Effect of CaO content on residual stress of CAS glass-ceramic

XIE Jun, CHENG Jin-shu, LONG Xin-jiang, YANG Shu-zhen

Key Laboratory of Silicate Materials Science and Engineering, Wuhan University of Technology,

Wuhan 430070, China

Received 10 April 2006; accepted 25 April 2006

Abstract: The mismatch in thermal expansion coefficient between crystalline phase and glass phase can result in large thermal stresses during thermal processing, as well as the low thermal conductivity, which is the most troublesome in the production of the CaO-Al2O3-SiO2 glass-ceramic. CaO content may influence the residual stress in the system. Therefore X-ray diffraction (XRD) ‘sin2ψ’ method was used to calculate the residual stress in samples containing various contents of CaO. The relationship between CaO content and residual stress in CAS system was investigated. Finally reasons causing such residual stress were analyzed.

Key words: CaO-Al2O3-SiO2; Glass-ceramic; Residual stress

1 Introduction

In recent years, more and more attention has been paid to CaO-Al2O3-SiO2 glass-ceramics whose main crystalline phase is needle-like or tree-like β-wollastonite. Unlike normal glass, the CAS glass-ceramic is a heterogeneous composite material, consisting of β-wollastonite crystal phase which have a lower coefficients of thermal expansion (CTE) and glass phase. Any CTE mismatch between the constituents in a composite material may result in residual stress which is called “thermal mismatch” stress upon cooling or heating again in service[1-3]. This thermal mismatch stress is usually several times bigger than that of the thermal gradient stress, sometimes even one or two order of magnitude. Such stress often results in micro-crack, which always decreases mechanical strength. Recently, effect of oxide contents on residual stress of CAS glass-ceramic have been investigated. For CaO content has main influence on the sintering and crystallization, thus CaO content is the predominant factor that determines residual stress. So in this research, in order to find the relation between CaO content and the residual stresses, CaO content is changed to form different contents of β-wollastonite crystal phase. And then X-ray diffraction (XRD) ‘sin2ψ’ [1] was used to measure the residual stress.

2 Experimental

2.1 Glass preparation and heat treatment

The base glass compositions are given in Table 1. All raw materials used to prepare the glasses were reagents in chemical purity grade. All reagents were thoroughly mixed and melted in an electric furnace at 1 450 ℃ for 1 h. The melts were then quenched in ambient temperature water to obtain granular frits. Dried and sieved grains were put into a mould and subjected to heat-treatment from room temperature to 1 120 ℃, then kept the temperature for 2 h, and the heating rate was 4 ℃/min up to 900 ℃ and 2 ℃/min between 900 ℃ and 1 120 ℃.

2.2 Microstructure analysis

Microstructure observations of the glass-ceramics were performed on polished and etched surfaces by scanning electron microscope with an accelerating voltage of 20 kV.

2.3 Residual stress measurements

Residual stresses on the surface are determined with XRD ‘sin2ψ’by measuring the changes in interplanar spacings (lattice d-spacings) in different angles of incidence (ψ). The relationship between the angle of incidence and strain is given by

(1)

(1)

where σ is the stress, d0 and dψ are the reference and measured d-spacings, respectively. Differentiate Bragg diffraction formula to obtain Eqn.(2), then combine Eqn.(1) with Eqn.(2) to deduce the relationship between diffraction peak position and the angle of incidence.

(2)

(2)

(3)

(3)

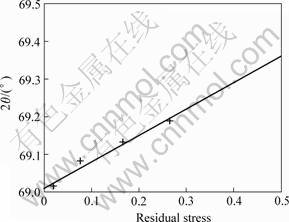

The stress is obtained from the slope of the plot of the peak position, 2θψ vs sin2ψ(Fig.4). The sin2ψ measurement is preferably made with the ( ) peak at 2θ0=69.06?, since d-spacing measurement accuracy increases with diffraction angle increase[4, 5]. In this way the average total stress in β-wollastonite crystal phase can be measured, while that of glass phase can not be determined for its particular non-crystal XRD spectra. Because the relaxation of the thermal residual stress in CAS class-ceramic is very little, the value determined by sin2ψ method is the sum of the thermal gradient residual stress and the thermal mismatch stress. Because of the unchanged size of the samples, the same thermal treatment technics and little change in the thermal conductivity, macroscopic stress is constant approximately, so this residual stress in β-wollastonite crystal phase can reflect approximately the magnitude of residual stress in CAS glass-ceramic.

