Trans. Nonferrous Met. Soc. China 24(2014) 2574-2580

Microwave absorption properties of FeSiBNbCu glass-covered amorphous wires

Xiao-dong WANG1, Jing-shun LIU2, Fa-xiang QIN3, Huan WANG1, Da-wei XING1, Jian-fei SUN1

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. School of Materials Science and Engineering, Inner Mongolia University of Technology, Hohhot 010051, China;

3. 1D Nanomaterials Group, National Institute for Materials Science, 1-2-1 Sengen, Tsukuba, Ibaraki 305-0047, Japan

Received 27 August 2013; accepted 28 April 2014

Abstract: Coaxially dielectric samples consisting of different packing ratios of glass-covered Fe73.5Si13.5B9Nb3Cu1 amorphous wires embedded in a paraffin wax matrix were fabricated, and the influence of short-wire packing ratio (3%-9% in mass fraction) and thickness (1-7 mm) on the microwave absorption properties was systematically investigated in microwave frequency range of 2-18 GHz. X-ray diffraction (XRD), differential scanning calorimetry (DSC), scanning electron microscopy (SEM) and scalar network analyzer (SNA) were used for characterizing microstructure and evaluating microwave absorption properties. Experimental results show the significant frequency (6-18 GHz) dependence of the complex relative permeability and permittivity. The reflection loss (RL) with different thickness and short-wire packing ratio reveals that the composite sample containing 7% exhibits better microwave absorption behavior with its minimum value of RL reaching -34 dB in thickness of 3 mm at 14 GHz. Therefore, it is significantly useful to develop microwire-dielectric materials with much wider absorption band for microwave absorption applications.

Key words: glass-covered amorphous wires; microwave absorption; short-wire packing ratio; microwave absorption property

1 Introduction

Fe-based glass-coated amorphous microwires have recently attracted much attention because of their potential engineering applications owing to their excellent electro-magnetic behaviors, which can be used as magnetostriction sensor elements, high-frequency absorbent composite or polymer and electro-magnetic shielding (EMS) materials [1-4]. They find wide applications particularly in the fields of sensor applications, radio-frequency applications and EMS (including EMS coating and textile) etc [5-8]. Taylor- Ulitovskiy method has prominent advantages as follows [9-11]: it has the highest cooling and solidification rate; the parameters, including feed velocity of glass and alloy, can be continuously controlled to produce wires with uniform roundness and glass-coating. Therefore, the ferromagnetic glass-coated microwires possess an excellent electromagnetic property, and they can satisfy the requirement of high-frequency absorbent composite materials with wider frequency band.

In another perspective, optimization of microwires and their composites are duly developed in order to improve the electro-magnetic performance of ferromagnetic microwires for specific applications of wider frequency band [12-14]. MONTIEL et al [15] elucidated the influence of microwire geometry on the microwave absorption behavior of microwire. They found out that a lower metal-to-glass ratio is in favor of anisotropy field corresponding to a shift of absorption peak to higher field. Therefore, it is worthwhile to conduct a detailed study on the effect of different geometric shapes for the novel dielectric composite on microwave absorption properties (in terms of effective permittivity, magnetic permeability and reflection loss), and further to seek the correlation between packing ratio and thickness with the aid of microwave absorption measurement.

This work aims to prepare a set of dielectric samples consisting of different packing ratios of glass-covered wires embedded in wax matrix, and compare the effect of packing ratio, thickness and annealing state on microwave absorption properties at microwave frequency (2-18 GHz) in order to explore the desirable material parameters for effective absorption. The results of microwire-dielectric samples with much wider absorption band presented here are useful for potential engineering applications.

