文章编号:1004-0609(2012)1-0194-07

钢芯铝绞架空导线微动疲劳断口形貌

王 煦1,陈国宏2,王家庆2,张建堃1,张 涛2,徐光青1,汤文明1

(1. 合肥工业大学 材料科学与工程学院,合肥 230009;2. 安徽省电力科学研究院 材料所,合肥 230601)

摘 要:在自制的微动疲劳试验装置上进行钢芯铝绞导线 (ACSR) 的微动疲劳试验,采用扫描电子显微镜观察分析内、外层铝股线断口特征,研究其微动疲劳断裂机制。结果表明:铝股线的断股大多发生于导线与线夹的最后接触点处。微动振幅为1.0 mm时,在较低循环周次下(1.6×107),铝股线只发生正断;随着循环次数增加,铝股线断股数量增加,且发生45°及“V”形断裂。铝股线疲劳断口由疲劳源区、疲劳裂纹扩展区、瞬断区构成,呈现弯曲疲劳和扭转疲劳两种不同的断裂方式。

关键词:钢芯铝绞导线;微动疲劳;疲劳断裂

中图分类号:TH117.3 文献标志码:A

Fretting fatigue fractographies of

aluminum conductor steel reinforced overhead conductor

WANG Xu1, CHEN Guo-hong2, WANG Jia-qing2, ZHANG Jian-kun1,

ZHANG Tao2, XU Guang-qing1, TANG Wen-ming1

(1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. Materials Department, Anhui Electric Power Research Institute, Hefei 230601, China)

Abstract: Fretting fatigue experiment of the aluminum conductor steel reinforced (ACSR) conductor was carried out using a conductor fretting fatigue testing equipment. The fractographies of the external and internal Al strands of the ACSR conductor were analyzed using scanning electron microscope (SEM), and the fracture mechanisms of the Al strands after fretting fatigue were also discussed. The results show that the Al strands mostly rupture at the last contact points of the conductor on the suspension clamp. Under the condition of the fretting amplitude equal to 1.0 mm, only the plane fracture of the Al strands takes place at low fretting cycles of 1.6×107. As the fretting cycles increasing from 1.6×107 to 2.6×107, the number of the broken Al strands increases, and new facture modes, i.e. the 45° and “V”-type fractures, are detected. All fatigue fracture surfaces of the Al strands consist of three regions, e.g. the fatigue source region, the fatigue crack extension region and the instant fracture region, respectively. Two fatigue fracture mechanisms of the Al strands, such as the bending fatigue and the torsional fatigue, are also revealed.

Key words: aluminum conductor steel reinforced conductor; fritting fatigue; fatigue fracture

架空导线是高压输电线路的主体,目前,国内外高压输配电网架空导线主要是钢芯铝绞导线(Aluminium conductor steel reinforced,ACSR)。世界范围的架空导线已服役25~40年,处于其寿命的中 期[1]。由于架空导线长期处于野外露天之下,经受风、雨、冰雪等恶劣的自然条件,容易发生各种事故,在役架空导线的维护和更新任务繁重[2-3]。如何对在役架空导线的运行状况进行科学评估,成为输电工程及管理的一个研究热点。

一般认为,风致振动导致导线内部股线之间、导线与线夹之间的微幅滑移和交变应力,由此产生微动磨损,继而引发疲劳裂纹的萌生和扩展是造成导线损伤,降低导线使用寿命的主要原因[4]。在线夹接触区附近,ACSR导线弯曲程度最大,且承受导线自身质量产生的轴向载荷及线夹的夹紧力作用,导致微动磨损;同时,导线的微动疲劳裂纹从微动磨损斑内形 核、扩展,最终导致线股断裂、失效[5-7]。

虽然国内外已开展ACSR导线微动疲劳研究[1-7],但通过对铝股线微动疲劳断口及受力状态分析,研究铝股线微动疲劳断裂机制的研究还未见报道。本文作者采用自制设备开展导线微动疲劳试验,通过对导线铝股线微动疲劳断口形貌进行观察分析,结合铝股线断股前后的受力状态分析,探讨ACSR导线的微动疲劳断裂机制。

