文章编号:1004-0609(2011)03-0597-07

泡沫铝的新型渗流法制备及其压缩性能

张 斌1, 左孝青1, 孙彦琳2, 陆建生1, 周 芸1, 王 红3

(1. 昆明理工大学 材料科学与工程学院,昆明 650093;

2. 昆明理工大学 化学工程学院,昆明 650093; 3. 昆明理工大学 理学院,昆明 650093)

摘 要:在热传计算的基础上,采用锌粒子为前驱体、铝熔体为渗流体,通过氩气渗流制备通孔泡沫铝;对泡沫铝的制备、压缩性能及锌残余量进行研究。结果表明:滑石粉隔热层厚度与渗流时间之间的关系为x2= 7.35×10-8τ;优化的渗流工艺如下:渗流温度740 ℃、锌粒子预热温度220 ℃、锌粒子直径3 mm;平均孔径为3 mm的泡沫铝的屈服强度随孔隙率的增加而减小;孔隙率为63%和67%的泡沫铝的屈服强度都随孔径的增大而提高;泡沫铝孔隙率从60%提高到71%,锌残余量从11.3%降低到4.5%。

关键词:泡沫铝;渗流;热传导;制备;压缩性能

中图分类号:TF125.6;TQ427.6 文献标志码:A

Novel penetrating fabricating process and compression properties of aluminum foams with open cell

ZHANG Bin1,ZUO Xiao-qing1,SUN Yan-lin2,LU Jian-sheng1,ZHOU Yun1, WANG Hong3

(1. School of Materials Science and Engineering, Kunming University of Science and Technology,

Kunming 650093, China;

2. School of Chemical Engineering, Kunming University of Science and Technology, Kunming 650093, China;

3. School of Science, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: Based on the heat conduction calculation, Al foam with open-cell was fabricated by a new penetrating process which takes zinc particles as the precursor and presses Al melt into the precursor by Ar gas. The fabricating process, the compression properties and the residual zinc content were studied. The results show that the relationship between the thickness of talcum heat insulation layer and the infiltration time is x2= 7.35×10-8τ; the optimized procession parameters are deduced as the aluminum melt infiltration temperature of 740 ℃, the preheating temperature of zinc particles of 220 ℃, and the diameter of zinc particles of 3 mm; the yield strength of Al foam with the mean pore diameter of 3 mm decreases with the increase of porosities. Yield strengths of both Al foams with porosities of 63% and 67% rise with the increase of their cell diameters; when porosity increases from 60% to 71%,the residual Zn content in the Al foams reduces from 11.3% to 4.5%.

Key words: aluminum foam; infiltration; heat conduction; fabrication; compressive property

泡沫铝具有低密度、高能量吸收、阻尼减振、 吸音、耐高温、可回收等特性,在建筑、交通、机械、航天航空及噪音控制等行业都具有巨大的应用前 景[1-4]。

目前,通孔泡沫铝的制备方法主要有电沉积法[5]和渗流铸造法[6],前者采用泡沫塑料(如聚氨酯泡沫)、后者采用NaCl作为渗流前躯体,渗流后将泡沫塑料燃烧去除或将NaCl水溶除[7]。聚氨酯燃烧会产生氰化氢、一氧化碳和异氰酸酯等有害气体;而NaCl具有腐蚀性,易污染、腐蚀环境和泡沫铝[8-10]。

本文作者利用不同金属的熔点差异,采用较低熔点及表面涂覆滑石粉隔热层的锌粒子为渗流前驱体、较高熔点的铝熔体为渗流体,通过氩气加压渗流方法获得锌-铝复合体,复合体加热到锌熔点以上温度进行锌熔除后获得通孔泡沫铝。该方法具有成本低、前驱体材料可循环利用及不污染环境的优点。在传热计算的基础上,研究渗流温度、锌粒子预热温度及锌粒子直径对泡沫铝孔结构的影响,并对所制备泡沫铝的压缩性能和残余锌含量进行分析。

1 传热计算

该渗流方法的关键是渗流过程中锌粒子在一定厚度滑石粉隔热层的保护下不熔化,以保证渗流过程的顺利进行。为此,进行传热计算,以确定锌粒子表面滑石粉层的厚度。

1.1 物理模型

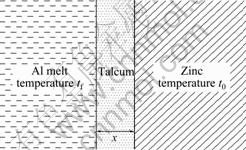

图1所示为热传导物理模型。铝液的热量通过滑石粉隔热层传递到锌粒子表面,渗流时间应小于锌粒子表面温度达到其熔点所需的时间。

图1 传热过程物理模型

Fig.1 Physical model of heat transfer process

为方便数学模型的建立,作如下假设:

1) 忽略渗流过程中渗流系统与环境间的热交换;

2) 锌粒子表面滑石粉涂敷均匀;

3) 导热系数和热扩散系数均为常数。

1.2 数学模型

1.2.1数学模型建立的方法及步骤

1) 依据能量守恒定律,建立空间直角坐标系中的热传导方程;

2) 边界条件的确定和求解;

3) 计算渗流时间和滑石粉层厚度的关系。

1.2.2热传导方程的建立

单位时间内进入滑石粉表面的能量Q1 等于单位时间内锌粒子和滑石粉的能量累积Q2,即

Q1 = Q2 (1)

Q1 = (2)

(2)

Q2= (3)

(3)

运用散度定理[11]将面积积分变换为体积积分:

Q1= (4)

(4)

式中:A为体积元dV的表面积;V为体积元dV的体积;n为面积元dA外法线方向上的单位向量;q(r, τ)为温度降低方向单位时间内的热流密度向量; 为

为

微分算子符号, ;r为涂有滑石粉锌

;r为涂有滑石粉锌

粒子内部的某一位置;ρ为锌的密度;cp为锌的定压比热容;负号表示热流方向指向体积元dV内部。

将式(3)和(4)代入式(1)整理得

(5)

(5)

利用傅里叶定律[12]将热流密度向量转换为导热系数和温度的关系:

(6)

(6)

将式(6)代入式(5)得到热传导方程:

(7)

(7)

式中:k为导热系数;a为热扩散系数, 。

。

将式(7)转换到空间直角坐标系中,得到

(8)

(8)

1.2.3边界条件的确定和求解

渗流过程中,滑石粉外表面温度从220 ℃(预热温度)突然变化到740 ℃(铝熔体温度)时,在滑石粉隔热层间形成热梯度,锌粒子表面温度t和渗流时间τ的关系为

t=f(τ) (9)

联立式(8)与式(9)并整理得:

, 0<x<∞, τ>0 (10)

, 0<x<∞, τ>0 (10)

t =f (τ), τ>0 (11)

, τ>0 (12)

, τ>0 (12)

, x≥0 (13)

, x≥0 (13)

式中:t0为锌粒子表面的初始温度;x为隔热层厚度。经拉普拉斯变换[13],将式(10)~(13)转换为x的函数,求解并进行拉普拉斯逆变换,得到

(14)

(14)

式中:tl为渗流铝液的温度;t ′为锌的熔点; 为误差函数。

为误差函数。

1.3 渗流时间和滑石粉厚度的关系

取t0=220 ℃,tl=740 ℃,t ′=418 ℃,a=1.5×10-7 m2/s[14],代入(14)得

(15)

(15)

查误差函数表得到

(16)

(16)

将a值代入式(16)整理得

x2=7.35×10-8 (17)

(17)

式(17)即为锌粒子表面滑石粉层厚度x和可利用的渗流时间τ的关系式。

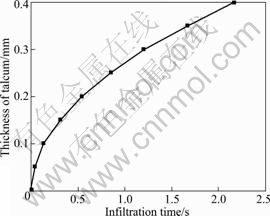

图2所示为式(17)的x—τ曲线。由图2可见,随

图2 滑石粉隔热层厚(x)与渗流时间(τ)的关系

Fig.2 Relationship between thickness of heat insulation layer of talcum and infiltration time

着渗流时间的增加,所需滑石粉层厚度增加。采用Ar气压渗流的时间通常小于0.5 s[15],0.5 s所对应的滑石粉厚度为0.19 mm。由此可知,在锌粒子表层涂有一定厚度滑石粉层的条件下,利用锌为前躯体进行渗流制备泡沫铝是可行的。

2 实验

2.1 渗流工艺

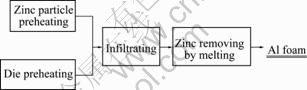

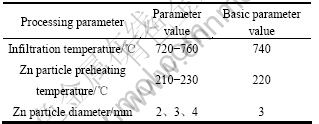

图3所示为渗流工艺流程。在氩气压力为5 MPa及滑石粉层厚度为0.19 mm的条件下,研究表1所列的渗流温度、锌粒子预热温度和锌粒子直径对泡沫铝孔结构的影响。

图3 渗流工艺流程图

Fig.3 Flow chart of infiltration process

表1 渗流工艺参数

Table 1 Experimental parameters of infiltration process

2.2 孔结构分析

线切割泡沫铝,对截面进行打磨、涂黑,用扫描仪采集图像,导入Photoshop进行二值化处理,然后利用BWJScan软件[16]计算泡沫铝的平均孔径和孔隙率。

2.3 压缩性能测试

将泡沫铝加工成d 34 mm×35 mm的圆柱体,在CSS-44100电子万能试验机上以1 mm/min的速度进行压缩实验,取σ0.2作为泡沫铝的屈服强度。

2.4 锌残余量分析

将泡沫铝重熔浇铸成形状规则的试样,利用混合法则计算泡沫铝的锌含量:

