DOI: 10.11817/j.issn.1672-7207.2015.10.034

机掘工作面旋转射流屏蔽通风最佳送风角度的确定

王鹏飞1,刘荣华1, 2,陈世强1, 2,贺俊星1

(1. 湖南科技大学 能源与安全工程学院,湖南 湘潭,411201;

2. 湖南科技大学 煤矿安全开采技术湖南省重点实验室,湖南 湘潭,411201)

摘要:为了确定最佳的送风角度,采用数值模拟和模型试验,对不同送风角度下机掘工作面旋转射流屏蔽通风流场和粉尘质量浓度分布进行研究。研究结果表明:在其他设计参数确定的情况下,工作面风流流场和粉尘质量浓度分布与送风角度密切相关;当送风角度θ为75°时,旋转射流屏蔽通风流场能在工作面形成完整的屏蔽风幕,且组合风口前方吸气速度和负压沿轴向衰减较其他送风角度吸气速度和负压沿轴向衰减缓慢,组合风口控尘效果最佳,组合风口后方粉尘质量浓度降至24 mg/m3,旋转风幕隔尘效率高达85.9%。

关键词:机掘工作面;旋转射流;流场;粉尘;送风角度

中图分类号: TD714,X964 文献标志码:A 文章编号:1672-7207(2015)10-3808-06

Determination of the best air-supply angle of the rotational jet shield ventilation at tunneling working face

WANG Pengfei1, LIU Ronghua1, 2, CHEN Shiqiang1, 2, HE Junxing1

(1. School of Energy & Safety Engineering, Hunan University of Science and Technology, Xiangtan 411201, China;

2. Hunan Provincial Key Laboratory of Safe Mining Techniques of Coal Mines,

Hunan University of Science and Technology, Xiangtan 411201, China)

Abstract: To determine the best air-supply angle, the flow field and dust mass concentration distribution of the rotational jet shield ventilation under different air-supply angles were investigated by numerical simulation and model experiments. The results show that the flow field and dust mass concentration distribution are closely related to air-supply angle with the other design parameters fixed. When the air-supply angle is θ=75°, a complete air curtain can be formed at the tunneling working face, and the suction velocity and negative pressure in front of the combined tuyere in the axial direction are lower than those of other air-supply angles. The best dust control effect is obtained, the dust mass concentration falls to 24 mg/m3, and the dust-isolating efficiency of rotational jet reaches up to 85.9%.

Key words: tunneling working face; rotational jet; flow field; dust; air-supply angle

目前,国内外机掘工作面主要采用通风控尘、除尘器抽尘净化、高压喷雾等防尘措施[1-2]。实践证明,采用上述防尘措施后,工作面仍然存在大量粉尘,尤其是呼吸性粉尘扩散至掘进机司机工作区域,严重危害着掘进机司机的身心健康[3-4]。因此,开展机掘工作面控尘研究具有理论和现实意义。为了提高机掘工作面通风控尘效果,刘荣华等[5]提出应用旋转射流屏蔽通风来改善工作面风流流场和粉尘质量浓度分布,从而改善工作面作业环境。近年来,对该种通风方式下的风流流场和粉尘质量浓度分布进行了较为全面的研究,涉及的影响因素包括送风量、排风量、吹吸流量比及喷口宽度等[6-9]。张景松等[10-11]通过建立三维掘进通风物理和数学模型,对旋转射流屏蔽抽吸的复杂流场进行了数值模拟,并对吹吸流量比进行了讨论,得出吹吸流量比对该种通风流场影响较大,吹吸流量比过大或过小都不利于有害物的抽吸。影响机掘工作面旋转射流屏蔽通风粉尘控制和捕集效果的相关设计参数包括送风速度、送风口宽度、吹吸流量比及送风角度等,送风速度、送风口宽度和吹吸流量比已在相关文献中进行了讨论,而送风角度的研究较少。因此,本文作者对旋转射流屏蔽通风不同送风角度下的风流流场和粉尘质量浓度分布进行数值模拟和模型试验研究,确定最佳送风角度,为旋转射流屏蔽通风在机掘工作面的应用提供理论参考。

