light weight construction design in the automotive industry, more and more body parts are manufactured out of high strength steels, which are characterized by a significant thinner sheet thickness but an higher strength as commonly used steels [1,2]. However, the multi-phase microstructure, which is at the base of the strengthening mechanisms in most of these steels, leads to unacceptably high stresses during forming and significant spring-back phenomena, thus making traditional sheet metal forming technologies unsuitable. The possibility to perform stamping operations at elevated temperatures represents a solution of these problems, allowing lower loads on tools and higher accuracy of formed components [3].

Hot stamping is a relatively new process that is becoming increasingly popular, especially in the manufacturing of lightweight steel car body parts. Thanks to the final martensitic microstructure, the reduced springback and the adequate formability that high strength steel exhibits at elevated temperatures, thinner and more complex sheet metal parts can be produced with a high or very high strength-to-mass ratio and high geometrical accuracy as well [4].

Despite its advantages, hot stamping is a complex manufacturing process where the properties and quality of the final part are strongly affected by the material and the numerous parameters in the thermo-mechanical cycle, such as strain- and strain rate-path, temperature and microstructure evolution that mutually interact during the forming and the cooling stages. Due to this complexity, some experiments and simulations were performed to get the knowledge about the effect of parameters on the final quality of hot stamped parts [5-8]. Formability is a key indicator for evaluation of hot stamping, therefore, many investigations were focused on the hot formability of high strength steels [9,10] by means of experiments and simulations. Most investigations are aimed at modeling the rheological behavior of steels (in terms of flow stress and plastic anisotropy [11-14]) and the phase transformation. Other recent contributions from the scientific literature dealt with the evaluation of heat transfer at the interface between sheet metal and dies and the FE modeling of the thermal cycles into the dies for optimal design of hot stamping tools with integrated cooling system [15,16].

For all we know, for the hot stamping without cooling system, no investigation has been published on the evaluation of hot formation quality (tensile strength, microstructure and wrinkle) of hot stamped part which are conditioned by many factors like the applied BHF, the tool temperature and the forming temperature. To obtain the knowledge on how the process parameters affect the hot formation qualities, in the present work, a hot stamping experiment used to manufacture square-box-shaped part is designed, meanwhile, to precisely control the hot stamping process, a hot stamping process control system combined with BHF control system is developed to control punch stroke, hot forming time, quenching time, BHF and thus the phase transformation and hot formation qualities. To model the real series of hot stamping production, the tools are heated to different temperatures by placing a metal block with high temperature on the tool.

2 Experimental

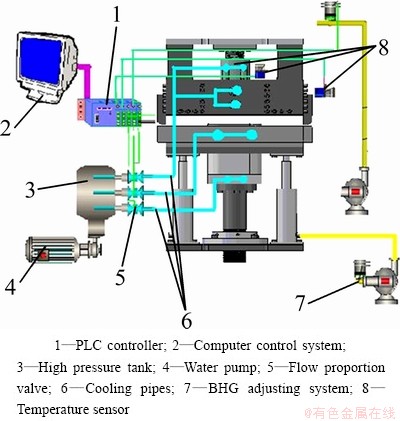

Hot stamping without cooling system includes the following stages: 1) blank is heated to around 950 °C and kept for around 300 s in a furnace to obtain austenite microstructure homogenization, 2) the heated blank is transferred from the furnace and placed on a press, 3) the heated blank with temperature of about 900 °C is formed into part via the press, and 4) the forming stage is followed by the cooling of the hot formed part (quenching) only via the tool with lower temperature and without employing cooling system. To ensure the high quality of hot formation, each stamping stage needs to be precisely controlled. In the present work, a hot stamping controlling system shown in Fig. 1 was developed. The punch stroke, forming time and quenching time can be controlled using this system. At the same time, some temperature sensors were built in tools to real-time measure and record the temperature variation of blank and tools. Since BHF has a significant effect on the hot formation quality, six hydraulic cylinders were used to control the applied BHF. Different forming temperatures ranging from around 500 °C to 900 °C can be obtained by air cooling the heated blank before blank was placed on the die. It should be noted that although the cooling system is shown in Fig. 1, it was not used in our present work. The used material of blank with dimensions of 340 mm × 280 mm × 1.5 mm is quenchable boron steel BR1500HS, which was developed by Chinese BAOSTEEL company to manufacture the reinforcement components. The chemical composition of BR1500HS are presented in Table 1.

