基于多孔介质模型的电厂凝汽器汽侧流动特性

何金桥1,肖波1,汤盛萍1,王运民1,曹雄1,孙振宇1, 2

(1. 长沙理工大学 能源与动力工程学院,湖南 长沙,410004;

2.中国广东核电集团有限公司,广东 深圳,518031)

摘要:针对凝汽器管束区的分形及其分布阻力特性,建立基于凝汽器管束区乏汽流动多孔隙率的多孔介质模型,并分析管束区乏汽的速度、流量及压力的变化。研究结果表明:在均匀管内换热条件下,该结构类型的凝汽器中的凝结效果主要取决于管板外边界附近的冷却管束的换热,而且上管束区域的冷凝效果比下管束区的冷凝效果差;在空冷区中,对称分布的高动压区使得流入空冷区中的乏汽转向流入凝结管束区中,一方面避免了工质直接通过排汽口排放的损失,另一方面,该动压区所处的位置以及动压随负荷发生变化,尤其是在240 MW负荷附近的工况条件下变化显著,将导致排气口带走更多的工质。

关键词:冷端;凝汽器;多孔介质;流动特性;数值模拟

中图分类号:TK262;TK264.1 文献标志码:A 文章编号:1672-7207(2013)05-2113-05

Steam flow characteristics of shell side of condenser based on porous medium model

HE Jinqiao1, XIAO Bo1, TANG Shengping1, WANG Yunmin1, CAO Xiong1, SUN Zhenyu1, 2

(1. Institute of Energy Source & Power Engineering, Changsha University of Science & Technology, Changsha 410004, China;

2. China Guangdong Nuclear Power Holding Co. Ltd., Shenzhen 518031, China)

Abstract: With regard to the characteristics of fractal and distribution resistance of the condenser tube bundle, a porous medium model with three kinds of porosity was established based on the steam exhaust flow in condenser tube bundle area, and the characteristics of speed, rate of flow and pressure of steam exhaust were analyzed. The results show that under the conditions of different loads and uniform tube heat transfers, the condensation effect of condenser relates to the heat exchange of the cooling tube bundle near outside border of the tube plate, and the condensation effect of lower tube bundle is the best among three tube bundles. The high dynamic pressure with symmetrical distribution in air cooled zone makes the steam exhaust steering into the tube bundle zone, which prevents the medium from being discharged directly through the exhaust port, but the position and the dynamic pressure will change with the load, especially when near 240 MW. The significant change will lead to more medium loss.

Key words: cold-side; condenser; porous medium; flow characteristic; numerical simulation

汽轮机冷端是指从汽轮机末级叶片出口→冷凝器→循环水系统范围内构成热力循环有效冷源的设备及其管路系统,其中的主要设备有凝汽器、循环水泵、真空泵及冷却塔等[1]。相关研究表明,冷端处汽轮机背压升高1 kPa,相应发电热耗率增加0.7%~ 0.9%[2]。电站汽轮机组凝汽器壳侧的蒸汽流动特性及凝结换热特性是决定冷端各设备运行工况的重要因素。随着大功率汽轮机组的发展,凝汽器结构越来越复杂,汽侧乏汽凝结换热时的流动特性也更加复杂[3-5],使得冷端汽轮机背压在变工况负荷下发生大范围波动,这将直接影响到整个火力发电机组的热经济性和安全性[1, 6]。多孔介质模型将管子看作多孔骨架,降低了网格生成的复杂度并大大减少了网格数量和计算负荷,有效反映了多孔介质换热时的流动特性。在目前管壳式换热器数值研究中,一般采用Patankar等[7-8]提出的分布阻力方法,对管壳式换热器建立二维或三维的数值模型并求解[9-12]。我国学者在应用多孔介质模型进行数值模拟方面进行了探索性研究,但对管束区换热时流动特性研究不多[13-14],这为研究结构复杂、管数众多的凝汽器管束区换热时的流动特性创造了有利条件。

1 火电厂凝汽器数学模型分析

1.1 凝汽器结构及工作特性分析

株洲电厂310 MW火电机组采用的凝汽器为单背压、单壳体、对分式、双流程、表面式、冷凝管束横向布置的凝汽器。

该种形式的凝汽器因管内冷却水流阻小,不易堵塞,易加工和大型化,故得到广泛应用。但是,壳侧内乏汽因复杂的布管导致气流进入管束后会产生较大波动,这将使汽轮机末级排汽背压波动,导致凝汽式汽轮机机组冷端运行工况劣化。