1 旋转射流屏蔽通风原理及设计参数

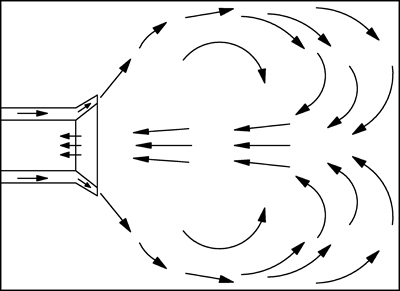

图1所示为旋转射流屏蔽通风的新型组合风口结构示意图。从图1可见:该组合风口由内、外两层组合而成,内层为抽风筒,连接抽风机;新鲜风流由送风机和风管从切向方向导入内、外风筒之间的夹层,从而诱导旋风,使得从环形送风口压出的风流为具有一定扩散角的旋转射流。图1中,D1为内风筒直径;D2为外风筒直径;D3为环形风口直径;θ为送风角度。图2所示为机掘工作面旋转射流屏蔽通风流场示意图,旋转射流屏蔽通风原理见文献[5-6]。

图1 组合风口结构示意图

Fig. 1 Structural diagram of combined tuyere

图2 旋转射流屏蔽通风工作面流场示意图

Fig. 2 Flow field diagram of tunneling working face

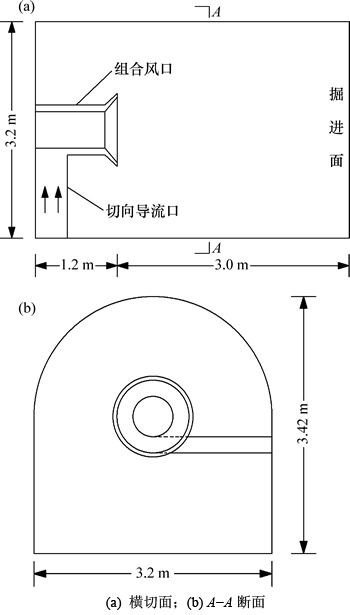

机掘工作面旋转射流屏蔽通风控尘效果与设计参数密切相关。影响该种通风方式控尘效果的主要设计参数包括D1、D2、D3、送风口宽度b0、吹吸流量比I及θ等。进行现场应用的机掘工作面高×宽为3.42 m×3.20 m,设计组合风口D1=0.6 m,D2=0.8 m和D3= 1.0 m,环形送风口宽度b0=5 cm,吹吸流量比取I=1.0(最佳吹吸流量比)[6]。

2 最佳送风角度数值模拟

2.1 物理模型和边界条件

利用前处理软件Gambit,建立与试验工作面等高宽的拱形三维机掘工作面巷道模型。同时,为简化计算,只选取机掘工作面前方4.2 m长度空间进行研究。组合风口D1=0.6 m,D2=0.8 m和D3=1.0 m,环形送风口宽度b0=5 cm,并将其放置于巷道中心高度,距离掘进端头3.0 m,数值模拟巷道物理模型如图3所示。当进行数值模拟时,综采工作面风流流场计算采用Realizable k-ε双方程紊流模型,使用SIMPLE算法求解气相流场。对工作面粉尘质量浓度分布计算时,在湍流模型的基础上增加欧拉-拉格朗日离散模型[12-13]。数值模拟采用相关数学模型控制方程组参见文献[9, 14],主要参数及边界条件设置见文献[6-7]。

2.2 结果与分析

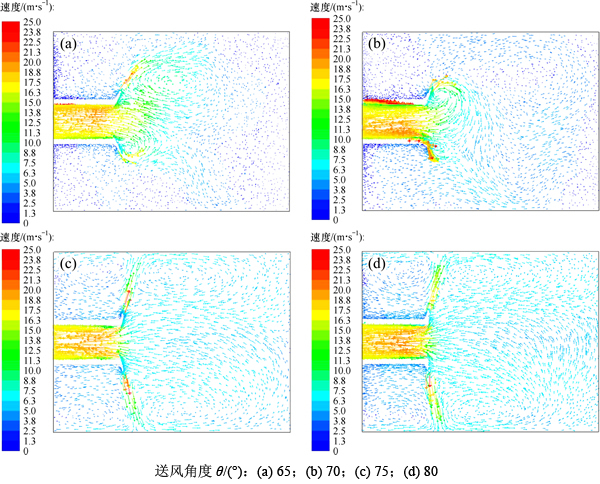

组合风口送风角度是影响机掘工作面旋转射流屏蔽通风流场和控尘效果的重要参数。数值模拟中送风量和抽风量均设置为300 m3/min,掘进面定义为粉尘源,其质量流量为120 g/min。通过改变送风角度(65°,70°,75°和80°),考察其对工作面流场及粉尘质量浓度分布的影响,从而分析得到最佳送风角度,模拟结果如图4~7所示。