2 Experimental

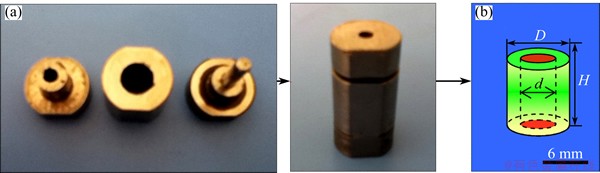

Soft magnetic amorphous Fe73.5Si13.5B9Nb3Cu1 glass-coated microwires owing to positive magnetostriction were prepared using an experimental facility based on the modified Taylor-Ulitovskiy method. The sample of coaxially microwire-dielectric samples containing different packing ratios of glass-covered microwires embedded in a paraffin wax matrix were fabricated. The corresponding steps depicted schematically in Fig. 1 are detailed as follows. Firstly, the glass-coated wires were selected as the absorbefacient materials with the geometrical parameters of metallic nucleus diameter, d=25 μm and the outer glass-coating thickness, t=2.5 μm, and the selected long wires were cut into short wires in the same length of 0.5 mm; and then the quantity of paraffin wax was set into drying box at the constant temperature of 80 °C for 6 min; subsequently, the previous short-cut microwires were added into the semi-solid state wax together with milling according to the packing ratios of 3%, 5%, 7% and 9% in mass fraction (these packing ratios of inclusions are calculated by the ratio of the wire mass to the whole sample mass); finally, short-wires and paraffin wax were mixed uniformly in mortar, and the mixture was obtained further to press for forming the coaxially dielectric samples with copper die assembly, and the dimensions of resultant coaxially measurement samples were inner diameter d’=3 mm, outer diameter D=7 mm, thickness T=(D-d’)/2=2 mm and height H=4 mm, as shown in Fig. 1. In addition, the selected wires were processed by vacuum-annealing treatment (at 300 °C for 30 min) in a pipe-still heater with 133.322 mPa vacuum, the annealed sample with 7% packing ratio was also formed by above mentioned method.

The amorphous nature was examined by X-ray diffraction (XRD, Rigaku D/max-γB). The surface morphology of the studied microwires was measured by scanning electron microscopy (SEM, HELIOS NanoLab 600i). Thermal analysis was employed to characterize the microwires by a differential scanning calorimeter (DSC) at a heating rate of 40 °C/min, and the heating was carried out with flowing purified argon gas during measurement. The magnetic properties were accurately measured by the electromagnetic inductive method with a maximum applied field of 2000 A/m. Microwave absorption measurement including reflection loss (RL) was conducted by transmission line method using the scalar network analyzer assembly (SNA, Agilent 8722ES) for evaluating microwave absorption properties in the frequency of 2-18 GHz. All measurements were performed at room temperature.

The reflection loss (R) of coaxially microwire- dielectric samples, namely power reflectivity, is expressed as [16]

(1)

(1)

where Zin, Z0 are the input impedance and the initial impedance respectively given by

(2)

(2)

where η and r are the intrinsic impedance and the propagation constant of electromagnetic wave, respectively, expressed as

(3)

(3)

where c is the velocity of light. The reflection loss of different sample thicknesses (T=1-7 mm) can be calculated by MATLAB procedure (not shown here) based on the experimental measurement thickness of 2 mm ranging from 2 to 18 GHz.

Fig. 1 Schematic diagram of coaxially dielectric samples (a) formed by using copper die (b) for scalar network analyzer (SNA) assembly

3 Results and discussion

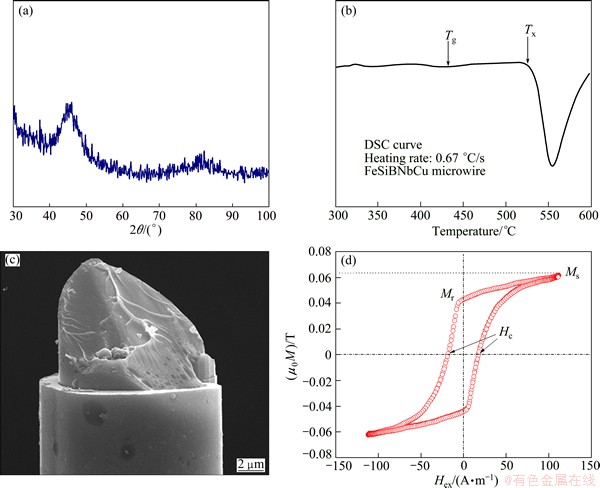

Figures 2 (a) and (b) shows the XRD pattern and differential scanning calorimety (DSC) curve of the as-cast ferromagnetic wire. The XRD pattern consists of one broad diffused diffraction maximum, which indicates that the microstructure of Fe-based wires is mainly of amorphous structure. The as-cast wire exhibits an endothermic peak, which was characterized by a glass transition temperature Tg=432 °C, and followed by a crystallization event at Tx=525 °C. This observation indicates that the amount of amorphous phase decreases with the increasing temperature. Figure 2(c) displays the SEM wire-terminal fracture morphology of as-cast microwires, which shows smooth and uniform glass- covered surface, typical fracture characteristics (a vein pattern caused by the rupture of the remaining section after the initial shear displacement and a relatively featureless zone caused by shear slip) of amorphous fibers even there is no serious casting defects or other imperfections, and has well rounded cross-sections. As shown in Fig. 2(d), the magnetic hysteresis loops of wires are nearly flat rectangles, which exhibit soft magnetic characteristics, including slight remnant magnetization Mr. The coercivity Hc, saturated magnetization Ms and the maximum magnetic permeability μm of glass-covered wire reach 14.49 A/m, 0.064 T and 0.0042, respectively.