ρmix=7.14ω(Zn) +2.7(1-ω(Zn)) (18)

式中:ω(Zn)为泡沫铝中残余锌含量;ρmix为泡沫铝重熔试样的密度。

3 实验结果

3.1 泡沫铝的渗流制备

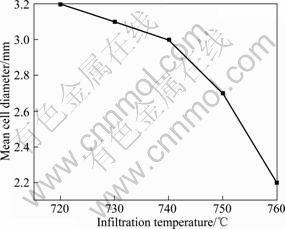

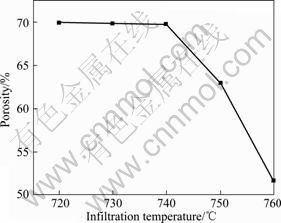

3.1.1渗流温度对泡沫铝孔结构的影响

图4和5所示分别为渗流温度对泡沫铝平均孔径和孔隙率的影响。由图4和5可见,随着渗流温度的提高,锌粒子因部分熔化而在渗流过程中熔失,造成锌粒子直径减小、平均孔径减小;同时,熔失的锌混入铝液并在渗流过程中凝固形成骨架,造成孔隙率降低。

图4 渗流温度对平均孔径的影响

Fig.4 Effect of infiltration temperature on mean cell diameter

图5 渗流温度对孔隙率的影响

Fig.5 Effect of infiltration temperature on porosity

当渗流温度较低时(720~740 ℃),滑石粉层的热障作用明显,锌粒子的完整性不会破坏,在此温度范围内,随着渗流温度的提高,铝熔体的粘度降低和流动性提高使铝熔体的充型能力提高,所以,孔径和孔隙率随渗流温度的提高而缓慢减小;当渗流温度较高时(740~760 ℃),滑石粉隔热层的热障作用减弱,过多的热量传递使锌熔化,致使孔壁增厚,孔径和孔隙率明显下降。

3.1.2锌粒子预热温度对泡沫铝孔结构的影响

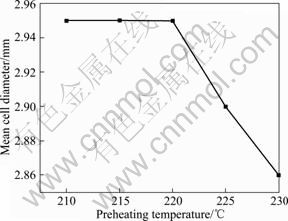

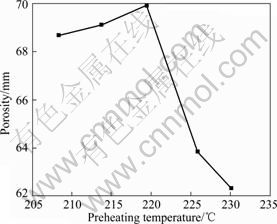

图6和7所示分别为锌粒子预热温度对泡沫铝平均孔径和孔隙率的影响。由图6和7可见,当锌粒子预热温度为210~220 ℃时,泡沫铝的平均孔径保持在2.95 mm,但孔隙率略有提高;当锌粒子预热温度为220~230 ℃时,随着预热温度的提高,铝液的流动性及充型能力提高,滑石粉层逐渐减薄,部分锌粒子表面出现熔化现象,使泡沫铝的孔径及孔隙明显减小。

图6 锌粒子预热温度对平均孔径的影响

Fig.6 Effect of preheating temperature of zinc particle on mean cell diameter

图7 锌粒子预热温度对孔隙率的影响

Fig.7 Effect of preheating temperature of zinc particle on porosity

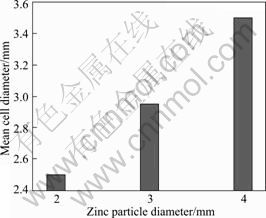

3.1.3锌粒子直径对孔结构的影响

图8所示为锌粒子直径对泡沫铝平均孔径的影响。由图8可见,当锌粒子直径为2 mm时,泡沫铝的平均孔径大于2 mm,为2.51 mm,?D =0.51 mm;当锌粒子直径为3 mm时,泡沫铝平均孔径小于3 mm,为2.95 mm, ?D =-0.05 mm;当锌粒子直径为4 mm时,泡沫铝平均孔径小于4 mm,为3.5 mm, ?D =-0.5 mm。