图3 数值模拟巷道物理模型

Fig. 3 Roadway physical model of numerical simulation

2.2.1 流场特性

图4所示为不同送风角度下巷道中心水平横截面的速度矢量图。从图4(a)可以看出:当送风角度θ=65°时,吹气流以该角度从环形送风口射出后,由于送风角度过小,组合风口中心吸气流对其约束较强,导致吹气流向内收缩明显,旋转射流还未到达巷道壁面即被吸走,不能形成封堵粉尘扩散的风幕。从图4(b)可以看出:当送风角度增加至θ=70°时,吹气流从环形风口射出后,由于送风角度的增加,组合风口中心吸气流对其约束减弱,射流收缩效应降低,部分射流能够到达巷道壁面,并在吸气流的作用下与壁面碰撞后向工作面端头移动,基本能形成屏蔽工作面粉尘的旋转风幕。如图4(c)可以看出:当送风角度增加至θ=75°时,由于送风角度进一步增加,从环形风口射出的气流基本能够克服中心吸气流的束缚,并在吸气流的共同作用下与壁面冲击后向工作面端头移动,能够形成具有一定强度的完整风幕。从图4(d)可以看出:继续增大送风角度,射流与巷道壁面接触角增大,同时由于吸气流对吹气流的束缚作用进一步减弱,射流与巷道周壁冲击后,形成方向相反的2股气流,其中,一股流向组合风口后方区域。由于部分气流被分流至组合风口后方区域,造成工作面掘进端头风量减少,不利于粉尘的控制。而且,分流至组合风口后方区域的气流会随着送风角度的不断增大而增加。

图4 不同送风角度θ下巷道中心水平横截面速度矢量图

Fig. 4 Velocity vector diagram of cross-section at height of roadway center under different air-supply angle

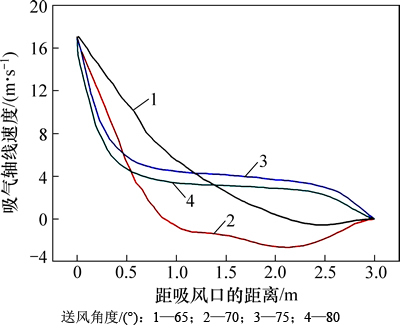

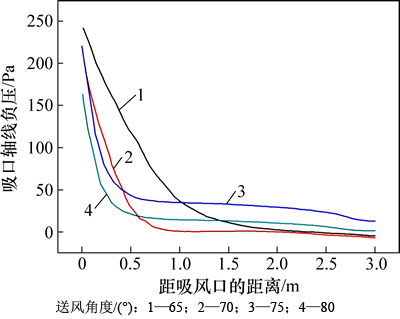

图5所示为不同送风角度下组合风口吸气轴线速度衰减曲线。从图5可以看出:在相同的送、排风量情况下,送风角度θ=75°的组合风口吸气轴线速度衰减最为缓慢。在该送风角度下,工作面掘进端头仍保持较高的吸气速度,从而有利于该区域粉尘的捕集。图6所示为不同送风角度下组合风口中心轴线负压衰减曲线。从图6可见:当送风角度θ分别为65°和70°时,工作面端头区域中心负压接近为0 Pa,不利于粉尘的汇集和抽吸。对比送风角度θ分别为75°和80°这2种情况下中心轴线负压衰减曲线发现:当送风角度θ为75°时在掘进端头产生的负压明显高于当送风角度θ为80°时产生的负压,掘进端头产生的粉尘汇集于该负压中心,并在吸气流的作用下排走。

