文章编号:1004-0609(2007)09-1486-04

激光冲击工艺对钛合金疲劳寿命的影响

任旭东1,张永康1, 2,周建忠1,顾永玉1,张新权1

(1. 江苏大学 机械学院 光子制造科学与技术省重点实验室,镇江 212013;

2. 华东理工大学 机械与动力工程学院,上海 200237)

摘 要:研究激光加工工艺对Ti6Al4V航空钛合金叶片表面粗糙度和残余应力的影响,并分析影响表面质量的激光加工工艺参数;探讨表面粗糙度和表面残余应力对叶片疲劳寿命的影响。结果表明,采用激光冲击航空叶片,叶片表面残余压应力大大增强,从而使得其抗疲劳破坏能力增强,而表面粗糙度减小;在激光脉冲功率允许的范围内,选择合适的冲击参数能有效降低叶片表面粗糙度,而表面残余压应力对疲劳寿命的影响起主导作用。

关键词:激光冲击;残余应力;表面粗糙度;疲劳寿命

中图分类号:TG 156 文献标识码:A

Influence of laser-shock processing on fatigue life of titanium alloy

REN Xu-dong1, ZHANG Yong-kang1, 2, ZHOU Jian-zhong1, GU Yong-yu1, ZHANG Xin-quan1

(1. Jiangsu Key Laboratory of Laser Manufacture Science and Technology Ministry, Jiangsu University, Zhenjiang 212013, China;

2. School of Mechanical and Power Engineering, East China University of Science and Technology, Shanghai 200237, China)

Abstract: The influence of laser shock processing on surface residual stress and roughness of the titanium alloy Ti6Al4V during laser shock processing was analyzed, and the effects of the surface residual stress and roughness on aircraft structures fatigue life were investigated by the theory of fracture dynamics. The results show that with the logical parameters of laser shock processing on the aircraft structures, the higher laser power density, the greater compressive residual stress on the surface of the sample is obtained. And the surface roughness could be descent by the correct selecting laser shock parameters. Near the surface, the yield strength is increased by the laser shock, and the compressive residual stress is the main factor to enhance the fatigue life of the titanium alloys.

Key words: laser shock processing; residual stress; surface roughness; fatigue life

飞机发动机叶片的工作条件非常恶劣,在高速运转中由于高频振动使叶片承受交变应力,使得叶片表面粗糙,在叶盆部分有肉眼可见的麻点和腐蚀坑,这些都是断裂的疲劳源,有的叶片能看到多个裂纹源。因此,在性能先进的航空发动机上,叶片都采用了性能优异但价格十分昂贵的钛合金材料以及复杂的定向凝固叶片和单晶叶片等制造工艺,但钛合金本身的低耐磨性和低耐腐蚀性限制了其使用范围。在发动机的使用过程中,叶片与热端部件是薄弱环节,为了有效提高航空发动机的工作可靠性和经济性,先进的叶片强化技术日益受到发动机用户和修理单位的重视,并获得了广泛的应用。

激光冲击强化技术是以提高金属材料表面硬度、耐磨性、抗蚀性和抗高温氧化性为目的的技术,由于高能量激光与材料相互作用时间非常短(ns级),并伴随有辐射、固化、分子取相及可能的结晶等物理变化,可以为材料表面强化提供一种新的技术手段[1?3]。国内外许多学者研究了表面强化对疲劳寿命的影响[4?10],但对激光冲击波加载下金属板料的疲劳寿命研究很少。本文作者以发动机叶片为研究对象,通过对钛合金叶片的激光冲击处理,探讨叶片表面的粗糙度和残余应力变化,对采用激光冲击工艺的钛合金疲劳寿命性能进行了分析研究。