图8 锌粒子直径对平均孔径的影响

Fig.8 Effect of zinc particle diameter on mean cell diameter

当锌粒径为2 mm时,粒子间的间隙小,渗流阻力大、渗流不充分,使平均孔径大于2 mm、孔隙率也较高,但孔结构不完整;当锌粒径为4 mm时,粒子的间隙大、渗流阻力小,渗流充分,铝液和锌粒子间的热交换强烈而使热障层破坏,部分锌熔化,导致泡沫铝孔径小于4 mm;当锌粒径为3 mm时,粒子的间隙适中,在保证充分渗流的同时热障层破坏,锌熔化现象大大减弱,泡沫铝孔径与锌粒子直径大致相等。

3.2 泡沫铝的压缩性能

3.2.1 孔隙率对泡沫铝压缩性能的影响

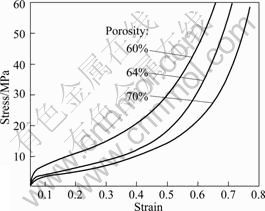

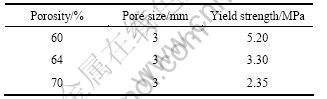

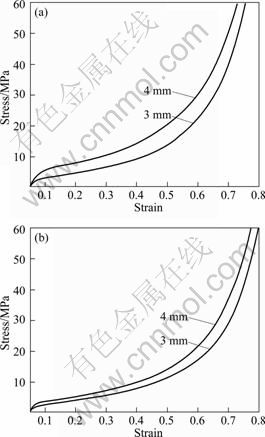

图9所示是孔径为3 mm,孔隙率分别为60%、64%和70%泡沫铝的压缩应力—应变关系曲线。由图9可以看出:随着孔隙率的提高,应变平台降低,且其压缩曲线为光滑曲线,没有明显的转折点。

表2所列为不同孔隙率泡沫铝的屈服强度。从表2可看到:对于相同孔径的泡沫铝,随着孔隙率的提高,泡沫铝的孔壁变薄,锌含量减少,泡沫铝的屈服强度减小,孔隙率为60%~70%泡沫铝的屈服强度为5.20~2.35 MPa。

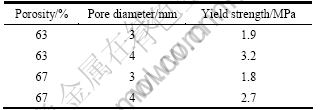

3.2.2 孔径对泡沫铝压缩性能的影响

图10所示是孔隙率为63%和67%,粒径为3和4 mm的泡沫铝应力—应变关系曲线;表3所列为相应

图9 孔径为3 mm和不同孔隙率泡沫铝的应力—应变关系曲线

Fig.9 Stress—strain curves of Al foams with different porosities and mean cell diameter of 3 mm

表2 不同孔隙率泡沫铝的屈服强度

Table 2 Yield strength of Al foam with different porosities

的屈服强度值。由图10和表3可以看出,在相同孔隙率情况下,泡沫铝的平台应变及屈服强度随泡沫铝孔径的增大而增大。

表3 相同孔隙率泡沫铝孔径对屈服强度的影响

Table 3 Effect of cell diameter of Al foams with same porosity on yield strength

在相同孔隙率下,孔径增加,则渗流时锌粒子之间的空隙增大,渗流阻力减小,渗流充分,泡沫铝的孔壁增厚,导致其屈服强度增大。

3.3 泡沫铝的锌残余量分析

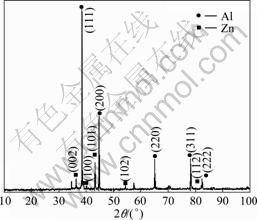

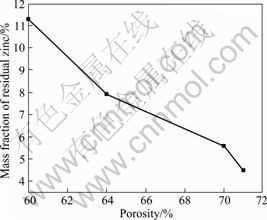

图11所示为泡沫铝基体的XRD谱。由图11可见,泡沫铝基体里残留了部分锌。图12所示为孔隙率分别为60%、64%、70%和71%的泡沫铝的锌残余含

图10 孔隙率为63%和67%时不同孔径泡沫铝的应力—应变关系曲线

Fig.10 Stress—strain curves of Al foam with different cell diameters and porosities of 63% (a) and 67% (b)