图5 吸风口中心轴线速度衰减曲线

Fig. 5 Attenuation curves of axial suction velocity

图6 吸风口中心轴线负压衰减曲线

Fig. 6 Attenuation curves of negative pressure in front of combined tuyere

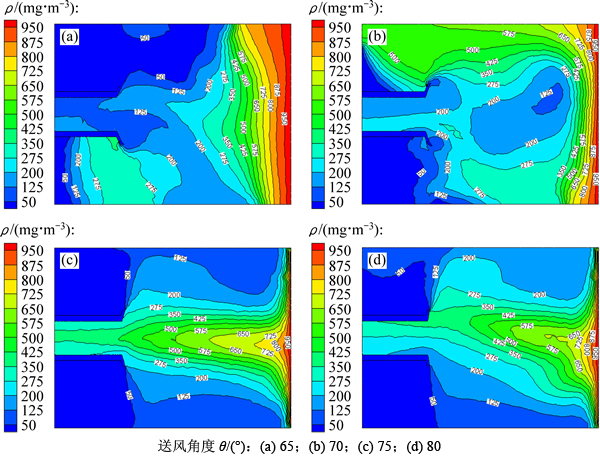

2.2.2 粉尘质量浓度分布

图7所示为不同送风角度下巷道中心水平横截面粉尘质量浓度分布。从图7(a)可见:由于送风角度较小,不能形成完整的风幕封堵粉尘,导致掘进端头粉尘从巷道周边扩散至组合风口后方,造成组合风口后方区域粉尘质量浓度较高。而在组合风口至工作面端头的控尘区域,由于组合风口吸气轴线速度衰减剧烈,工作面端头区域吸气轴线速度接近0 m/s,且负压几乎为0 Pa,导致大量粉尘滞留在工作面端头不能及时排走,工作面粉尘质量浓度明显偏高。从图7(b)可以看出:当送风角度增加至θ=70°时,控尘区粉尘质量浓度有明显下降。但由于旋转风幕强度较弱,工作面粉尘仍有部分扩散至组合风口后方的区域,造成组合风口后方区域粉尘质量浓度仍偏高。从图7(c)可以看出:当送风角度θ=75°时,由于旋转风幕强度增加,旋转风幕将粉尘控制在组合风口和掘进端头的有限空间内,并在吸气流的作用下将其排走,保证了组合风口后方区域较低的粉尘质量浓度。从图7(d)可知:随着送风角度θ的增大,组合风口后方区域粉尘质量浓度有所升高,原因是由于接触角的增加和吸气束缚作用的减弱,环形风口射出的气流与壁面冲击后携带部分粉尘流向组合风口后方区域。

图7 不同送风角度θ下巷道中心水平横截面粉尘质量浓度分布

Fig. 7 Dust mass concentration distribution of cross-section at height of roadway center under different air-supply angle

从图4~7的分析表明,机掘工作面采用旋转射流屏蔽通风时,在其他设计参数确定的情况下,工作面风流流场和粉尘质量浓度分布与送风角度密切相关。在进行该种通风方式参数设计时,组合风口的送风角度θ不能过小,也不能太大,存在一个最佳送风角度使得工作面粉尘能够得到较好的控制和捕集。分析认为:当采用最佳吹吸流量比I=1时,组合风口送风角度θ=75°时,旋转射流屏蔽通风流场能在工作面形成完整的屏蔽风幕,且组合风口前方吸气速度和负压沿轴向衰减较其他送风角度前方速度和负压沿轴向衰减缓慢,并对工作面粉尘控制效果最佳。因此,可以确定组合风口的最佳送风角度θ为75°。

3 最佳送风角度试验研究

3.1 试验系统

根据机掘工作面旋转射流屏蔽通风的具体情况,在设计模型试验时,只要保证原型和模型的几何相似、运动相似及二者的边界条件相似,就可以保证两者相似。

根据应用现场实际情况,取长度比例系数λl=8,速度比例系数λv =4,建立长×宽×高为1.50 m×0.40 m×0.42 m拱形机掘工作面巷道模型。为便于实验观测,巷道模型采用透明有机玻璃制作,板厚为5 mm。整个试验系统由巷道模型、组合风口、离心式压风机、离心式抽风机、发尘器、粉尘质量浓度测定仪、涡街流量传感器、配电箱、流量控制阀及相关管道等组成。采用不锈钢加工制作4种不同送风角度的组合风口,组合风口D1=75 mm,D2=100 mm和D3= 125 mm,环形送风口宽度b0=6.25 mm。粉尘由巷道模型端头的发尘器发散送入,模拟掘进机截割产尘。在组合风口前、后区域内分别布置CCZ-1000型粉尘质量浓度测定仪,对该区域的粉尘质量浓度进行采样测定。