Fig. 1 Experimental apparatus in hot stamping for square-box-shaped part

Table 1 Chemical composition of quenchable boron steel BR1500HS (mass fraction, %)

Wrinkle is a main indicator for evaluating the formation quality of hot stamped part. In the present work, the height of wrinkle was considered a parameter for quantitative evaluation of wrinkle. Microstructure analysis and tensile test on the weakest material were performed with different process parameters. The different die temperatures can be changed by placing a metal bulk with 1300 °C on the die and thus increasing the die temperatures to around 60 °C, 100 °C, 150 °C and 200 °C, respectively.

3 Results and discussion

The hot stamping experiments to manufacture square-box-shaped part were performed at different process parameters. For hot formed square-box-shaped part, the weakest material is the side wall of this part due to the fact that the side wall has worse contact state with the tool and the material can not be fully cooled. Therefore, in the present work, phase transformation and tensile strength analysis were conducted with the material of sidewall.

3.1 Phase transformation

Figure 2 shows the final microstructures of the material of sidewall of square-box-shaped part at different forming temperatures with the tool temperature of 25 °C. Apparently, the forming temperature has significant effect on the final microstructure, and it has also an important effect on the microstructure evolution of material during hot stamping. It is found from Fig. 2 that the final microstructure is the mixture of martensite and bainite with bigger fraction of martensite when the forming temperature is 850 °C. In contrast, when the forming temperature is 550 °C, the pearlite dominates the final microstructure. With the forming temperature increasing from 550 °C to 850 °C, the final microstructure changes from the mixture of pearlite and bainite to the mixture of martensite and bainite. Meanwhile, the fraction of martensite is increasing, while the fraction of pearlite and bainite is decreasing. The possible reason is that lower forming temperature leads to the lower cooling rate of blank or semi-hot formed part. Therefore, it can be concluded that the low forming temperature impedes the phase transformation from austenite to the higher phase like bainite or martensite. Another process parameter affecting the final microstructure is the tool temperature. At the forming temperature of around 900 °C, the final microstructures with different tool temperatures are shown in Fig. 3. The analogous results in Fig. 3 are also found that with tool temperature increasing from 25 °C to 200 °C, the microstructure changes from the mixture of martensite and bainite with finer grain and bigger fraction of martensite to pearlite or the mixture of pearlite and bainite with coarse grain. Such results are rooted in the reason that the cooling rate is seriously affected by the tool temperature. The lower tool temperature leads to higher cooling rate of material during hot stamping, vice versa. For the practical application of hot stamping in industry field, the tool temperature will reach around 200 °C after cycles of hot stamping [17], to obtain the final microstructure with bigger fraction of martensite. The forming temperature of around 900 °C is recommended.

3.2 Tensile strength

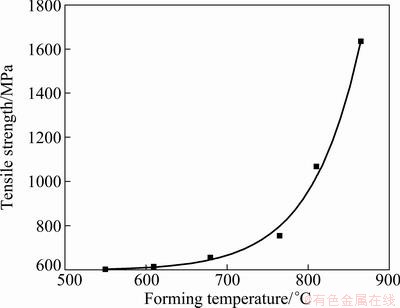

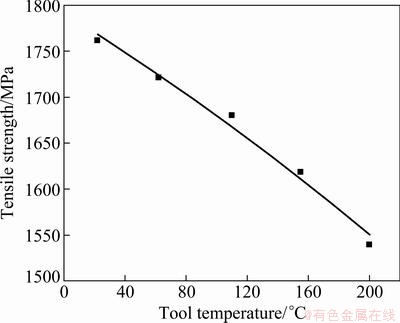

From the above investigations, it is observed that both tool temperature and forming temperature have significant effect on the final microstructure of the material of hot stamped part. Such conclusion can be further verified by the results shown in Figs. 4 and 5. Figure 4 shows that the tensile strength drastically increases from around 600 MPa to 1670 MPa as the forming temperature increases from 550 °C to 860 °C. The tensile strength presents an exponential relationship with the forming temperature. This result is due to the fact that the mechanical properties of the material closely depend on the microstructures. At the same time, the effect of tool temperature on the tensile strength was also investigated. Compared to the exponential effect of the forming temperature on the tensile strength, the tensile strength presents a linear relationship with the tool temperature (shown in Fig. 5). The tensile strength varies within a narrow range from 1550 MPa to 1770 MPa with the tool temperature increasing. Compared to the tool temperature, the forming temperature has the most intensive effect on the tensile strength. Therefore, in some cases that tensile strength is not the most important factor, the effect of tool temperature can be ignored, that is, the cooling system cannot be necessary.