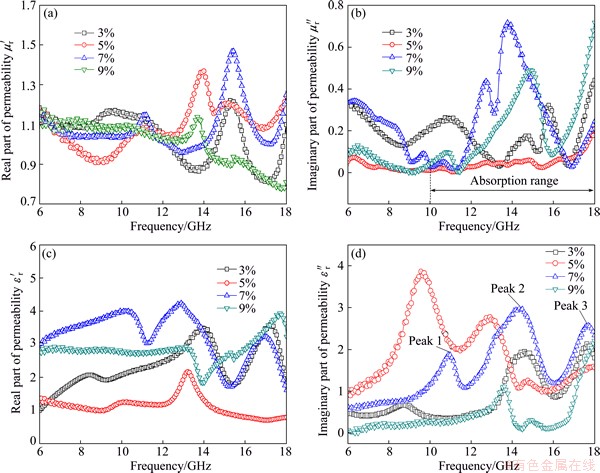

Figure 3 reveals m′r and m′′r of relative complex permeability, e′r and e′′r of relative complex permittivity (namely dielectric coefficient) profiles with different packing ratios (3%-9%) of as-cast microwires at 6-18 GHz. Firstly, it is well known that the electromagnetic parameters (m′r and e′r) measure the magnetization and polarization extents under the actions of magnetic field and electric field, respectively. And the other two electromagnetic parameters (m′′r and e′′r) are the losses mainly caused by rearrangements of magnetic dipole moment and electric dipole moment, respectively. Generally, the main electromagnetic parameters (the imaginary parts of relative complex permeability and permittivity, namely m′′r and e′′r) represent the electromagnetic energy loss ability and convert the electromagnetic energy to heat energy [17], exhibiting the electromagnetic absorption property, as shown in Figs. 3(b) and (d), while the real parts (m′r and e′r) of relative complex permeability and permittivity represent the storage or loading ability of electromagnetic energy of materials [17], as shown in Figs. 3(a) and (c). Here, as for the semi-solid state wax, on one hand it has the actions of bonding microwire and fixing sample; on the other hand, it has nearly unity relative complex permeability mr and permittivity er due to its nonmagnetic and nonconductive property, therefore, the electromagnetic absorption property of samples is mainly attributed to the absorption property of glass-covered microwire. Figures 3(a) and (b) exhibit, respectively, the real and imaginary parts of permeability of samples with different packing ratios (3%-9%) microwires. Notably, the m′′r of samples with different packing ratios tends to increase with the increasing frequency, and the peaks appear near 14 GHz. While compared with other packing ratios (3%, 5% and 9%), the sample with 7% packing ratio exhibits an excellent and broad absorption range (10-18 GHz). As shown in Fig. 3(d), the imaginary part of permittivity of samples with different packing ratios (3%-9%) microwires starts to increase and then decrease as the frequency is increased, exhibiting obvious frequency-dependent dielectric response, till reaching the main peaks in the frequency range from 13.5 GHz to 14.5 GHz. Notably, e′′r for the sample with 5% and 7% packing ratio exhibits nearly three peaks with an increase of frequency. This may arise from the lag of the induced charges to follow the reversing external field at high frequencies and finally causes a reduction in the electronic oscillations. The emergence of three relaxation peaks may hint the variation of local properties of the sample arising from the non-uniform distribution of wires. The bandwidth of microwave absorption for sample with 5% packing ratio is 8-15 GHz, while the range of sample with 7% packing ratio is enlarged to 10-18 GHz, which is consistent with the trend of imaginary part of complex relative permeability. Meanwhile, three peaks of sample with 7% packing ratio can also indicate a resonance behavior, which usually emerges when the material is highly conductive since high conductivity would result in high permittivity according to the free electron theory [18,19].