3.2 试验方法

试验开始时,先启动压风机,将其风量调节为预定风量。然后,启动抽风机,并通过流量控制阀调节吸气速度。第1组试验为送风角度θ=65°的控尘效果测试,试验中将压风机风量调节为70 m3/h,维持环形送风口出口平均风速为8.0 m/s。抽风机的排风量设置为70 m3/h,保证组合风口吸气速度约为4.5 m/s。待风流稳定后,将粉碎烘干的后煤粉装入发尘器,启动发尘器,并开始计时。第2~4组试验分别为送风角度θ=70°,75°和80°的控尘效果测试,将对应送风角度的组合风口安装于模型巷道内,考察送、排风量和发尘量相同情况下,不同送风角度的组合风口控尘效果。在组合风口前、后方各0.30 m处分别布置粉尘质量浓度测点,采用定时采样模式进行测量,采样时间为5 min,采样流量为2 L/min。

3.3 试验结果与分析

在送、排风量及发尘量相同的情况下,对4种不同送风角度组合风口通风下的巷道中粉尘质量浓度进行测试,以组合风口前、后方各0.30 m处粉尘质量浓度及其隔尘效率作为评价指标,考察4种不同送风角度组合风口的控尘效果,试验结果如表1所示。

从表1可以看出:机掘工作面采用旋转射流屏蔽通风能够取到较好的控尘效果,组合风口后方区域粉尘质量浓度明显低于工作面端头,旋转风幕的隔尘效率高达70%以上。对比4种不同送风角度组合风口的控尘效果,送风角度θ=75°的组合风口控尘效果最佳,组合风口后方粉尘质量浓度降至24 mg/m3,旋转风幕隔尘效率高达85.9%。模型试验结果与数值模拟分析所得结论基本吻合。

表1 不同送风角度组合风口的控尘效果

Table 1 Dust control effect of combined tuyeres with different air-supply angle

4 结论

1) 机掘工作面采用旋转射流屏蔽通风时,在其他设计参数确定的情况下,工作面风流流场和粉尘质量浓度分布与送风角度密切相关。

2) 当采用最佳吹吸流量比I=1,组合风口送风角度θ=75°时,旋转射流屏蔽通风流场能在工作面形成完整的屏蔽风幕,且组合风口前方吸气速度和负压沿轴向衰减较其他送风角度吸气速度和负压沿轴向衰减缓慢,并对工作面粉尘控制效果最佳。

3) 送风角度θ=75°的组合风口控尘效果最佳,组合风口后方粉尘质量浓度降至24 mg/m3,旋转风幕隔尘效率高达85.9%。

参考文献:

[1] 王显政, 杨富, 朱凤山. 煤矿安全新技术[M]. 北京: 煤炭工业出版社, 2002: 312-319.

WANG Xianzheng, YANG Fu, ZHU Fengshan. New Technologies of Coal Mine Safety[M]. Beijing: Coal Industry Press, 2002: 312-319.

[2] 张义坤. 煤矿综掘泡沫降尘技术研究与实施[J]. 中国安全科学学报, 2012, 22(2): 151-156.

ZHANG Yikun. Study on dust control technology with foam in fully mechanized workface of coal mine[J]. China Safety Science Journal, 2012, 22(2): 151-156.

[3] 陈贵, 王德明, 王和堂, 等. 大断面全岩巷综掘工作面泡沫降尘技术[J]. 煤炭学报, 2012, 37(11): 1859-1864.

CHEN Gui, WANG Deming, WANG Hetang, et al. The technology of controlling dust with foam for fully mechanized excavation face of large cross-section rock tunnel[J]. Journal of China Coal Society, 2012, 37(11): 1859-1864.

[4] 程卫民, 聂文, 姚玉静, 等. 综掘工作面旋流气幕抽吸控尘流场的数值模拟[J]. 煤炭学报, 2011, 36(8): 1342-1348.

CHENG Weimin, NIE Wen, YAO Yujing, et al. Numerical simulation on the flow field of swirling flow air curtain aspiration control dust in fully mechanized workface[J]. Journal of China Coal Society, 2011, 36(8): 1342-1348.

[5] 刘荣华, 王海桥. 机掘工作面旋转射流通风理论探讨[J]. 中国安全科学学报, 2002, 12(2): 76-79.