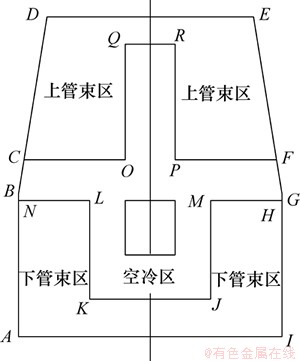

图1所示为该型凝汽器布置管束的管板分区结构简图。由图1可知:该凝汽器不同管束区结构存在较大差异,具有分型特性[9-13],布管数量并不均匀,相应区间的孔隙率也不一致。因此,应根据分型多孔介质模型的特点,将管束区分为不同孔隙率的3个区域,即上管束区、下管束区和空冷区。不同管束区域的结构特点如表1所示。

图1 株洲电厂310 MW机组凝汽器管束布置

Fig.1 Condenser tube bundle distribution of 310 MW unit in Zhuzhou Power Plant

表1 管板结构特点

Table 1 Structure characteristics of tube plate

上、下管束区通过凝汽器壳体外部的弯头连接形成双流程的冷却效果,管束区中部的空冷区在管束边缘的上、下管束区之间存在明显空隙,这会使得一部分乏汽直接进入到空冷区,因此,空冷区中也布置一定数量的冷却水管,以进一步提高凝汽器的凝结效率。

1.2 管束区乏汽换热特性分析

该凝汽器采用水平管外凝结的工作形式,即在凝汽器内部,冷却水在循环水泵的驱动下连续不断地流过冷却管,乏汽不断地在冷却管外壁凝结。由于乏汽温度不高,一般不考虑凝汽器与外界的散热,故凝汽器的传热系数主要受凝汽器水侧污垢、汽侧凝结液膜厚度、管子的排列、蒸汽中空气含量等影响。显然,凝结液膜的厚度主要取决于材料的表面特性,水侧污垢通过定期清洗也可以消除其对换热的影响,所以,影响凝汽器管束区不同位置换热性能的因素在于管子的排列和乏汽中空气的含量。凝汽器内少量从外界漏入的不凝结气体随着乏汽的凝结,其浓度逐渐增大,这将导致乏汽的分压力降低,难以凝结在冷却管表面,对凝结换热过程产生重要影响[2, 10],但不凝结气体含量小,因此,主要影响空冷区的换热凝结。

1.3 多孔介质模型分析

凝汽器壳侧蒸汽流动是发生在冷却管束内外的多组分同时伴有相变的复杂过程。合理研究凝汽器内发起流动特性需对该凝汽器内部的流动与传热过程进行以下几方面简化和假设:忽略温度及液相体积的影响;空气泵具有足够抽除空气和未凝结蒸汽的能力;凝汽器外壳绝热,蒸汽凝结释放的热量全部传给冷却水;忽略管板、支撑件及抽气导出管等的影响,各汽室的流动可近似看成是乏汽横掠管束的二维定常流动。

此外,对凝汽器的工作条件也进行如下假设:蒸汽在饱和状态下凝结;冷却水流量在同一流程的各冷却管中始终相等;忽略不凝结气体对换热的影响,凝汽器内的空气和蒸汽均匀混合;壳侧管束外各处压力相等。

根据上述假设,影响汽轮机末级排汽压力的因素主要集中在凝汽器管束区,因此,只需将管束区当作多孔介质区域,将蒸汽在其中的流动看作是在多孔介质内的流动,就可以建立具有分布阻力和分布质量汇的多孔介质模型。

质量连续性方程:

(1)

(1)

X方向动量守恒方程为

(2)

(2)

Y方向动量守恒方程为

(3)

(3)

式中: 为孔隙率,主要取决于管束区布管特性;

为孔隙率,主要取决于管束区布管特性; 为惯性阻力系数;

为惯性阻力系数; 为当量黏性系数;

