基于模糊自适应控制的水泥生料粉磨系统

优化控制方法

庞强1, 2,苑明哲1,康浩博 2

(1. 中国科学院 沈阳自动化研究所,辽宁 沈阳,110016;

2. 东北大学 信息科学与工程学院,辽宁 沈阳,110819)

摘要:为提高水泥生料粉磨系统的生料产量,降低耗电量,提高生料成品合格率,针对球磨机加选粉机的生料粉磨系统,提出了模糊自适应PID控制,综合考虑负荷优化和粉磨系统运行稳定情况,调整磨机的喂料输入。工业实验结果表明:该方法能有效地对粉磨过程进行优化控制,入库提升机电流值、出磨提升机电流值都维持在相对高的范围内,说明粉磨系统高效运行,提高了产量;磨音、主电机电流波动也逐渐趋稳,表明磨机整体运行平稳,提高了电能的利用效率;出磨提升机电流平稳,稳定的出磨提升机电流决定入选粉机的料流比较稳定,使生料成品合格率提高,最终能提高产量5%以上,节约电能3%以上;将粉磨系统的运行稳定性作为系统优化的一个重要指标,符合实际生产需要,是对产量提高与磨机耗电量降低之间矛盾的一种综合平衡。

关键词:水泥生料粉磨系统;模糊自适应;优化控制;节能降耗

中图分类号:TP273 文献标志码:A 文章编号:1672-7207(2011)S1-0924-06

Optimizing control method of cement raw material pulverizing system based on fuzzy self-adaptive control

PANG Qiang1, 2, YUAN Ming-zhe1, KANG Hao-bo2

(1. Shenyang Institute of Automation, Chinese Academy of Sciences, Shenyang 110016, China;

2. College of Information Science and Engineering, Northeastern University, Shenyang 110819, China)

Abstract: To improve the raw material output, reduce energy consumption and improve raw material qualification rate, fuzzy self-adaptive PID control was proposed for co-using ball mill and separator raw material pulverizing system. Load optimization and stability running condition of pulverizing system were considered, and the input of feed mill was adjusted. Industrial experiment results show that the pulverizing process can be controlled effectively. Meanwhile, storage elevator and mill elevator current value maintain at a relatively high range, indicating that pulverizing system ran efficiently and production increase; mill and main motor current fluctuation gradually stabilize, suggesting that the overall mill ran smoothly, the power is utilized efficiently. The mill elevator current is stable, which is related to the selected separator flow stability, show that raw material qualification rate is improved. Ultimately production increases by more than 5%, energy save is more than 3%. The stability of the pulverizing system as an important indicator of system optimization, which is in line with actual production needs, is a overall balance between the production increased and mill energy consumption decreased.

Key words: cement raw material pulverizing system; fuzzy self-adaptive; optimizing control; energy-saving and cost- reducing

水泥行业中,粉磨消耗占水泥生产过程电能消耗的70%以上,磨机有效能源利用率仅在2%~20%。为了有效地利用能源,国内外很多专家、学者在粉磨系统的节能优化方面做了很多研究。Chen等[1-6]分别采用了模型预测控制(MPC)、专家系统以及它们的改进算法在球磨机回路系统中的应用,进行了科学分析和研究。周荣亮等[7]通过在线的自寻优算确定水泥磨的最佳负荷状态,利用Fuzzy采样PI控制器实现了对水泥磨负荷的控制,取得了很好的运行效果。马景娣 等[8]设计了出磨物料量的极值自校正控制器,并进行了仿真,与传统PID控制器相比,具有很多优点。姚伯威[9]提出了球磨机负荷系统的模型辨识方法,并设计了专家智能控制系统,在实践中取得了良好的效果。郝勇生等[10]提出了一种新的混沌遍历粒子群算法,用于球磨机运行目标的优化,从而获得最佳运行参数值。Wang等[11]提出了NETFUZZY控制方法,Zhou等[12]提出了Fuzzy-Neural Decoupling控制系统, Rajamani等[13]对球磨机回路系统建立了数学模型并进行了仿真,并基于模型,进行了离线的优化控制,控制器能够适应控制对象的变化[14]。Ramasamy等[15]将MPC应用于球磨机粉磨系统,解决多个控制回路之间的耦合问题;Andon Venelinov Topalov等[16]利于基于在线学习机制的变结构系统理论对水泥磨进行建模和控制;Conradie等[17]将SANE算法应用到粉磨系统,以克服喂料粒度和硬度不确定性带来的扰动。还有很多专家提出了各种控制方法来优化球磨机粉磨系统,寻找球磨机的最佳填充料位。但实际生产中还有一个比较重要的因素要考虑,即粉磨系统的稳定运行状况,因为粉磨系统是一个大滞后、强耦合、非线性的系统,系统稳定下来需要很长的时间,少则十几分钟,多则1 h,甚至更长时间,如果磨机不能够很稳定地运行,最终将影响生料的合格率,同时磨机主轴震动会比较厉害,增加耗电量和磨损。当磨机喂料不断向最优点优化调整的过程,常常会打破原来系统的稳定运行状态,有时这种调整会得不偿失。因此,本文作者提出了一种基于模糊自适应控制的增量式PID控制方法,能够合理地平衡磨机在最大出力点附近工作和粉磨系统稳定运行之间的矛盾。