) peak at 2θ0=69.06?, since d-spacing measurement accuracy increases with diffraction angle increase[4, 5]. In this way the average total stress in β-wollastonite crystal phase can be measured, while that of glass phase can not be determined for its particular non-crystal XRD spectra. Because the relaxation of the thermal residual stress in CAS class-ceramic is very little, the value determined by sin2ψ method is the sum of the thermal gradient residual stress and the thermal mismatch stress. Because of the unchanged size of the samples, the same thermal treatment technics and little change in the thermal conductivity, macroscopic stress is constant approximately, so this residual stress in β-wollastonite crystal phase can reflect approximately the magnitude of residual stress in CAS glass-ceramic.

3 Results and discussion

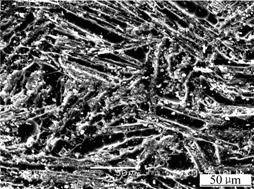

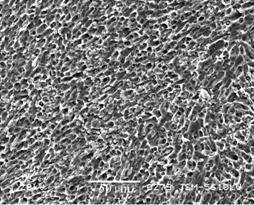

Fractured surfaces of sample 1 (CaO 15%) and sample 6 (CaO 20%) are needle-like and granular

β-wollastonite crystal phase(Figs.1 and 2). In sample No.1, crystallites are about 100 μm average in length and 5 μm average in width, the grain size of crystallites is about 10 μm in diameter in sample 6. By increasing the content of CaO at the expense of SiO2 the crystallization activation energy is reduced, initial crystallization temperature is decreased, and nucleation is efficient, which causes the crystallites to impinge on each other before they can grow larger, and results in a fine microstructure[6, 7].

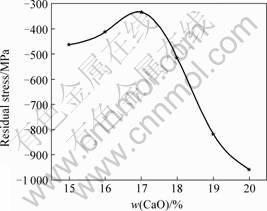

The results of residual stress measure are reported in Fig.3. As an example, Fig.4 shows the graph of residual stress measure of sample 4. And the value of 2θ, determined by the center of full width at half maximum (FWHM) of the ( ) peaks, increases as sin2ψ increases, so the residual stress calculated by Eqn.(3) is negative, which implies compressive stress. It must be noted that the values show the residual stress at the boundary betweenβ-wollastonite crystal phase and glass phase. It is seen that the values of residual stress decrease from -463.2 MPa to -333.9 MPa as CaO content varies from 15% to 17%, and increase to -959.9 MPa with CaO content increasing to 20 %.

) peaks, increases as sin2ψ increases, so the residual stress calculated by Eqn.(3) is negative, which implies compressive stress. It must be noted that the values show the residual stress at the boundary betweenβ-wollastonite crystal phase and glass phase. It is seen that the values of residual stress decrease from -463.2 MPa to -333.9 MPa as CaO content varies from 15% to 17%, and increase to -959.9 MPa with CaO content increasing to 20 %.

Fig. 1 SEM micrograph of sample 1

Fig. 2 SEM micrograph of sample 6

Fig.3 Plot of residual stress of sample 4

Fig. 4 Relationship between residual stress and CaO content

The residual stress is determined by two factors as follows:

1) The increase of the β-wollastonite crystal phase content induced by the increase of CaO content has a positive effect on the rise of the residual stress value.

2) The grain size of β-wollastonite crystal decreases with increasing CaO content, which decreases the residual stress. Therefore, at the beginning, the residual stress is predominated by the second factor, and decreases with the increase of the CaO content, and then augmented with the increase of CaO content, which shows the first factor is prevailing now.

The residual stress is large magnitude and the maximum value in this study reaches -959.9 MPa, whereas the slope of the curve in Fig.4 becomes less and less, which shows that the residual stress will not increase endlessly. It is possible to predict that the residual stress will reach some value and then decrease.

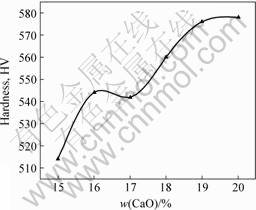

Fig. 5 Microhardness as function of CaO content

The microhardness as a function of CaO content is shown in Fig.5. Each point represents the average value for five test points. It can be concluded that with the increase of CaO content, the microhardness values also increase[8, 9] except for sample 3 (CaO 17%).

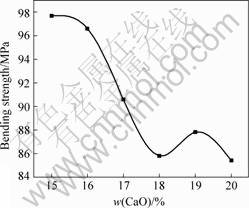

Fig.6 shows the results of the three points bending strength test. Each point represents the average value for five specimens. Unlike the microhardness(Fig.5), the bending strength values decrease with increasing CaO content. The microcrack induced by the large residual stress is a rational answer for the exceptional behaviour.