1 实验

本研究选用LGJ150/20型ACSR导线,该导线是由24股直径为2.78 mm的 LY9硬铝线(铝含量(质量分数)≥99.5%,抗拉强度170 MPa)[8]和7股直径1.8 mm的A级镀锌钢绞线(抗拉强度大于1 270 MPa)[9]绞制而成;铝线分两层缠绕,外层15股、内层9股铝线,中心为7股钢芯线。自制的导线微动疲劳装置如图1(a)所示。导线采用带U型螺栓的XGU-3型可锻铸铁悬垂线夹夹持,线夹上方由压板固定,2个U 型螺栓通过压板将导线夹持在线夹中,施加在U型螺栓上的扭矩为常数。该导线、线夹系统如图1(b)所示。导线2个固定端间的水平距离为5 m,导线与水平方向夹角为10°(与导线的实际架设角度一致),导线振动由固定在电动机轴上的偏心轮转动带动悬垂线夹上下往复运动来实现。悬垂线夹处导线的振幅由偏心轮的偏心距大小调节,振动频率由电机变频器调节。导线的轴向静载荷通过微动装置端部弹簧加载系统施加,静载拉力由拉力传感器测量。试验参数参照相关文献[10],设定为:导线轴向静载荷为51 MPa(导线额定抗拉强度的25%),振动频率为10 Hz,振幅1.0 mm。导线微动循环振动周次依次为1.6×107、2.0×107和2.6×107。采用Zeiss EVO MA15型扫描电子显微镜(SEM)对铝股线疲劳断口及其微动磨损区进行观测;同时,在铝股线的磨损区域取样,其截面经研磨、抛光后用10% NaOH水溶液腐蚀,用SEM观察截面形貌。

图1 ACSR导线微动疲劳试验设备及悬垂线夹系统结构图

Fig. 1 Schematic illustrations of fretting fatigue equipment and structure of suspension clamp system: (a) Fretting fatigue equipment; (b) Structure of suspension clamp system (unit: mm)

2 结果与讨论

2.1 ACSR导线微动疲劳断裂状态

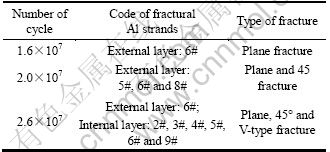

一般来说,导线的微动磨损区域分为微动粘着区、微动滑移区和微动混合区,各微区的位置关系见图1(b)。铝股线间及铝股线与钢芯线微动接触斑的形貌与结构见文献[11],在此不再赘述。注意到ACSR导线微动疲劳试验结果的分散性,经多次重复实验后,总结研究结果表明:ACSR导线微动1.6×107周次后,铝股线断股位置一般位于导线与线夹最后接触点处。不同微动周次下铝股线断股的数量、形态及分布情况如表1所列。经历2.6×107周次微动,出现多根内外层铝股线的断裂(见图2(a)),各断口在截面上所处位 置见图2(b)和2(c)。

2.2 铝股线微动疲劳断口特征

内外层铝股线断口分别呈现正断、45°断及“V”形断3种不同形态特征(见图3)。但不论呈何种断口形态,内外层铝股线都具有典型的微动疲劳断口特征,即由疲劳源区、疲劳裂纹扩展区、瞬断区3个微区构成,如图3(a)的微区A、B和C所示。

表1 铝股线的断股及断裂类型

Table 1 Code and type of fractural Al strands

2.2.1 疲劳源区

图3(a)中的微区A为疲劳源区。疲劳源区是疲劳裂纹的萌生区,由局部应力集中引起。在导线微动过程中,已接触区与未接触区边界是高应力区[12],对应于导线微动混合区的最后接触点位置(见图1(b))。此处的微动磨损表面分布大量径向裂纹,是最容易发生铝线股疲劳断裂的区域[11]。

在图4(a)中导线微动混合区磨损表面以下,依次为磨屑层、微动暗层及塑性变形层。通常白(暗)层是构件摩擦磨损过程重要的组织特征,在钢的磨损中称为白层;而对于铝材来说,在常规侵蚀剂下一般呈暗色,称之为暗层[10,13]。暗层具有非侵蚀性、高硬度等特征,其中的高密度微裂纹促使磨屑的形成[14];部分较大裂纹则穿过暗层和塑性变形层,深入到铝股线中,形成扩展裂纹。图4(a)中箭头所示的扩展裂纹长度约为50 μm,微动疲劳裂纹已萌生[10, 15]。