1 水泥生料粉磨系统

1.1 工艺流程

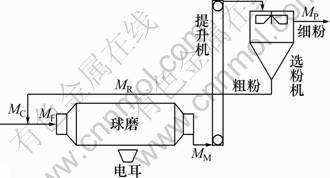

图1所示为水泥工业中的闭路粉磨系统。整个系统主要由球磨机和选粉机构成。球磨机负责物料的破碎、粉磨,选粉机负责分离出合格的细粉物料作为产品输出。喂料流MF由经过配料的生料流MC及选粉机返回的粗粉流MR混合构成,进入旋转的球磨机进行粉磨,经过一段时间的粉磨后,磨机输出流量MM,经过提升机提升,加入到选粉机中,经过选粉机选粉,粗粉返回喂料口,重新进入磨机,经过选出的细粉MP作为成品,经入库提升机,送到料仓保存。其中电耳为球磨机负荷的主要检测手段。

图1 闭路粉磨系统的工艺流程图

Fig.1 Flow chart of closed-circuit pulverizing system

1.2 有用功率与料位的关系

图2所示为球磨机功率与料位之间的关系。图中曲线1反映的是球磨机功率为总功率,空载时料位为零,功率为最大功率的90%左右,随着料位的提高先升后降。曲线2表示钢球碰撞功率,即无效功率,它与钢球损耗成正比。曲线3反映的是粉磨功率,为有效功率,与磨机出力成正比例关系。球磨机功率是钢球碰撞功率与粉磨功率之和。目前实际生产中多运行在习惯区,以保证不堵磨,而磨机的最大出力区在优化区,优化控制的目标是让磨机料位处在优化区。

图2 功率与料位的关系

Fig.2 Relationship between power and material level

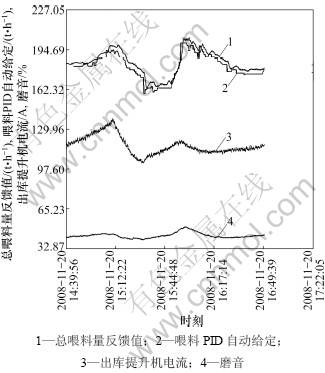

2 粉磨系统优化控制过程中存在的技术难点

生料粉磨是一种复杂的生产过程,具有非线性、大滞后、生料易磨性的不确定性等特点。所以,现在工业现场大多是用电耳听到的磨音来判断磨机填充率。一般都会以磨音作为被控制变量,以喂料作为操作变量来构成闭环控制,在前言中提到的很多优化方法中,也是以磨音作为优化变量,通过各种算法给磨音一个优化设定值。在实际生产过程中,各变量的趋势图如图3所示。由图3可见:磨音与磨机填充率呈反比关系,在14:56:00时磨音升高,反映磨内料位较低,而当时的磨音设定值为43%,因此,要增加喂料量来调整磨机的料位,使磨音回到设定值。在实际操作中,发现直到2008年11月20日16:28:00时,磨音开始平稳,出磨提升机电流也开始平稳,说明磨机的运行状态趋于稳定。在这个过程中用了92 min,由于磨机本身的喂料机构不能进行频繁的操作,至少要 2 min调节1次;另外,生料磨系统本身的非线性、大延迟的特点,最终导致磨机重新恢复平稳运行状态,需要很长时间,在这段时间内,喂料的不断调整会使系统的料位波动很大,磨机的主电机电流波动也很大,最终造成磨机用电量升高,浪费很多电能,也会影响磨机的使用寿命,还会影响成品的的合格率。所以,有时为了使磨音向设定值靠近,而改变喂料量,就会破坏粉磨系统现有的稳定运行状态,提高了产量,但也会消耗更多电能。因此,系统的稳定运行状态成为粉磨系统优化控制必须要考虑的一个因素。