图11 泡沫铝基体的XRD谱

Fig.11 XRD pattern of aluminum foam matrix

量曲线。由图12可见:泡沫铝中的锌残余量随孔隙率的增大而降低;当孔隙率从60%增加到71%时,残余锌含量从11.3%降低到4.5%。

图12 孔隙率对泡沫铝基体锌残余量的影响

Fig.12 Effect of porosity on residual zinc content in Al foam matrix

锌粒子表面滑石粉涂覆不均匀及渗流熔体温度场的不均匀等因素使渗流过程中锌熔化,熔融锌和铝形成合金熔体,最终导致泡沫铝基体密度增加。

4 结论

1) 传热计算结果表明,随着渗流时间的延长,所需滑石粉层厚度增加,滑石粉隔热层厚度与渗流时间的关系式为x2=7.35×10-8τ。

2) 锌粒子前驱体渗流制备泡沫铝优化的工艺参数如下:渗流温度740 ℃,锌粒子预热温度220 ℃,锌粒子直径3 mm。

3) 孔径相同的泡沫铝的屈服强度随孔隙率的增大而减小。当孔径为3 mm、孔隙率为60%~70%时,泡沫铝的屈服强度为5.20~2.35 MPa;相同孔隙率泡沫铝的屈服强度随孔径的增大而增大。

4)泡沫铝中的残余锌含量随孔隙率的增加而降低。

REFERENCES

[1] BANHAR J. Manufacture, characterization and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46(6): 609-621.

[2] DVISE G J, ZHEN S. Metallic foams: Their production, properties and applications[J]. Journal of Materials Science, 1983, 18: 1899-1911.

[3] DUARTE B J. A study of aluminum foam formation kinetics and microstructure[J]. Acta Materialia, 2000, 48(9): 2349-2362.

[4] GIBSON L J, ASHBY M F. Cellular solids: Structure and properties[M]. Oxford: Pergamon Press, 1988: 283-343.

[5] BOONYONGMANEERAT Y, SCHUH C A, DUNAND D C. Mechanical properties of reticulated aluminum foams with electrodeposited Ni-W coatings[J]. Scripta Materialia, 2008, 59: 336-339.

[6] DESPOIS J F, MARMOTTANT A, SALVO L, MORTENSEN A. Influence of the infiltration pressure on the structure and properties of replicated aluminium foams[J]. Materials Science and Engineering A, 2006, 462: 68-75.

[7] K?D?R C, CHMEL?K F. Acoustic emission of metal foams during tension[J]. Materials Science and Engineering A, 2006, 462: 316-319.

[8] KESKIN M, BEYDES T, TOSUN Z, SAVACT N. Polyurethane spray foam burn[J]. Burns, 2008, 34(7): 1041-1043.

[9] XIAO Lin-wei, YANG Wang, DIAN Fu-liu, HONG Zhi-sheng. Influence of HCl on CO and NO emissions in combustion[J]. Fuel, 2009, 88: 1998-2003.

[10] GUSEVA O, SCHMUTZ P, SUTER T, von TRZEBIATOWSKII O. Modelling of anodic dissolution of pure aluminum in sodium chloride[J]. Electrochimica Acta, 2009, 54: 4514-4524.

[11] THOMAS G B. 托马斯微积分[M]. 北京: 高等教育出版社, 2003: 1147-1148.

THOMAS G B. Thomas’ calculus[M]. Beijing: Higher Education Press, 2003: 1147-1148.

[12] 齐民友. 重温微积分[M]. 北京: 高等教育出版社, 2004: 316.

QI Ming-you. Calculus review[M]. Beijing: Higher Education Press, 2004: 316.

[13] 沈永欢, 梁在中, 许履瑚, 蔡倩倩. 实用数学手册[M]. 北京: 科学出版社, 1992: 645-647.

SHEN Yong-huan, LIANG Zai-zhong, XU Lü-hu, CAI Qian-qian. Practical handbook of mathematics[M]. Beijing: Science Press, 1992: 645-647.

[14] ECKERT E R G, DRAKE R M. 传热与传质[M]. 北京: 科学出版社, 1963: 524-528.

ECKERT E R G, DRAKE R M. Heat and mass transfer [M]. Beijing: Science Press, 1963: 524-528.

[15] LEONG K C, JIN L W. Effect of oscillatory frequency on heat transfer in metal foam heat sinks of various pore densities[J]. International Journal of Heat and Mass Transfer, 2006, 49: 671-681.

[16] 左孝青, 廖明顺, 潘晓亮. VB和计算机图形学在多孔材料中的应用[J]. 金属热处理, 2006, 31( S): 98-101.

ZUO Xiao-qing, LIAO Ming-shun, PAN Xiao-liang. Application of VB and computer graphics in cellular materials[J]. Heat Treatment of Metals, 2006, 31(S): 98-101.

(编辑 陈卫萍)

基金项目:云南省人才培养项目(2006PY01-06);云南省国际合作项目(2006GH21); 云南省应用基础研究重点项目(2010CC004)

收稿日期:2010-03-14;修订日期:2010-07-12

通信作者:左孝青, 教授;电话:0871-6735058; E-mail:zxqdzhhm@hotmail.com