Fig. 2 Final microstructures of sidewall of square-box-shaped part at different forming temperatures

Fig. 3 Final microstructures of sidewall of square-box-shaped part at forming temperature of around 900 °C with different tool temperatures

Fig. 4 Effect of forming temperature on tensile strength of sidewall of hot stamped part

Fig. 5 Effect of tool temperature on tensile strength of sidewall of hot stamped part

3.3 Wrinkle

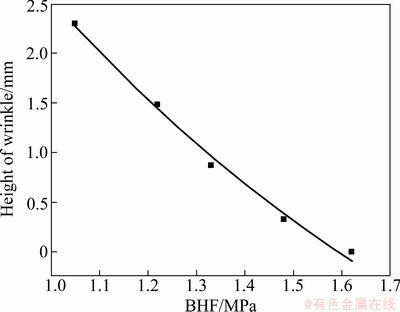

The height of wrinkle that seriously affects the quality of hot stamped part was investigated at different BHFs. As presented in Fig. 6, the wrinkle occurs at the flange of box and the height of wrinkle becomes more and more big as the applied BHF decreases from 1.62 MPa to 1.05 MPa. The wrinkle is avoided totally with the BHF approaching 1.62 MPa. While BHF is more than 1.62 MPa, for example 1.80 MPa, crack occurs which affects the hot formation quality. This issue is beyond the topic of the present work. A significant effect of BHF on the height of wrinkle as shown in Fig. 7 was observed. An appropriate bigger value of BHF is advantageous in avoiding the occurrence of wrinkle. Compared to the applied BHF in traditional sheet metal forming, the BHF used in hot stamping is smaller due to the fact that the material is softened at elevated temperature and the resistance force for avoiding the occurrence of wrinkle becomes smaller. It should be noted that, compared to the position where the crack occurs in the traditional cold forming of sheet metal [18], the crack position in hot stamping is located in the across corner flange of square-box-shaped part. The possible reason is that the material is softened during hot stamping and in the beginning of hot stamping. The material of the straight flange flows into the cavity of die at the same flow rate as that of the across corner flange. Therefore, at first the homogeneous material flow rate of the two areas avoids the occurrence of wrinkle, but after that the shrink of material of the across corner flange leads to wrinkle.

Fig. 6 Wrinkles of hot formed square-box-shaped part at different BHFs

Fig. 7 Effect of BHF on height of wrinkle

4 Conclusions

1) Among the three main factors affecting the hot formation qualities, like BHF, forming temperature and tool temperature, the forming temperature has the largest influence.

2) From the microstructure and tensile strength analysis, the appropriate forming temperature is 850-900 °C, at which the tensile strength of the hot stamped part can reach about 1800 MPa, while lower forming temperature, e.g. 550 °C, leads to a significant decrease of 1000 MPa in tensile strength.

3) Tool temperature of 200 °C doesn’t substantially lower the tensile strength of the hot stamped part. It means that the effect of tool temperature on the hot formation quality can be ignored in the case that the high tensile strength of above 1600 MPa is not necessary.

4) The BHF of around 1.62 MPa is verified to be suitable to avoid both wrinkle and crack during the hot stamping without cooling system.

References

[1] MHYUNWOO S, DENNIS F, HARTTMUT H, ROLAND G, MIRKO S. An investigation of the blanking process of the quenchable boron alloyed steel 22MnB5 before and after hot stamping process [J]. Journal of Materials Processing Technology, 2012, 22(2): 437-449.

[2] GEORE R, BARDELCIK A, WORSWICK M J. Hot forming of boron steels using heated and cooled tooling for tailored properties [J]. Journal of Materials Processing Technology, 2012, 212: 2386-2399.

[3] ABDULHAY B, BOUROUGA B, DESSAIN C. Experimental and theoretical study of thermal aspects of the hot stamping process [J]. Applied Thermal Engineering, 2011, 31(5): 674-685.

[4] HOFFMANN H, SO H, STEINBEISS H. Design of hot stamping tools with cooling system [J]. Annals of the CIRP, 2007, 56(1): 262-272.

[5] LIU Hong-sheng, XING Zhong-wen, BAO Jun. Investigation of the hot stamping process for advanced high strength steel sheet by numerical simulation [J]. Journal of Materials Engineering and Performance, 2010, 19(3): 325-334.