图3 变量趋势曲线

Fig.3 Trend curves of variable

3 基于模糊自适应的控制策略

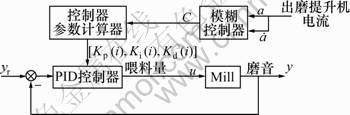

本文选择增量式PID控制器作为主环控制的控制器。因为出磨提升机电流反映了粉磨系统的实际负载情况,而它的变化量反映了粉磨系统的稳定运行情况,所以,选择出磨提升机电流为模糊控制器的输入变 量。根据出磨提升机电流和它的变化量的变化情况,制定模糊规则库,最后通过计算修正PID参数,改变PID调整的超调量和调节时间,以适应不同工况下系统调整幅度大小的不同,使系统能高效稳定地控制在优化区内。模糊自适应PID控制的结构如图4所示。

图4 模糊自适应PID控制的结构

Fig.4 Control structure of fuzzy self-adaptive PID

在图4中,yr为系统的设定值,即负荷给定值,y为系统的反馈值,即被控制变量,这里间接地用磨音来反映系统负荷。A和 分别为出磨提升机电流值与它的变化量;A和

分别为出磨提升机电流值与它的变化量;A和 分别为模糊量化处理后,电流与电流变化量形成的模糊量;C为经模糊判决得到的模糊控制器输出变量。[Kp(i),Ki(i),Kd(i)]为第i个控制器参数。经调整的PID控制器的输出为:

分别为模糊量化处理后,电流与电流变化量形成的模糊量;C为经模糊判决得到的模糊控制器输出变量。[Kp(i),Ki(i),Kd(i)]为第i个控制器参数。经调整的PID控制器的输出为:

(1)

(1)

(2)

(2)

e(k)=yr(k)-y(k) (3)

根据模糊控制器的结构,模糊控制的基本过程主要分为3个部分:

(1) 精确输入量的模糊化,即把精确的输入量转换成模糊集合的隶属函数。

(2) 模糊规则的形成和推理,根据有经验的操作者或者专家的经验制定出模糊控制规则,并进行模糊逻辑推理,以得到一个模糊输出集合,即一个新的模糊隶属函数。

(3) 精确输出量的解模糊判决,根据模糊逻辑推理得到的模糊隶属函数,用重心法找到一个具有代表性的精确值作为控制量。

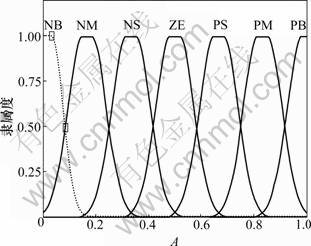

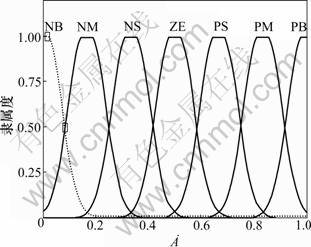

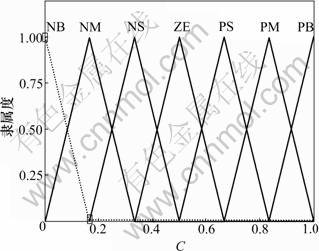

3.1 精确输入量的模糊化

经过对某水泥生产线运行数据的观测,选择采样周期为1 min,可以确定出磨提升机电流和它的变化量的变化范围。

基本论域为:a的变化范围为[0, …, 150]; 的变化范围为[-50, …, 50]。

的变化范围为[-50, …, 50]。

设定A和 的模糊集与模糊子集的论域分别为:A,

的模糊集与模糊子集的论域分别为:A, 和C的模糊集都为{NB,NM,NS,ZO,PS,PM,PB};A和

和C的模糊集都为{NB,NM,NS,ZO,PS,PM,PB};A和 的论域均为{0,…,1};C的论域均为{0,…,6}。

的论域均为{0,…,1};C的论域均为{0,…,6}。

从基本论域[a, b]到模糊子集论域[-n, n]的转换公式为:

(4)

(4)