1 激光冲击实验

采用的航空发动机叶片材料为Ti6Al4V优质钛合金,其具有复合弯扭、复杂型面和圆弧榫齿的特征,具有现代航空涡扇和涡喷发动机高压缩器、压气机叶片和风扇叶片所需的性能。对叶片激光冲击处理前在叶片的待冲击表面涂覆涂层,涂层的作用为:1) 提高叶片被处理表面对激光的吸收率;2) 保护叶片被加工表面。采用自主研制的硅酸乙脂黑漆涂层将试样涂黑,在试样表面形成均匀致密的增吸薄膜,使其对激光能量的吸收率大于98%,且有效地保护了叶片被加工表面。

实验在高功率钕玻璃激光强化系统上进行。激光输出波长为1.054 μm,以d 8 mm×200 mm的磷酸盐钕玻璃棒作振荡级激光棒,一级磷酸盐钕玻璃激光预放大级(d 14 mm×350 mm),四级磷酸盐钕玻璃激光主放大级(分为二路,每路光束由d 16 mm× 350 mm及d 20 mm×350 mm两根钕玻璃棒串联)。

2 激光冲击对残余应力的影响

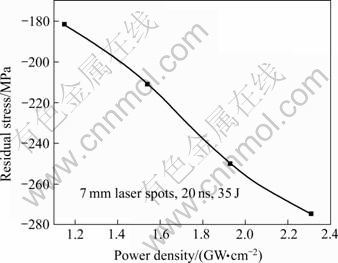

激光冲击实验后采用河北爱斯特应力技术有限公司的X?350A型X射线应力分析仪对Ti6Al4V钛合金试样进行残余应力测定,为了提高测量精度采用侧倾固定ψ法测量残余应力。不同激光功率密度下处理试件的残余应力结果见图1。可以看出,随着激光脉冲功率密度的增大,表层最大残余应力相应增大。

图 1 不同激光功率密度下的Ti6Al4V合金表面残余应力 分布

Fig.1 Surface residual stress distributing in Ti6Al4V alloy with different power densities

残余应力的产生是冲击压力和相变应力共同影响的结果。两种应力分布叠加时就造成表层最终为压应力状态, 即外压内拉状态。这是因为激光冲击作用使吸收涂层气化形成等离子体爆炸,产生的高压冲击波分别向金属靶和约束层中传播,传向靶中的高压冲击波对金属靶起到强化和变形作用。实验中硅酸乙脂有机溶剂涂层激光吸收率高,与激光能量的耦合性能较好,在冲击过程中形成的等离子能高效产生高压冲击波,故表面残余压应力大大提高,效果明显。

当激光冲击引起叶片表层材料塑性变形时,与表层相邻的次表层材料也将由于表层变形而变形。但与表层相比较,次表层的变形程度较小,未达到该材料屈服点而保持弹性变形状态,因此,表层与次表层的这种不均匀塑性变形,能引起材料受激光冲击后的残余应力场(即应力分布)的改变。实验表明,激光冲击后表层呈现残余压应力,而在一定深度的次表层则为拉伸应力。表层的残余压应力可比次表层的拉伸应力高出数倍。这种残余应力分步模式有利于疲劳强度和抗应力腐蚀性能的提高。叶片根处的激光冲击尤为重要,通过激光冲击,增加表面残余压应力,使表面实际承受的交变拉应力水平降低,提高抗疲劳性能,避免裂纹的生成。

3 激光冲击对表面粗糙度的影响

航空叶片的表面加工要求一定的精度和表面质量,表面质量除了与残余应力相关外,还与表面粗糙度、划痕、磨痕以及显露在表面的各种缺陷有关。激光冲击后叶片表面形貌如图2所示。不同的表面粗糙度对叶片的疲劳强度有明显的影响,表面越粗糙,其疲劳强度越低。在相同的情况下,疲劳极限下降的幅度会更大,这主要归因于疲劳裂纹过早地在表面加工纹路的凹槽处萌生。

图2 激光冲击后叶片的表面形貌

Fig.2 Samples of Ti6Al4V alloy after successive laser shock processing: (a) Surface panorama; (b) Magnification of part