图2 微动断股ACSR导线的整体和横截面示意图

Fig. 2 General and cross-sectional illustrations of fretted ACSR conductor: (a) General illustration; (b) Cross-sectional illustration at fracture 1; (c) Cross-sectional illustration at fracture 2

图3 铝股线断口的SEM像

Fig. 3 SEM images showing three typical fractographies of Al strands: (a) Plane fracture of external 6# strand; (b) 45° fracture of internal 5# strand; (c) V-type fracture of internal 6# strand

图4(b)所示为疲劳源区Ⅰ型裂纹[4]。在表面摩擦力(切向载荷)和外加载荷(正向载荷)共同作用下,Ⅰ型裂纹沿45°方向扩展,扩展深度达到40 μm。因表面摩擦力随深度增加逐渐衰减,并逐渐衰减为0;此时,在外加载荷单独作用下该裂纹偏转,促使Ⅱ型裂纹的形成[12]。

图4 微动磨损面下亚表层形貌

Fig. 4 Cross-sectional images of sublayer under fretting wear surface: (a) Dark layer; (b) Fatigue crack

2.2.2 裂纹扩展区

在导线微动过程中,铝股线经历高周次的应力循环,疲劳裂纹经过反复闭合与张开,缓慢向导线内部扩展。裂纹扩展区(图3中的微区B)是铝股线断口最重要的特征区域,其典型特征是贝纹线和疲劳辉纹(见图5(a)和5(b))。

贝纹线是疲劳断口的主要宏观特征。一般认为,贝纹线是疲劳裂纹扩展过程中线股承受载荷剧烈变化引起的[16]。因本研究中ACSR导线的微动疲劳试验是由固定在电动机轴上的偏心轮转动带动悬垂线夹做上下往复运动来实现,当导线与线夹运动到最高点时,导线所受载荷最大;相反,当导线与线夹运动到最低点时,导线所受载荷最小(即为外加载荷)。这造成导线中的铝股线所受载荷发生周期性的变化,导致在铝股线微动疲劳断口上出现贝纹线(见图5(a))。

疲劳辉纹是疲劳断口的主要微观特征,表现为一系列弯曲呈波浪形并基本相互平行的条纹(见图5(b)),其弯曲凸面指向裂纹扩展方向,如图5(b)中箭头所示。

图5 疲劳裂纹扩展区形貌

Fig. 5 SEM images of fatigue crack extension region: (a) Cowrie pattern lines; (b) Fatigue striations

2.2.3 瞬时破断区

瞬时破断区(图3中微区C)是微动疲劳铝股线最后断裂的区域,是疲劳裂纹失稳扩展后形成的塑性断口,呈现大量的韧窝结构(见图6)。

图6 瞬时断裂区断口上的韧窝

Fig. 6 Dimples in instant fracture region

2.3 铝股线微动疲劳断裂机制

由表1和图3可见,在较低的循环周次下(1.6×107),铝股线只发生正断;随循环次数增加,铝股线断股数量增加,并出现了45°及“V”形断口。铝股线正断断口的疲劳源区都位于内外层铝股线接触点处或最外层铝股线与线夹的接触点处;而45°及“V”形断口疲劳源都位于同层铝线股的侧接触处,该结果与文献[17]的结论相吻合。当内外层铝股线断裂后,剩余铝股线的受力状态发生改变,引起其疲劳断裂方式的改变。微动状态下,铝股线的疲劳断裂具有弯曲疲劳断裂及扭转疲劳断裂[16]两种类型。

2.3.1 弯曲疲劳断裂

ACSR导线承受微动载荷时,导线与线夹最后接触点处的铝股线承受弯曲疲劳载荷[4],其中外层铝股线表面的疲劳应力最大,疲劳源在磨损表面形成,然后沿垂直于轴向应力的方向扩展,当疲劳裂纹尺寸达到临界尺寸后,铝股线发生瞬时破断,形成弯曲疲劳断口。铝股线弯曲疲劳又可分为单向弯曲、双向弯曲以及旋转弯曲疲劳3种。

如图2(b)所示,外层6#铝股线在与线夹接触处受到较大的弯曲拉应力,疲劳源在接触点处产生,因先前微动磨损产生较深磨损坑,磨损坑底部应力集中大,疲劳裂纹迅速扩展,形成如图3(a)图所示的单向弯曲疲劳断口,其瞬时破断区在疲劳源正对侧,所占面积达到整个断口面积的40%。