为当量黏性系数; 和

和 为冷却管束间的摩擦阻力系数,均取决于凝汽器负荷特性;Q,Qu和Qv为源项。

为冷却管束间的摩擦阻力系数,均取决于凝汽器负荷特性;Q,Qu和Qv为源项。

2 凝汽器管束区乏汽流场特性分析

2.1 流动特性分析

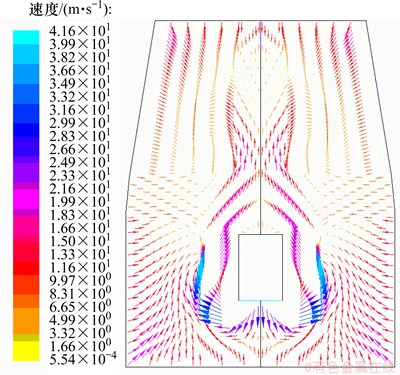

图2所示为300 MW负荷下管束区乏汽的速度分布矢量图。由图2可知:下管束区气流速度分布较均匀,且较大;上管束区顶部气流速度较大,下部气流速度较低,且低于空冷区及下管束区中大部分区域的气流速度;空冷区中仅有部分气流流向不凝结气体排气口,大量的气流又回流到上、下冷凝管束区。其中,回流到下管束区中乏汽气流速较大且较均匀;回流到上管束中的乏汽流速较小且主要回流到上管束区侧向区域,顶部区域回流量较小。

经测试,上、下管束区之间间隙的垂直距离为600 mm,空冷区经该间隙直接与凝汽器壳体中的乏汽联通,必然导致大量乏汽直接流入空冷区,加之空冷区中冷却管数量少且主要集中在排气口周围及其顶部轴线上,因此,乏汽一旦流入空冷区,其流动方向将主要取决于排气口初始压力及上、下冷却管束的冷凝作用所导致的真空效应。图2所示的速度场表明:空冷区中的乏汽大量流入到下管束区,而只有一小部分进入空冷区,使得下管束区形成多面进气,因此,其中气流速度分布较均匀;而上管束虽然在与空冷区的界面处也有乏汽流入,但由于排气口置于下管束区中,且上管束与空冷区之间的内边界较狭长,因此,上管束区中间除顶部外的管束中基本上没有气流,也难以达到较好的冷凝作用。

图2 300 MW负荷下管束区乏汽速度分布

Fig.2 Velocity of flow distribution of tube bundle under load of 300 MW

2.2 流量特性分析

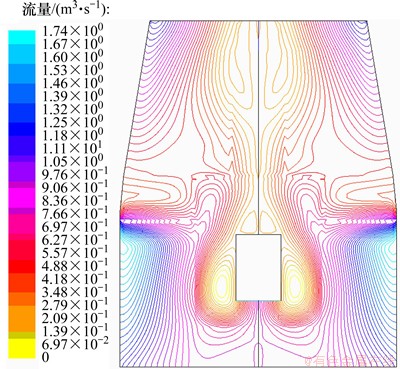

图3所示为300 MW负荷下管束区乏汽的流量分布等值线图。乏汽在3个不同管束区中的流量存在显著差异,上管束区中流量极大值出现在顶部转弯处,即图1所示的D和E处;下管束区的则分布在其与空冷区的界面处,即图1中所示的N和H处。空冷区中靠近排气口处的气流存在显著的回流现象,这使得排气口处的乏汽量大大减少,有利于减少乏汽中可用工质的损失,但是,由于汽轮机末级工质已经大大低于环境大气的压力,必然会有极少量的不凝性空气泄露进入到乏汽中,若不能及时排除,则会影响冷凝管束外侧的换热。

上管束区中部的乏汽流量等值线表明其中乏汽流量较低,但变化梯度不大,这主要由冷凝管束的冷凝作用及空冷区中的乏汽热浮升作用共同导致。下管束底部中间位置处的流量等值线表明该处乏汽流量较少而且变化梯度较大,这说明乏汽自汽轮机末级排入到凝汽器后,经过凝汽器管束区上部不同位置的冷凝和流动,到达底部中间位置处的乏汽量很少,其中冷凝管束难以起到冷凝作用。