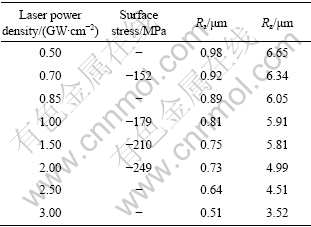

表面粗糙度是表面微观形状误差,是加工过程中产生的微观不平度,其评价参数常用Ra (轮廓算术平均值)和Rz (微观不平度加上点高度)表示。激光冲击所产生的表面粗糙度用英国产Tayior 5M 型表面轮廓仪检测,整个试样的粗糙度为2~4 个测量结果的算术平均值。由表1可以看出,随着激光冲击功率的提高,钛合金表层最大残余应力相应增大, 而且其粗糙度减小。这是由于在激光冲击处理过程中,表层金属发生塑性流动,使金属表面的不平度减小,并减轻了加工造成的刀痕、划伤和类裂纹,使得表面粗糙度变小。激光冲击功率越高,激光冲击波产生的冲击效果越强,当激光冲击功率超过1 GW/cm2后,随着激光功率的进一步提高,加工表面粗糙度的降低并不明显,从而对钛合金表面疲劳寿命的影响越来越小。因此合理选择激光冲击功率有利于改善钛合金工件的加工表面质量。

表1 激光冲击功率对Ra/Rz的影响

Table 1 Effect of laser shock power density on surface roughness Ra/Rz

4 表面质量对疲劳寿命的影响

叶片的疲劳寿命直接影响着飞机的可靠性和安全性,而加工表面质量又是影响叶片疲劳寿命的关键所在。在零件尺寸和材料性能一定的情况下,加工工艺是影响表面质量的重要因素。根据断裂力学原理,表面粗糙度值越大,切口效应就越大,即应力集中系数越大,故疲劳性能越差。因为机械加工表面总是存在高低不平的加工痕迹(如刀痕、裂痕),这些痕迹就相当于许多微小缺口,结果使得零件工作表面上形成应力集中。零件加工后的表面可看作由无数微观缺口组成,这些粗糙不平的缺口可以视作微小的疲劳裂纹,根据EI Haddad[11]等提出的修正关系能计算出短裂纹或表面粗糙度的疲劳极限为

由式(1)可知,粗糙度波谷越深,曲率半径越小,越容易形成应力集中。表面粗糙度越大,疲劳极限应力越小,越容易形成疲劳断裂,疲劳寿命越低;反之,疲劳寿命越高。

但是激光冲击在叶片表面形成了高残余压应力,在高残余压应力下,表面粗糙度将微动局限于微凸体峰顶,而且激光冲击产生的残余压应力分布较深,能抑制裂纹的萌生和扩展。残余压应力使疲劳裂纹的萌生和扩展减缓,从而提高了试件的疲劳寿命。

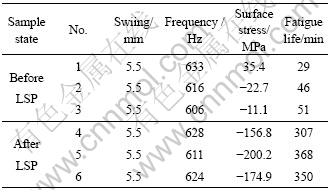

与此同时,激光处理提高了试件表面硬化层的塑变抗力,使材料的疲劳强度得以提高。当材料疲劳强度与试件表面承受应力的比值大于1时,就能大大降低疲劳裂纹形成的机率[12]。可见残余压应力可降低疲劳裂纹的扩展速率,也即能提高试件的疲劳裂纹扩展抗力。表2列出了激光冲击前后的叶片高频疲劳寿命。

表2 激光冲击强化前后叶片高频疲劳寿命

Table 2 Fatigue lifes of blades before and after laser shock processing

5 结论

1) 激光冲击钛合金叶片过程中,由于激光冲击功率的提高,钛合金表层最大残余应力相应增大,其粗糙度也相应变小。在本实验条件下,激光功率密度达到1 GW/cm2时,其表面质量达到最优值,激光功率超过1 GW/cm2时,由于逆轫辐射效应的增强,激光冲击对钛合金表面质量的效果提高越来越小。

2) 激光冲击在叶片表面形成了高残余压应力,能抑制裂纹的萌生和扩展,使材料的疲劳强度得以提高,使疲劳裂纹的萌生和扩展减缓,从而提高了试件的疲劳寿命。

REFERENCES

[1] Hackel L A, Chen H L. Laser peening—A processing tool to strengthen metals or alloys to improve fatigue lifetime and retard stress-induced corrosion cracking[J]. Laser Science and Technology, 2003(S1): 487.