双向弯曲疲劳断口如图7(a)所示。内层9#铝股线因距离最后接触点位置较远,两侧面与外层14#及钢芯线股接触(见图2(b)),在微动过程中的拉、压交变应力作用下,在接触面间发生微动磨损,形成疲劳源;因两侧面的受力状态基本相同,两侧疲劳裂纹同时萌生,并向铝股线内部扩展,发生正断,瞬时破断区在断裂面中部。

图7 铝股线弯曲疲劳断口的SEM像

Fig. 7 SEM images showing bending fatigue fractographies of Al strands after fretting for 2.0×107 cycles: (a) Dual bending fatigue (internal 9# strand); (b) Rotating bending fatigue (external 8# strand)

旋转弯曲疲劳断口如图7(b)所示。当ACSR导线微动2.0×107次后,外层8#铝股线在外层5#铝股线断裂之后发生断裂(见图2及表1)。当外层5#铝股线断裂之后,导线的整体受力平衡被打破,导致导线发生一定角度旋转。在随后的微动过程中,外层8#铝股线在弯曲载荷和导线旋转共同作用下,发生疲劳断裂,瞬时破断区不在疲劳源正对面,而是偏转了一个角度,形成旋转弯曲疲劳断口。

2.3.2 扭转疲劳断口

当ACSR导线微动2.6×107次后,内层5#、6#铝股线在外层6#、内层4#铝股线断裂之后发生断裂。因此时已有较多铝股线断裂,导线整体受力状态发生了大的变化,剩余铝股线承受较大扭矩作用[1],铝股线承受沿径向线性分布的剪应力,且在与轴线成45°的斜面上有最大拉应力[18]。

内层5#铝股线与邻近的同层铝股线间发生侧接触磨损,疲劳源形成于长条形磨损斑下(见图3(b))。裂纹在此次处萌生后沿最大拉应力方向扩展,形成与轴线成45°夹角的倾斜断口,瞬断区位于疲劳源对侧(见图8(a))。而内层6#铝股线在反复扭转应力作用下,在与邻近的同层铝股线间侧接触位置形成多个疲劳源,在拉应力作用下,各疲劳源的疲劳裂纹都沿与轴线成45°角的方向,以螺旋状向中心扩展,当裂纹扩展到一定深度时,铝股线在中心部位发生瞬时断裂,形成具有棘轮状花样的放射形断口,或“V”形断口(见图8(b))。

3 结论

1) ACSR导线微动疲劳过程中,内外层铝股线断股都发生在高应力区,即导线与线夹的最后接触点处,该处铝股线严重的微动磨损易促使疲劳裂纹萌生和扩展,最终导致铝股线断裂。

2) 导线断口呈现正断口、45°断口和”V”形断口3种形态,断口由疲劳源区、疲劳裂纹扩展区及瞬断区3个特征区域构成。

3) 外层铝股线与线夹最后接触点处微动磨损最为严重,疲劳裂纹最早萌生,在反复弯曲应力下较早发生单向弯曲疲劳断裂、双向弯曲疲劳断裂及旋转弯曲疲劳断裂。弯曲疲劳断裂形成正断断口。

图8 铝股线扭转疲劳断口的SEM像

Fig. 8 SEM images showing torsional fatigue fractographies of Al strands after fretting for 2.6×107 cycles: (a) Internal 5# strand; (b) Internal 6# strand

4) 大量铝股线断股后,ACSR导线受力发生变化,导线旋转,产生扭矩,在微动载荷和扭矩力偶作用下,内层铝股线易发生扭转疲劳断裂,形成45°断口和”V”形断口。

REFERENCES

[1] AZEVEDO C R F, HENRIQUES A M D, PULINO F A R. Fretting fatigue in overhead conductors: Rig design and failure analysis of a Grosbeak aluminium cable steel reinforced conductor[J]. Engineering Failure Analysis, 2009, 16: 136-151.

[2] FERGUNSON J M, GIBBON R R. Overhead transmission lines-refurbishment and developments[J]. Power Engineering Journal, 1994, 8: 109-118.