Fig. 2 XRD pattern (a) and DSC profile (b) of as-cast microwires (crystallization temperature, Tx=525 °C), SEM image (c) of end-surface (inner metallic nucleus and outer glass-coating) of experimental glass-covered microwire and longitudinal hysteresis loops of Fe73.5Si13.5B9Nb3Cu1 glass-covered wire (d)

Fig. 3 Electromagnetic spectra of constitutive parameters for samples with different packing ratios (3%-9%) of as-cast microwires at frequency ranging from 6 GHz to 18 GHz, including real part m′r (a) and imaginary part m′′r (b) of permeability, and real part e′r (c) and imaginary part e′′r (d) of permittivity, respectively

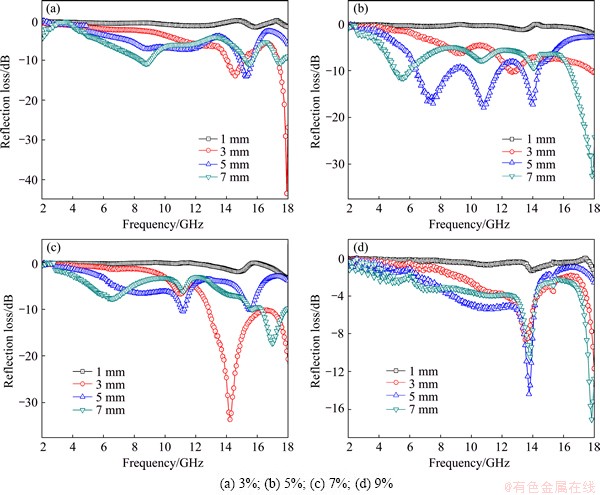

Figure 4 reveals the calculation results evaluated by equation (1) of microwave absorption (reflection loss, RL) property of different sample thicknesses (1-7 mm) based on experimental measurement dependence of frequency (2-18 GHz) with different as-cast short-wire packing ratios. According to Fig. 3, both dielectric loss and magnetic loss should contribute to the absorption. With the increase of short-wire packing ratio, the microwire dielectric samples with 3, 5 and 7 mm in thickness exhibit excellent microwave absorption property, while these with 1 mm in thickness have little variation of RL, as shown in Fig. 4. When the packing ratio is 3% (as shown in Fig. 3(a)), there is a relatively dramatic decrease between 14 and 15 GHz, the wire-sample with 3 mm in thickness has a remarkable peak, and its minimum value of reflection loss reaches -43.5 dB at 18 GHz. For sample with 5% packing ratio (see Fig. 3(b)), there exist variations of peak values and curve shape at such frequencies as 4-18 GHz, the curve shapes of the wire samples with 5 and 7 mm in thickness take on “M-type” shape, especially for 7 mm in thickness, it has the minimum RL value of -32.5 dB at 18 GHz. And for sample with 7% packing ratio (see Fig. 3(c)), the curve shapes with different thicknesses are similar to those with 5% packing ratio, but differently, the wire sample with 3 mm in thickness has a wider microwave absorption range (8-18 GHz) and outstanding peak, and its minimum RL value reaches -34 dB at 14 GHz. Finally, the variation trend of the sample with 9% packing ratio (see Fig. 3(d)) shows a similar behavious to the other three kinds of wire samples with different packing ratios and 1 mm in thickness, respectively. While, the wire samples with 3, 5 and 7 mm in thickness have almost consistent curve shapes. The minimum RL value reaches -14.4 dB for 5 mm in thickness at 14 GHz. Moreover, it presents the second peak value of -17.1 dB with the thickness of 7 mm. Overall, as the packing ratio increases from 3% to 9%, the absorption spectra tend to appear multiple absorption peaks at a frequency in the range of 2-18 GHz. In addition, from above mentioned calculation comparison of the influence of sample thickness (1-7 mm) on reflection loss (RL) at different short-wire packing ratios, it should be noted that the microwires/wax sample with 7% packing ratio and 3 mm in thickness is different from other wire samples, exhibiting better microwave absorption behavior. And this result can be explained in terms of impedance match, and the microwave absorption property is closely related to dielectric loss, magnetic loss and another important concept referring to impedance match [20,21]. If the permittivity and permeability of absorber differ significantly, it is harmful to the impedance match and results in strong reflection loss and weak absorption [22]. Therefore, there exist the critical values of packing ratio and sample thickness in order to achieve the ideal impedance match.

Fig. 4 Calculations of reflection loss (RL) profiles of different composite thicknesses (1-7 mm) based on experimental complex permittivity and permeability spectra (2-18 GHz) of samples with different as-cast short-wire packing ratios

4 Conclusions

1) Packing ratio (3%-9%) and thickness (1-7 mm) of short-wire have a profound effect on microwave absorption properties of coaxially dielectric samples in a relatively broad microwave frequency range of 2-18 GHz and their microwave electromagnetic properties exhibit significant frequency (6-18 GHz) dependence of the complex permeability and complex permittivity.