[2] 任旭东, 张永康. 航空铝合金材料的两种表面冲击加工技术的比较[J]. 金属热处理, 2004, 29(11): 37?39.

REN Xu-dong, ZHANG Yong-kang. Comparison of two kinds of laser shock processing for aerospace aluminum alloys[J]. Heat Treatment of Metals, 2004, 29(11): 37?39.

[3] Montross C S, Tao Wei, Lin Ye, et al. Laser shock processing and its effects on microstructure and properties of metal alloys: A review[J]. International Journal of Fatigue, 2002, 24: 1021? 1036.

[4] 杜百平, 李 年, 马宝钿, 朱维斗. 疲劳损伤钢件延寿机理及效果[J]. 机械强度, 2006, 28(1): 40?45.

DU Bai-ping, LI Nian, MA Bao-tian, ZHU Wei-dou. Mechanism of prolonging life and effect for fatigue damaged steel specimens[J]. Journal of Mechanical Strength, 2006, 28(1): 40?45.

[5] 胡志忠, 曹淑珍. 表面粗糙度对构件疲劳强度影响的预测[J]. 西安交通大学学报, 1995, 29(6): 90?95.

HU Zhi-zhong, CAO Shu-zhen. The prediction of fatigue strengthen for component surface roughness[J]. Journal of Xi’an Jiaotong University, 1995, 29(6): 90?95.

[6] 何家文. 表层强度及其对疲劳的影响[J]. 金属热处理学报, 1997, 18(3): 61?64.

HE Jia-wen. Surface Strength and its effect on fatigue[J]. Transactions of Metal Heat Treatment, 1997, 18(3): 61?64.

[7] 任旭东, 张永康, 周建忠, 等. 激光参数对Ti-6Al-4V激光冲击成形性能的影响[J]. 中国有色金属学报, 2006, 16(11): 1850?1854.

[8] REN Xu-dong, ZHANG Yong-kang, ZHOU Jian-zhong, et al. Study of the effect of coatings on mechanical properties of TC4 titanium alloy during laser shock processing[J]. Materials Science Forum, 2006, 532?533: 73?76.

[9] 杨建阳, 左敦稳, 黎向锋, 等. 激光冲击成形TA2钛合金板的变形与残余应力[J]. 南京航空航天大学学报, 2005, 37(增刊): 31?35.

YANG Jian-yang, ZUO Dun-wen, LI Xiang-feng. Deformation and residua stresses of titanium alloy TA2 sheet after laser shock forming[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2005, 37(Sl): 31?35.

[10] 高长伟, 黎向锋, 左敦稳, 等. TC4 钛合金板激光冲击成形实验研究[J]. 应用激光, 2005, 25(3): 158?160.

GAO Chang-wei, LI Xiang-feng, ZUO Dun-wen. The experimental study on the laser shock forming of TC4 titanium alloy sheet[J]. Applied Laser, 2005, 25(3): 158?160.

[11] EI Haddad M H, Topper K J, Pook L P. Metal fatigue[M]. London: Oxford University Press, 1974: 130?195.

[12] 王淑琴, 王静宜. 激光硬化处理对34CrNiMo钢疲劳强度的影响[J]. 兵器材料科学与工程, 1997, 20(4): 29?34.

WANG Shu-qin, WANG Jing-yi. Effect of laser hardening treatment on fatigue strength of 34CrNiMo steel[J]. Ordnance Material Science and Engineering, 1997, 20(4): 29?34.

基金项目:江苏省“六大人才高峰”第三批资助项目(06-D-023); 江苏省高校自然科学研究资助项目(07KJB460012)

收稿日期:2006-09-07;修订日期:2007-06-19

通讯作者:任旭东,讲师;电话:0511-88797898;E-mail: renxd@ujs.edu.cn

(编辑 陈爱华)