LIU Ronghua, WANG Haiqiao. Study on swirling jet ventilation at tunneling working face[J]. China Safety Science Journal, 2002, 12(2): 76-79.

[6] 刘荣华, 王鹏飞, 张登春, 等. 机掘工作面旋转射流屏蔽通风吹吸流量比研究[J]. 中国安全科学学报, 2012, 22(9): 133-139.

LIU Ronghua, WANG Pengfei, ZHANG Dengchun, et al. Study on flow ratio of blowing to drawing of rotational jet shield ventilation at tunneling working face[J]. China Safety Science Journal, 2012, 22(9): 133-139.

[7] 刘荣华, 王鹏飞, 宋佳, 等. 机掘工作面旋转射流屏蔽通风流场特性数值研究[J]. 安全与环境学报, 2012, 12(6): 198-203.

LIU Ronghua, WANG Pengfei, SONG Jia, et al. Numerical Study of the efflux features of the rotational efflux shield ventilation at tunneling working face[J]. Journal of Safety and Environment, 2012, 12(6): 198-203.

[8] 王鹏飞, 刘荣华, 丘汉锋, 等. 旋转射流作用下吸气流动的特性研究[J]. 环境工程, 2011, 29(3): 58-62.

WANG Pengfei, LIU Ronghua, QIU Hanfeng, et al. Study on the characteristics of suction-airflow under rotary jet[J]. Environmental Engineering, 2011, 29(3): 58-62.

[9] 丘汉锋. 机掘工作面旋转射流屏蔽通风数值模拟及实验研究[D]. 湘潭: 湖南科技大学能源与安全工程学院, 2012: 34-39.

QIU Hanfeng. Numerical simulation and experimental research of rotational jet shield ventilation at tunneling working face[D]. Xiangtan: Hunan University of Science and Technology. School of Energy & Safety Engineering, 2012: 34-39.

[10] 张景松, 闫小康, 王凯, 等. 环形旋转射流屏蔽抽吸流场的数值模拟[J]. 中国矿业大学学报, 2006, 35(2): 173-177.

ZHANG Jingsong, YAN Xiaokang, WANG Kai, et al. Suction controlled by man-made hurricane[J]. Journal of China University of Mining, 2006, 35(2): 173-177.

[11] 张景松, 周世宁. 人造龙卷风控制抽吸[J]. 中国矿业大学学报, 1996, 25(1): 1-5.

ZHANG Jingsong, ZHOU Shining. Suction controlled by man-made hurricane[J]. Journal of China University of Mining & Technology, 1996, 25(1): 1-5.

[12] 张建卓, 祝天姿, 高猛, 等. 综掘面风幕集尘除尘系统的参数优化与数值模拟[J]. 中国安全科学学报, 2011, 21(4): 128-131.

ZHANG Jianzhuo, ZHU Tianzi, GAO Meng, et al. Parameter optimization and numerical simulation of dust-collecting and dedusting system with air curtain in fully mechanized excavation face[J]. China Safety Science Journal, 2011, 21(4): 128-131.

[13] 蒋仲安, 陈梅岭, 陈举师. 巷道型采场爆破粉尘质量浓度分布及变化规律的数值模拟[J]. 中南大学学报(自然科学版), 2013, 44(3): 1190-1196.

JIANG Zhongan, CHEN Meiling, CHEN Junshi. Numerical simulation of dust concentration distribution and changing regularities in roadway stope blasting[J]. Journal of Central South University (Science and Technology), 2013, 44(3): 1190-1196.

[14] 刘荣华, 李夕兵, 施式亮, 等. 一种新型旋风气幕式排风罩数值模拟研究[J]. 环境工程, 2009, 27(4): 68-72.

LIU Ronghua, LI Xibing, SHI Shiliang, et al. Study on numerical simulation of new type of rotary air curtain exhaust hood[J]. Environmental Engineering, 2009, 27(4): 68-72.

(编辑 罗金花)

收稿日期:2014-08-04;修回日期:2014-10-10

基金项目(Foundation item):国家自然科学基金资助项目(51574123, 51306047)(Projects (51574123, 51306047) supported by the National Natural Science Foundation of China; )

通信作者:王鹏飞,博士,讲师,从事矿井通风和环境保护研究;E-mail:pfwang@sina.cn