2) The microwire-dielectric sample containing 7% of packing ratio exhibits better microwave absorption behavior in comparison with calculations of reflection loss (RL) of different sample thicknesses (1-7 mm) with different short-wire packing ratios, and its minimum value of reflection loss reaches -34 dB in the thickness of 3 mm at 14 GHz.

3) The Fe-based glass-covered microwires are suitable for developing microwire-dielectric samples with broadband absorption at gigahertz frequencies.

Acknowledgements

The first author Xiao-dong WANG is especially grateful to Dr. JIANG, Harbin Institute of Technology, China, for his warm assistance to the preparation of test samples, SNA measurement and valuable discussion. Jing-shun LIU acknowledges the support from Scientific Research Foundation of the Higher Education Institutions (SRFHEI) of Inner Mongolia Autonomous Region of China under grant No. NJZY14062. Fa-xiang QIN is supported by JSPS fellowship 2013.

References

[1] STANKOVICH S, DIKIN D A, DOMMETT G H B, KOHLHAAS K M, ZIMNEY E J, STACH E A, PINER R D, NGUYEN S T, RUOFF R S. Graphene-based composite materials [J]. Nature, 2006, 442: 282-286.

[2] RAMANATHAN T, ABDALA A A, STANKOVICH S, DIKIN D A, HERRERA-ALONSO M, PINER R D, ADAMSON D H, SCHNIEPP H C, CHEN X, RUOFF R S, NGUYEN S T, AKSAY I A, PRUDHOMME R K, BRINSON L C. Functionalized graphene sheets for polymer nanocomposites [J]. Nature Nanotechnology, 2008, 3: 327-331.

[3] QIN F, BROSSEAU C. A review and analysis of microwave absorption in polymer composites filled with carbonaceous particles [J]. Journal of Applied Physics, 2012, 111(6): 061301.

[4] LIU J, QIN F, CHEN D, SHEN H, WANG H, XING D, PHAN M H, SUN J. Combined current-modulation annealing induced enhancement of giant magnetoimpedance effect of Co-rich amorphous microwires [J]. Journal of Applied Physics, 2014, 115: 17A326.

[5]  M, ADENOT-ENGELVIN A L. Glass-coated amorphous ferromagnetic microwires at microwave frequencies [J]. Journal of Magnetism and Magnetic Materials, 2009, 321(14): 2066-2073.

M, ADENOT-ENGELVIN A L. Glass-coated amorphous ferromagnetic microwires at microwave frequencies [J]. Journal of Magnetism and Magnetic Materials, 2009, 321(14): 2066-2073.

[6] QIN F, POPOV V V, PENG H X. Stress tunable microwave absorption of ferromagnetic microwires for sensing applications [J]. Journal of Alloys and Compounds, 2011, 509(39): 9508-9512.

[7] HAN M, LIANG D, DENG L. Fabrication and electromagnetic wave absorption properties of amorphous Fe79Si16B5 microwires [J]. Applied Physics Letters, 2011, 99: 082503.

[8] ZHANG Jun-feng, CHEN Zheng, ZHANG Hong-hao, LIU Tian-cheng, LI De-ren, LU Zhi-chao, ZHOU Shao-xiong. Influence of wire length on noise suppression of composite films containing CoFeSiBCr glass-covered wires [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 504-508. (in Chinese)

[9] LIU J S, WANG X D, QIN F X, CAO F Y, XING D W, PENG H X, XUE X, SUN J F. GMI output stability of glass-coated co-based microwires for sensor application [C]//Progress in Electromagnetics Research Symposium Proceedings. Suzhou: The Electromagnetics Academy, 2011: 1151-1155.

[10] WANG Jing, LIU Xue-feng, XIE Jian-xin. Preparation and characterization of glass-coated pure copper microwire [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 1953-1961. (in Chinese)

[11] WANG Jie-li, LIN Wen-song, JIANG Zi-wang, YANG Guo-liang, DUAN Li-hui. Fabrication and structure properties of fiber-structured Mo-Cu composites [J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 174-178. (in Chinese)

[12] QIN F, PENG H X. Ferromagnetic microwires enabled multifunctional composite materials [J]. Progress in Materials Science, 2013, 58: 183-259.