图3 300 MW负荷下的管束区乏汽流量分布

Fig.3 Rate of flow distribution of tube bundle under load of 300 MW

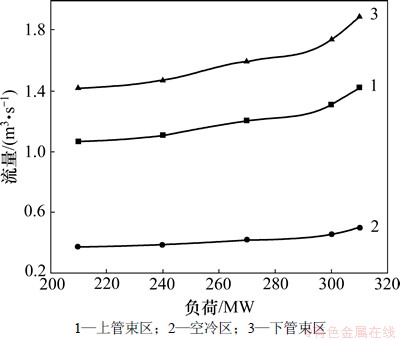

图4所示为不同负荷下不同管束区中的最大流量分布情况。由图4可知:下管束区中的最大流量最大,空冷区中的最大流量虽然最小,三者随负荷的增大基本上近似平行增大,只是在由300 MW增加到310 MW的负荷时,个管束区中的最大流量变化较大。由此可见:导致该种结构形式的凝汽器冷凝管束的换热不均的首要原因应在于管板管束区内边和外边缘的进汽不均匀,内边缘需通过空冷区到达主凝结区凝结换热,这将增加流动阻力,导致流量减少;此外,管束底仍有部分区域气流难以到达,也降低了其冷凝作用。

图4 不同负荷下的管束区中最大乏汽流量分布

Fig.4 The maximum rate of flow distribution of tube bundle under different loads

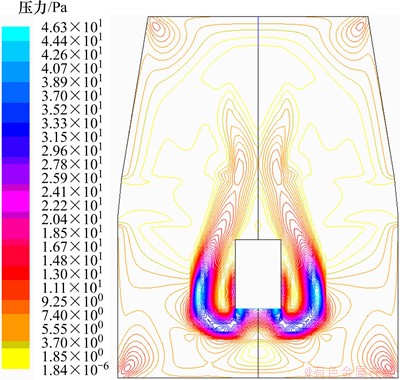

2.3 压力分布特性

图5所示为300 MW负荷下管束区的乏汽动压分布等值线图。由图5可知:空冷区中存在一对称分布的高动压区。该动压区紧靠下管束的垂直内边界。结合图2所示乏汽速度分布可知:正是由于该动压区才使得流入空冷区中的乏汽转向流入到凝结管束区中,避免了工质直接通过排汽口排放的损失。但是,由于负荷工况的变化,该动压区所处的位置以及动压均将发生变化,若在确定的排汽压力下,排汽口排出气体中的可凝结性工质的含量也随之发生改变。图5中,管束区中的压力为对应负荷下的最大计算值;而非管束区中的乏汽压力则为实际测量值。

图5 300 MW负荷下的管束区乏汽压力分布

Fig.5 Steam exhaust dynamic pressure distribution of tube bundle under load of 300 MW

图5还表明:在整个管束区中,位于管板4个转角及外边界处的动压较大,而且等值线之间的间距较小,说明动压减少的梯度小;上、下管束区中其他区域动压等值线之间的间距随之增大,相应地,动压减小得更快,即流动阻力增加,这将导致乏汽主要通过上、下管束区外边界附近的冷却管换热凝结。

图6所示为不同负荷下,不同管束区外边界上最大动压。由图6可知:上、下2管束区外边界上的动压变化基本一致,而且均在大于额定负荷后出现显著增大;下管束区中的最大动压大,说明下管束的凝结换热效果更好。空冷区外边界为图1所示的CBN及FGH边所在位置,其上的最大动压在240 MW附近也出现了较大波动。由此可见:在240 MW附近的负荷下,若不及时调整排汽口压力,将明显导致不良运行工况出现。

图6 不同负荷下管束区入口乏汽动压分布

Fig.6 Steam exhaust dynamic pressure distribution of inlet of tube bundle under different loads

3 结论

(1) 在均匀管内换热条件下,该结构类型凝汽器中的凝结效果主要取决于换热管束的外边界附近的冷却管束的换热,而且上管束区域的冷凝效果比下管束区的冷凝效果差。

(2) 导致该种结构形式的凝汽器冷凝管束换热不均的首要原因在于管板管束区内边和外边缘的进汽不均匀,内边缘需通过空冷区到达主凝结区凝结换热,这将增加流动阻力,导致流量减少;此外,管束底仍有部分区域气流难以到达,也降低了其冷凝作用。

(3) 空冷区中存在一对称分布的高动压区。该动压区紧靠下管束的垂直内边界。该动压区使得流入空冷区中的乏汽转向流入到凝结管束区中,一方面,避免了工质直接通过排汽口排放的损失;另一方面,该动压区所处的位置以及动压随负荷均将发生变化,尤其在240 MW负荷附近工况下变化显著,这将导致排气口带走更多的工质。

参考文献:

[1] 徐仿优, 胡光明, 刘光耀, 等.沙角 A电厂 300 MW机组冷端系统经济性诊断及优化运行[J]. 热力发电, 2010, 31(7): 7-10.