[6] LIU Hong-sheng, LIU Wei, BAO Jun, XING Zhong-wen, SONG Bao-yu. Numerical and experimental investigation into hot forming of ultra high strength steel sheet [J]. Journal of Materials Engineering and Performance, 2011, 20(1): 1-10.

[7] YANAGIDA A, KURIHARA T, AZUSHIMA A. Development of tribo-simulator for hot stamping [J]. Journal of Materials Processing Technology, 2010, 210(3): 456-460.

[8] LIU Hong-sheng, LIU Wei, XING Zhong-wen, BAO Jun, SONG Bao-yu. Modeling and FE simulation of quenchable high strength steels sheet metal hot forming process [J]. Journal of Materials Engineering and Performance, 2011, 20(6): 894-902.

[9] XIN L J, MIN J Y, LIN J P, FENG Q. Investigation on the failure mechanism of DP590-22MnB5(quenched) and DP590-DP590 spot-welding joints [J]. Journal of Iron and Steel Research International, 2011, 18: 936-940.

[10] MALEK N, MOSTAFA K, MAHMOUD A, WOLFGANG B. Semi-hot stamping as an improved process of hot stamping [J]. Journal of Materials Science and Technology, 2011, 27(4): 369-376.

[11] MERKLEIN M, LECHLER J, GOEDEL V, BRUSCHI S, GHIOTTI A, TURETTA A. Mechanical properties and plastic anisotropy of the quenchenable high strength steel 22MnB5 at elevated temperatures [J]. Key Engineering Materials, 2007, 344: 79-86.

[12] LIU He-ping, JIN Xue-jun, HAN Dong, JIE Shi. Martensitic microstructural transformations from the hot stamping, quenching and partitioning process [J]. Materials Characterization, 2011, 62: 223-227.

[13] QU Feng-sheng, LIU Xu-guang, XING Fei, ZHANG Kai-feng. High temperature tensile properties of laser butt welded plate of Inconel718 super alloy with ultra fine grains [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2379-2388.

[14] JANG J H, LEE J H, JOO B D, MOON Y H. Flow characteristics of aluminum coated boron steel in hot press forming [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(4): 913-916.

[15] MOHAMED S, ALISTAIR D F, LIN J G, DANIEL S. Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modeling [J]. International Journal of Machine Tools and Manufacture, 2012, 53(1): 27-38.

[16] NADERIA M, KETABCHIA M, ABBASIA M, BLECK M. Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping [J]. Journal of Materials Processing Technology, 2011, 211: 1117-1125.

[17] CUI Jun-jia, LEI Cheng-xi, XING Zhong-wen, LI Chun-feng. Predictions of the mechanical properties and microstructure evolution of high strength steel in hot stamping [J]. Journal of Materials Engineering and Performance, DOI: 10.1007/s11665- 012-0180-9.

[18] LIU Hong-sheng, XING Zhong-wen, YANG Yu-ying. Simulation of sheet metal forming process using reproducing kernel particle method [J]. International Journal for Numerical Methods in Biomedical Engineering, 2010, 26(11): 1462-1476.

不具冷却系统下高强钢BR1500HS的热冲压成形质量

刘红生,邢忠文,雷成喜

哈尔滨工业大学 机电工程学院,哈尔滨 150001

摘 要:研究工艺参数包括成形温度、模具温度和压边力对热冲压成形质量的影响。针对方盒形件热冲成形进行实验研究。由于热冲压成形质量对压边力具有很高的敏感性,采用液压缸设计压边力精确控制系统,采用该系统可使所施加压边力精度达到±10 N。实验结果表明,当成形温度为850 °C左右,热冲压件内部微观组织为马氏体和贝氏体混合相,而当成形温度为550 °C时,其微观组织主要为珠光体组织。当模具温度从200 °C降低至环境温度时,热冲压件的抗拉强度从1550 MPa增加至1750 MPa。通过实验确定了最优压边力1.62 MPa可避免热冲压件起皱和破裂。

关键词:热冲压;高强钢;马氏体;微观组织;冷却系统

(Edited by YUAN Sai-qian)

Foundation item: Project (RC2009QN006004) supported by Harbin Science and Technology Innovation Talents of Special Fund, China

Corresponding author: LIU Hong-sheng; Tel: +86-451-86418033; E-mail: hs_liu_hit@163.com

DIO: 10.1016/S1003-6326(12)61758-0