[13] YANG Hai-lin, LI Jing, FANG Hua-chan, ZHANG Xiang, ZHOU Zhong-cheng, TONG Xiao-yang, RUAN Jian-ming. Influence of FeCrAl fiber on microstructure and mechanical properties of FeCrAl(f)/HA composites [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 711-717.

[14] LIU J S, CAO F Y, XING D W, ZHANG L Y, QIN F X, PENG H X, XUE X, SUN J F. Enhancing GMI properties of melt-extracted Co-based amorphous wires by twin-zone Joule annealing [J]. Journal of Alloys and Compounds, 2012, 541: 215-221.

[15] MONTIEL H, ALVAREZ G, GUTIERREZ M P, ZAMORANO R, VALENZUELA R. The effect of metal-to-glass ratio on the low-field microwave absorption at 9.4 GHz of glass-coated CoFeBSi microwires [J]. IEEE Transactions on Magnetics, 2006, 42: 3380-3382.

[16] WANG C, HAN X, XU P, ZHANG X, DU Y, HU S, WANG J, WANG X. The electromagnetic property of chemically reduced graphene oxide and its application as microwave absorbing material [J]. Applied Physics Letters, 2011, 98(7): 072906.

[17] ZHANG X F, GUAN P F, DONG X L. Multidielectric polarizations in the core/shell Co/graphite nanoparticles [J]. Applied Physics Letters, 2010, 96(22): 223111.

[18] XU P, HAN X J, WANG C, ZHOU D H, LV Z S, WEN A H, WANG X H, ZHANG B. Synthesis of electromagnetic functionalized nickel/polypyrrole core/shell composites [J]. The Journal of Physical Chemistry B, 2008, 112(34): 10443-10448.

[19] ZHANG X F, DONG X L, HUANG H, LIU Y Y, WANG W N, ZHU X G, LV B, LEI J P, LEE C G. Microwave absorption properties of the carbon-coated nickel nanocapsules [J]. Applied Physics Letters, 2006, 89(5): 053115.

[20] HE Pu-zhen, WANG Zi-dong, ZHANG Hong, LIN Guo-biao. Study on microwave absorption properties of glass-coated Fe-rich microwires [J]. Journal of Functional Materials, 2007, A08(38): 2975-2977. (in Chinese)

[21] LIANG D, HAN M, YAN B, DENG L. Effect of annealing treatments on the microwave electromagnetic properties of amorphous FeCuNbSiB microwires [J]. Chinese Physics, 2007, 16(2): 542-547.

[22] CHE R C, PENG L M, DUAN X F, CHEN Q, LIANG X L. Microwave absorption enhancement and complex permittivity and permeability of Fe encapsulated within carbon nanotubes [J]. Advanced Materials, 2004, 16 (5): 401-405.

玻璃包覆FeSiBNbCu非晶丝的微波吸收性能

王晓冬1,刘景顺2,秦发祥3,王 欢1,邢大伟1,孙剑飞1

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 内蒙古工业大学 材料科学与工程学院,呼和浩特 010051;

3. 1D Nanomaterials Group, National Institute for Materials Science, 1-2-1 Sengen, Tsukuba, Ibaraki 305-0047, Japan

摘 要:制备以石蜡为基体并具有玻璃包覆Fe73.5Si13.5B9Nb3Cu1非晶丝不同填充比的同轴介电样品,在相对较高的微波吸收频段(2~18 GHz)下研究短丝填充比(质量分数3%~9%)和样品厚度(1~7 mm)对同轴介电样品的微波吸收性能的影响规律。采用X射线衍射谱(XRD)、差示扫描量热分析(DSC)、扫描电子显微分析(SEM)和矢量网格分析仪(SNA)表征材料的微结构并评价其吸波性能。结果表明,不同填充比的同轴介电样品的复磁导率和复介电常数存在重要的频率范围(6~18 GHz)。模拟结果显示,具有3 mm厚度和7%填充比的样品具有较好的微波吸收性能,其反射率在14 GHz时达到峰值-34 dB。这对于开发具有更宽微波吸收范围应用的微丝介电材料是十分有益的。

关键词:玻璃包覆非晶丝;微波吸收;短丝填充比;微波吸收性能

(Edited by Xiang-qun LI)

Foundation item: Project (51371067) supported by the National Natural Science Foundation of China

Corresponding author: Jian-fei SUN; Tel/Fax: +86-451-86413904; E-mail: jfsun_hit@263.net

DOI: 10.1016/S1003-6326(14)63385-9