[3] AGGARWAL R K, JOHNS A T, JAYASINGHE J A S B, SU W. An overview of the condition monitoring of overhead lines[J]. Electr Power System Research, 2000, 53: 15-22.

[4] OUAKI B, GOUDREAU S, CARDOU A, FISET M. Fretting fatigue analysis of aluminium conductor wires near the suspension clamp: Metallurgical and fracture mechanics analysis [J]. Journal of Strain Analysis, 2003, 38: 133-146.

[5] ZHOU Z R, CARDOU A, GOUDREAU S. Fundamental investigations of electrical conductor fretting fatigue[J]. Tribology International, 1996, 29: 221-232.

[6] AZEVEDO C R F, CESCON T. Failure analysis of aluminum cable steel reinforced (ACSR) conductor of the transmission line crossing the Parana River[J]. Engineering Failure Analysis, 2002, 9: 645-664.

[7] 陈 荐, 黄志杰, 李录平. 架空导线微动磨损表面的微观分析[J]. 润滑与密封, 2004, 29(6): 24-26.

CHEN Jian, HUANG Zhi-jie, LI Lu-ping. Microanalysis on fretting wear surface of overhead electrical conductors[J]. Lubrication Engineering, 2004, 29(6): 24-26.

[8] GB/T 17048—1997. 架空绞线用硬铝线[S]. 1997.

GB/T 17048—1997. Hard-drawn aluminium wire used in overhead ACSR conductor[S]. 1997.

[9] YB/T 5004—2001, 镀锌钢绞线[S]. 2001.

YB/T 5004—2001, Galvanized stranded wire[S]. 2001.

[10] 周仲荣, VICENT L. 微动磨损[M]. 北京: 科学出版社, 2002.

ZHOU Zhong-rong, VICENT L. Fretting wear[M]. Beijing: Science Press, 2002.

[11] 陈国宏, 王家庆, 张建堃, 汤文明. 钢芯Al绞导线架空导线微动磨损行为[J]. 润滑与密封, 2010, 35(5): 55-59.

CHEN Guo-hong,WANG Jia-qing, ZHANG Jian-kun, TANG Wen-ming. Fretting wear behavior of overhead ACSR conductor[J]. Lubrication Engineering, 2010, 35(5): 55-59.

[12] 何明鉴. 机械构件的微动疲劳[M]. 北京: 国防工业出版社, 1994.

HE Ming-jian. Fretting fatigue of mechanical components[M]. Beijing: National Defense Industry Press, 1994.

[13] ZHOU Z R, SAUGER E, LIU J J, VINCENT L. Nucleation and early growth of tribologically transformed structure (TTS) induced by fretting [J]. Wear, 1997, 212: 50-58.

[14] 朱昊昊, 周仲荣, 刘家浚. 摩擦学白层的研究现状[J]. 摩擦学学报, 1999, 19(3): 281-287.

ZHU Hao-hao, ZHOU Zhong-rong, LIU Jia-jun. Current state of the research of tribological white layers[J]. Journal of Tribology, 1999, 19(3): 281-287.

[15] FELLOWS L J, NOWELL D, HILLS D A. Analysis of crack initiation and propagation in fretting fatigue: The effective initial flaw size methodology[J]. Fatigue and Fracture of Engineering Materials and Structures, 1997, 20(1): 61-70.

[16] 赵建生. 断裂力学及断裂物理[M]. 武汉: 华中科技大学出版社, 2003.

ZHAO Jian-sheng. Fractural mechanics and fractural physics[M]. Wuhan: Huazhong University of Science and Technology Press, 2003.

[17] BONIARDI M, CINCERA S, D’ERRICO F, TAQLIABUE C. Fretting fatigue phenomena on an all aluminium alloy conductor [J]. Key Engineering Materials, 2007, 348/349: 5-8.

[18] 崔约贤, 王长利. 金属断口分析[M]. 哈尔滨: 哈尔滨工业大学出版社, 1998.

CUI Yue-xian, WANG Chang-li. Fracture analysis of metals[M]. Harbin: Harbin University of Technology Press, 1998.

(编辑 何学锋)

基金项目:国家电网科技攻关项目(2009144)

收稿日期:2011-03-29;修订日期:2011-09-20

通信作者:汤文明,教授,博士;电话:0551-2901373; E-mail: wmtang69@126.com