XU Fangyou, HU Guangming, LIU Guangyao, et al. Operation optimization and economic efficiency diagnosis on cold end system of 300 MW unit Shajiao A power plant[J]. Thermal Power Generation, 2010, 31(7): 7-10.

[2] 王学栋, 袁建华, 曲建丽, 等. 330 MW机组凝汽器改造的数值模拟及性能分析[J]. 汽轮机技术, 2010, 52(4): 150-154.

WANG Xuedong, YUAN Jianhua, QU Jianli, et al. Numerical simulation and performance analysis of condenser retrofit of 330 MW unit[J]. Turbine Technology, 2010, 52(4): 150-154.

[3] 周兰欣, 李富云, 李卫华. 凝汽器壳侧准三维数值研究[J]. 中国电机工程学报, 2008, 28(23): 25-30.

ZHOU Lanxin, LI Fuyun, LI Weihua. Quasi-three-dimensional numerical study of shell side of condenser[J]. Proceedings of the CSEE,2008, 28(23): 25-30.

[4] Zhu Q Y, Li Y. Numerical simulation of the transient heat and liquid moisture transfer through porous textiles with consideration of electric double layer[J]. Int J Heat Mass Transfer, 2010, 53(7): 1417-1425.

[5] 俞茂铮, 姚秀平, 汪国山. 大功率汽轮机凝汽器汽相流动与传热特性的数值模拟[J]. 动力工程, 1995, 15(6): 42-49.

YU Maozheng, YAO Xiuping, WANG Guoshan. Numerical analysis of the steam flow behavior and heat transfer performance of condensers of large steam turbines[J]. Power Engineering, 1995, 15(6): 42-49.

[6] 张卓澄. 大型电站凝汽器[M]. 北京: 机械工业出版社, 1993: 4-5.

ZHANG zhuocheng. Large power station condenser[M]. Beijing: China Machine Press, 1993: 4-5.

[7] Spalding D B. The calculation of free-convertion phenomenon in gas-liquid mixtures[C]//ICHMT Semonar. Dubrovnil, 1967: 1-15.

[8] Patankar S V, Spalding D B. Computer analysis of three- dimensional flow and heat transfer in a steam generator[C]// Forsch. Ingenieurwes, 1978: 4.

[9] Zhu Q Y, Xie M H, Yang J, et al. Investigation of the 3D model of coupled heat and mass moisture transfer in hygroscopic porous fibrous media[J]. Int J Heat Mass Transfer, 2010, 53(8): 3914-3927.

[10] KOU Jianlong, LIU Yang, WU Fengmin, et al. Fractal analysis of effective thermal conductivity for three-phase (unsaturated) porous media[J]. Journal of Applied Physics, 2009(5): 106.

[11] Ono Y, Mayama H, Furo I, et al. Characterization and structural investigation of fractal porous-silica over an extremely wide scale range of pore size[J]. J Colloid Interf Sci, 2009, 336: 215-225.

[12] Wu J S, Yu B M. A fractal resistance model for flow through porous media[J]. Int J Heat Mass Transfer, 2007, 50(8): 3925-3932.

[13] Zhu Q Y, Xie M H, Yang J, et al. A fractal model for the coupled heat and mass transfer in porous fibrous media[J]. Int J Heat Mass Transfer, 2011, 54(7): 1400-1409.

[14] 曾辉, 孟继安, 李志信. N-17000型凝汽器的热力性能的数值分析[J]. 工程热物理学报, 2010, 31(7): 1213-1214.

ZENG Hui, MENG Jian, LI Zhixin. Numerical analsis on the thermal performan[J]. Journal of Engineering Thermal Physics, 2010, 31(7): 1212-1214.

(编辑 陈灿华)

收稿日期:2012-07-22;修回日期:2012-10-08

基金项目:国家重点基础研究发展规划(“973”计划)项目( 2009CB219803-03);湖南省教育厅一般项目(11C0026);长沙理工大学热能工程学科基金资助项目(2009年)

通信作者:何金桥(1973-),男,湖南衡阳人,博士,从事热能工程研究;电话:13117318879;E-mail: 8710054@163.com