隶属函数选择的是双高斯函数和三角型函数。

A和 和C的隶属函数图形如图5~7所示。

和C的隶属函数图形如图5~7所示。

图5 A的隶属函数图形

Fig.5 Membership function graph of A

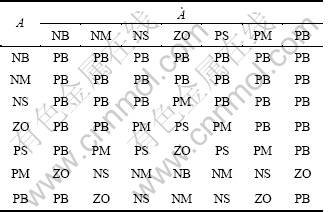

3.2 模糊控制规则的建立

通过试验调试,得到表1所示规则表。

从表1可以看出:当粉磨系统的出磨提升机电流(A)处在PM(125 A左右)区域,且变化( )比较稳定时,说明系统稳定高效,是最佳状态,调整最小(NB);当出磨提升机电流和变化量有所变化时,根据具体变化幅度,适当调整C的等级,即调整PID参数。例如:当出磨提升机电流已经稳定地运行在高位时,即使磨音高出设定值,由于C的输出为最小,PID的参数设置为最小,输出的喂料量增量u几乎为0,所以,不会改变喂料量。使系统能继续稳定运行,而不会频繁调整,打乱了粉磨系统稳定的运行状态。模糊规则的三维立体图如图8所示。

)比较稳定时,说明系统稳定高效,是最佳状态,调整最小(NB);当出磨提升机电流和变化量有所变化时,根据具体变化幅度,适当调整C的等级,即调整PID参数。例如:当出磨提升机电流已经稳定地运行在高位时,即使磨音高出设定值,由于C的输出为最小,PID的参数设置为最小,输出的喂料量增量u几乎为0,所以,不会改变喂料量。使系统能继续稳定运行,而不会频繁调整,打乱了粉磨系统稳定的运行状态。模糊规则的三维立体图如图8所示。

图6  的隶属函数图形

的隶属函数图形

Fig.6 Membership function graph of

图7 C的隶属函数图形

Fig.7 Membership function graph of C

表1 模糊规则表

Table 1 Fuzzy rule table

图8 模糊规则的三维立体图

Fig.8 Three-dimensional map of fuzzy rules

3.3 模糊判决

采用重心法对精确输出量的解模糊判决。为了在调试阶段比较好调试,将判决结果取整,将[(0, 0, 0), (1, 1, 1), (1.4, 1.4, 1), (1.8, 1.8, 1), (2.2, 2.2, 1), (2.6, 2.6, 1), (3, 3, 1)]与论域{0,…,6}中的值一一映射,例如判决结果为2,则控制器的参数[Kp,Ki,Kd]为(1.4, 1.4, 1),达到对PID参数的自适应调整。

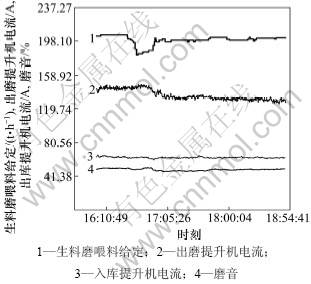

4 结果分析

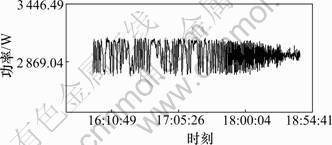

本文作者编译了一个软件,用于磨机系统的优化控制,在考虑粉磨系统是否稳定运行的情况下,运用模糊自适应PID控制算法,实现优化和稳定运行的综合考虑,将负荷设定值控制在一个控制带内。经过系统的调试和投运,最终实验结果如图9和10所示,可见:磨机27 min后就恢复了稳定,调节时间要比图3中经过的92 min缩短了1 h以上;喂料平稳,磨况异常的情况下,能够及时减料,保证磨机安全;出磨提升机电流平稳,稳定的出磨提升机电流决定入选粉机的料流比较稳定,最终使生料成品质量合格率提高;同时磨音稳定,表明磨机整体运行平稳,主电机功率波动也逐渐趋稳,减少了磨机的主轴晃动,节省了电能。同时入库提升机电流始终运行在高位(62 A以上),说明产量也得到了很大提升。据统计本班次台时为206 t/h,比上月平均196 t/h增加了10 t/h,提产了5.1%;电耗为18.4 (kW·h)/t,比上月19 (kW·h)/t降低了0.6 (kW·h)/t,节能3.1%。上班次12 h的总产量为2 450 t,比上月平均2 284 t提高了7.2%。

图9 粉磨系统各变量运行趋势曲线

Fig.9 Pulverizing system running trend curve of each variable

图10 磨机主电机功率曲线

Fig.10 Mill main motor power curve

5 结论

由于水泥生料粉磨系统的负荷调整到设定点需要很长一段时间,所以,有时牺牲系统的稳定而增加磨机的负荷,会增加磨机的电能损耗。本文利用模糊自适应控制策略协调负荷优化与系统的稳定运行状态之间的矛盾,取得了很好的效果。

参考文献:

[1] CHEN Xi-song, ZHA Jun-yong, LI Shi-hua, et al. Application of model predictive control in ball mill grinding circuit[J]. Minerals Engineering, 2007, 20(11): 1099-1108.