The increase of the β-wollastonite crystal phase content induce by the increase of CaO content, and the hardness value of β-wollastonite is higher than that of glass phase, so the microhardness shows in Fig.5 increase with CaO content increase(Microhardness instrument, type HVS-1000 ). But the crystal phase separated out will have a counterwork effect on transference of particle and flowage of glass phase when CaO content exceeds 20%. Then, the microhardness reduce evidently, because pit point protuberance and rupture appear. However, the shape β-wollastonite change according to the augment of β-wollastonite content. At first, the β-wollastonite are needle-like and then change in shape of pole, in other way, the length diameter ratio of β-wollastonite crystal decrease. This change have a negative effect on bending strength, because the needle-like crystal will contribute to enhance the toughness in composite material. Therefore, the bending strength of glass-ceramics will not always enhance with the CaO content increase. In Fig.6, the bending strength decrease when the CaO content is between 15% and 20%. Considering comprehensively the aspects of the production and performance of the glass-ceramics[10, 11], the optional content for CaO is from 16% to 18%.

Fig. 6 Curve of three points bending strength vs content of CaO

4 Conclusions

1) X-ray diffraction (XRD) ‘sin2ψ’is a suitable method for the measurement of the residual stress in the CAS glass-ceramic.

2) Increase of the CaO content leads to the increase of the β-wollastonite crystal phase and higher residual stress. While the β-wollastonite crystal phase grain size decreases with the increase of CaO content, which has a negative effect on the rise of the residual stress. Those two contrary factors may determine the residual stress, and in our research, the residual stress in the CAS glass-ceramic is decreased initially, and then a speedy rise takes place.

3) The CaO content have a serious effect on the properties, so the optional content for CaO is from 16 % to 18%.

4) The residual stress affects the properties of the glass-ceramic, such as the bending strength.

References

[1] G?NG?R S. Residual stress measurements in fibre reinforced titanium alloy composites[J]. Acta Mater, 2002, 50: 2053-2073.

[2] VAIDYA R U, RANGASWAMY P, BOURKE M A M, et al. Measurement of bulk residual stresses in molybdenum desilicide/stainless steel joints using neutron scattering[J]. Acta Mater, 1998, 46(6): 2047- 2061.

[3] FITZPATRICK M E, HUTCHINGS M T, WOTHERS P J. The determination of the profile of macrostress and thermal mismatch stress through an Al/SiCp composite plate from the average residual strains measured in each phase[J]. Physica B, 1995, 213: 790-792.

[4] WINDISCHMANN H, GRAY K J. Stress measurement of CVD diamond films[J]. Diamond and Related Materials, 1995, 4: 837-842.

[5] CHENG Jin-shu, LONG Xin-jiang, XIE Jun. Effect of Al2O3 Content on Residual Stress and Properties of CAS Glass-ceramics[R]. ISG/ICG2005.

[6] ALIZADEH P, MARGHUSSIAN V K. Effect of nucleating agents on the crystallization behaviour and microstructure of SiO2-CaO-MgO (Na2O) glass-ceramics[J]. Journal of European Ceramic Society, 2000, 20: 775-782.

[7] CHENG C M, YANG C F, LO S H. Influence of crystallization on the flexural strength of MgO-CaO-Al2O3-SiO2 composite glass[J]. Ceram Int, 1999, 25(6): 581-586.

[8] MARGHUSIAN V K, DAYI-NIAKI M H. Effects of composition changes on the crystallization behaviour and properties of SiO2-Al2O3-CaO-MgO (Fe2O3-Na2O-K2O) glass-ceramics[J]. Journal of the European Ceramic Society, 1995, 15: 343-348.

[9] ZHAO Qian, WANG Huai-de, QUAN Jian. The effect of basic composition of glass-ceramic on sintering and crystallization[J]. Advanced Ceramics, 1997 (3): 25-29.

[10] CHENG J S, XIAO J. Research and production of glass-ceramic decorated material containing chromium[J]. Journal of Wuhan University of Technology(Mater Sci Ed), 2000, 15(3): 158-162.

[11] CHENG Jin-shu, HE Feng, YUAN Jian, WNG Quan. Influence of CaO content on sintering process of CaO-Al2O3-SiO2 glass ceramic decorated material[J]. Journal of Wuhan University of Technology, 1997, 19(4): 1-4.

(Edited by LONG Huai-zhong)

Foundation item: Project(50272043) supported by the National Natural Science Foundation of China

Corresponding author: XIE Jun; E-mail: xiejunobert2001@hotmail.com