[2] CHEN Xi-song, LI Qi, FEI Shu-min. Constrained model predictive control in ball mill grinding process[J]. Powder Technology, 2008, 186(1): 31-39.

[3] YANG Jun, LI Shi-hua, CHEN Xi-song, et al. Disturbance rejection of ball mill grinding circuits using DOB and MPC[J]. Powder Technology, 2010, 198(2): 219-228.

[4] CHEN Xi-song, YANG Jun, LI Shi-hua, et al. Disturbance observer based multi-variable control of ball mill grinding circuits[J]. Journal of Process Control, 2009, 19(7): 1205-1213.

[5] CHEN Xi-song, YANG Jun, ZHAI Jun-yong, et al. Expert system based adaptive dynamic matrix control for ball mill grinding circuit[J]. Expert Systems with Applications, 2009, 36(1): 716-723.

[6] CHEN Xi-song, LI Qi, FEI Shu-min. Supervisory expert control for ball mill grinding circuits[J]. Expert Systems with Applications, 2008, 34(3): 1877-1885.

[7] 周荣亮,张彦斌,崔栋刚, 等. 水泥磨负荷控制系统研究及应用[J]. 控制工程, 2003, 10(6): 518-520.

ZHOU Rong-liang, ZHANG Yan-bin, CUI Dong-gang, et al. Load Control System of Cement Ball Mill and its Applica- tion[J]. Control Engineering of China, 2003, 10(6): 518-520.

[8] 马景娣, 顾钟文, 周春晖. 闭路球磨机产量极值自适应控制方法的研究[J]. 浙江大学学报: 自然科学版, 1996, 30(2): 211-216.

MA Jing-di, GU Zhong-wen, ZHOU Chun-hui. Extremum self-tuning control of product quantity of ground material at a ball mill[J]. Journal of Zhejiang University: Science and Technology, 1996, 30(2): 211-216.

[9] 姚伯威. 球磨机负荷系统辨识及专家控制器[J]. 电子科技大学学报, 1995, 24(5): 495-498.

YAO Bo-wei. Identification and experts controller of ball mill load system [J]. Journal of UEST of China, 1995, 24(5): 495-498.

[10] 郝勇生, 于向军, 赵刚, 等. 基于改进粒子群算法的球磨机运行优化[J]. 东南大学学报: 自然科学版, 2008, 38(3): 419-423.

HAO Yong-sheng, YU Xiang-jun, ZHAO Gang, et al. Optimization for ball mill operation based on improved particle swarm optimization algorithm[J]. Journal of Southeast University: Natural Science Edition, 2008, 38(3): 419-423.

[11] WANG Dong-feng, HAN Pu, PENG Dao-gang. Optimal for ball mill pulverizing system and its applications[C]//Hebei University and the IEEE Systems. 2002 International Conference on Machine Learning and Cybernetics. Beijing, 2002: 2131-2136.

[12] ZHOU Hong, LI Zhi-bin, ZHOU Di-sha. Fazzy-neural decoupling control system based on PLC for ball mill of power plant[C]//China Electric Power Research Institute. 2002 International Conference on Power System Technology Proceedings. Kunming: Yunnan Science & Technology Press, 2002: 2340-2343.

[13] Rajamani R K, Herbst J A. Optimal control of a ball mill grinding circuit—I. Grinding circuit modeling and dynamic simulation[J]. Chemical Engineering Science, 1991, 46(3): 861- 870.

[14] Rajamani R K, Herbst J A. Optimal control of a ball mill grinding circuit—II. Feedback and optimal control[J]. Chemical Engineering Science, 1991, 46(3): 871-879.

[15] Ramasamy M, Narayanan S S, Rao C D P. Control of ball mill grinding circuit using model predictive control scheme[J]. Journal of Process Control, 2005, 15: 273-283.

[16] Andon Venelinov Topalov, Okyay Kaynak. Neural network modeling and control of cement mills using available structure systems theory based on-line learning mechanism[J]. Journal of Process Control, 2004, 14: 581-589.

[17] Conradie A V E, Aldrich C. Neurocontrol of a ball mill grinding circuit using evolutionary reinforcement learning[J]. Minerals Engineering, 2001, 14(10): 1277-1294.

(编辑 李向群)

收稿日期:2011-04-15;修回日期:2011-06-15

基金项目:国家高技术研究发展计划项目(2008AA042901);沈阳市科技攻关项目(F10-015-2-00)

通信作者:庞强(1981-),男,辽宁凌源人,助理研究员,博士研究生,从事先进过程控制与优化、能源管理与能效评估的研究;电话:024-23970338;E-mail:pangqiang@sia.cn